Patents

Literature

32results about How to "Large coefficient of linear expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

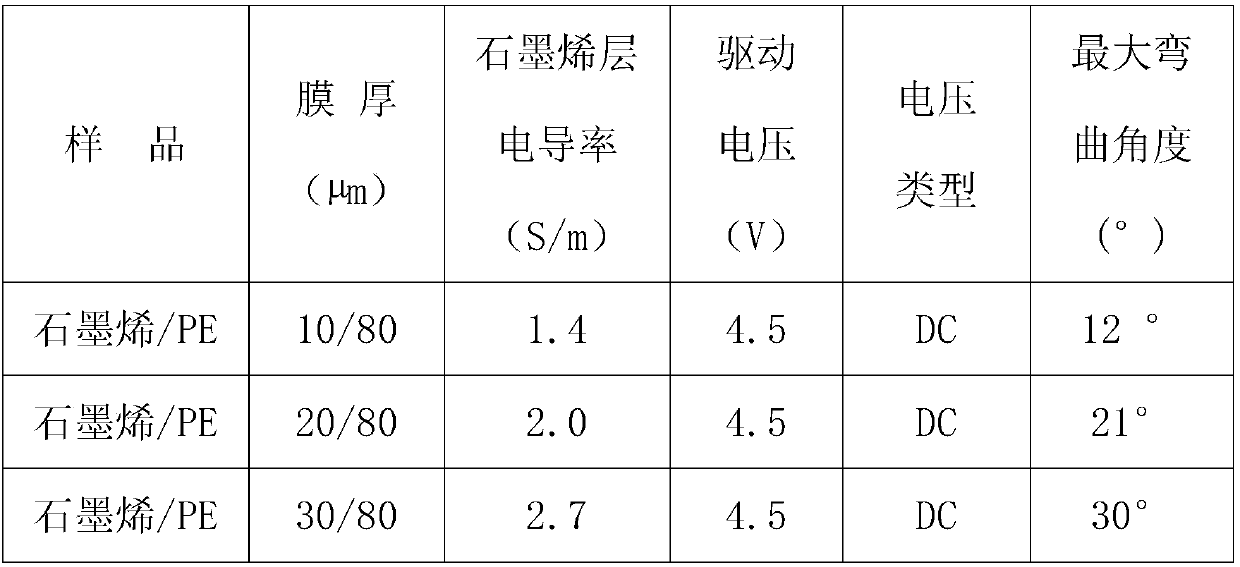

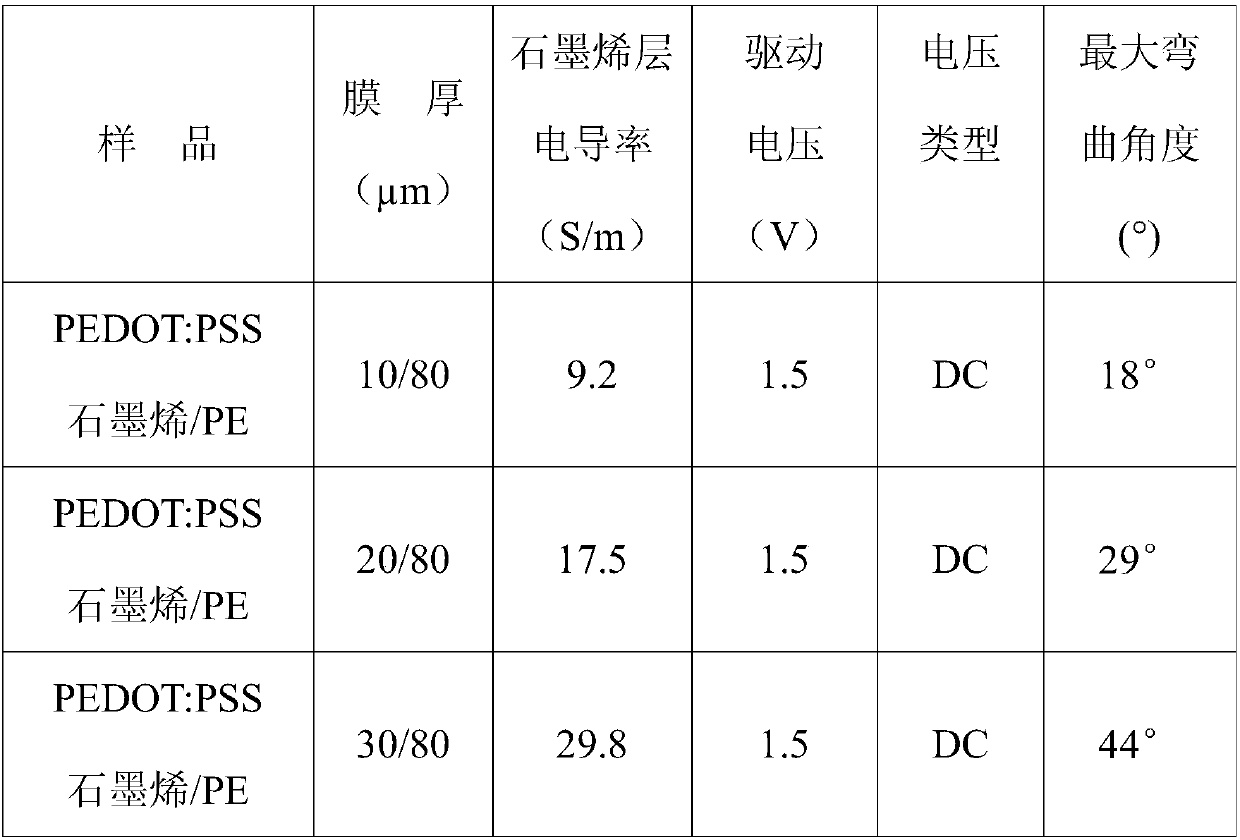

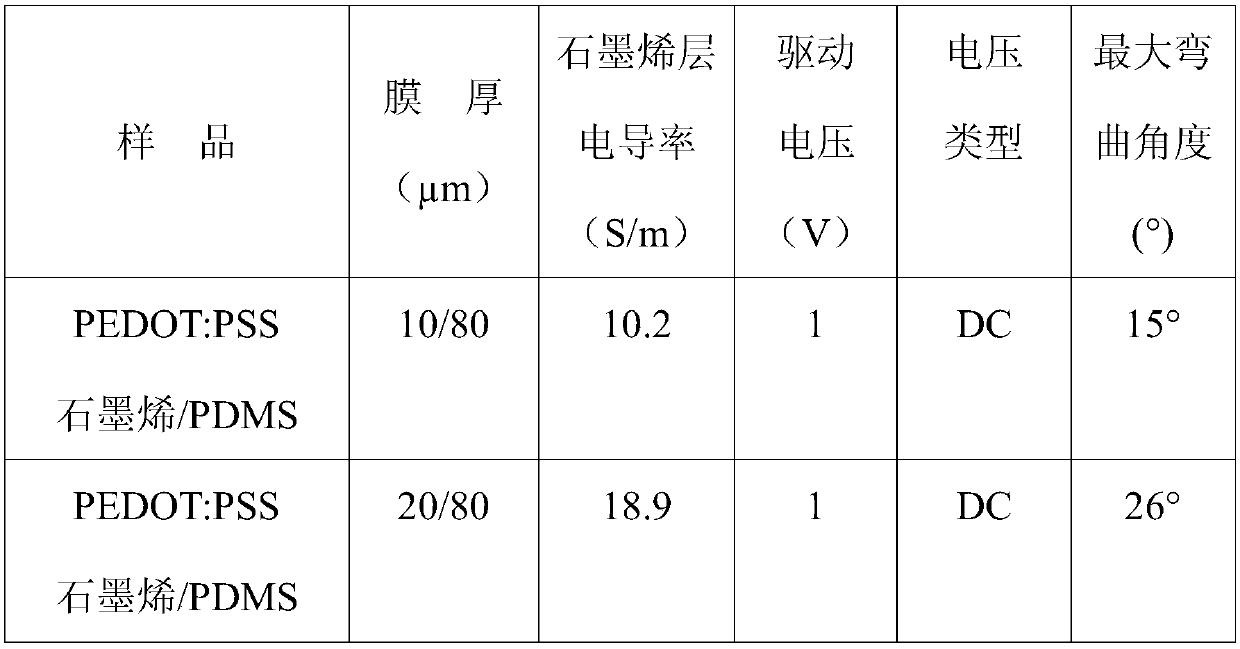

Graphene double-layer electroactive membrane and preparation method thereof

InactiveCN107778514AImprove flexibilityLarge coefficient of linear expansionGrapheneElectrically-conductive paintsPolymer thin filmsActuator

The invention discloses a graphene double-layer electroactive membrane and a preparation method thereof. The graphene double-layer electroactive membrane is composed of a flexible conducting layer anda flexible polymer layer. The preparation method comprises mixing and reacting flake graphite powder, NaNO3, sulfuric acid, KMnO4 and deionized water, and performing washing and drying processes to obtain graphene oxide; mixing and ultrasonic-dispersing the graphene oxide, hydrazine hydrate, ammonium hydroxide and deionized water for reaction to obtain reduced graphene oxide dispersion liquid; dropwise or rotatingly applying the reduced graphene oxide dispersion liquid onto a flexible polymer layer-polymer membrane and performing a drying process to form the flexible conducting layer onto thepolymer membrane to obtain the graphene double-layer electroactive membrane. The graphene double-layer electroactive membrane has the advantages of high responsiveness, low power, broad pressure range and the like when being electrically driven, and can be applied to the fields of flexible wearable equipment, micro motor actuators and micro-robots.

Owner:SOUTHWEAT UNIV OF SCI & TECH

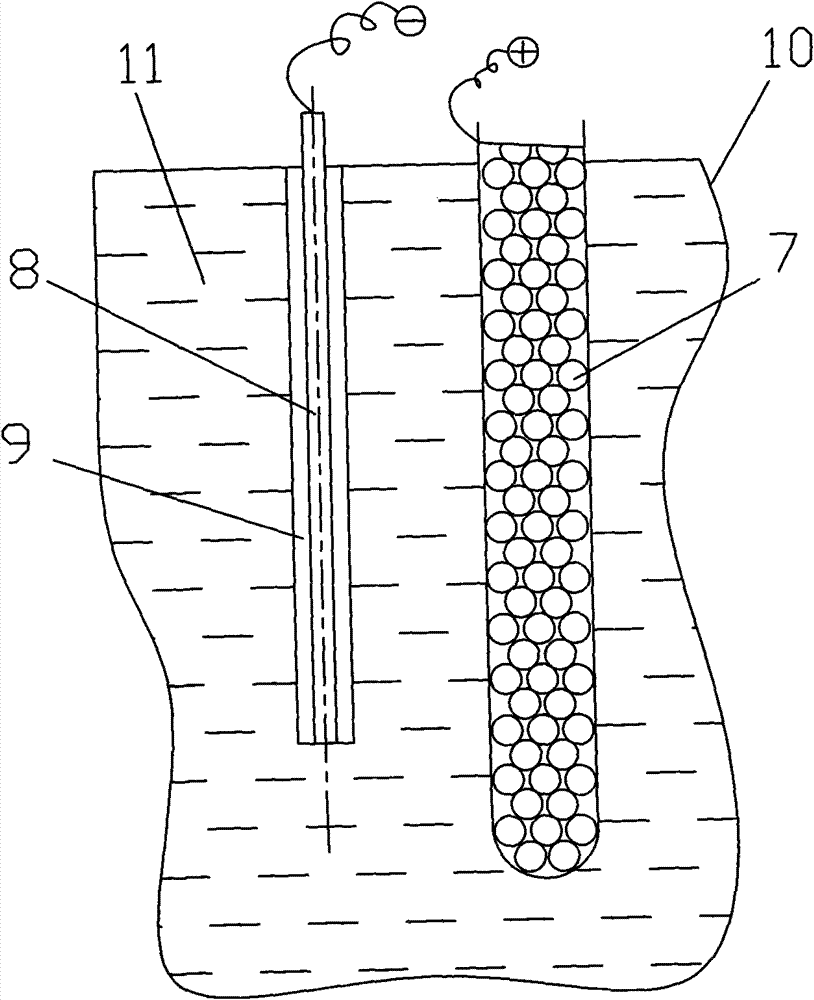

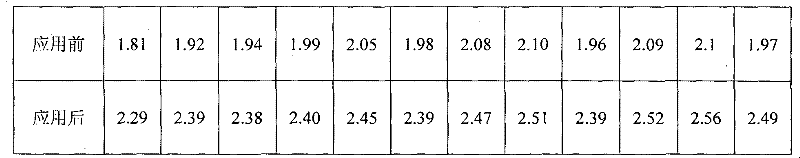

Composition for repairing surfaces of metallic rubbing pairs and preparation thereof

InactiveCN101412943AReduce repair costsReduce difficultyAdditivesRestorative materialPhysical chemistry

The invention provides a composition for restoring the surface of a metallic rubbing pair and a preparation method thereof, and relates to the composition for restoring the surface of the metallic rubbing pair and the preparation method thereof. The invention solves the problem that the restoring film formed by the prior restoring material has limited thickness which can not reach over 0.5 millimeter and can not effectively control the clearance between the metallic rubbing pair. The composition consists of nickelous chloride powder, aluminum powder, nickel powder, ferric oxide powder, silicon dioxide powder, a powder suspending agent, a surface modifier and mineral lubricating oil. The preparation method is to put the nickelous chloride powder, the aluminum powder, the nickel powder, the ferric oxide powder, the silicon dioxide powder, the powder suspending agent, the surface modifier and the mineral lubricating oil in a high-speed viscolizer to be homogenized for 30 to 40 minutes. The composition for restoring the surface of the metallic rubbing pair and the preparation method thereof realize restoring modification to the surface of the metallic rubbing pair of which a restoration layer reaches 1.5 millimeters, and effectively control the clearance between the metallic rubbing pair.

Owner:三亚圣龙新材料开发有限公司

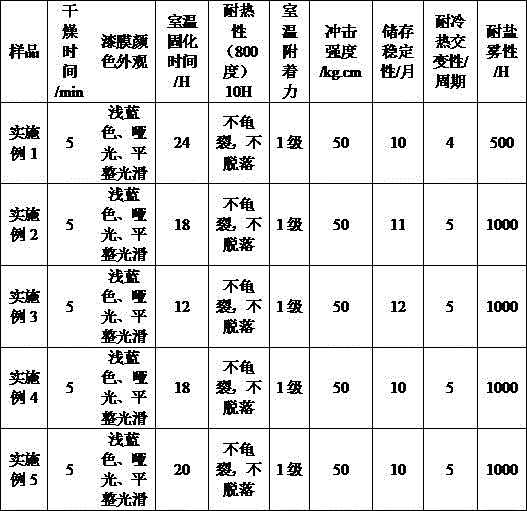

Novolac epoxy resin radiation protective paint and preparation method thereof

InactiveCN105694677AHigh transparencyHigh hardnessFireproof paintsAntifouling/underwater paintsEpoxyTemperature resistance

The invention provides a phenolic epoxy resin radiation protection coating, which comprises the following raw materials in parts by weight: 20-30 parts of phenolic epoxy resin, 10-15 parts of expanded graphite, 5-10 parts of carbon nanotubes, 1-30 parts of titanium dioxide 5 parts, 0.5-3 parts of hydroxypropyl methylcellulose, 8-14 parts of glass powder, 5-10 parts of talc powder, 8-12 parts of kaolin powder, 5-10 parts of perlite, 10-15 parts of wollastonite powder , 1-5 parts of dicyclopentenyloxyethyl acrylate and 20-30 parts of water. The present invention also provides a preparation method of the above-mentioned phenolic epoxy resin radiation protection coating. The components in the above-mentioned phenolic epoxy resin radiation-proof coating provided by the present invention cooperate with each other and complement each other, so that the coating has excellent anti-corrosion, radiation protection, antibacterial, flame-retardant, and anti-corrosion properties under the premise of maintaining good adhesion. High temperature, anti-cracking, anti-corrosion, resistance to alternating cold and heat, storage stability and other characteristics.

