Graphene double-layer electroactive membrane and preparation method thereof

A graphene and graphene dispersion technology, applied in graphene, coatings, conductive coatings, etc., can solve the problems of large flexural modulus, slow response rate, large actuation voltage, etc., to achieve improved conductivity and sensitive response , large deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

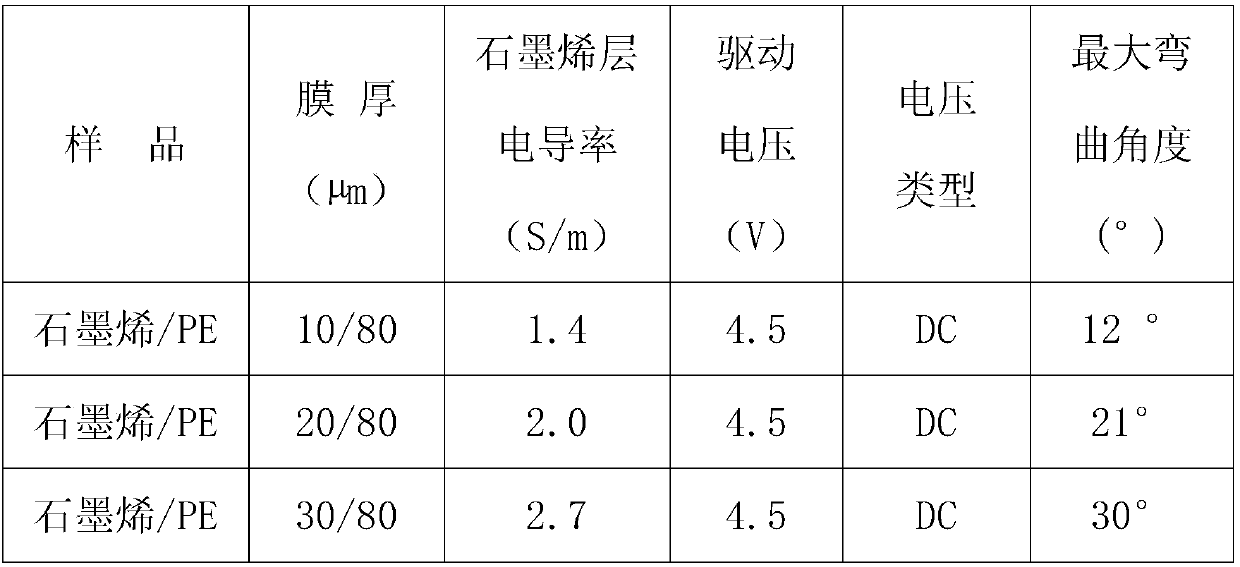

Embodiment 1

[0042] A preparation method and application of an electrically actuated graphene-polymer functional film material, wherein the graphene-polymer functional film (i.e. graphene double-layer electric actuation film) is composed of a reduced graphene oxide layer (i.e. Flexible conductive layer) and a double-layer film composed of a polymer film. Proceed as follows:

[0043] a, the synthesis of graphene oxide:

[0044] ① Graphene oxide is synthesized by the Hummers method, taking 2g flake graphite powder and 1g NaNO 3 , add concentrated sulfuric acid (mass percentage concentration is 98%) 46ml under ice-bath condition (temperature 0~5 ℃), add 6g KMnO under the situation of stirring 4 , and control the reaction temperature at 4-10°C;

[0045] ② After reacting for 100 minutes, heat up to 40°C, stir vigorously for 60 minutes, then heat up to 90°C and add 90ml of deionized water, stir at a medium speed (50r / min) for 30 minutes, then cool to room temperature;

[0046] ③Add 100ml of ...

