Technique for removing alumina-titanium dioxide coating of engine labyrinth disc type part

The technology of disc parts and titanium dioxide is applied in the field of removing aluminum oxide-titanium dioxide coating of engine grate disc parts, which can solve the problems of non-destructive inspection of grate teeth by technicians, damage of grate teeth coating, and scrapping of parts, etc. Achieving the effect of avoiding the risk of scrap parts, extending the service life and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

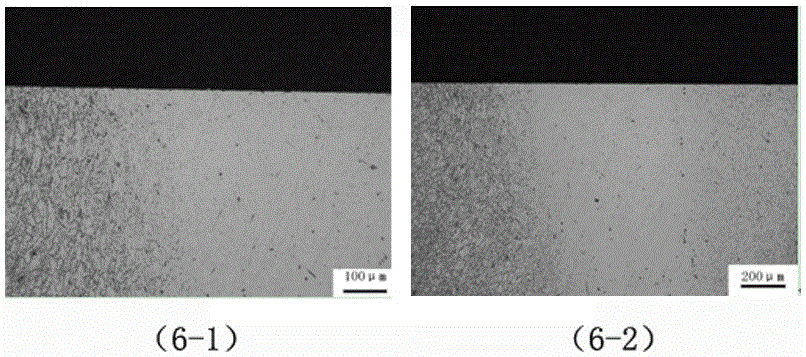

[0024] A technology for removing aluminum oxide-titania coatings on titanium alloy grate discs for engines, including using hanging tooling to immerse titanium alloy grate discs for engines in a strong alkaline solution for 20 minutes for chemical degreasing. The solution contains sodium hydroxide at a concentration of 10g / L, sodium carbonate at 22g / L, trisodium phosphate at 50g / L and water glass at 15g / L, and the temperature of the solution is controlled at 80°C; parts after chemical degreasing Rinse with warm water and cold water at 45°C in turn, and the water film on the surface of the washed parts will remain continuous within 10 to 30 seconds; use a hanging tool to immerse the washed parts in concentrated nitric acid with a concentration of 500g / L for 20 hours, The temperature of concentrated nitric acid was controlled at 50°C, during which the parts were taken out every 2 hours to brush off the surface of the alumina-titania coating; the surface of the parts after picklin...

Embodiment 2

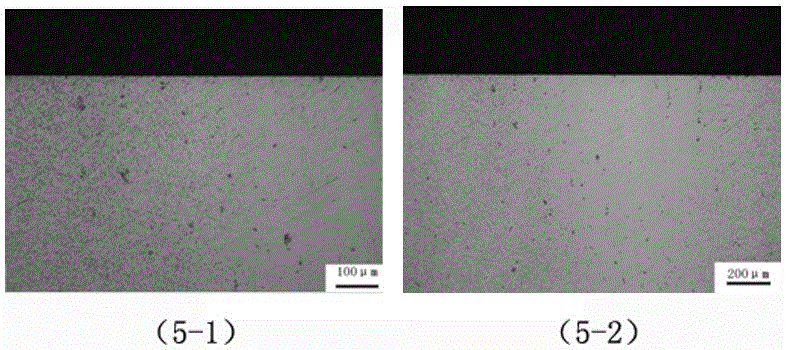

[0029] A technology for removing the alumina-titanium dioxide coating on engine solid-melt superalloy (GH4169) grate tooth disc parts, including using hanging tooling to immerse the solid-melt high-temperature grate tooth disc parts of the engine in a strong alkaline solution for 30 minutes for chemical Degreasing, containing the sodium hydroxide that concentration is 15g / L, the sodium carbonate of 25g / L, the trisodium phosphate of 70g / L and the water glass of 20g / L in the strong alkaline solution, the temperature of solution is controlled at 90 ℃ ; Rinse the parts after chemical degreasing with warm water and cold water at 45°C in sequence, and the water film on the surface of the washed parts will remain continuous within the time range of 10~30S; 433g / L concentrated nitric acid for 15 hours, the temperature of the concentrated nitric acid was controlled at 58°C, during which the parts were taken out every 2 hours to brush the surface of the alumina-titania coating; the surfa...

Embodiment 3

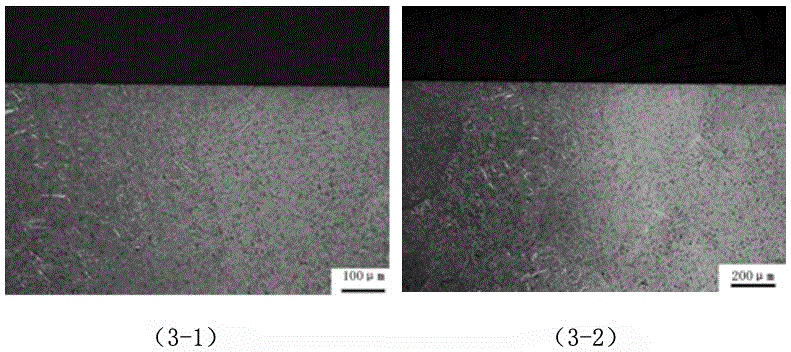

[0033]A technology for removing the alumina-titania coating on high-strength superalloy (GH4169) grate tooth disc parts of an engine, including using acetone to degrease the engine high-strength superalloy superalloy grate tooth disc parts with an organic solvent; Immerse the parts degreased by organic solvents in a strong alkaline solution for 30 minutes for chemical degreasing. Sodium and 10g / L water glass, the temperature of the solution is controlled at 70°C; the parts after chemical degreasing are washed with warm water and cold water at 40~50°C in sequence, and the water film on the surface of the washed parts is in the time range of 10~30S The interior is kept continuous; the washed parts are immersed in concentrated nitric acid with a concentration of 345g / L for 15 hours by hanging tooling, and the temperature of the concentrated nitric acid is controlled at 65°C. Surface brushing; use a pressure water gun to rinse the surface of the pickled part until the alumina-tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com