Owner:HUANGHE S & T COLLEGE

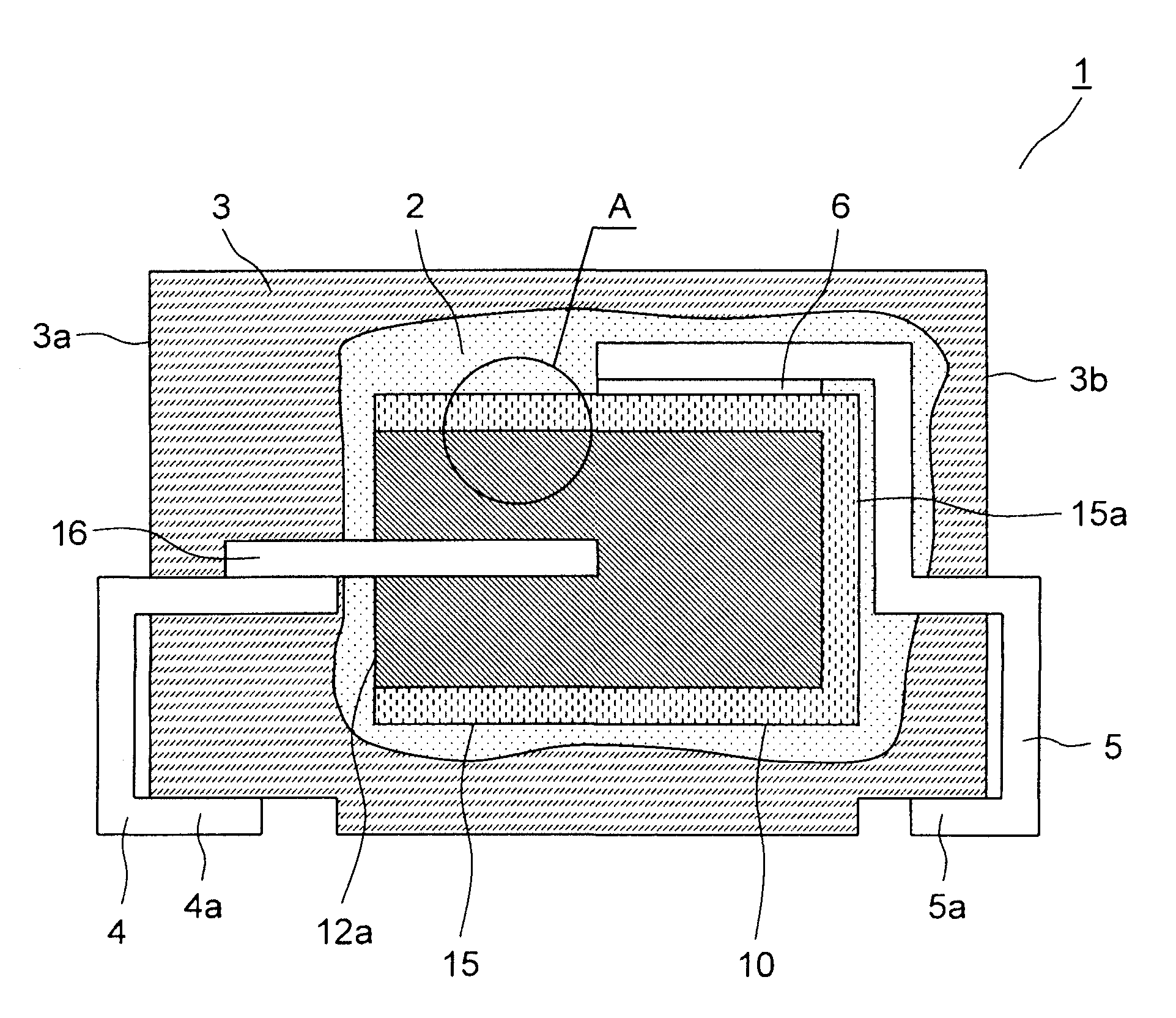

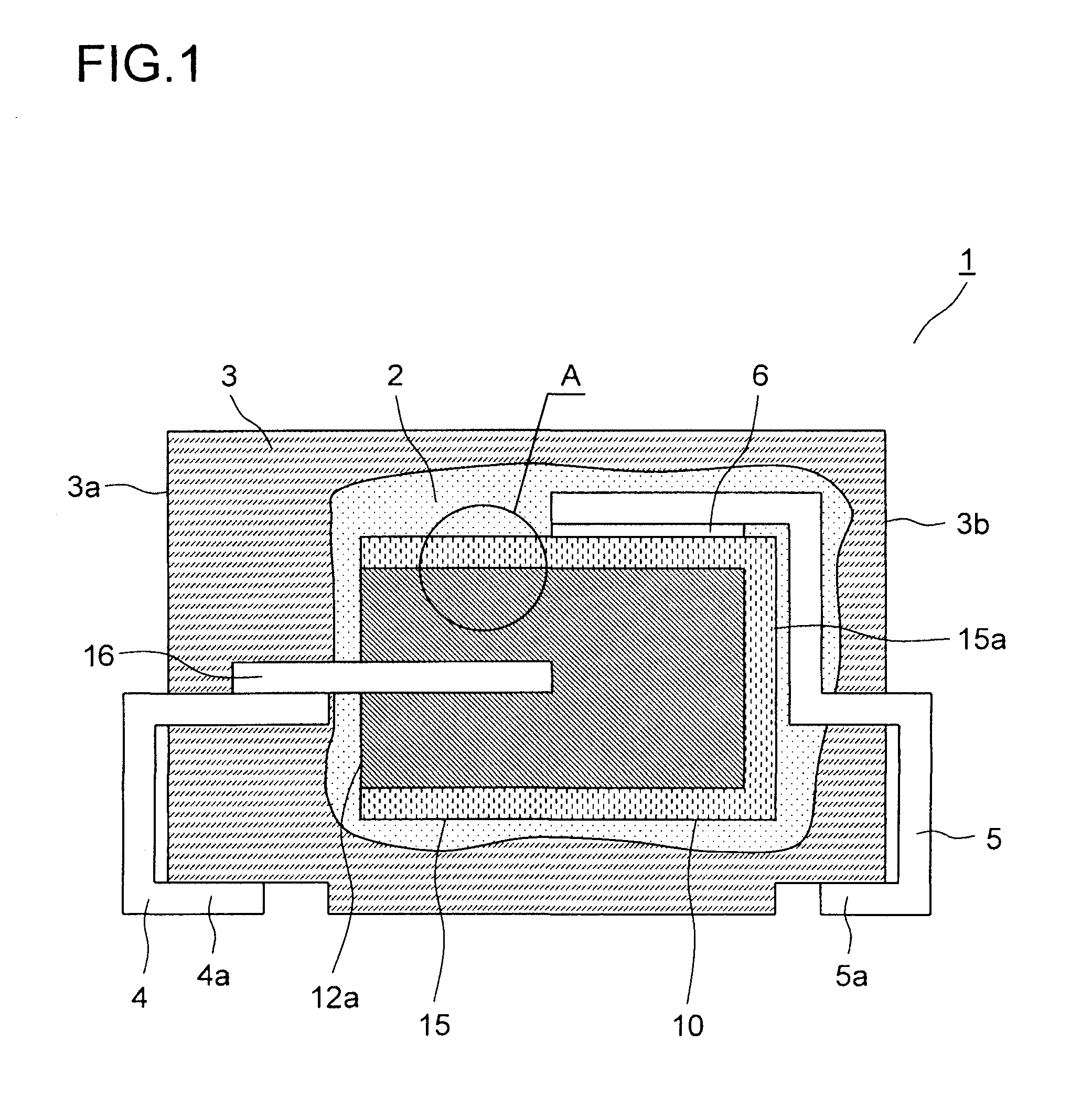

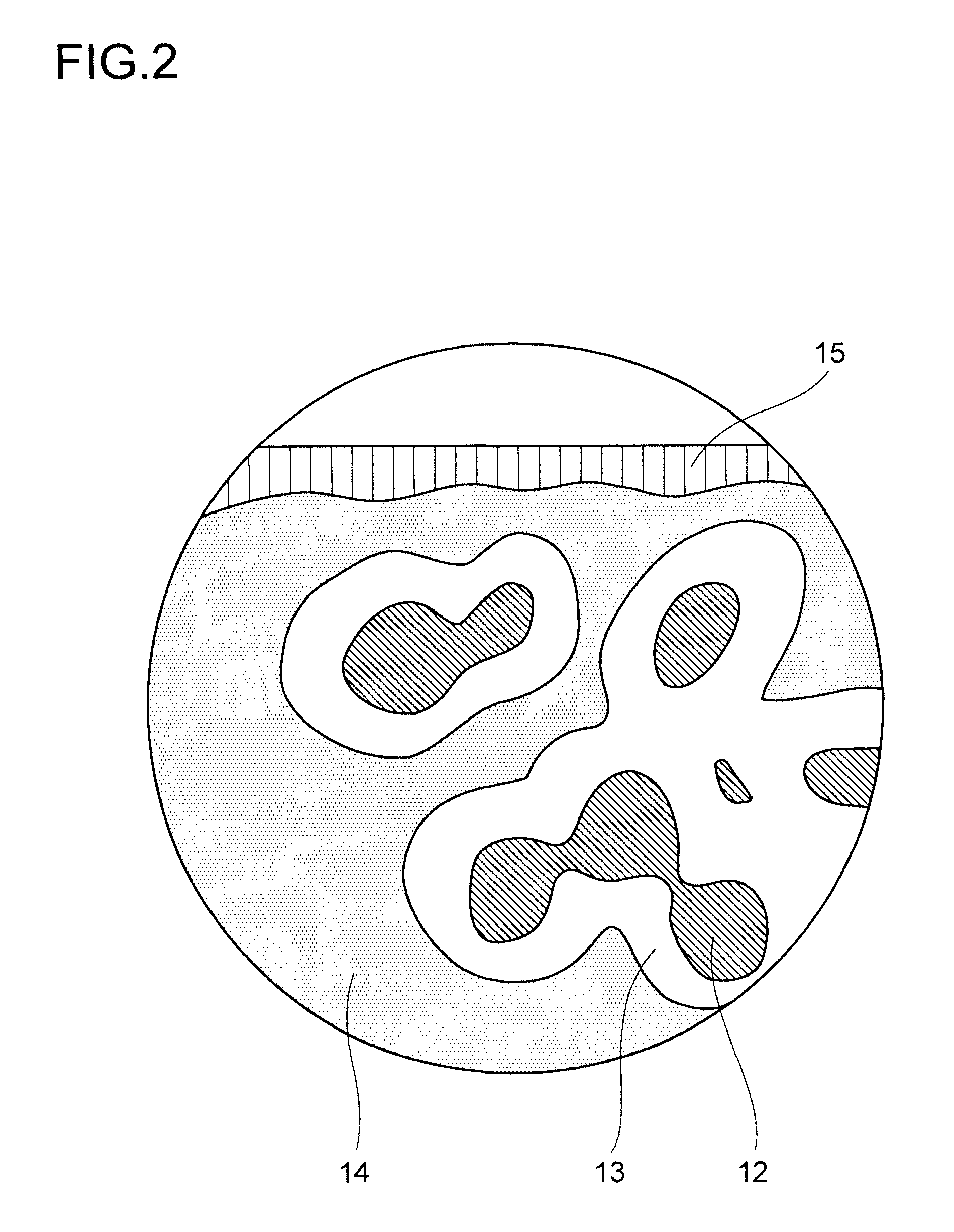

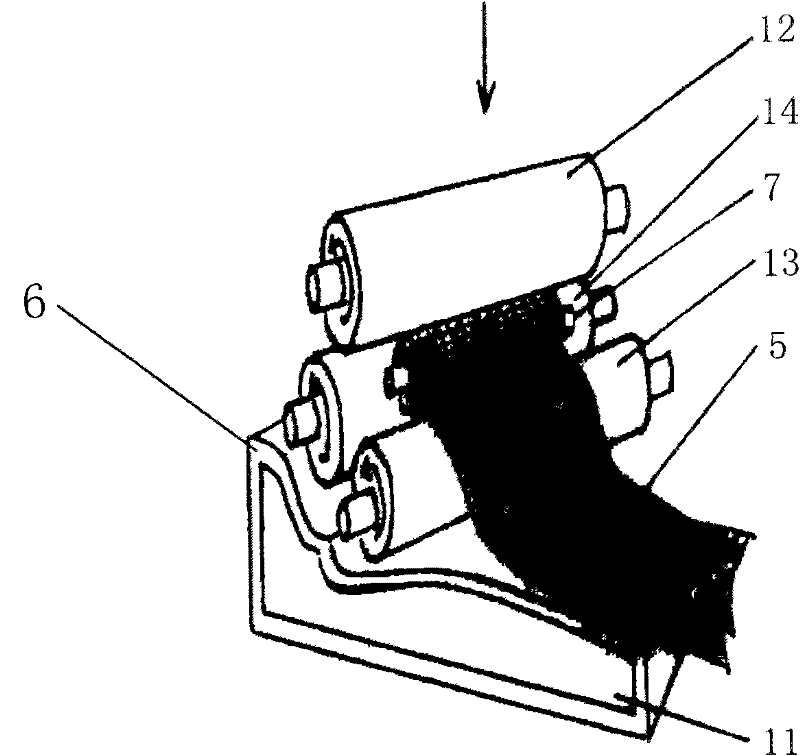

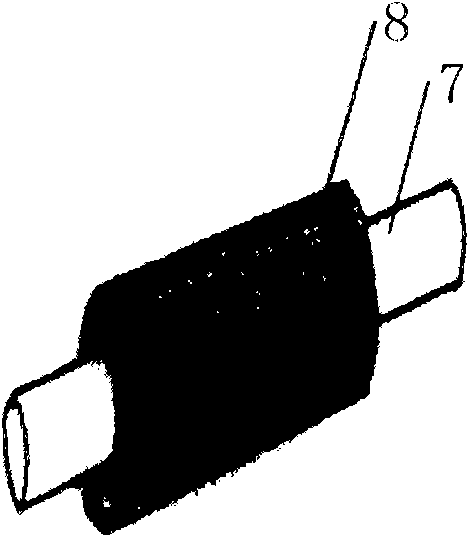

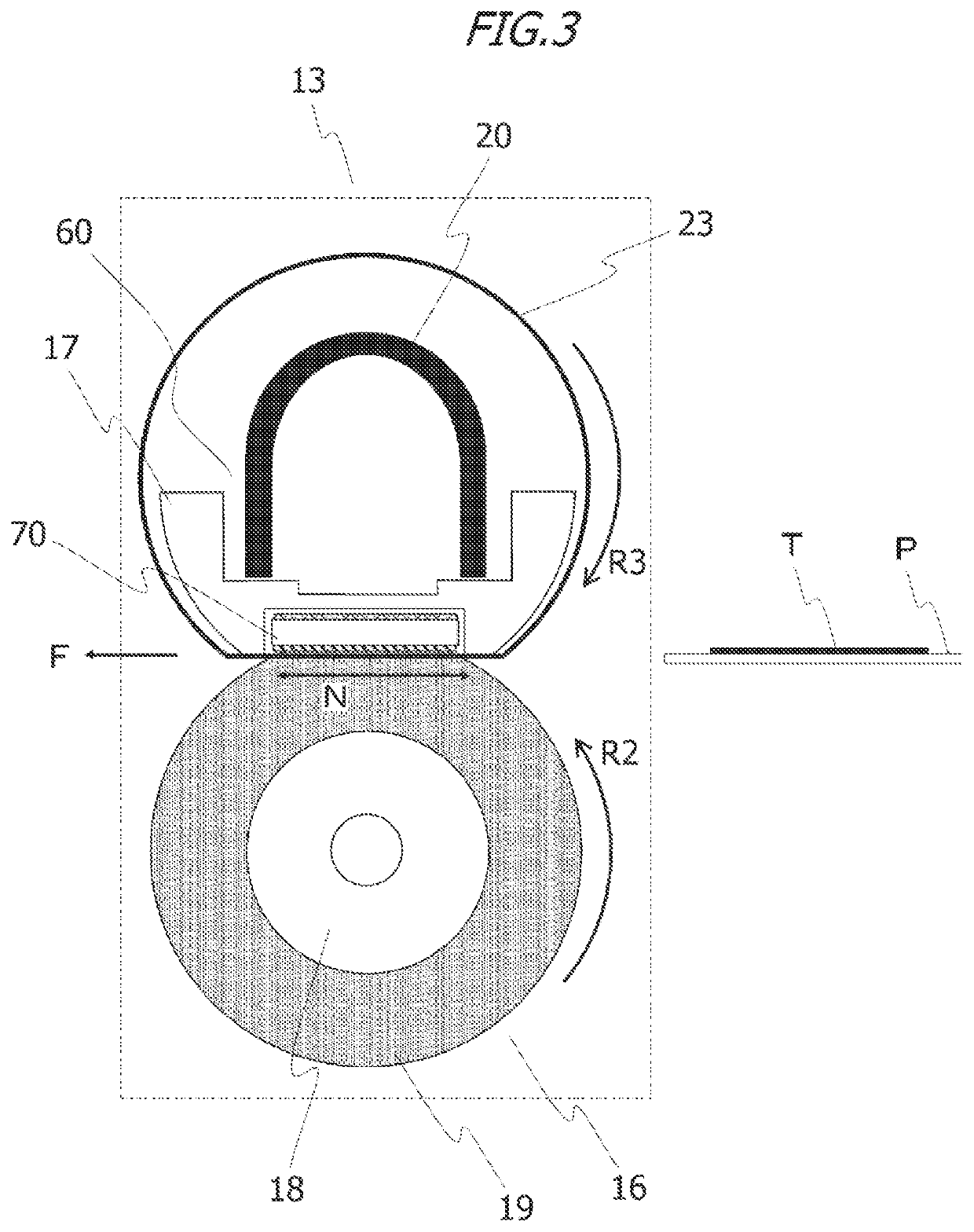

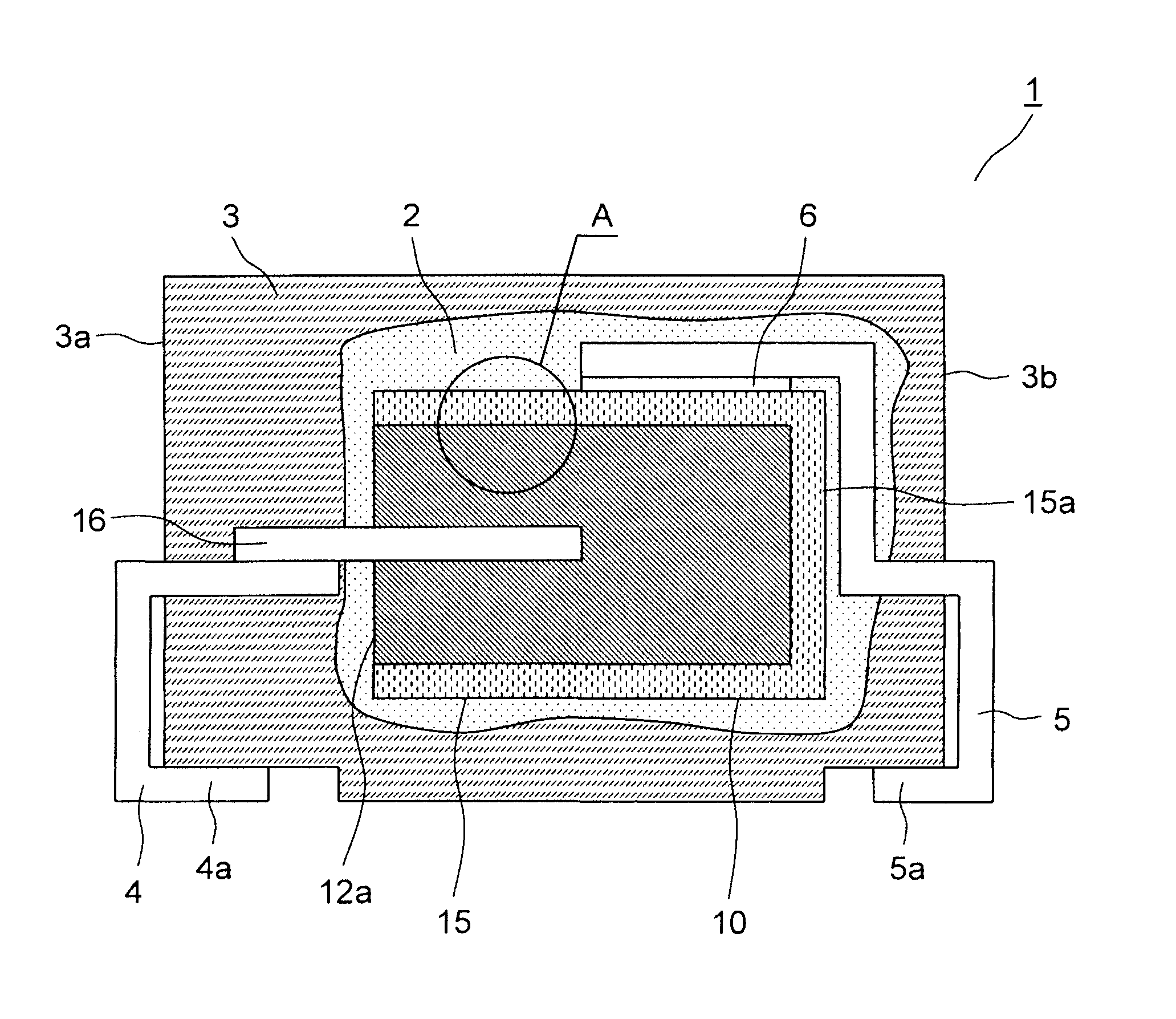

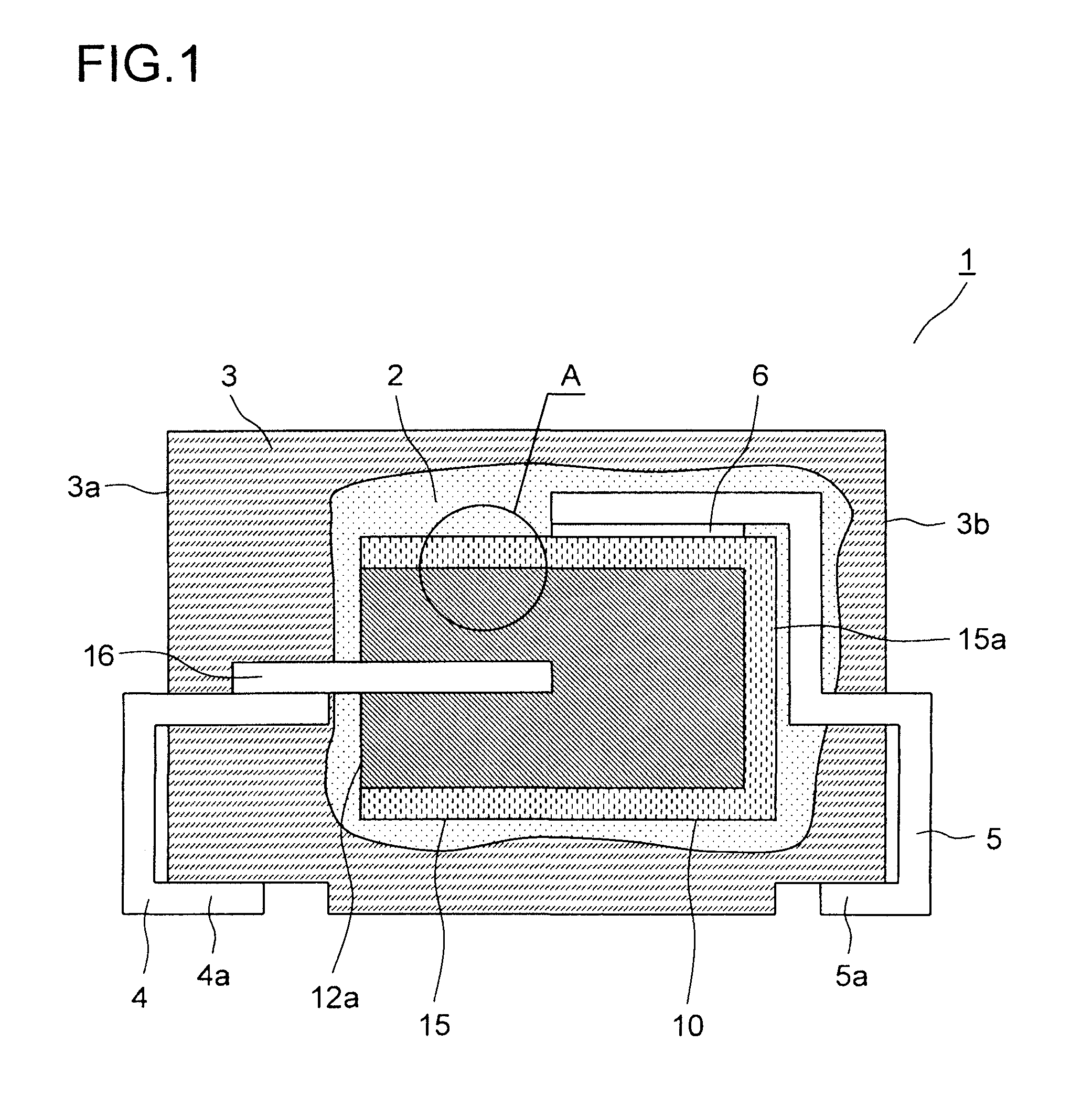

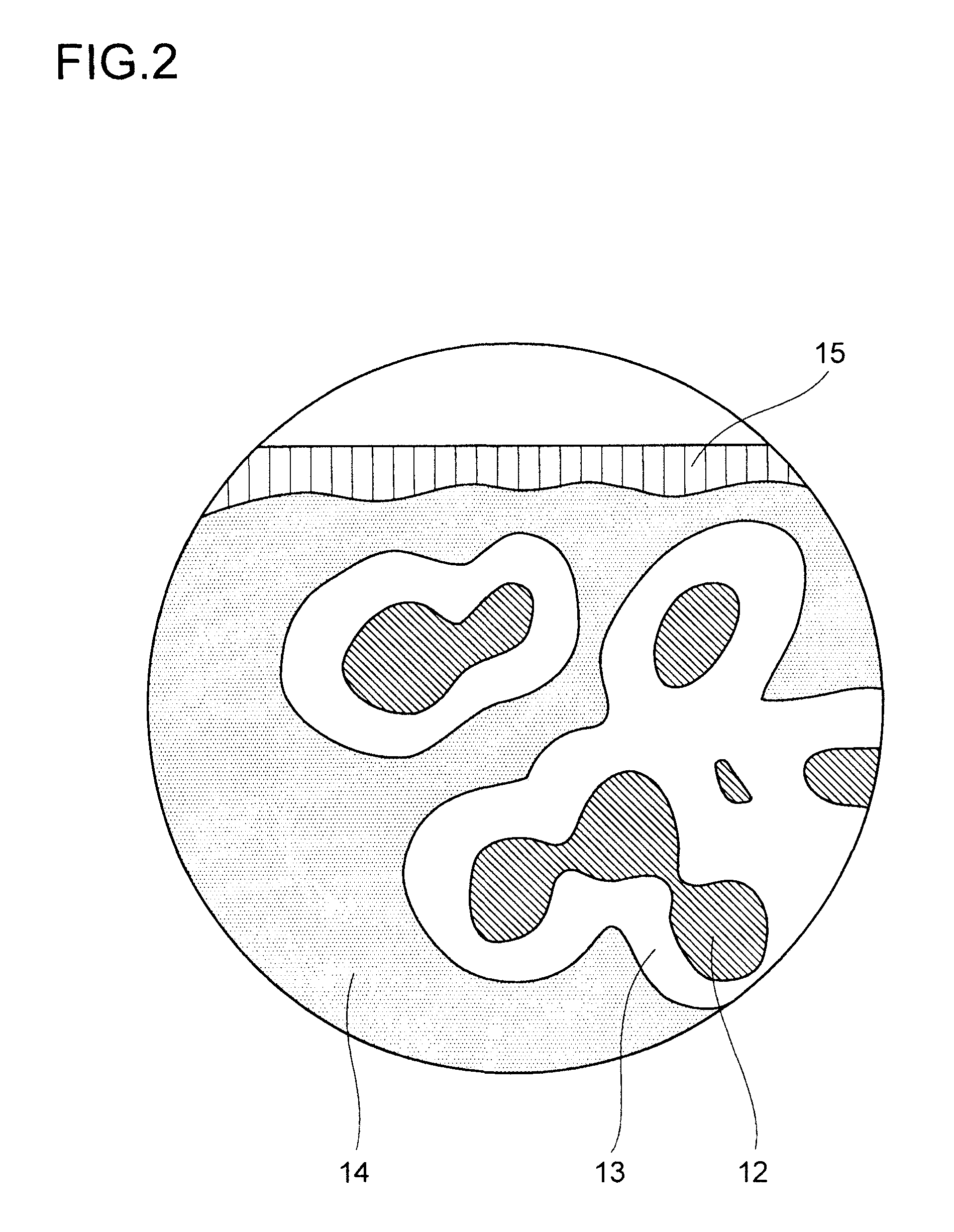

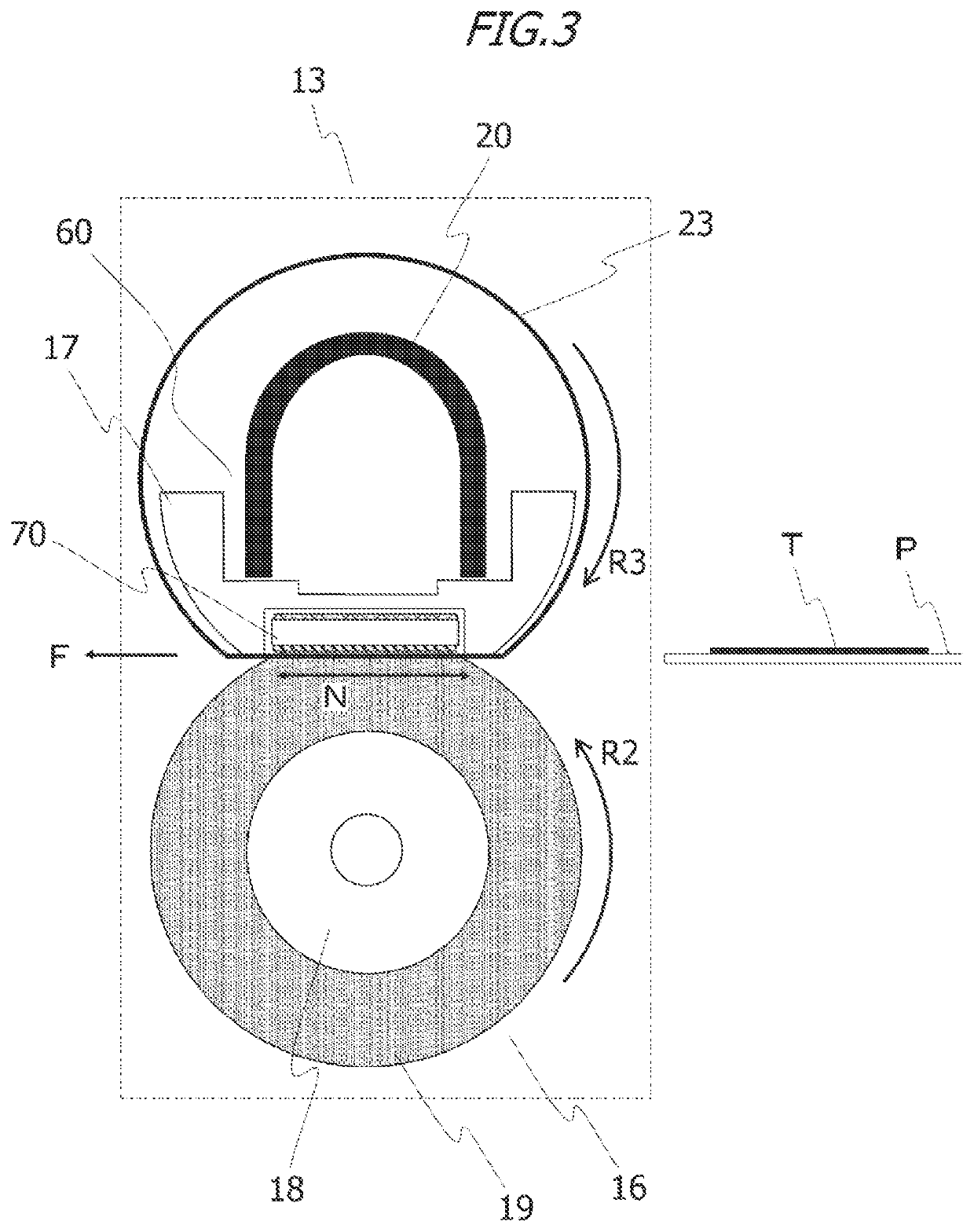

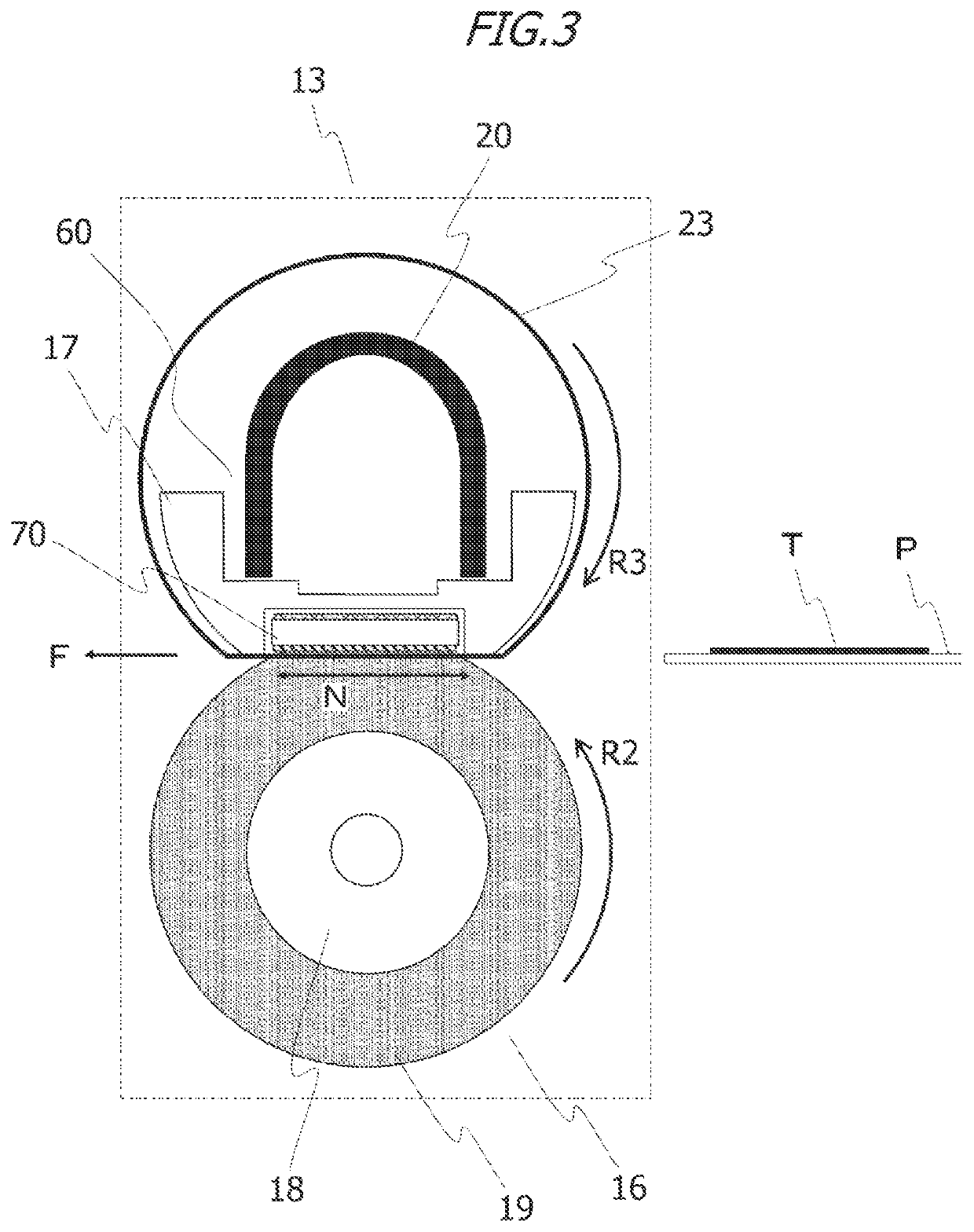

Solid electrolytic capacitor and method for manufacture thereof

ActiveUS20110096467A1Suppress leakage currentLow costSolid electrolytic capacitorsClosuresElectrolytic capacitorLinear expansion coefficient

On a surface of an anode member 12 having a valve action, a cathode layer 14 is formed, and at a terminal lead-out face 12a at one end of the anode member 12, an anode wire 16 is led out of it; thus a capacitor element 10 is formed. An anode terminal 4 is joined to the anode wire 16. A cathode terminal 5 is joined to the cathode layer 14. A protective layer 2 of resin covers part or all of the capacitor element 10. A packaging member 3 of resin harder than the protective layer 2 covers around the capacitor element 10 including the protective layer 2 and the anode wire 16 to form a package. The protective layer 2 has a larger linear expansion coefficient than the packaging member 3. The mass ratio of the packaging member 3 to the total mass of the packaging member 3 and the protective layer 2 between the terminal lead-out face 12a and the exterior face of the packaging member 3 opposite the terminal lead-out face 12a is 50% or more.

