Patents

Literature

98results about How to "Change flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

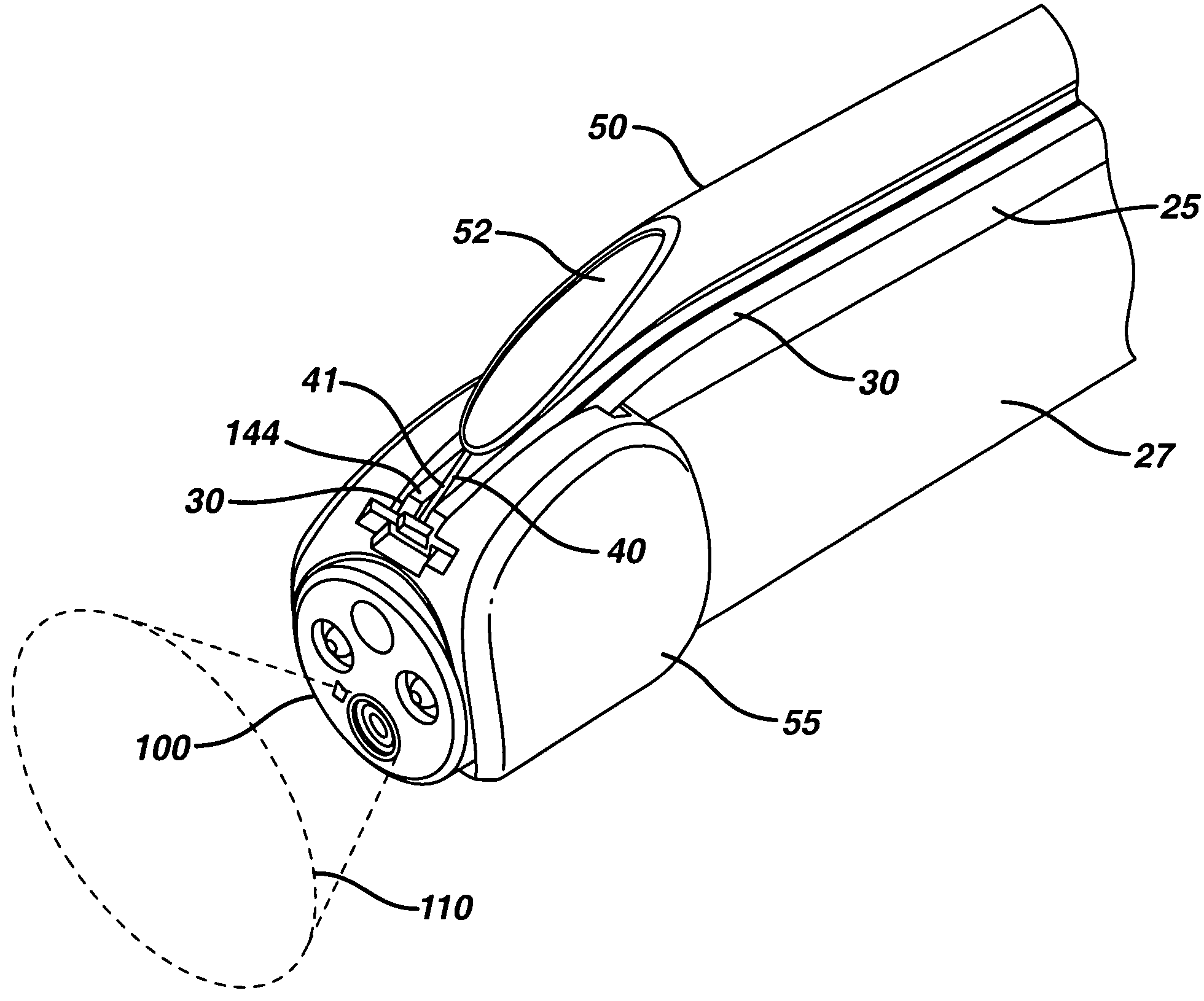

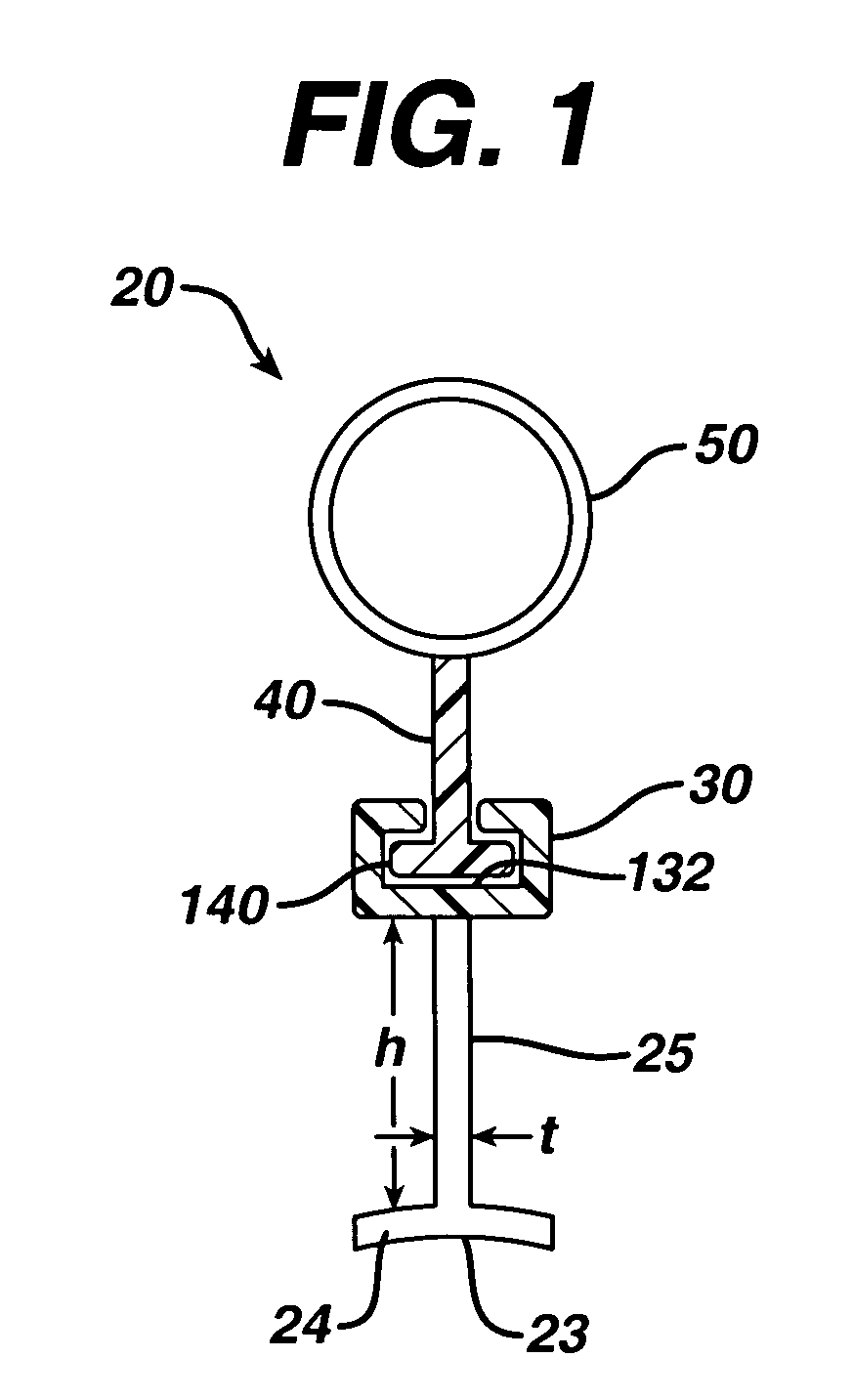