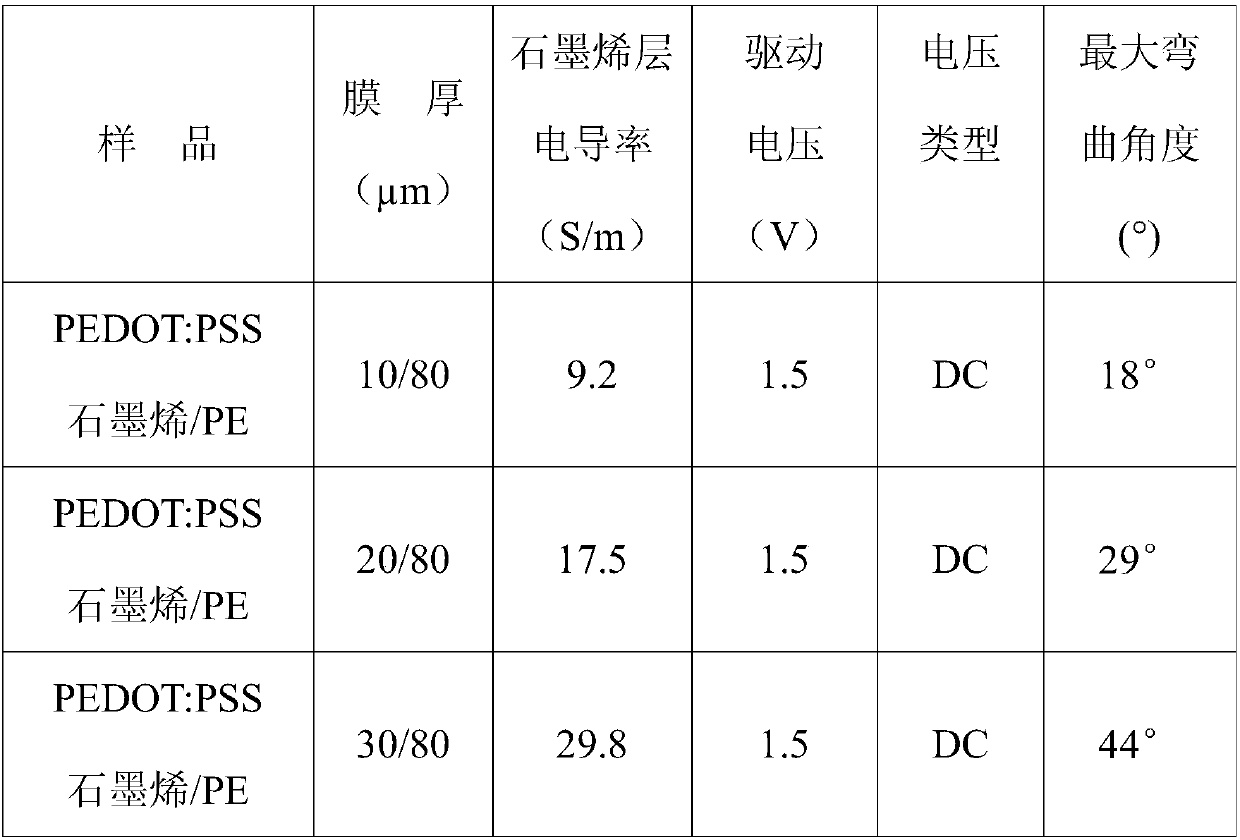

Embodiment 2

[0060] A preparation method and application of an electrically actuated graphene-polymer functional film material. conductive layer) and a polymer film, the preparation method of reduced graphene oxide (i.e. reduced graphene oxide dispersion) is the same as in Example 1, and this embodiment 2 adds PEDOT / PSS (poly3 , 4-ethylenedioxythiophene / polystyrene sulfonate) solution to increase the conductivity of the membrane.

[0061] a, the synthesis of graphene oxide:

[0062] ① Graphene oxide is synthesized by the Hummers method, taking 2g flake graphite powder and 1g NaNO 3 46 ml of concentrated sulfuric acid (98% by mass concentration) was added under the temperature condition of an ice bath (0-5° C.). Add 6 g KMnO while stirring 4 , and control the reaction temperature at 4-10°C;

[0063] ② After reacting for 100 minutes, heat up to 40°C, stir vigorously for 60 minutes, then heat up to 90°C and add 90ml of deionized water, stir at a medium speed (50r / min) for 30 minutes, then...