Owner:SAN DENSHI INDS

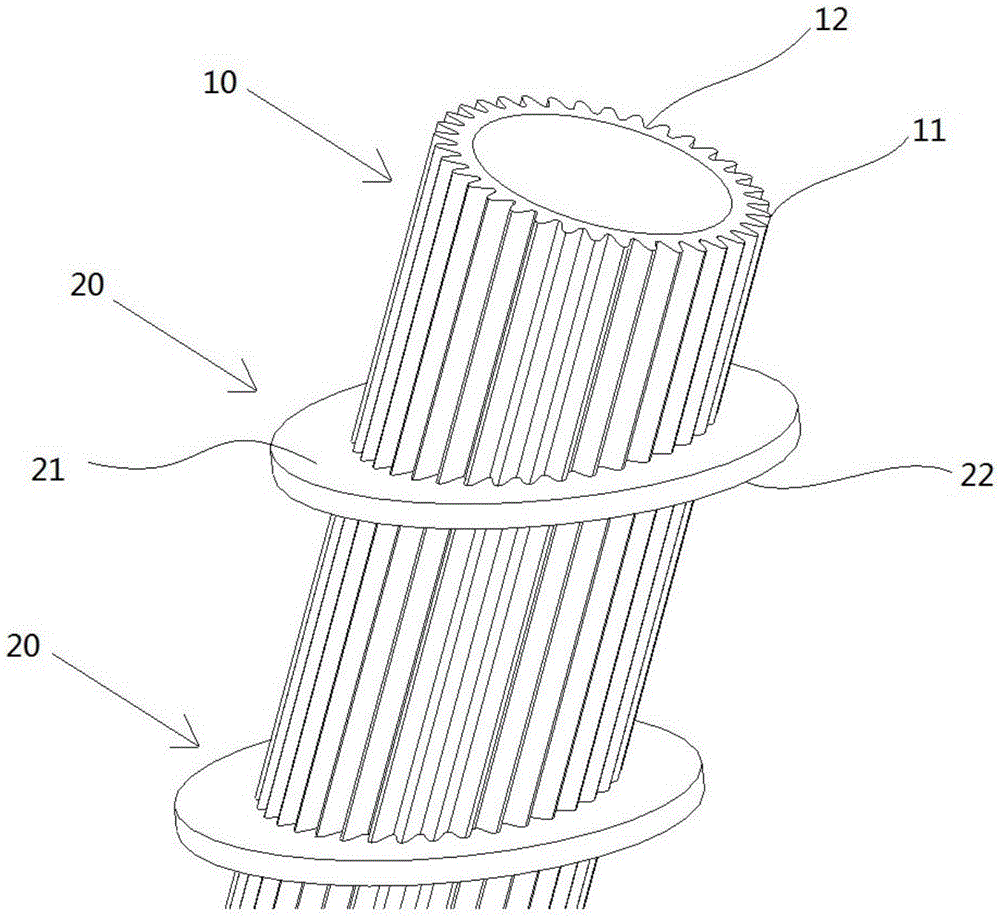

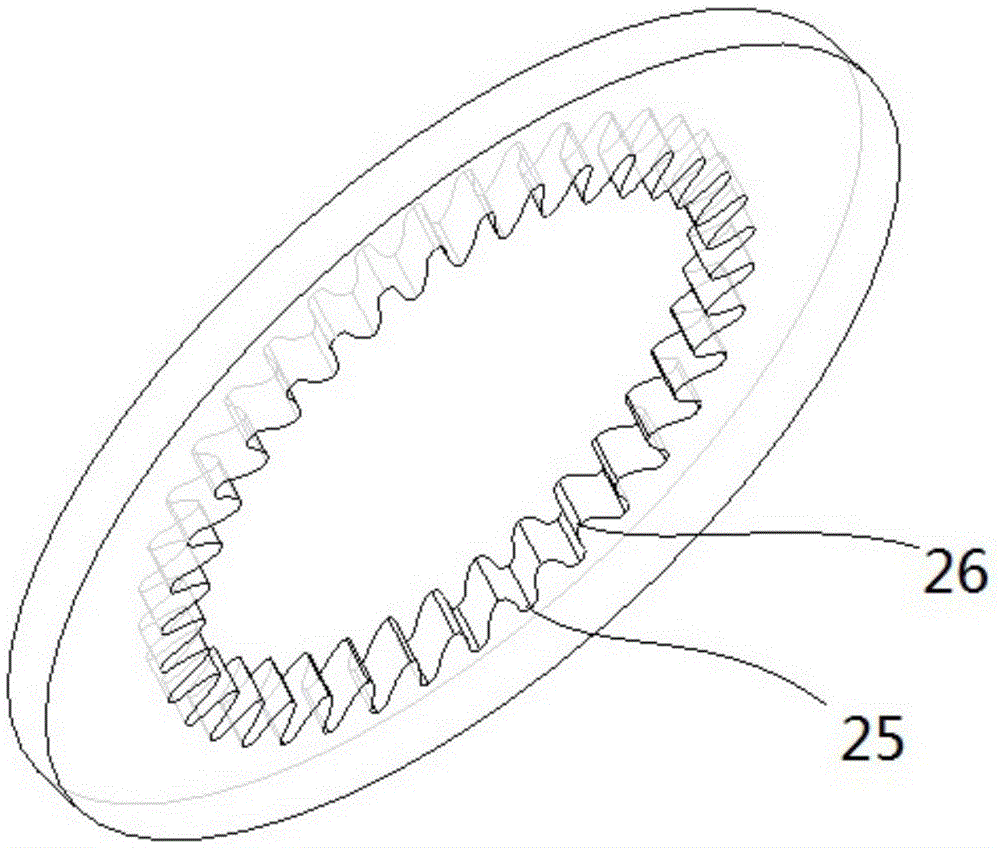

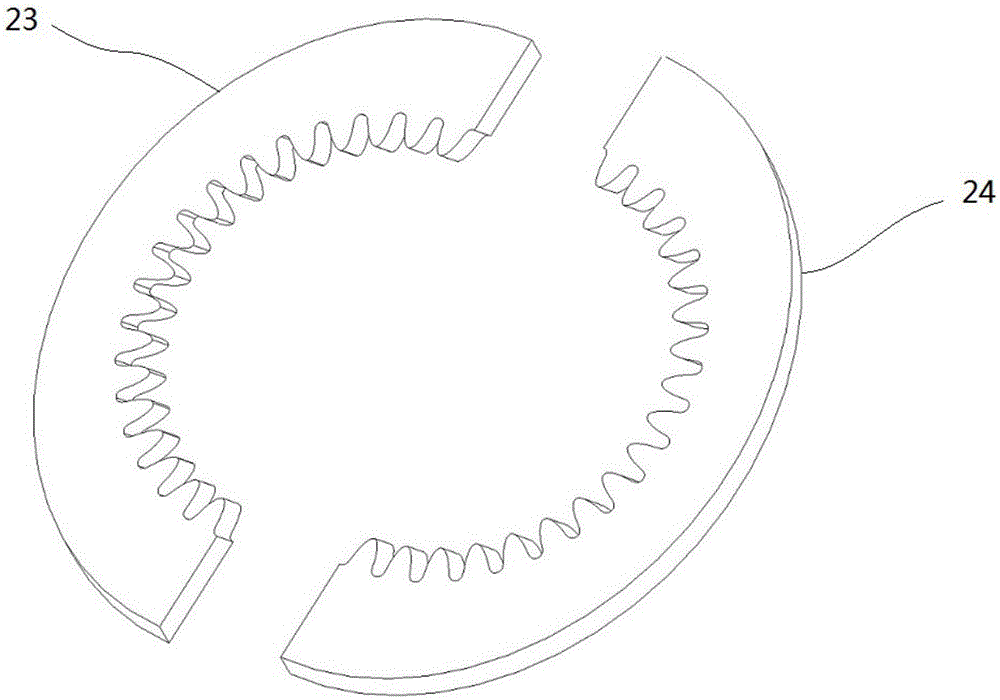

Polyester-aramid guide bearing, thrust disc friction pair and manufacturing method thereof

ActiveCN101865206BImprove wear resistanceHigh mechanical strengthBearing componentsSliding contact bearingsPolyesterPolymer science

The invention provides a polyester-aramid guide bearing, a thrust disc friction plate and a manufacturing method thereof. The invention is characterized in that the guide bearing made of polyester and aramid and the thrust disc friction plate form a friction pair; the outer part of the guide bearing is a tube wall, and a water flow groove is arranged in the tube wall; and the thrust disc frictionplate is arranged on a cast iron base. The manufacturing method comprises the following steps: drying polyester-aramid resin cloth soaked with polyvinyl butyral modified phenolic resin, extruding thecloth with a tube coiling machine, placing the cloth into a guide bearing compression die and a thrust disc friction plate formation die, and pressing for formation under the certain pressure and certain temperature. The invention improves the wear resistance and mechanical strength of the polyester-aramid guide bearing and the thrust disc friction plate manufactured in the method. Moreover, the polyester-aramid guide bearing and the thrust disc friction plate have the advantages of simple structure, low cost, less pollution, long service life and the like.

Owner:沈阳深潜泵业有限公司

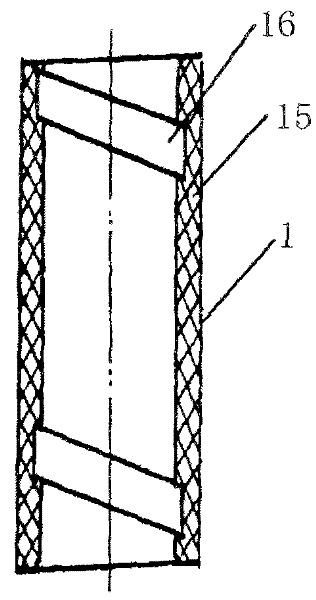

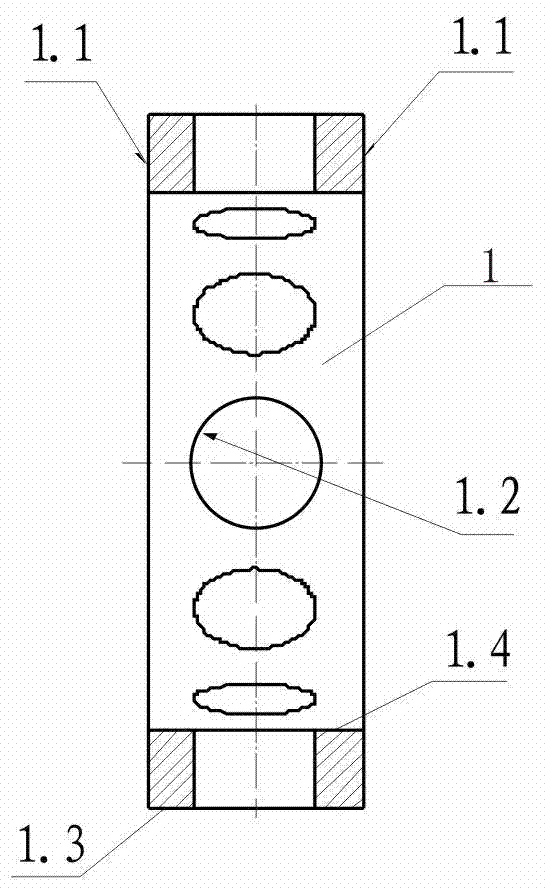

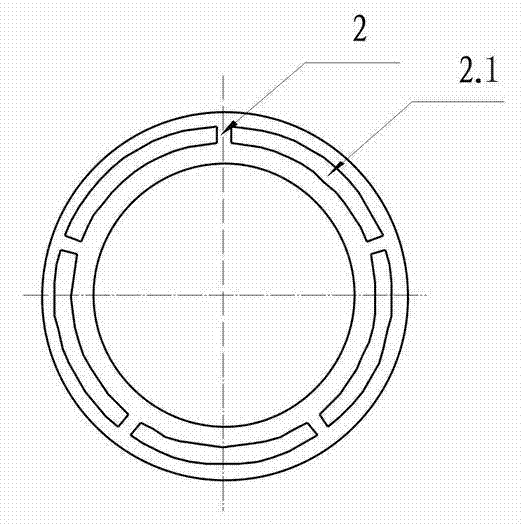

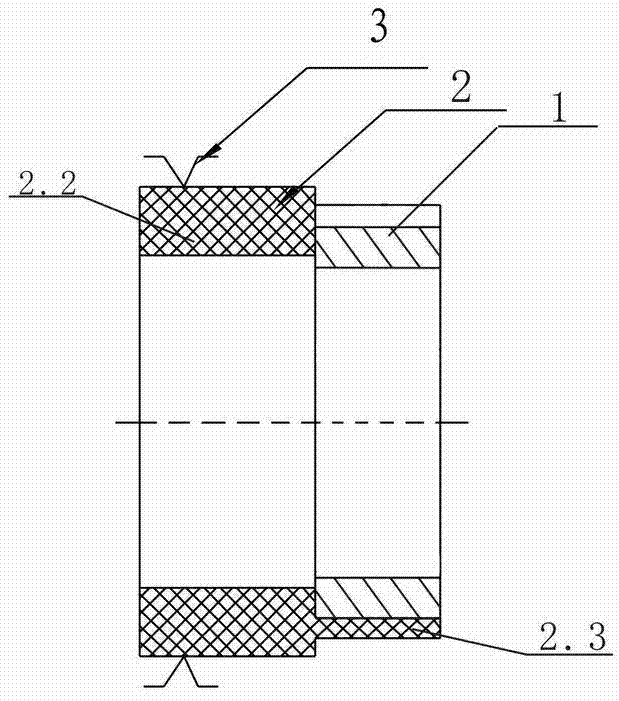

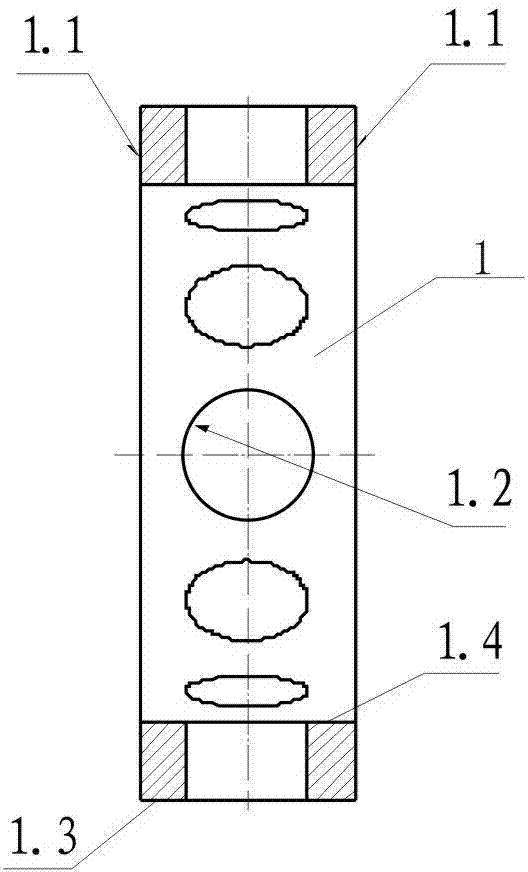

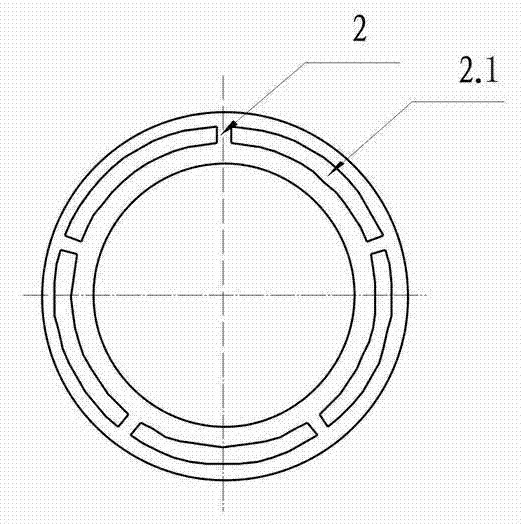

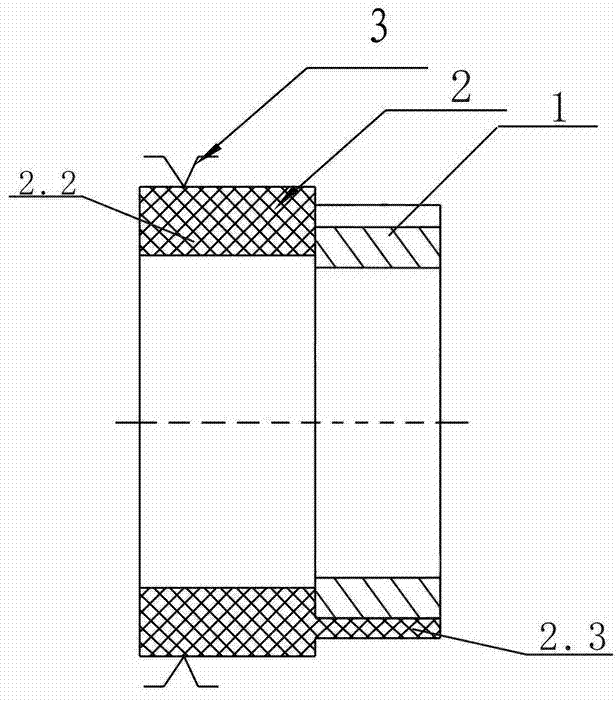

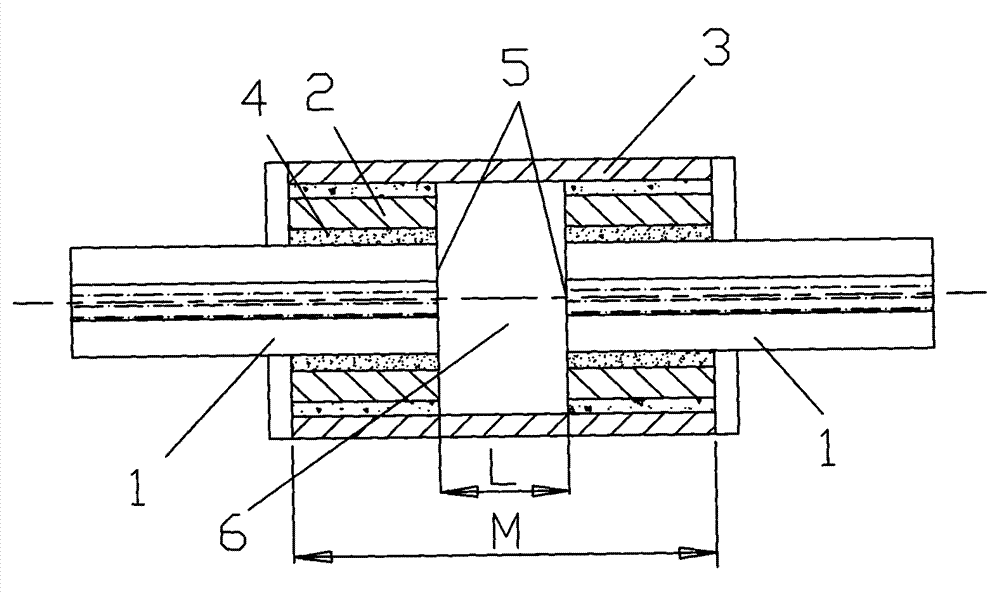

Processing method of aramid fiber reinforced polytetrafluoroethylene holder

ActiveCN103089818AImprove processing pass rateHigh card loading accuracyBearing componentsEngineeringAramid

The invention discloses a processing method of an aramid fiber reinforced polytetrafluoroethylene holder. The aramid fiber reinforced polytetrafluoroethylene holder (1) comprises two lateral end faces (1.1), a pocket (1.2), an outer-diameter end face (1.3) and an inner-diameter end face (1.4); stable treatment I, semi-finish turning on the outer-diameter end face, semi-finish turning on the inner-diameter end face and stable treatment II are added on the basis of the conventional processing; a bakelite expander (2) is used in the semi-finish turning on the outer-diameter end face and semi-finish turning on the inner-diameter end face; the bakelite expander comprises a lathe clamping section (2.2) and a holder fixing section (2.3); and the whole processes of rough turning on the inner-diameter end face, rough turning on the outer-diameter end face, stable treatment I, turning on the two lateral end faces, semi-finish turning on the outer-diameter end face, semi-finish turning on the inner-diameter end face, distributing and drilling pocket, stable treatment II, finish turning on the inner-diameter end face, finish turning on the outer-diameter end face, and final detection are finally formed. The demands on the processing environment temperature are provided, so that the manufacturing percent of pass of the aramid fiber reinforced polytetrafluoroethylene holder is improved to 80% from below 20% in the prior art.

Owner:LUOYANG BEARING RES INST CO LTD

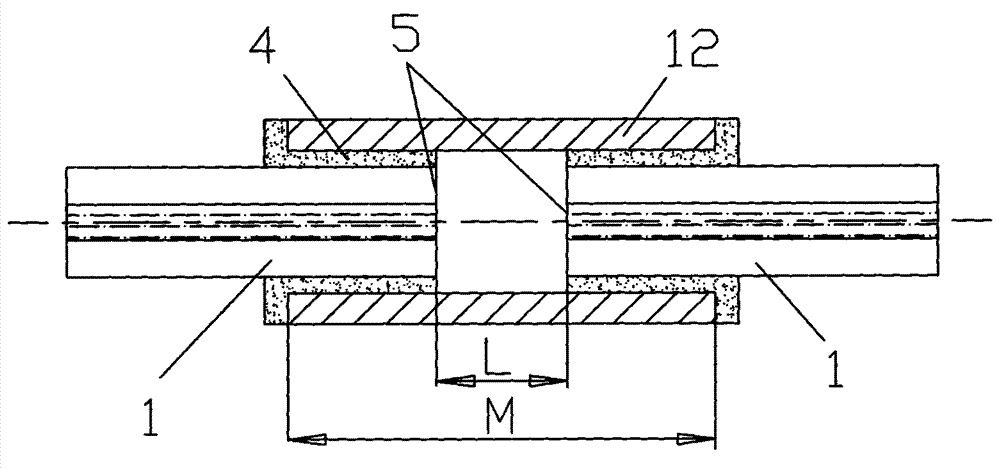

Condensation heat exchange pipe and manufacturing and using method thereof

InactiveCN105547032AIncrease yieldStrong heat transferHeat exchanger fasteningTubular elementsEngineering

The invention provides a condensation heat exchange pipe. The condensation heat exchange pipe comprises a heat exchange base pipe and a plurality of fins connected to the outside of the heat exchange base pipe in a sleeving mode. Each fin is provided with a first surface which is a plane. The heat exchange base pipe is provided with an axis and extends along the axis. The plane where the first surface of each fin is located and the axis of the heat exchange base pipe intersect obliquely. Accumulating of condensation water on the fins can be effectively inhibited through the condensation heat exchange pipe provided by the invention. The invention further provides a manufacturing and using method of the condensation heat exchange pipe.