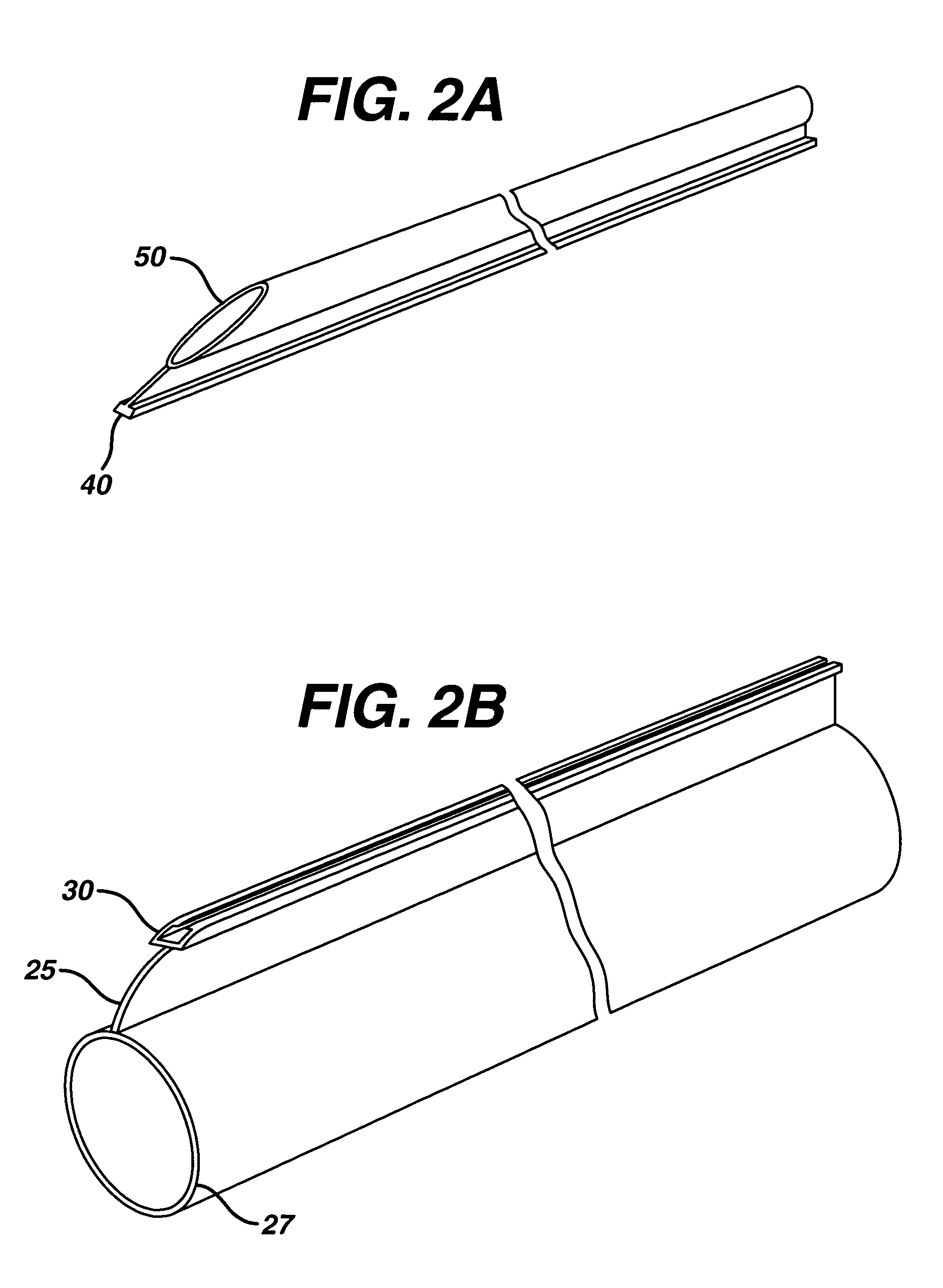

