Three-phase AC motor stator winding coil mismatched wiring detection apparatus and the detection method

A technology for winding coils and motor stators, which is applied in the field of a three-phase AC motor stator winding coil wiring error detection device, can solve the problems of a large number of stator coils, waste of materials, and difficulty in timely detection, and achieves improved quality controllability and operability. The effect of strong performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

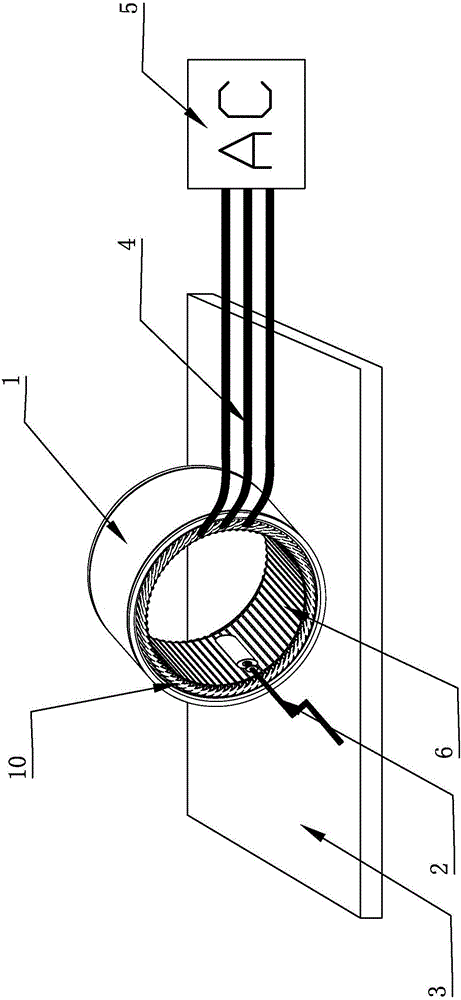

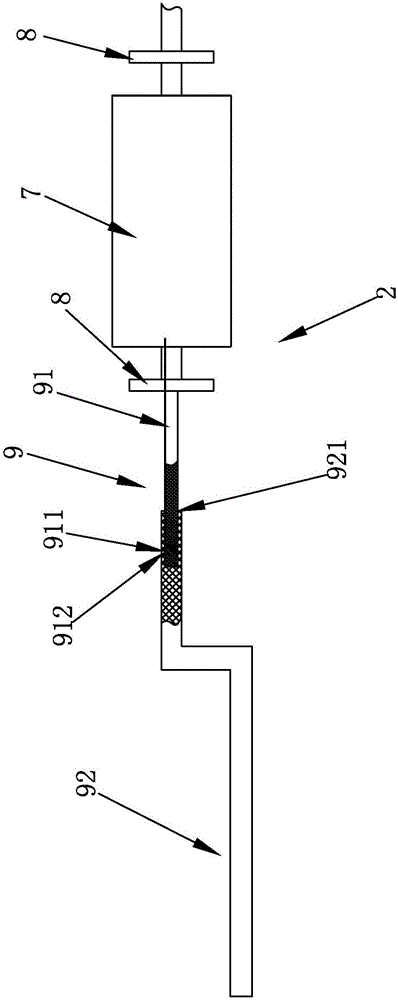

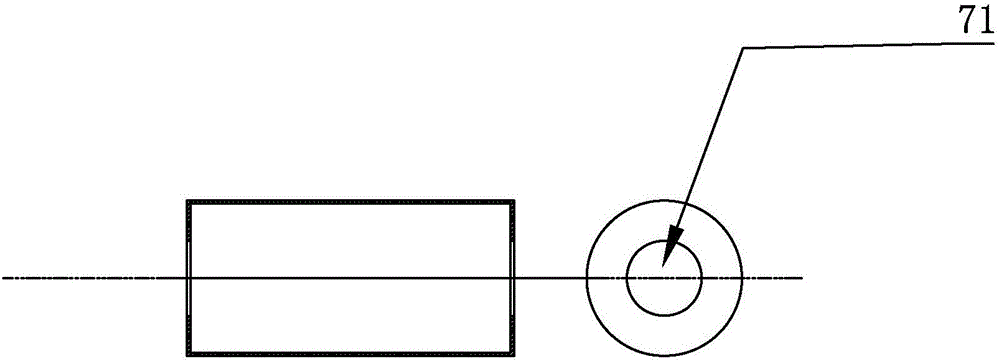

[0016] Such as Figure 1-Figure 3 As shown, the present invention provides a three-phase AC motor stator winding coil wiring error detection device, which includes an insulating workbench 3, a stator core 1, a three-phase winding power line 4, and a three-phase The AC power source 5 connected to the winding power line 4, the inner surface 6 of the stator core 1 is provided with a winding coil 10, and the other end of the three-phase winding power line 4 connected to the AC power source 5 is attached to the winding coil 10 A rotating magnetic field is formed on the surface. A squirrel-cage thin-walled rotor detection assembly 2 is provided on the winding coil 10, and a certain gap is provided between the squirrel-cage thin-walled rotor detection assembly 2 and the winding coil 10. The rotor detection assembly 2 can smoothly rotate and move along the circumferential direction of the winding coil 10. In the above solution, the three-phase AC motor stator winding coil wiring error ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com