Owner:SHANGHAI JIAO TONG UNIV

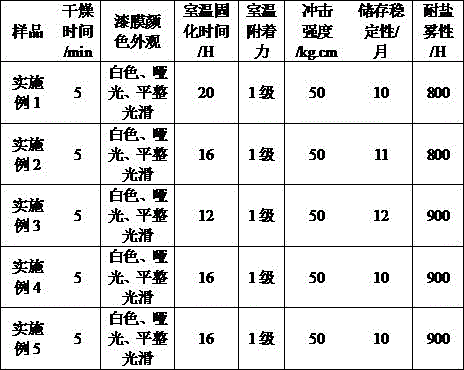

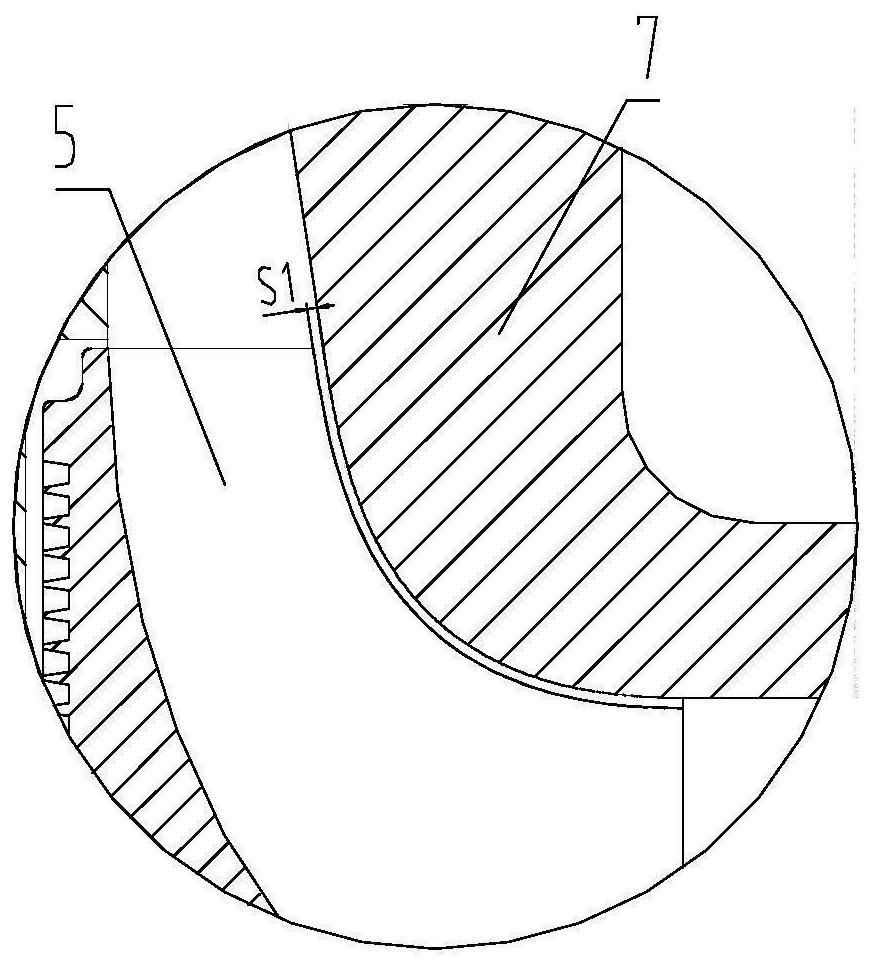

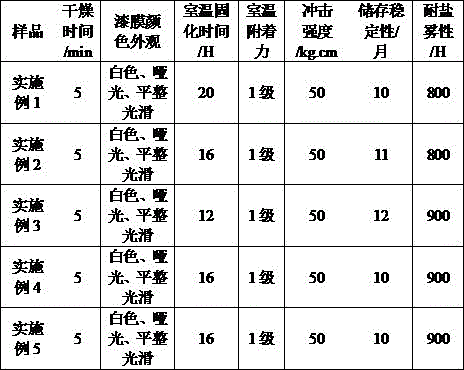

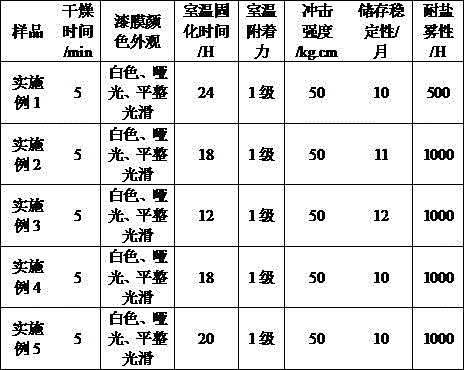

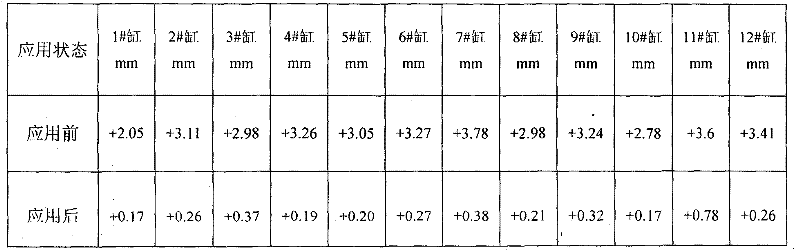

Environment-friendly high-temperature-resistant paint and preparation method thereof

InactiveCN105802287AHigh hardnessImprove cold and heat alternating performanceFireproof paintsAnti-corrosive paintsCrack resistancePhosphate

The invention provides environment-friendly high-temperature-resistant paint, which is prepared from the following ingredients in parts by weight: 10 to 15 parts of silica sol, 15 to 20 parts of aluminium dihydrogen phosphate, 5 to 10 parts of glass powder, 5 to 10 parts of talcum powder, 10 to 15 parts of kaolin powder, 10 to 15 parts of aedelforsite powder, 1 to 5 parts of bis(cyclopentadienyl) ethoxyethyl acrylate and 20 to 30 parts of water. The invention also provides a preparation method of the environment-friendly high-temperature-resistant paint. All ingredients in the environment-friendly high-temperature-resistant paint are mutually matched; the advantages are complementary, so that on the premise of maintaining good attachment force of the paint, the paint has the excellent characteristics of corrosion resistance, high-temperature resistance, crack resistance, corrosion resistance, cold and heat exchange resistance, storage stability and the like.

Owner:HUANGHE S & T COLLEGE

Environment-friendly anti-radiation coating and preparation method thereof

InactiveCN105838197AHigh hardnessImprove cold and heat alternating performanceFireproof paintsAntifouling/underwater paintsEpoxyTemperature resistance

The invention provides an environment-friendly anti-radiation coating .The environment-friendly anti-radiation coating is prepared from, by weight, 20-30 parts of novolac epoxy, 10-20 parts of expanded graphite, 5-10 parts of carbon nano tubes, 1-5 parts of titanium dioxide, 5-10 parts of glass powder, 5-10 parts of talcum powder, 10-15 parts of kaolin powder, 10-15 parts of wollastonite powder, 0.5-3 parts of hydroxypropyl methyl cellulose, 1-5 parts of acrylic acid bicyclo-pentenyl oxy-ethyl ester and 20-30 parts of water .The invention further provides a preparation method of the environment-friendly anti-radiation coating .All the components in the environment-friendly anti-radiation coating are matched and make respective advantages complementary to one another, and on the premise that good adhesive force is kept, the coating has the advantages of excellent corrosion prevention, radiation protection, bacterium resistance, flame retardance, high temperature resistance, fracturing resistance, corrosion resistance, cold and hot alternation resistance, storage stability and the like .

Owner:HUANGHE S & T COLLEGE

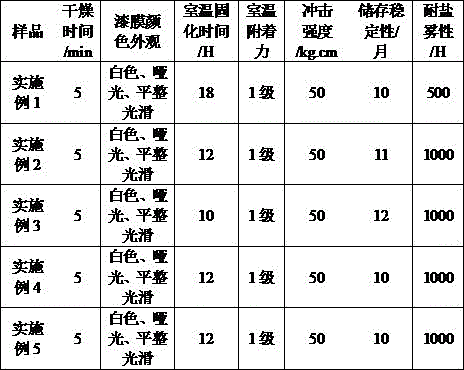

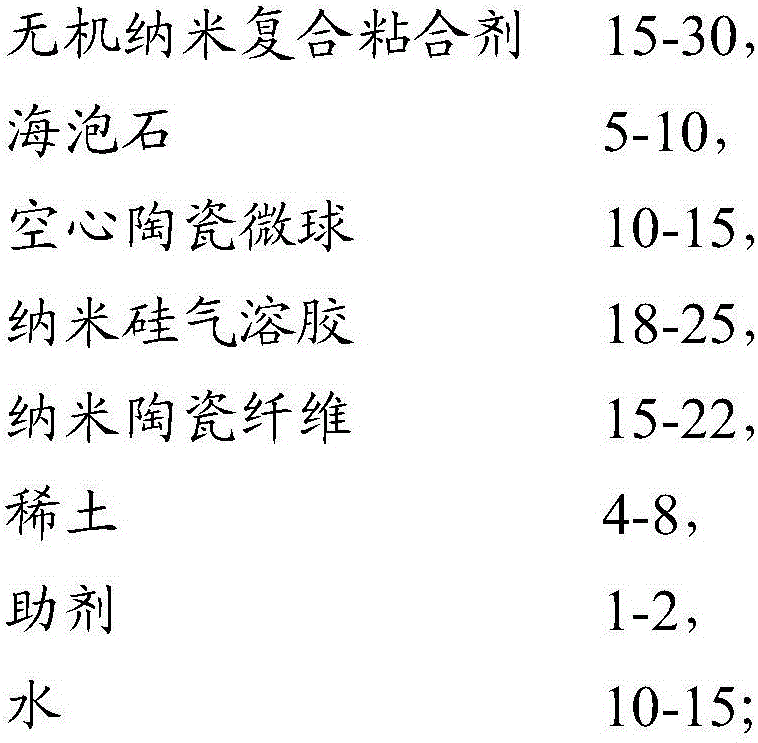

A fireproof and thermal insulation coating

The invention provides a fireproof heat insulation coating. The coating mainly comprises, by mass, 15-30 parts of an inorganic nanometer composite adhesive, 5-10 parts of meerschaum, 10-15 parts of a hollow ceramic microsphere, 18-25 parts of nanometer silicon aerosol, 15-22 parts of nanometer ceramic fiber, 4-8 parts of rare earth, 1-2 parts of an assistant and 10-15 parts of water. The fireproof limit reaches 4h when a coat layer with the thickness of 24mm and of the fireproof heat insulation coating accords with a GB14907-2002 steel structure fireproof heat insulation coating; the heat conduction coefficient is below 0.030W / (m.K), so the coating is a novel heat insulation material for oil tanks, and can realize an energy saving effect; the liner expansion coefficient of the coating is large, so products coated with the coating have stable non-cracking and non-shedding mechanical properties under alternated cooling and heating conditions; and the coating can resist shock waves generated in the blasting process when a fire hazard occurs in order to avoid destroys of a paint film.

Owner:顾国清

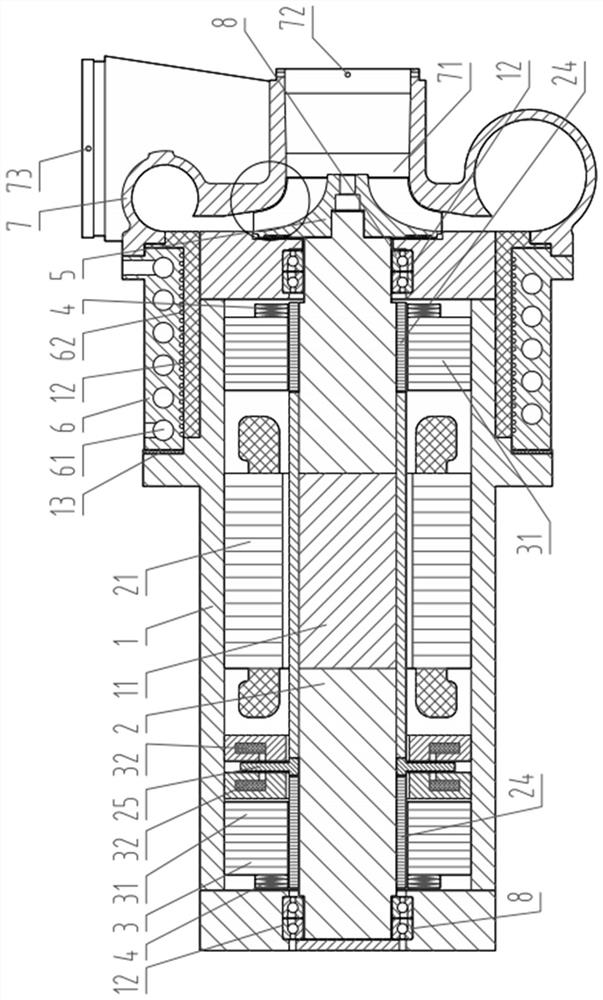

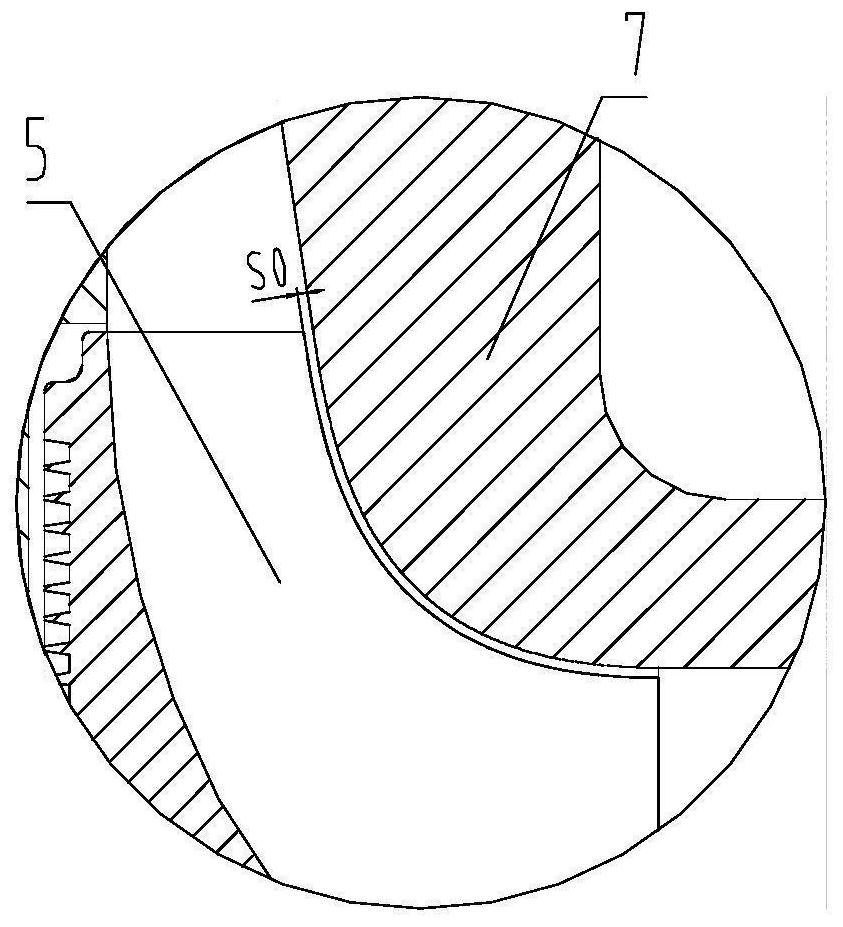

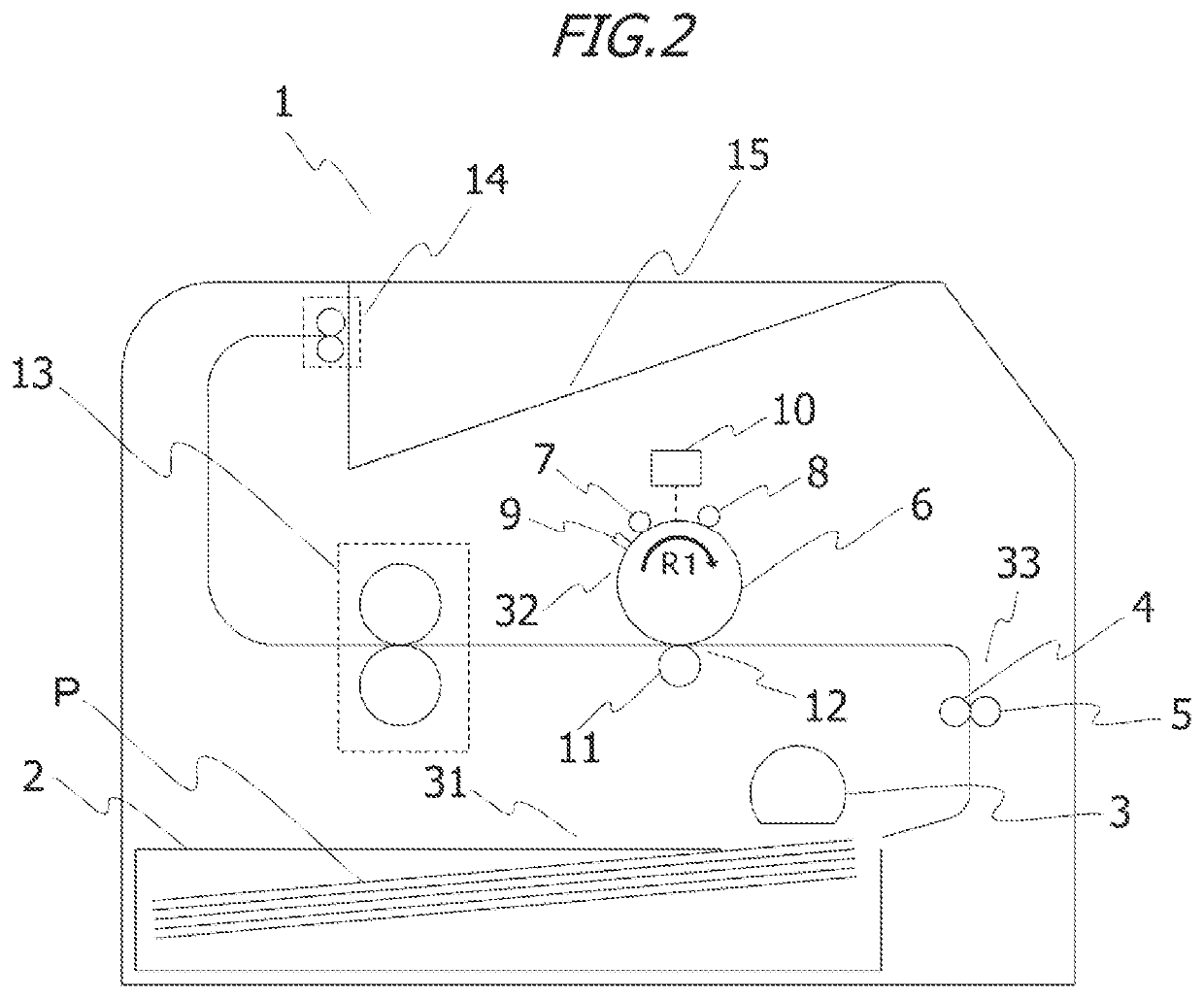

Magnetic suspension blower with adjustable blade tip clearance and debugging method

PendingCN113738674AImprove thermal conductivityLarge coefficient of linear expansionPump componentsPump controlMagnetic bearingEngineering

The invention relates to the field of magnetic suspension air blowers, in particular to a magnetic suspension blower with an adjustable blade tip clearance and a debugging method. The blower comprises a machine shell, a motor shaft, a magnetic bearing device, a plurality of radial and axial sensors, an impeller, an axial adjusting block and a volute; the axial adjusting block is fixed to the machine shell, and the volute is fixed to the axial adjusting block; the volute is provided with an air blowing channel, and the impeller is located in the air blowing channel; the axial adjusting block is made of an aluminum alloy material and is provided with a cooling water channel and a resistance wire; the water inlet end and the water outlet end of the cooling water channel are used for being communicated with a water inlet device and a water outlet device correspondingly, and the resistance wire is used for heating the axial adjusting block; and the air inlet end and the air outlet end of the air blowing channel are provided with a differential pressure flowmeter and a pressure gauge respectively, and the differential pressure flowmeter and the pressure gauge are used for detecting the air flow of the air inlet end of the air blowing channel and the air pressure of the air outlet end of the air blowing channel respectively. The blower can dynamically adjust the blade top gap, and the blowing quality of the magnetic suspension blower is improved.

