Method for machining a reverse hole of large sandwich blind hole structure of aircraft

A processing method and hole structure technology, which is applied in the direction of drilling dies for workpieces, boring/drilling, metal processing equipment, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

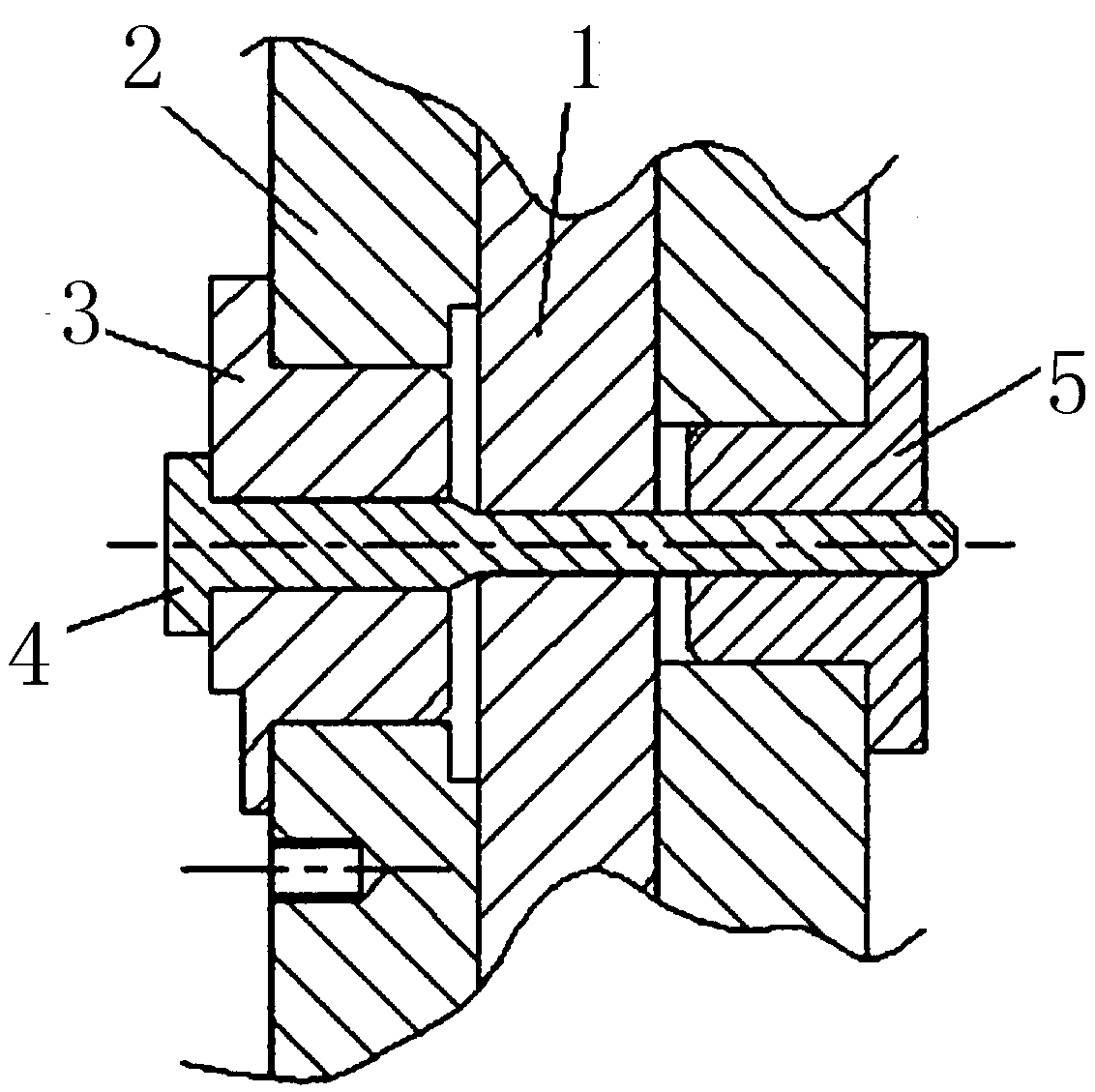

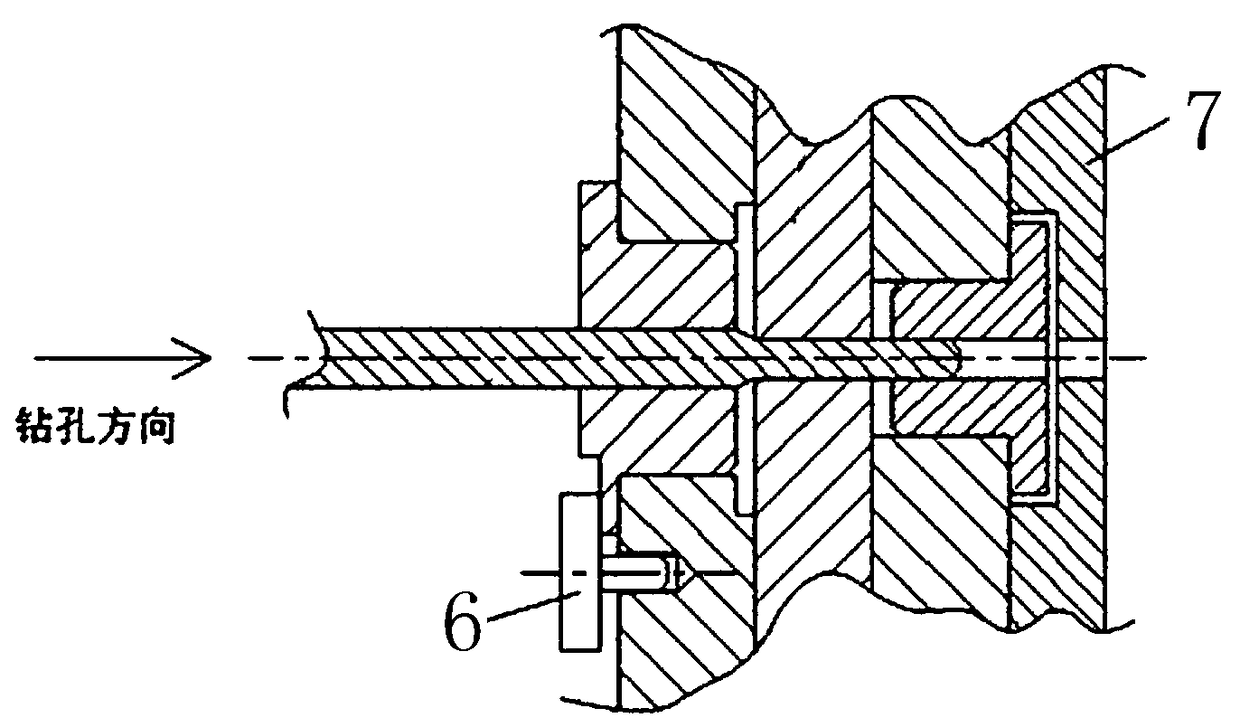

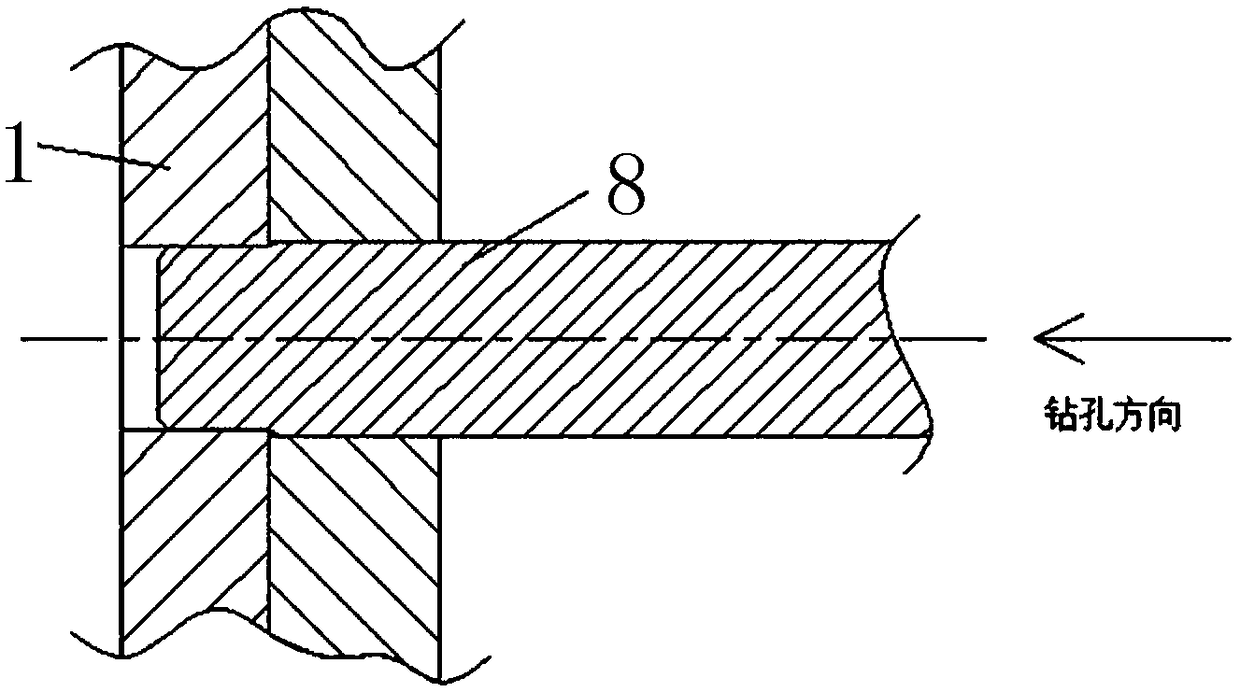

[0016] Example: 1) Use the original final hole in the structure to drill the initial hole of 3.26mm into the product structure that needs to be reversed through the guide pin 5 with the initial hole of φ3.26mm;

[0017] 2) Use the step pin 4 to locate the drill template 2 for the reverse hole on the side of the product structure where the hole needs to be reversed to realize the precise positioning of the drill template 2 so that the drill template 2 is coaxial with the original final hole on the structure to ensure the reverse hole The rear end hole is coaxial with the original end hole. The positioning process of the drill template 2 is to place the drill template 2 and the drill sleeve 3 on the side of the product structure that needs to be reversed, and then insert the stepped pin 4. The front end of the stepped pin 4 has a diameter of 3.26mm and is matched with the guide pin 5. The diameter of the rear end is φ4.1mm, which is matched with the drill sleeve 3. By continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com