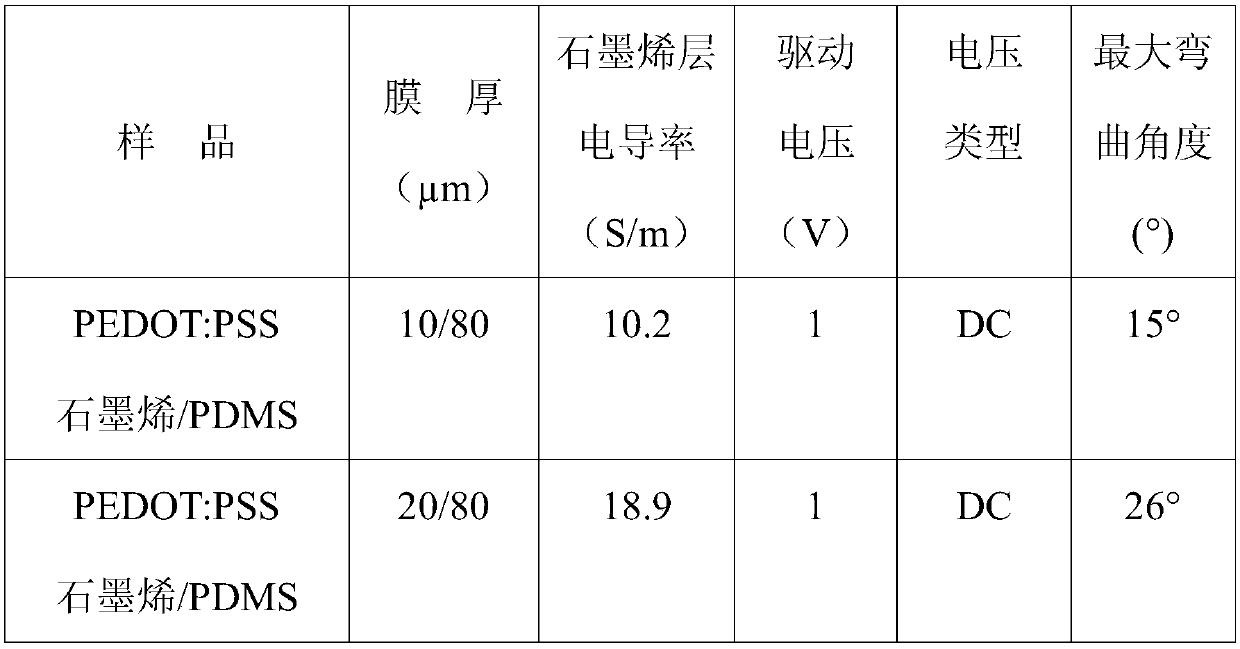

Embodiment 3

[0078] A preparation method and application of an electrically actuated graphene-polymer functional film material. conductive layer) and a polymer film, the preparation method of reduced graphene oxide (i.e. reduced graphene oxide dispersion) is basically the same as the step in Example 2, and the reduced graphene oxide dispersion is drop-coated on PDMS in this embodiment 3 (Polydimethylsiloxane) polymer film substrate, to test the response characteristics of actuation films (ie, graphene bilayer electro-actuation films) prepared from different polymer films.

[0079] The preparation method of graphene-polymer functional film:

[0080] Take a PDMS film of appropriate size, and drop-coat the above-mentioned reduced graphene oxide dispersion containing doped PEDOT / PSS. The thickness of the graphene layer is controlled by the concentration of the reduced graphene oxide dispersion and the amount of dripping. Then place it in an oven and dry at 45° C. for 3 to 5 hours to form a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com