Water-soluble high-temperature-resistant coating and preparation method thereof

A high temperature resistant coating, water-soluble technology, applied in the field of coatings, can solve the problems of long surface drying time of the paint film, affecting the appearance of the paint film, poor corrosion resistance, etc., and achieves the effect of easy operation, broad application prospects and excellent anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

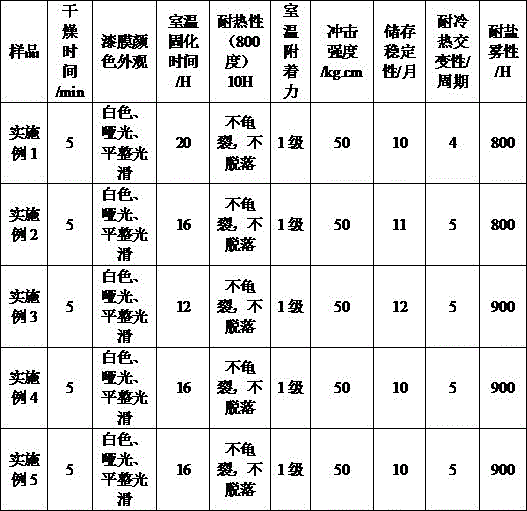

Examples

Embodiment 1

[0019] Embodiment 1 of the present invention provides a water-soluble high-temperature-resistant coating, which includes the following raw materials in parts by weight: 8 parts of aluminum sol, 15 parts of aluminum dihydrogen phosphate, 8 parts of glass powder, 5 parts of talcum powder, 10 parts of kaolin powder, silicon 10 parts of limestone powder, 1 part of dicyclopentenyloxyethyl acrylate and 20 parts of water, wherein, each raw material in this embodiment is industrial grade.

[0020] Preparation method: Under the condition of 40°C, uniformly mix aluminum sol, aluminum dihydrogen phosphate and water to form the first mixed solution; add glass powder, talc powder, wollastonite powder and kaolin powder to the first mixed solution , and ultrasonically dispersed for 30 minutes to obtain a second mixed solution; dicyclopentenyloxyethyl acrylate was added to the second mixed solution, and stirred at a speed of 1200r / min for 6 hours at 40°C , to prepare the water-soluble high-te...

Embodiment 2

[0022] Embodiment 2 of the present invention provides a water-soluble high-temperature-resistant coating, which includes the following raw materials in parts by weight: 9 parts of aluminum sol, 16 parts of aluminum dihydrogen phosphate, 10 parts of glass powder, 7 parts of talcum powder, 12 parts of kaolin powder, silicon 11 parts of limestone powder, 2 parts of dicyclopentenyloxyethyl acrylate and 23 parts of water, wherein, each raw material in this embodiment is industrial grade.

[0023] Preparation method: Under the condition of 50°C, uniformly mix aluminum sol, aluminum dihydrogen phosphate and water to form the first mixed solution; add glass powder, talc powder, wollastonite powder and kaolin powder to the first mixed solution , and ultrasonically dispersed for 30 minutes to obtain a second mixed solution; dicyclopentenyloxyethyl acrylate was added to the second mixed solution, and stirred at a speed of 1100r / min for 6 hours at 50°C , to prepare the water-soluble high-...

Embodiment 3

[0025] Embodiment 3 of the present invention provides a water-soluble high-temperature-resistant coating, which includes the following raw materials in parts by weight: 10 parts of aluminum sol, 17 parts of aluminum dihydrogen phosphate, 11 parts of glass powder, 8 parts of talcum powder, 13 parts of kaolin powder, silicon 13 parts of limestone powder, 2 parts of dicyclopentenyloxyethyl acrylate and 25 parts of water, wherein, each raw material in this embodiment is industrial grade.

[0026] Preparation method: Under the condition of 60°C, uniformly mix aluminum sol, aluminum dihydrogen phosphate and water to form the first mixed solution; add glass powder, kaolin powder, wollastonite powder and talc powder to the first mixed solution , and ultrasonically dispersed for 35 minutes to obtain a second mixed solution; dicyclopentenyloxyethyl acrylate was added to the second mixed solution, and stirred at a speed of 1000r / min for 5 hours under the condition of 60°C , to prepare th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com