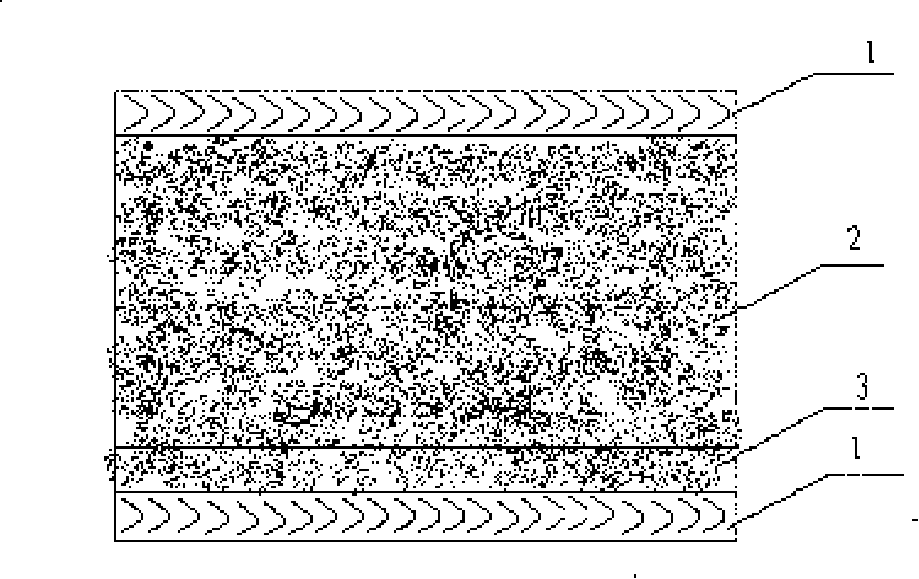

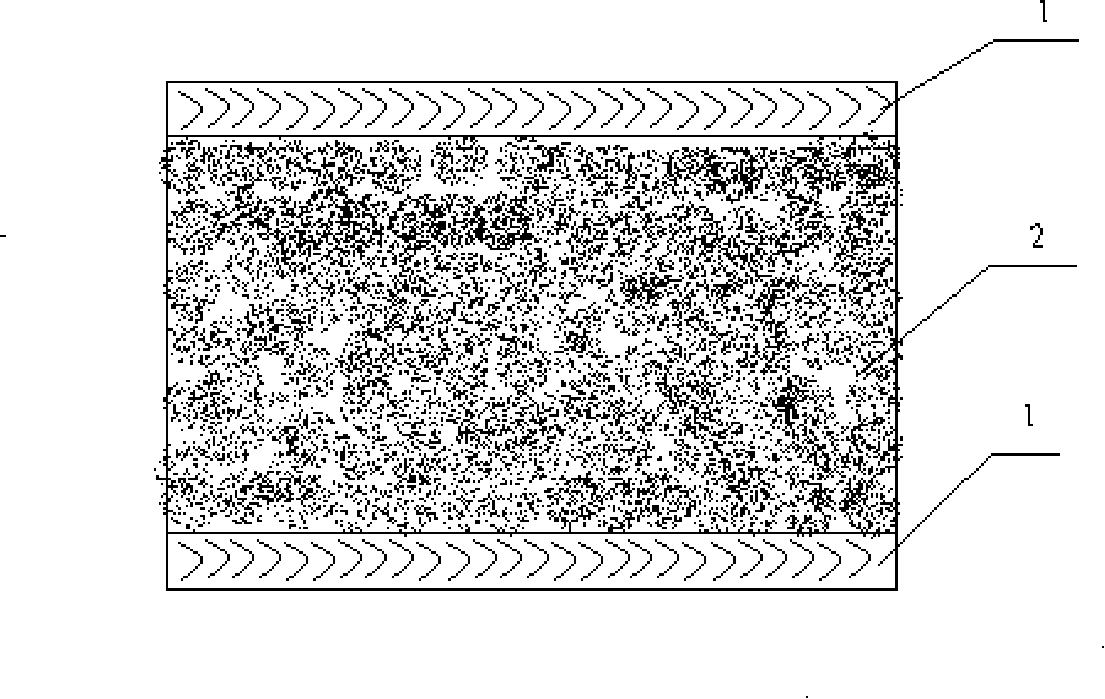

Biomass composite material wall modules and processing technology thereof

A composite material and biomass technology, which is applied in the field of biomass composite material wall module and its processing technology, can solve the problems of increasing cost, increasing energy consumption, multi-energy, etc., so as to reduce self-weight, reduce consumption and solve resource waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the inner wall module is made, and the plant fiber is a mixture of corn stalks, reeds, cotton stalks, sunflower stalks, rapeseed stalks and hemp stalks; the protein glue in the biomass adhesive is first obtained from rapeseed cakes, palm cakes, Extract crude protein from the leftover mixture of cottonseed cake, tea tree seed cake, castor cake and tung tree seed cake, and then extract protein glue; spices are powder or fine crumb solid lavender, mint, camphor, mugwort, pine and cypress leaves , eucalyptus leaves, pears, bay leaves, sandalwood, orange peel and activated carbon and other mixtures of arbitrary components.

[0037] The production steps of the inner wall module in this example:

[0038] 1. Classify and select the collected straw, cut it to a length of about 6cm and a width of about 2cm;

[0039] 2. The above raw materials are weighed according to the following mass ratios:

[0040] Straw: 75kg;

[0041] Biomass adhesive: 15kg, including pr...

Embodiment 2

[0053] In this example, the inner wall module is made, and the components are the same as in Example 1. The plant fiber is a mixture of any ratio of corn stalks, reeds, cotton stalks, sunflower stalks, rape stalks and hemp stalks; the protein glue in the biomass adhesive is Firstly, crude protein is extracted from the leftover mixture of rapeseed cake, palm cake, cottonseed cake, tea tree seed cake, castor cake and tung tree seed cake, and then the protein glue is extracted; spices are powder or fine crumb solid lavender, mint , camphor, mugwort, pine and cypress leaves, eucalyptus leaves, pears, bay leaves, sandalwood, orange peel and activated carbon, etc.

[0054] The production steps of the inner wall module in this example are as follows:

[0055] 1. Classify and select the collected straw, cut it to a length of about 5cm and a width of about 1.5cm;

[0056] 2. Weigh the raw materials according to the following raw material mass ratios:

[0057] Straw: 85kg;

[0058] B...

Embodiment 3

[0070] In this example, the external wall module is made, and the components are plant fiber, biomass adhesive, spices, limestone and slaked lime. Different from Example 1, the plant fiber is a mixture of corn stalks, reeds, rape stalks and hemp stalks; the protein glue in the biomass adhesive is first obtained from rapeseed cakes, palm cakes, cottonseed cakes and tung oil Crude protein is extracted from the leftover mixture of the cake, and then the protein glue is extracted; the spices are powder or fine crumb solid lavender, mint, camphor, mugwort, pine and cypress leaves, eucalyptus leaves, pears, bay leaves, sandalwood, orange peel and Activated carbon and other mixtures are mixed with any components. The manufacturing steps of this exception wall module are as follows:

[0071] 1. Classify and select the collected straw, and cut it to 0.5cm in length and 0.5cm in width;

[0072] 2. The above raw materials are weighed according to the following mass ratios:

[0073] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com