Owner:XINLEI COMPRESSOR CO LTD

Anti-radiation anti-corrosion coating and preparation method thereof

InactiveCN105754385AHigh transparencyHigh hardnessFireproof paintsAntifouling/underwater paintsPhosphateCarbon nanotube

The invention provides an anti-radiation anti-corrosion coating which comprises the following raw materials in parts by weight: 10-15 parts of zirconium sol, 6-10 parts of aluminum dihydrogen phosphate, 8-12 parts of expanded graphite, 5-10 parts of carbon nanotubes, 1-5 parts of titanium dioxide, 5-10 parts of glass powder, 5-10 parts of talcum powder, 10-15 parts of kaolin powder, 10-15 parts of wollastonite powder, 0.5-3 parts of hydroxypropyl methyl cellulose, 1-5 parts of crylic acid bicyclo-pentenyl yloxyethyl ester and 20-30 parts of water. The invention further provides a preparation method of the anti-radiation anti-corrosion coating. Components of the anti-radiation anti-corrosion coating provided by the invention work together and complement advantages of one another, so that on the premise that the good adhesion property is maintained, the coating has the characteristics of excellent corrosion resistance, radiation resistance, bacterium prevention, flame retardancy, high temperature resistance, cracking prevention, corrosion resistance, cold and heat alternation denaturation, storage stability and the like.

Owner:HENAN SPECIAL EQUIP INSPECTION INST XINXIANG BRANCH

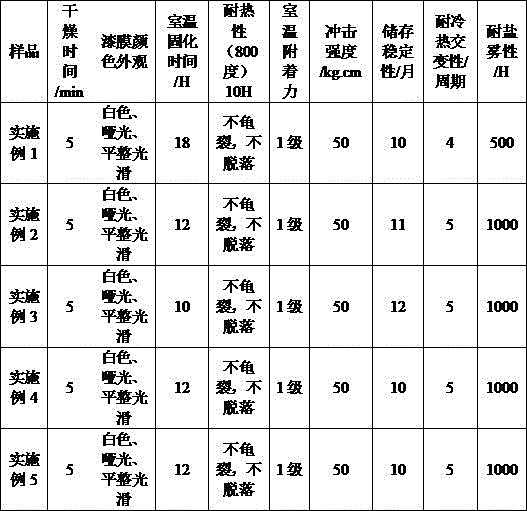

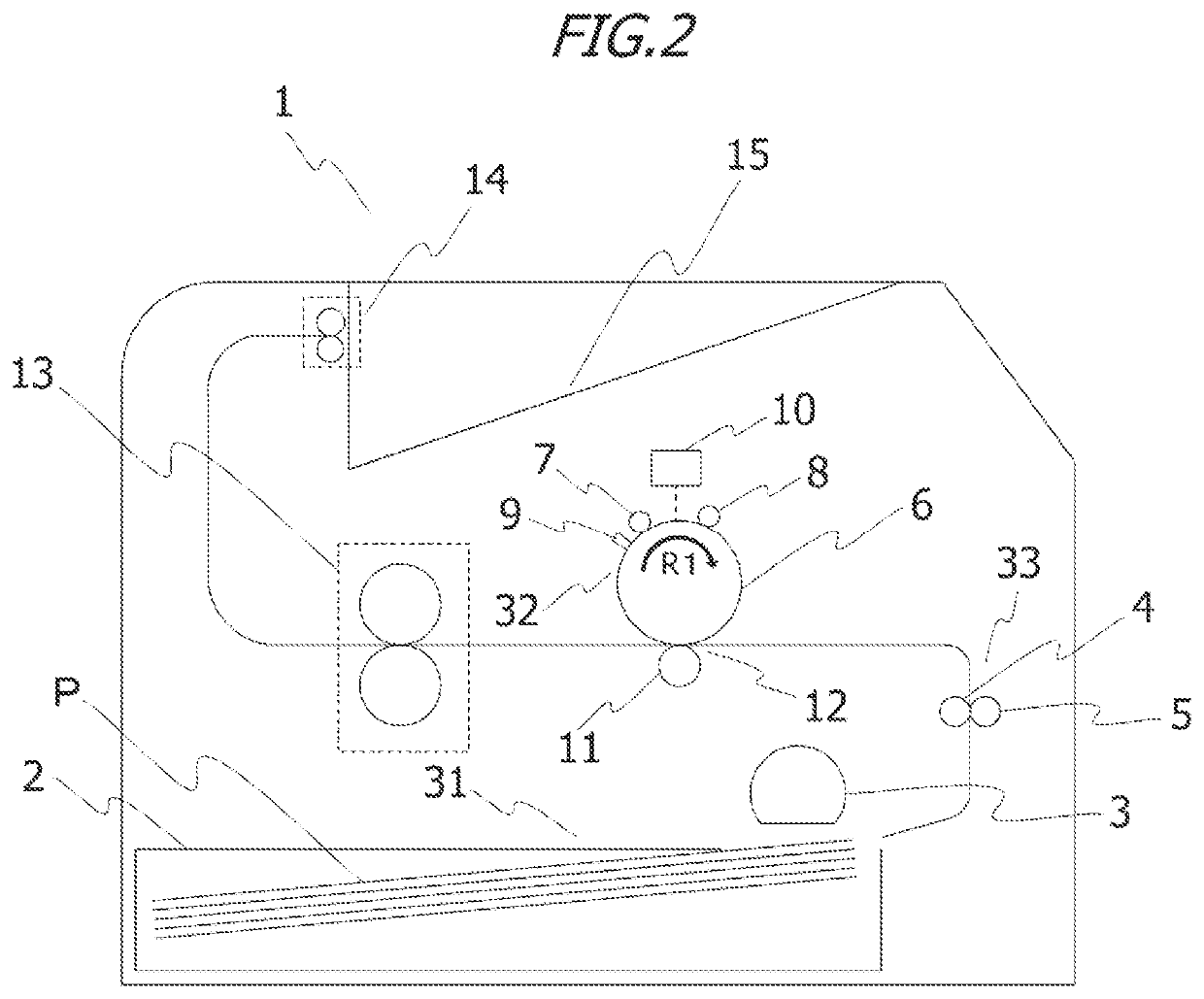

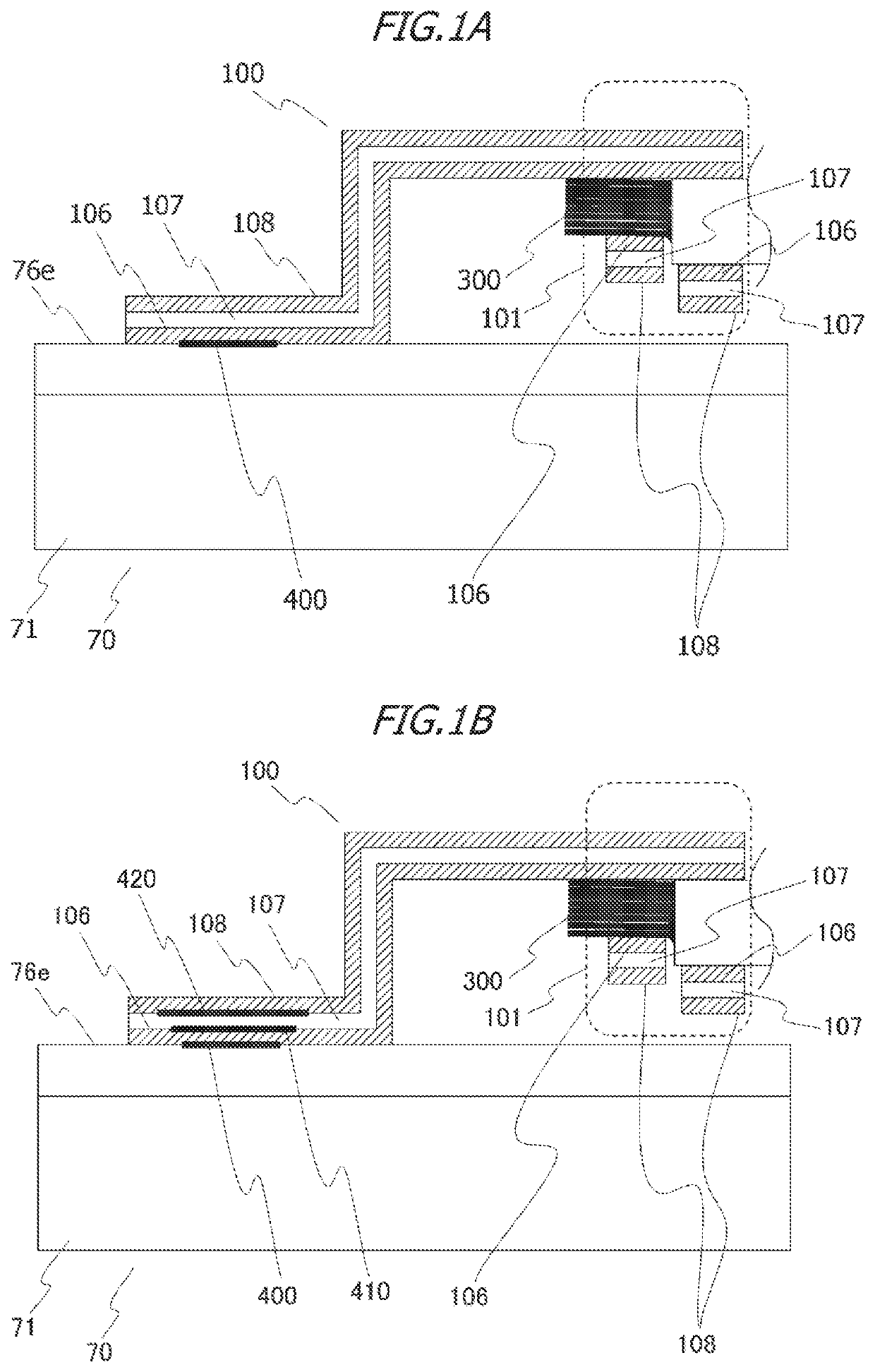

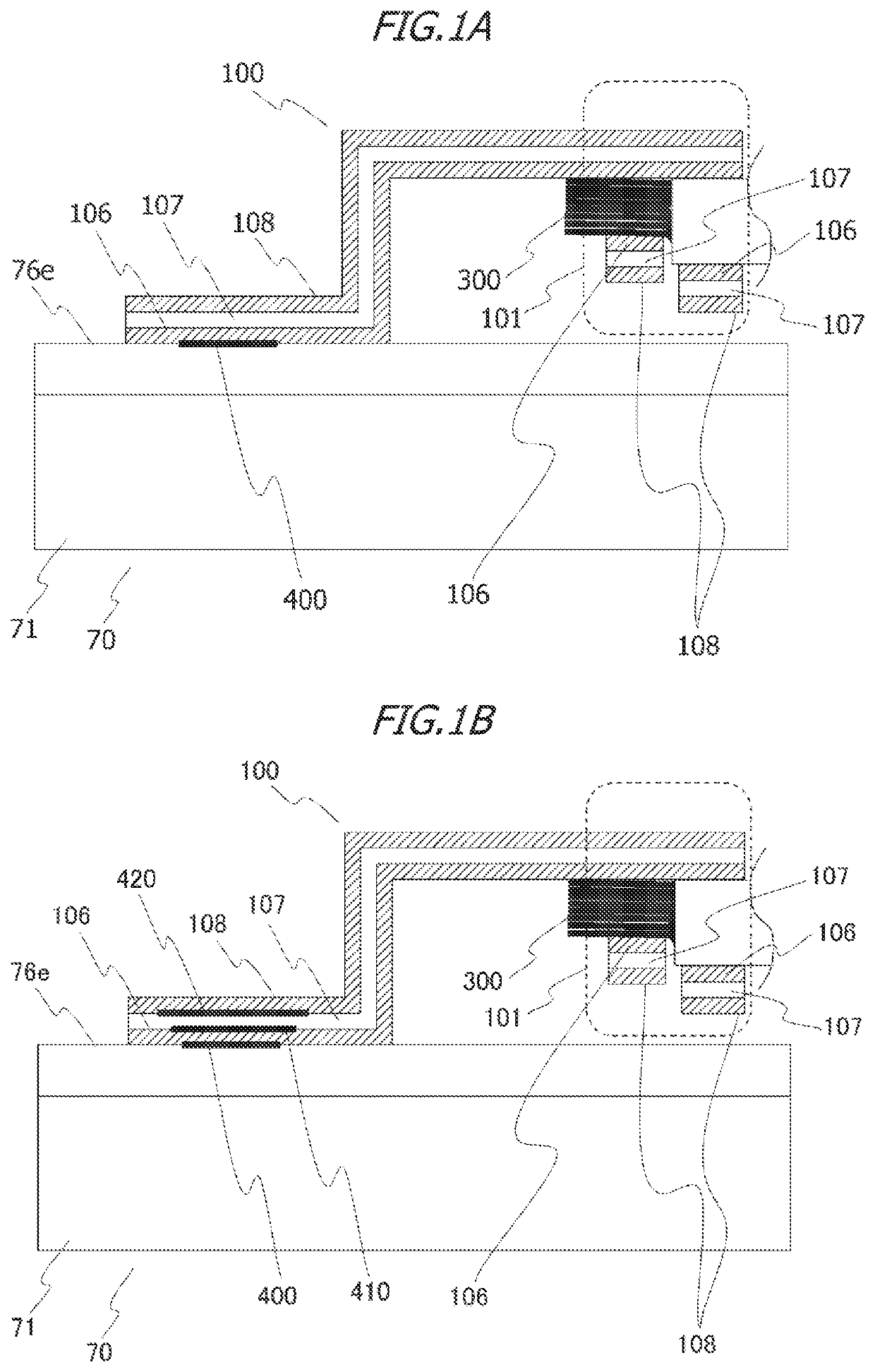

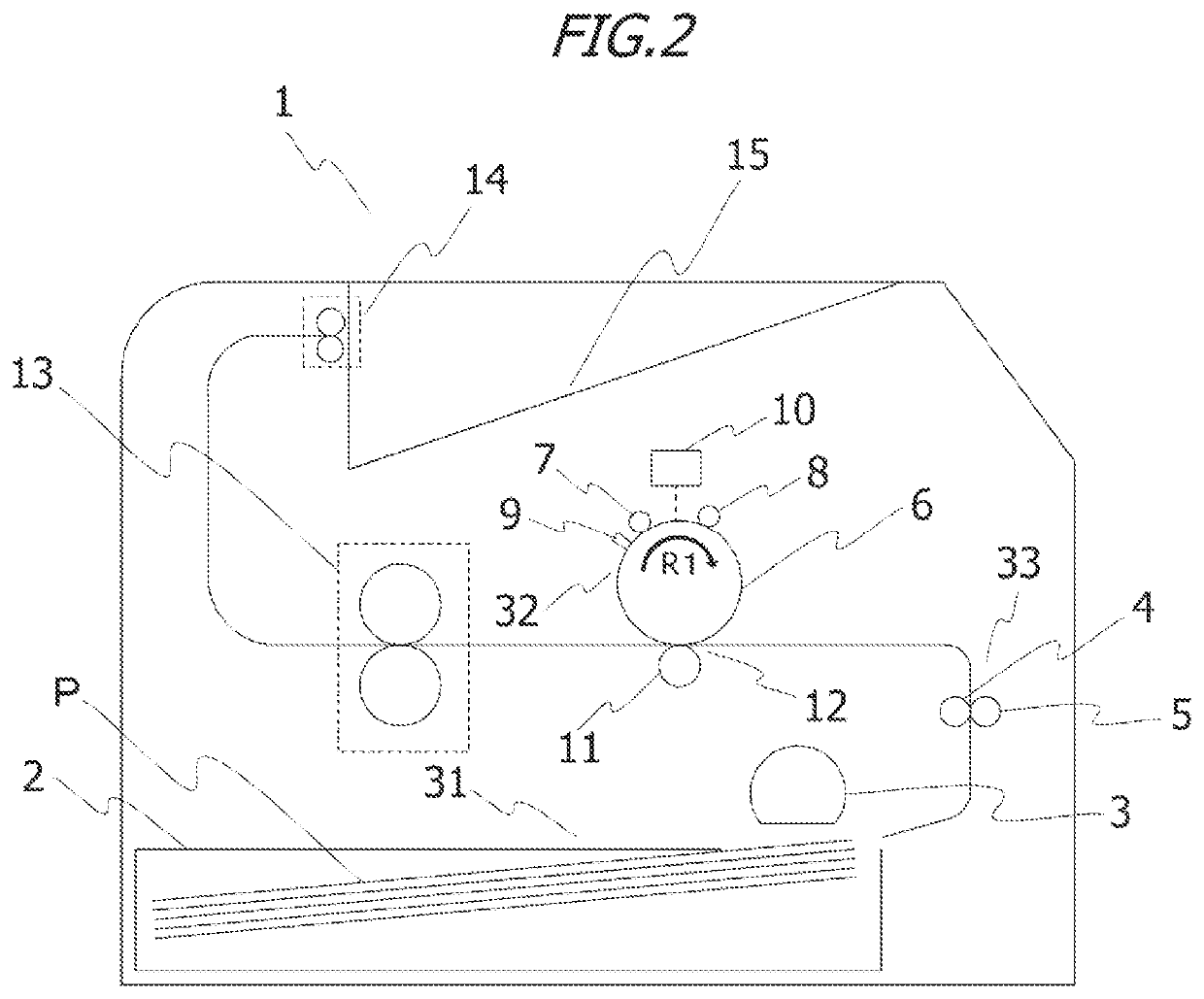

Fixing apparatus and image forming apparatus

ActiveUS20210373472A1Large coefficient of linear expansionReduced life-timeElectrographic process apparatusImage formationElectrical connection

A fixing apparatus according includes: a heater that includes a substrate, a heating element provided on the substrate, and an electrode provided on the substrate and electrically connected to the heating element; and a power supply member that includes a first member bonded or coupled to the electrode to supply power to the heating element and a second member bonded or coupled to an opposite surface of the first member to a surface, which is bonded or coupled to the electrode, of the first member, wherein the heater generates heat by power supplied via the power supply member, and an image formed on a recording material is heated by heat of the heater; and a liner expansion coefficient of the first member is different from a liner expansion coefficient of the second member.

Owner:CANON KK

Copper alloy sliding bearing repairing technology

The invention belongs to the field of bearing renovation, and relates to a copper alloy sliding bearing repairing technology. The copper alloy sliding bearing repairing technology is suitable for repairing of various kinds of copper alloy sliding bearings. The copper alloy sliding bearing repairing technology comprises the following steps that (1) a surface defect is inspected, and the damaged position of the copper alloy sliding bearing is determined and marked; (2) a gas etching part is ground; (3) welding repairing is carried out; and (4) finish machining is carried out. Aiming at the copper alloy sliding bearing renovation, a welding technology method of precise impulse welding is provided, by grinding the gas etching part, the welding technology method of precise impulse welding is adopted, and the bearing is machined to an original size, so that the using performance of the bearing is recovered.

