Coaxial cavity filter

A filter and coaxial cavity technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve problems such as restricting filter cost control, complex processing and assembly processes, and inability to reuse products, and achieves convenient equipment maintenance. The effect of simplifying the production process and improving the utilization rate of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

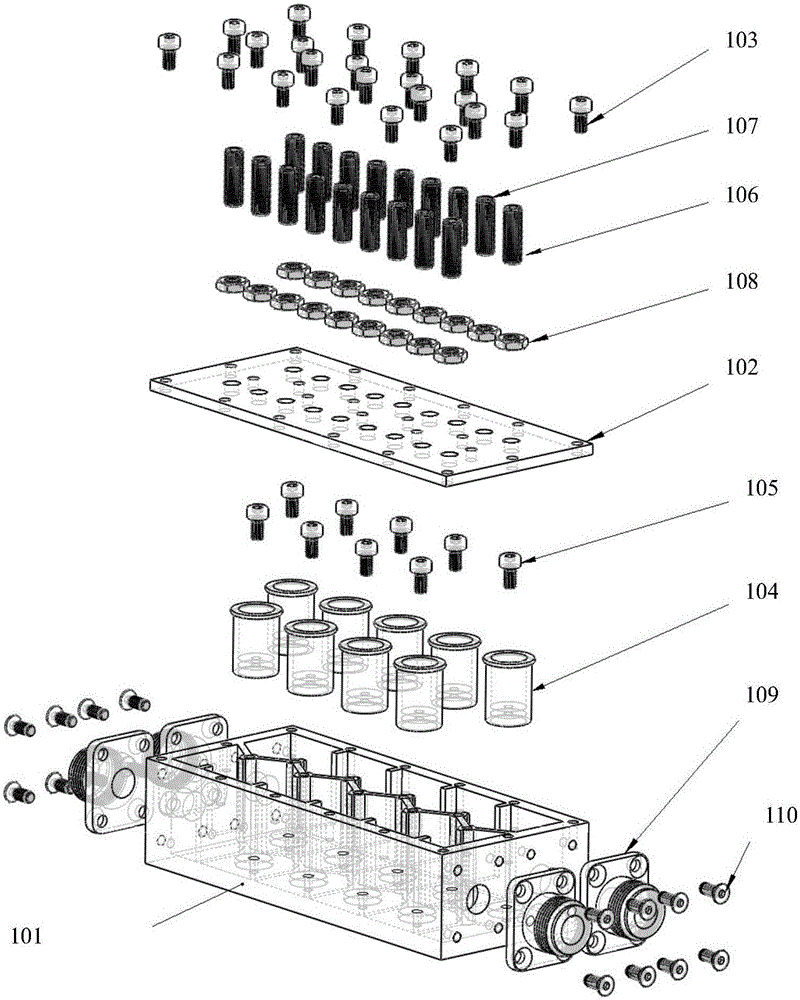

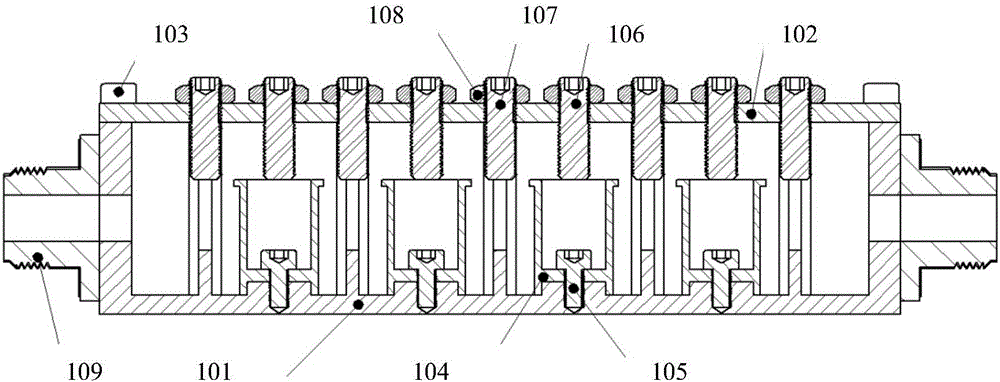

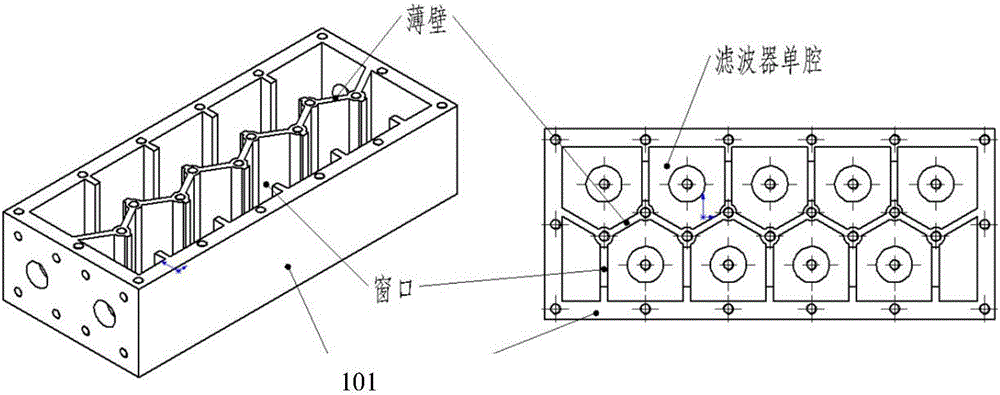

[0034] Please also refer to Figure 4 to Figure 9 , is a schematic structural diagram of a coaxial cavity filter provided by an embodiment of the present invention. For ease of description, only parts related to the embodiments of the present invention are shown.

[0035] The coaxial cavity filter includes: a modular single cavity 200, a resonant rod 201, a resonant rod fastening pin 202, a spring washer 203, a cover plate 204, a tuning screw 205, a coupling screw 206, a fastening nut 207 and a filter connector 208.

[0036] Wherein, a groove is opened on the cover plate 204, and the groove is used for installing the modularized single cavity 200, and screw holes for installing the tuning screw 205 and the coupling screw 206 are also provided on the cover plate 204, such as Figure 6 shown. The upper end of the modular single chamber 200 is fixed in the groove of the cover plate by welding or conductive glue bonding or pressing, so as to be closed with the cover plate 204 t...

Embodiment 2

[0046] Please also refer to Figure 10 to Figure 12 , is a schematic structural diagram of the coaxial cavity filter provided by Embodiment 2 of the present invention. For ease of description, only parts related to the embodiments of the present invention are shown.

[0047] The coaxial cavity filter includes: a modular single cavity 300 , a locking collar 301 , a resonant rod 302 , a cover plate 303 , a tuning screw 304 , a coupling screw 305 , a fastening nut 306 and a filter connector 307 .

[0048] Wherein, a slot is opened on the cover plate 303 for installing the modular single chamber 300 , and screw holes for installing the tuning screw 304 and the coupling screw 305 are also provided on the cover plate 303 . The upper end of the modular single cavity 300 is fixed in the groove of the cover plate by welding or conductive glue bonding or pressing, so as to be closed with the cover plate 303 to form a resonant cavity. At the same time, a locking hoop 301 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com