Owner:浙江翰德圣智能再制造技术有限公司

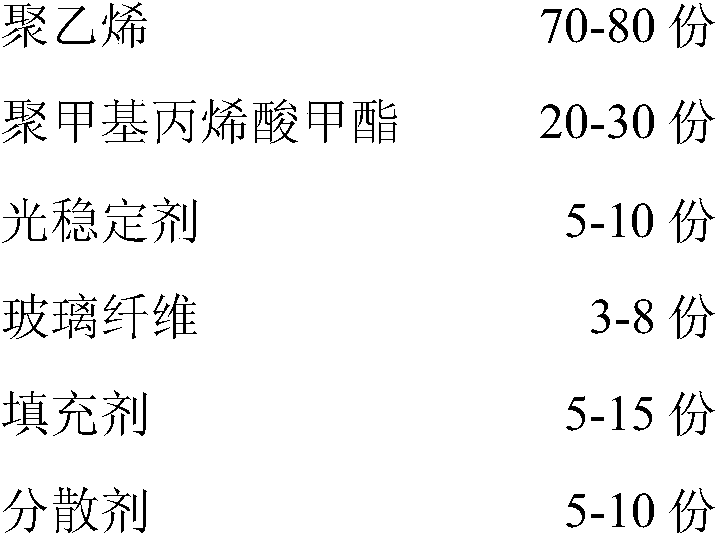

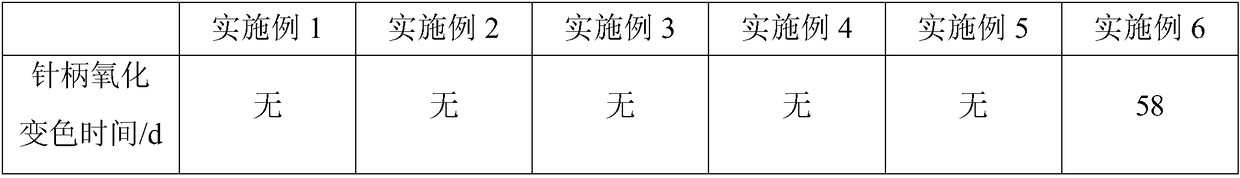

acupuncture needles

ActiveCN106009183BGood chemical stabilityLarge coefficient of linear expansionAcupunctureSilicon dioxideNano titania

Owner:江苏凯邦医疗器械有限公司

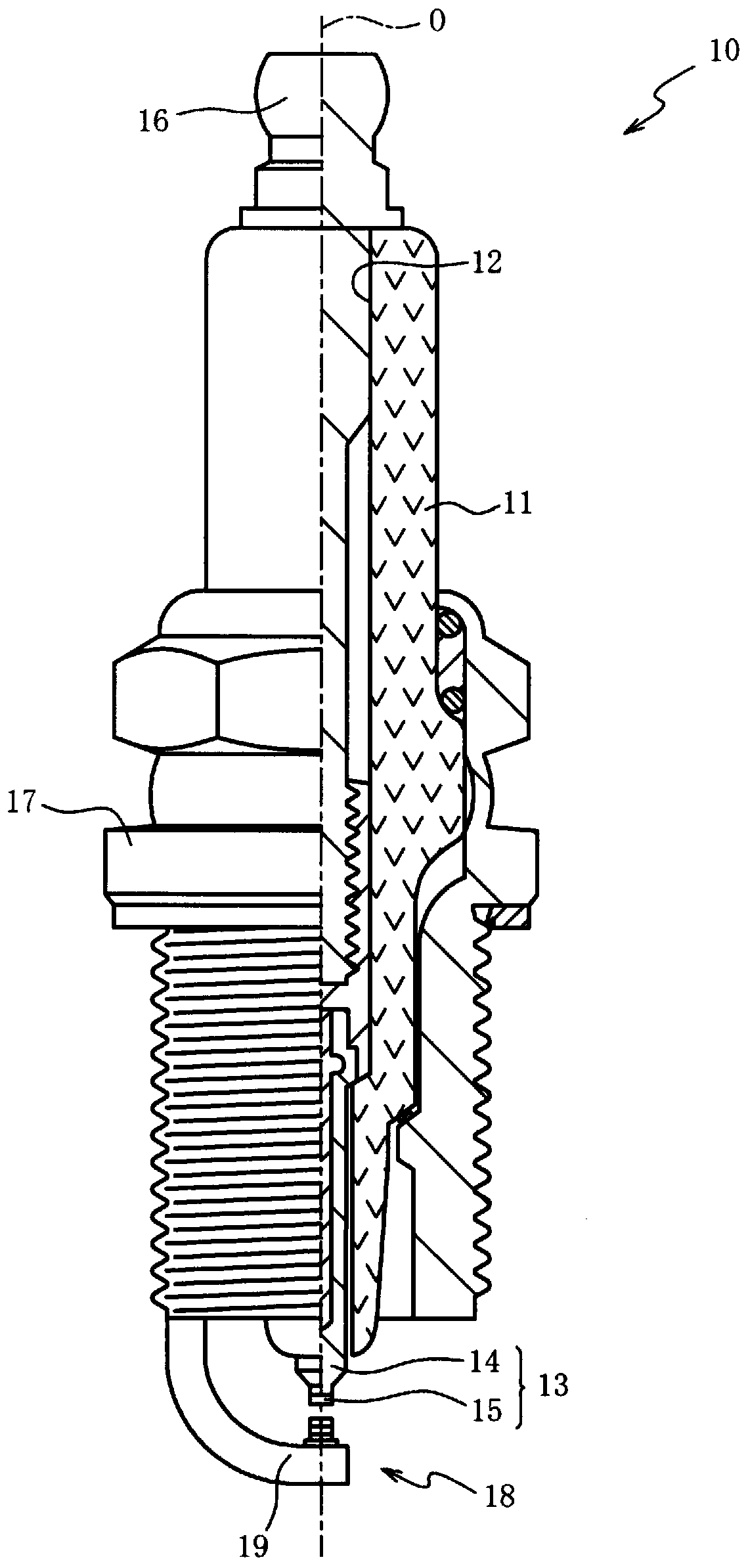

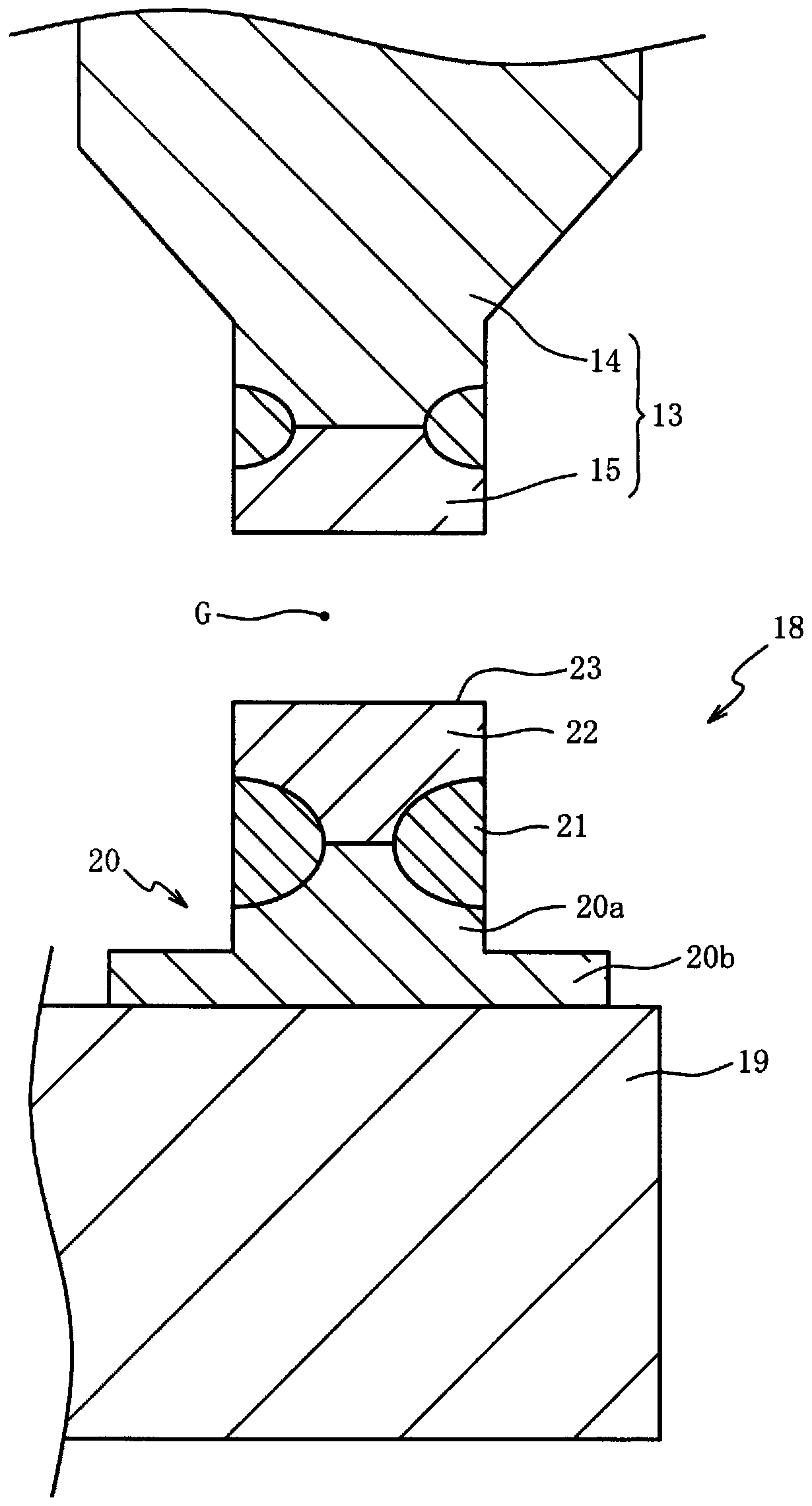

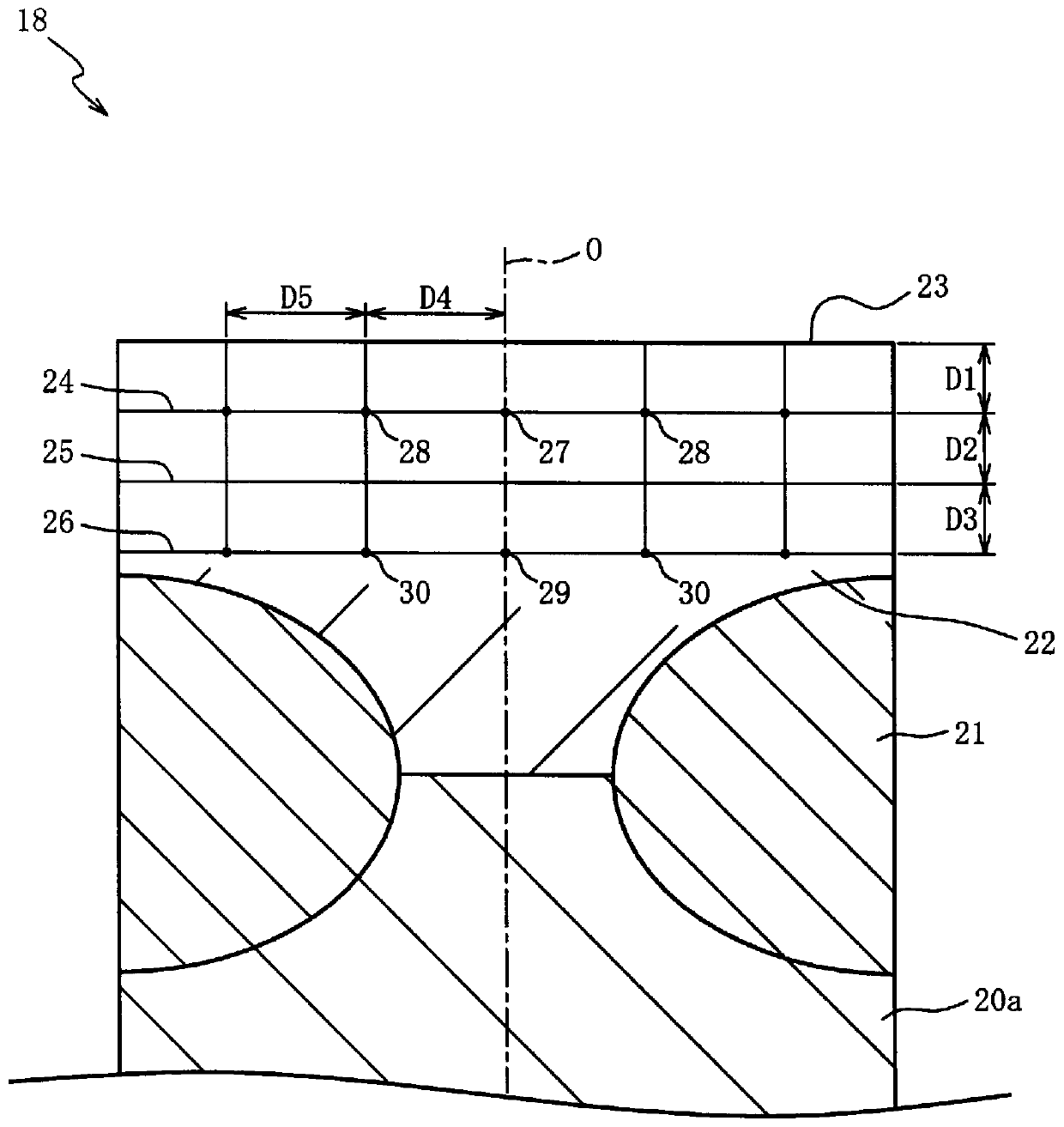

spark plug

ActiveCN108429130BAvoid deformationInhibit oxidative wearSparking plugs manufactureAlloyWear resistance

The present invention provides a spark plug capable of improving the wear resistance of an intermediate member and a melting portion. The spark plug includes: an intermediate piece composed of an alloy mainly composed of Ni and welded to the electrode base material in a state protruding from the electrode base material; a tip composed of an alloy mainly composed of Pt; into the fusion zone. The terminal contains: 6% by mass or more of Rh; at least one selected from the group R consisting of Rh, Re, Ir, Ru, W, Mo, and Nb; 5% by mass or more of Ni; At least one selected from the N group consisting of , Fe and Cu. Rh is the most contained in the R group, and Ni is the most contained in the N group. The total content of Pt, Rh, and Ni is 91% by mass or more, and the total content of Pt, R group, and N group is 95% by mass or more. The value obtained by dividing the content of the R group by the content of the N group is 0.7 or more and 8 or less.

Owner:NGK SPARK PLUG CO LTD

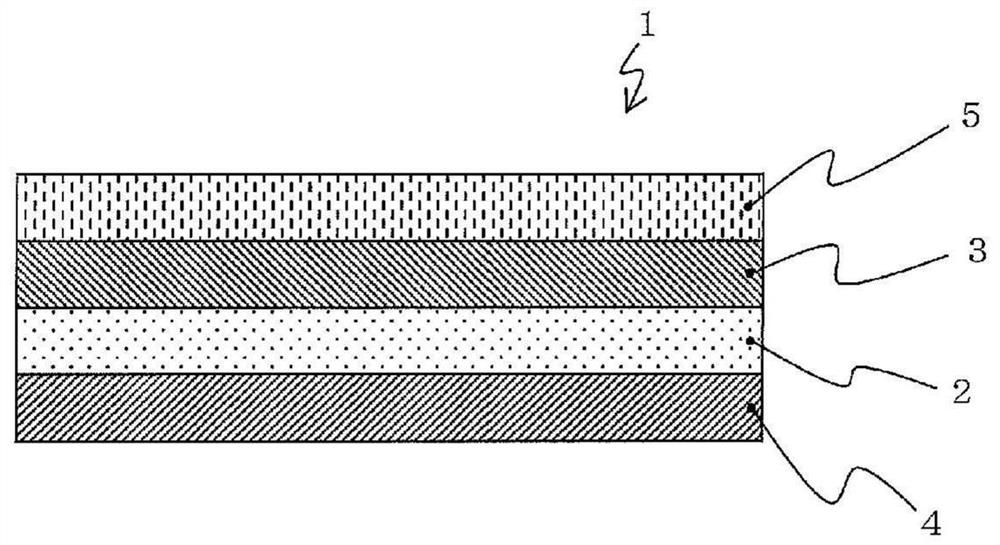

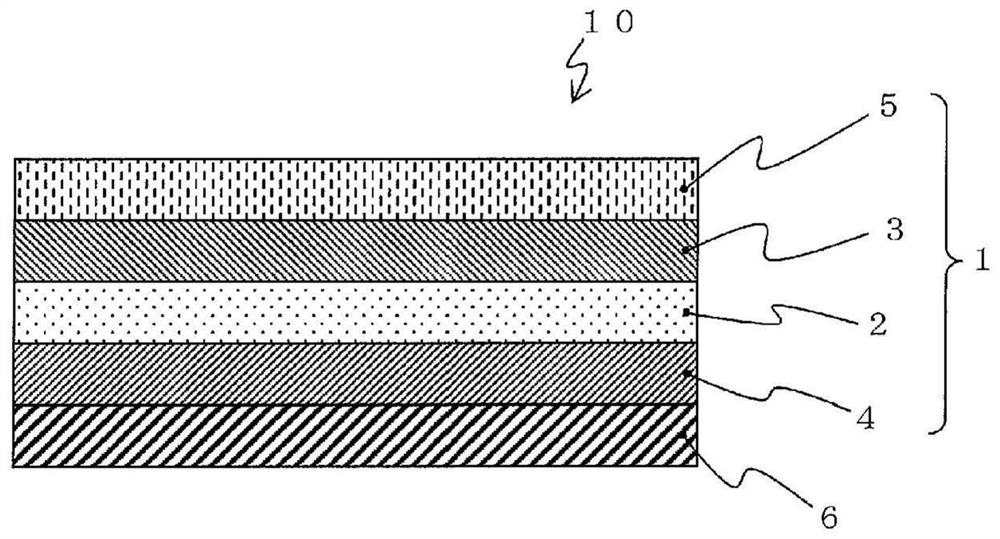

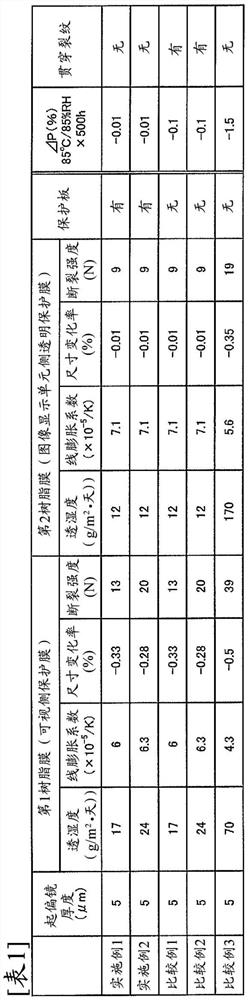

Polarizing film, polarizing film with adhesive layer, and image display device

ActiveCN109154689BInhibit deteriorationSmall dimensional change rateFilm/foil adhesivesPolarising elementsWater vaporMoisture permeability

The polarizing film of the present invention has a first resin film on one side of a polarizer having a thickness of 10 μm or less, and a second resin film on the other side, wherein the moisture permeability of the first resin film and the second resin film is 30 g / m. (m 2 ·Day) or less, there is a protective plate on the surface of the side opposite to the side which has the said polarizer of the said 1st resin film. The polarizing film of the present invention is formed by laminating resin films with extremely low moisture permeability on both sides of a polarizer with a thickness of 10 μm or less, which can suppress the deterioration of the polarizer due to humidification (humidification reliability), and even Generation of through cracks can be suppressed even under severe environments such as thermal shock.

Owner:NITTO DENKO CORP

Solid electrolytic capacitor and method for manufacture thereof

ActiveUS8081420B2Suppress leakage currentLow costSolid electrolytic capacitorsClosuresEngineeringElectrolytic capacitor

On a surface of an anode member 12 having a valve action, a cathode layer 14 is formed, and at a terminal lead-out face 12a at one end of the anode member 12, an anode wire 16 is led out of it; thus a capacitor element 10 is formed. An anode terminal 4 is joined to the anode wire 16. A cathode terminal 5 is joined to the cathode layer 14. A protective layer 2 of resin covers part or all of the capacitor element 10. A packaging member 3 of resin harder than the protective layer 2 covers around the capacitor element 10 including the protective layer 2 and the anode wire 16 to form a package. The protective layer 2 has a larger linear expansion coefficient than the packaging member 3. The mass ratio of the packaging member 3 to the total mass of the packaging member 3 and the protective layer 2 between the terminal lead-out face 12a and the exterior face of the packaging member 3 opposite the terminal lead-out face 12a is 50% or more.

Owner:SAN DENSHI INDS

Novolac epoxy resin multifunctional radiation-resistant paint and preparation method thereof

The invention provides a novolac epoxy resin multifunctional radiation-resistant paint. The novolac epoxy resin multifunctional radiation-resistant paint comprises the following raw materials in parts by weight: 20-30 parts of novolac epoxy resin, 10-15 parts of expanded graphite, 5-10 parts of carbon nanotube, 0.5-3 parts of hydroxypropyl methylcellulose, 8-14 parts of glass powder, 5-10 parts of talcum powder, 18-22 parts of kaolin powder, 10-15 parts of wollastonite powder, 1-5 parts of bicyclopentenyloxyethyl acrylate and 20-30 parts of water. The invention also provides a preparation method of the novolac epoxy resin multifunctional radiation-resistant paint. Various components in the novolac epoxy resin multifunctional radiation-resistant paint interact and complement each other's advantages, so that the paint has the characteristics of excellent corrosion resistance, excellent radiation resistance, excellent flame retardancy, excellent high temperature resistance, excellent crack resistance, excellent rust resistance, excellent cold-heat alternation resistance, high storage stability and the like.

Owner:HUANGHE S & T COLLEGE

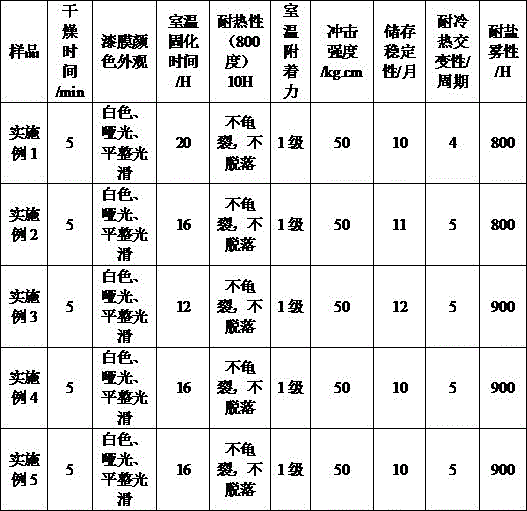

Nano graphene steel-based self-lubricating composite material and preparation method thereof

InactiveCN110626018AHigh friction and wearHigh mechanical strengthLamination ancillary operationsSynthetic resin layered productsGrapheneUltimate tensile strength

The invention discloses a nano graphene steel-based self-lubricating composite material and a preparation method thereof, and relates to the field of materials. The nano graphene steel-based self-lubricating composite material is composed of a nano working layer and a steel matrix in sequence from top to bottom; wherein the nano working layer material comprises the following components in percentage by mass: 20-30% of nano graphene, 50-60% of polytetrafluoroethylene, 10-20% of polyethylene and 10% of poly-p-hydroxybenzoate. The nano graphene steel-based self-lubricating composite material is capable of avoiding the defects of low bonding strength, high friction and wear resistance, short service life and the like of the conventional steel-based self-lubricating composite materials; and thenano steel-based composite material which is prepared through firmly bonding of a steel base with a mixed nano material, and has the advantages of high friction and wear resistance, high mechanical strength, good wear resistance and good impact resistance is provided.

Owner:JIANGSU UNIV

Fixing apparatus having a power supply member including first and second members with different linear expansion coefficients, and image forming apparatus

ActiveUS11397395B2Large coefficient of linear expansionReduced life-timeElectrographic process apparatusThermodynamicsElectric power

A fixing apparatus according includes: a heater that includes a substrate, a heating element provided on the substrate, and an electrode provided on the substrate and electrically connected to the heating element; and a power supply member that includes a first member bonded or coupled to the electrode to supply power to the heating element and a second member bonded or coupled to an opposite surface of the first member to a surface, which is bonded or coupled to the electrode, of the first member, wherein the heater generates heat by power supplied via the power supply member, and an image formed on a recording material is heated by heat of the heater; and a liner expansion coefficient of the first member is different from a liner expansion coefficient of the second member.

Owner:CANON KK

Radiation-resistant novolac epoxy resin paint and preparation method thereof

InactiveCN105860622AHigh hardnessUniform particle size distributionFireproof paintsAnti-corrosive paintsEpoxyCrack resistance

The invention provides a radiation-resistant novolac epoxy resin paint, comprising the following raw materials in parts by weight: 20-30 parts of novolac epoxy resin, 15-20 parts of expanded graphite, 10-15 parts of perlite, 5-10 parts of glass powder, 5-10 parts of French chalk, 10-15 parts of kaolin powder, 10-15 parts of wollastonite in powder, 1-5 parts of acrylic acid dicyclopentadiene-oxygen-ethyl ester and 20-30 parts of water. The invention also provides a preparation method of the radiation-resistant novolac epoxy resin paint. The radiation-resistant novolac epoxy resin paint provided by the invention has the advantages of interaction and complementation of advantages of the components, so that the paint has the characteristics of good adhesive force as well as excellent corrosion resistance, high temperature resistance, cracking resistance, cold and hot alternation resistance, stability in storage and the like.

Owner:HUANGHE S & T COLLEGE

Fixing apparatus and image forming apparatus

ActiveUS20220326644A1Large coefficient of linear expansionReduced life-timeElectrographic process apparatusElectrical connectionPhysics

A fixing apparatus according includes: a heater that includes a substrate, a heating element provided on the substrate, and an electrode provided on the substrate and electrically connected to the heating element; and a power supply member that includes a first member bonded or coupled to the electrode to supply power to the heating element and a second member bonded or coupled to an opposite surface of the first member to a surface, which is bonded or coupled to the electrode, of the first member, wherein the heater generates heat by power supplied via the power supply member, and an image formed on a recording material is heated by heat of the heater; and a liner expansion coefficient of the first member is different from a liner expansion coefficient of the second member.

Owner:CANON KK

Processing method of aramid fiber reinforced polytetrafluoroethylene holder

ActiveCN103089818BImprove processing pass rateHigh card loading accuracyBearing componentsEngineeringAramid

The invention discloses a processing method of an aramid fiber reinforced polytetrafluoroethylene holder. The aramid fiber reinforced polytetrafluoroethylene holder (1) comprises two lateral end faces (1.1), a pocket (1.2), an outer-diameter end face (1.3) and an inner-diameter end face (1.4); stable treatment I, semi-finish turning on the outer-diameter end face, semi-finish turning on the inner-diameter end face and stable treatment II are added on the basis of the conventional processing; a bakelite expander (2) is used in the semi-finish turning on the outer-diameter end face and semi-finish turning on the inner-diameter end face; the bakelite expander comprises a lathe clamping section (2.2) and a holder fixing section (2.3); and the whole processes of rough turning on the inner-diameter end face, rough turning on the outer-diameter end face, stable treatment I, turning on the two lateral end faces, semi-finish turning on the outer-diameter end face, semi-finish turning on the inner-diameter end face, distributing and drilling pocket, stable treatment II, finish turning on the inner-diameter end face, finish turning on the outer-diameter end face, and final detection are finally formed. The demands on the processing environment temperature are provided, so that the manufacturing percent of pass of the aramid fiber reinforced polytetrafluoroethylene holder is improved to 80% from below 20% in the prior art.

Owner:LUOYANG BEARING RES INST CO LTD

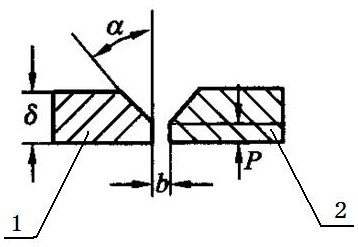

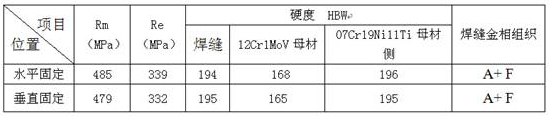

Welding method for 12Cr1MoV and 07Cr19Ni 11Ti dissimilar steel

PendingCN113878207ASolve the problem of welding processGuaranteed safe service lifeArc welding apparatusWelding/soldering/cutting articlesWeld seamSS - Stainless steel

The invention relates to a welding method for 12Cr1MoV and 07Cr19Ni 11Ti dissimilar steel. In the prior art, austenite and pearlitic steel are mostly welded by adopting constantan welding wires, so that the cost is higher, weld joints are deformed and cracked, and welding in the prior art is not suitable for batch production. The dissimilar steel comprises dissimilar steel A (1) and dissimilar steel B (2), the butt gap b of the dissimilar steel A and the dissimilar steel B is 2.0 mm-3.0 mm, the groove angle a is 30 degrees-35 degrees, the truncated edge p is 1.5 mm-2.0 mm, the thickness delta of a pipe is 5 mm, a TGS-347 welding wire is adopted, the diameter of the welding wire is 2.4 mm, assembling is conducted in a free state during welding, manual tungsten electrode argon arc welding is adopted, an internal wire adding welding method is adopted during bottoming, after the pipeline is filled with argon and is stable, root layer welding is conducted, and the temperature between layers is controlled to be smaller than or equal to 350 DEG C; and the method comprises the steps that firstly, grooves in the base metal sides of the dissimilar steel A and the dissimilar steel B are machined, the surfaces of the grooves and the outer walls, within 10 mm, of the two sides of the base metal are cleaned, and then horizontal fixed welding and vertical fixed welding are conducted. The welding method is used for the dissimilar steel of pearlite steel and austenitic stainless steel.

Owner:HUANENG GANSU XIGU THERMAL POWER CO LTD

Extrinsic type Fabry-Perot sensor and manufacture method thereof

ActiveCN101788700BConvenient and flexible manufacturing processPrecise control of cavity lengthForce measurement by measuring optical property variationThermometers using physical/chemical changesQuartzOptical fiber cable

The invention relates to an extrinsic type Fabry-Perot sensor which comprises two segments of optical fibers, two segments of metallic plugging cores and metallic sleeves, wherein the inner side of each segment of the metallic plugging core is fixed with one segment of the optical fiber, the outer sides of the two segments of the metallic plugging core are encapsulated with the metallic sleeves, an end face group is oppositely formed on the end parts of the two segments of the optical fibers and / or the two segments of the metallic plugging cores, a hollow cavity is formed by the end face group and the metallic sleeves, and the end face group is coated with a reflecting film. Compared with the cavity structure of a common optical fiber method Fabry-Perot sensor manufactured by using capillary quartz glass, the cavity structure of the invention has the advantages of simple process, convenient manufacturing, low cost and the like.

Owner:JIANGSU NANFANG COMM TECH

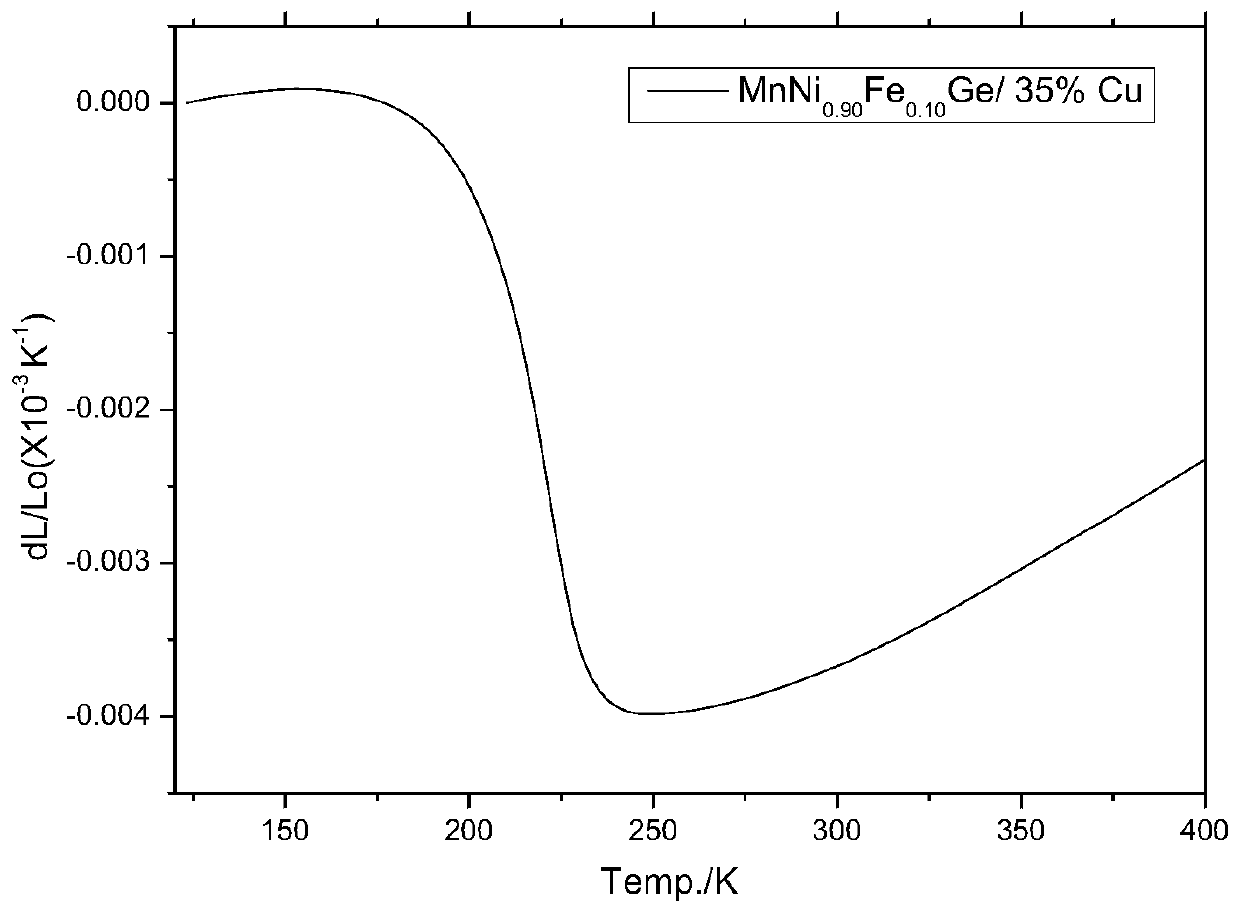

A kind of alloy material with negative thermal expansion property and preparation method thereof

ActiveCN107385305BLarge coefficient of linear expansionLarge temperature rangeHeat-exchange elementsAlloySolid metal

A majority of materials in the natural world have positive thermal expansion properties, namely, within the certain temperature range, with increasing of the temperature, the materials are expanded in one direction or multiple directions. In actual engineering application, the great influence on the stability, accuracy, the service life and the like of engineering components is achieved. A negative thermal expansion material is a good expansive retarder which can be used for reconciling positive thermal expansion, improving the accuracy of the engineering components, prolonging the service life of the engineering components and the like. The invention provides a solid metal alloy material with the negative thermal expansion property and a preparation method thereof, the solid metal alloy material can serve as an expansive retarder material for using, the alloy material has the negative thermal expansion property within the certain temperature interval, and the general chemical formula of the alloy material is MnNi(1-x)FexGe / Cu or Mn(1-y)FeyNiGe / Cu (0<=x<=1, and 0<=y<=1), for example, the MnNi0.90Fe0.10Ge / 35wt% Cu alloy material has the negative thermal expansion property under the condition of 176K<T<247K, and the thermal expansion coefficient of the alloy material is -56.7357*10<-6>K<-1>.

Owner:BEIHANG UNIV

Composition for repairing surfaces of metallic rubbing pairs and preparation thereof

The invention provides a composition for restoring the surface of a metallic rubbing pair and a preparation method thereof, and relates to the composition for restoring the surface of the metallic rubbing pair and the preparation method thereof. The invention solves the problem that the restoring film formed by the prior restoring material has limited thickness which can not reach over 0.5 millimeter and can not effectively control the clearance between the metallic rubbing pair. The composition consists of nickelous chloride powder, aluminum powder, nickel powder, ferric oxide powder, silicon dioxide powder, a powder suspending agent, a surface modifier and mineral lubricating oil. The preparation method is to put the nickelous chloride powder, the aluminum powder, the nickel powder, theferric oxide powder, the silicon dioxide powder, the powder suspending agent, the surface modifier and the mineral lubricating oil in a high-speed viscolizer to be homogenized for 30 to 40 minutes. The composition for restoring the surface of the metallic rubbing pair and the preparation method thereof realize restoring modification to the surface of the metallic rubbing pair of which a restoration layer reaches 1.5 millimeters, and effectively control the clearance between the metallic rubbing pair.

Owner:三亚圣龙新材料开发有限公司

Water-soluble high-temperature-resistant coating and preparation method thereof

The invention provides a water-soluble high-temperature-resistant coating. The water-soluble high-temperature-resistant coating comprises, by weight, 8-12 parts of aluminum sol, 15-20 parts of aluminum dihydrogen phosphate, 8-14 parts of ground glass, 5-10 parts of talcum powder, 10-15 parts of kaolin powder, 10-15 parts of wollastonite powder, 1-5 parts of dicyclopenteneoxyethyl acrylate and 20-30 parts of water. The invention also discloses a preparation method of the water-soluble high-temperature-resistant coating. With all components in the water-soluble high-temperature-resistant coating matched mutually and complementing mutual advantages, the water-soluble high-temperature-resistant coating has the advantages of excellent corrosion prevention performance, resistance to high temperature and cracking, thermal shock resistance, good storage stability and the like on the premise of keeping good adhesive force.

Owner:HUANGHE S & T COLLEGE

Anti-oxidization and wear-resistance composite coating for four pipes of power plant boiler

InactiveCN102345086BHigh strengthGuaranteed resistance to hot corrosionMolten spray coatingOxidation resistantMaterials science

The invention belongs to the protection field of high-temperature coatings, and in particular relates to an anti-oxidization and wear-resistance composite coating for four pipes of a power plant boiler. The composite coating comprises the following components in percent by weight: 70-80wt% of NiCoCrAlY and 20-30wt% of ZrC, wherein the thickness of the coating is 200-300mu m. During the preparation, by adopting a plasma spraying or supersonic speed flame spraying method, the NiCoCrAlY and ZrC with a certain proportion and granularity are stirred uniformly to form powder required by spraying, and a required coating is formed under a certain spraying process condition. The coating has high hardness at high temperature, and anti-oxidization, wear and corrosion properties of the coating are greatly improved, thus the defects of microcracks formed in the preparation process and the embrittlement of the existing coating are overcome, and the service life of the four pipes of the power plant boiler is greatly prolonged.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com