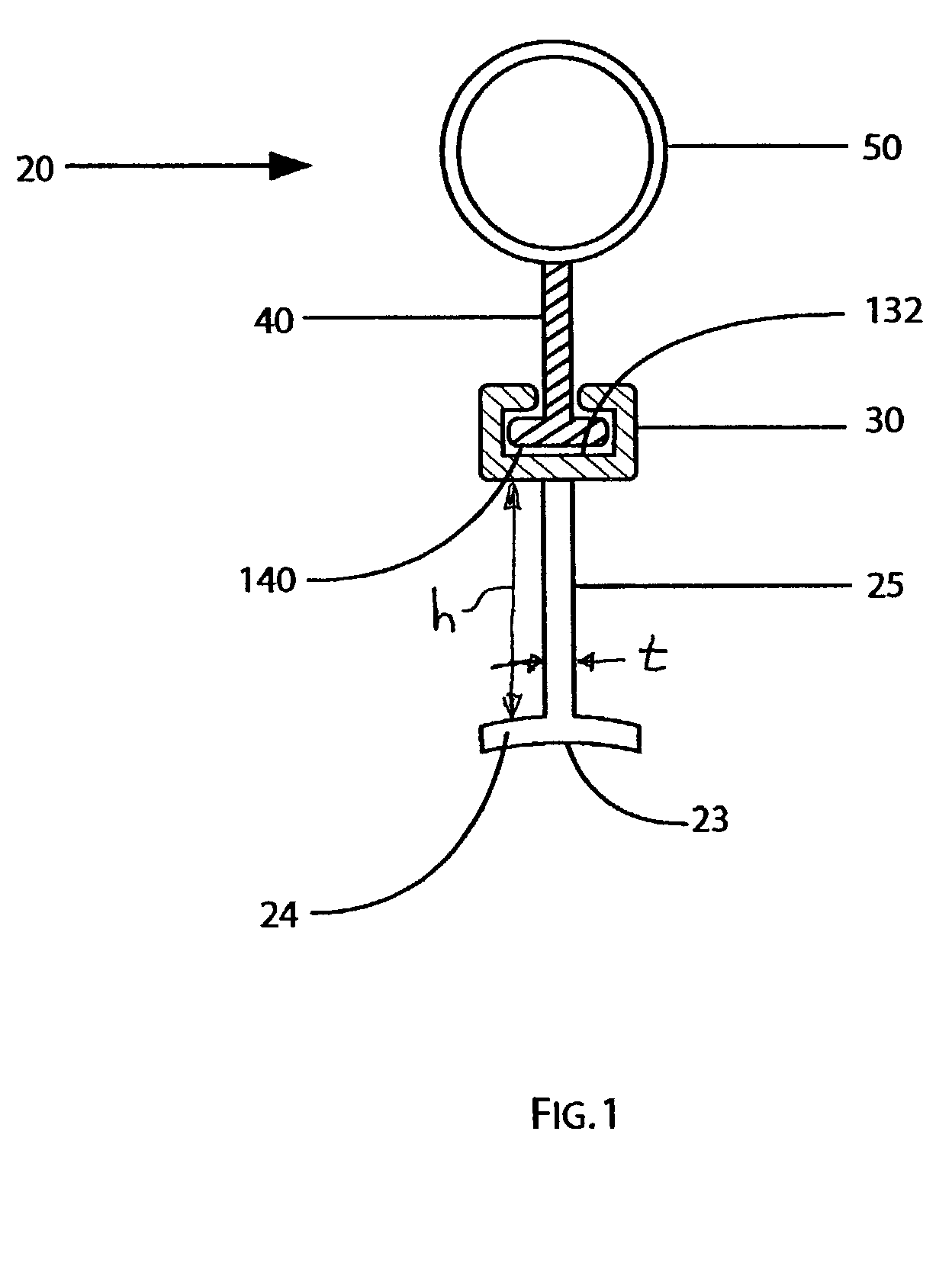

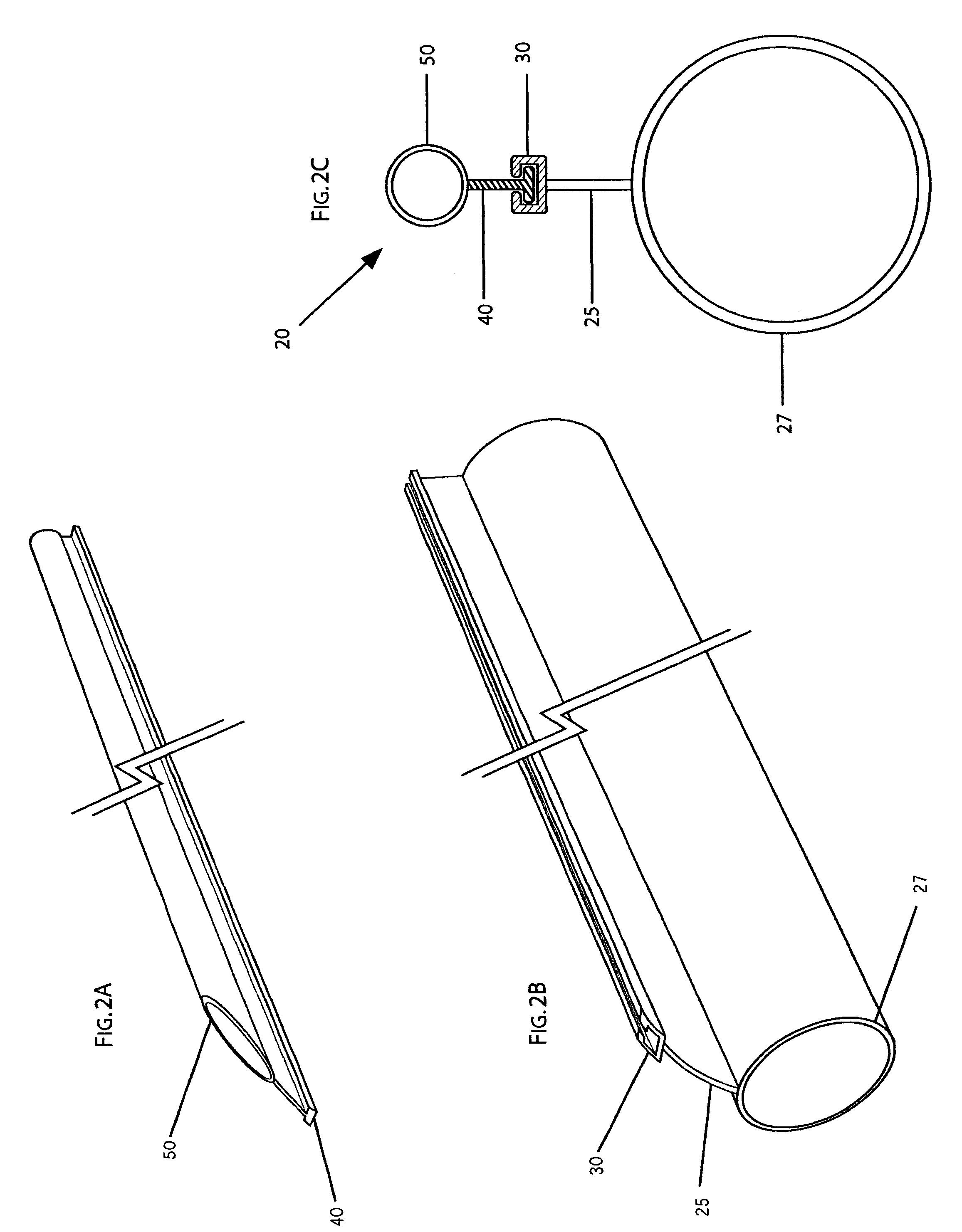

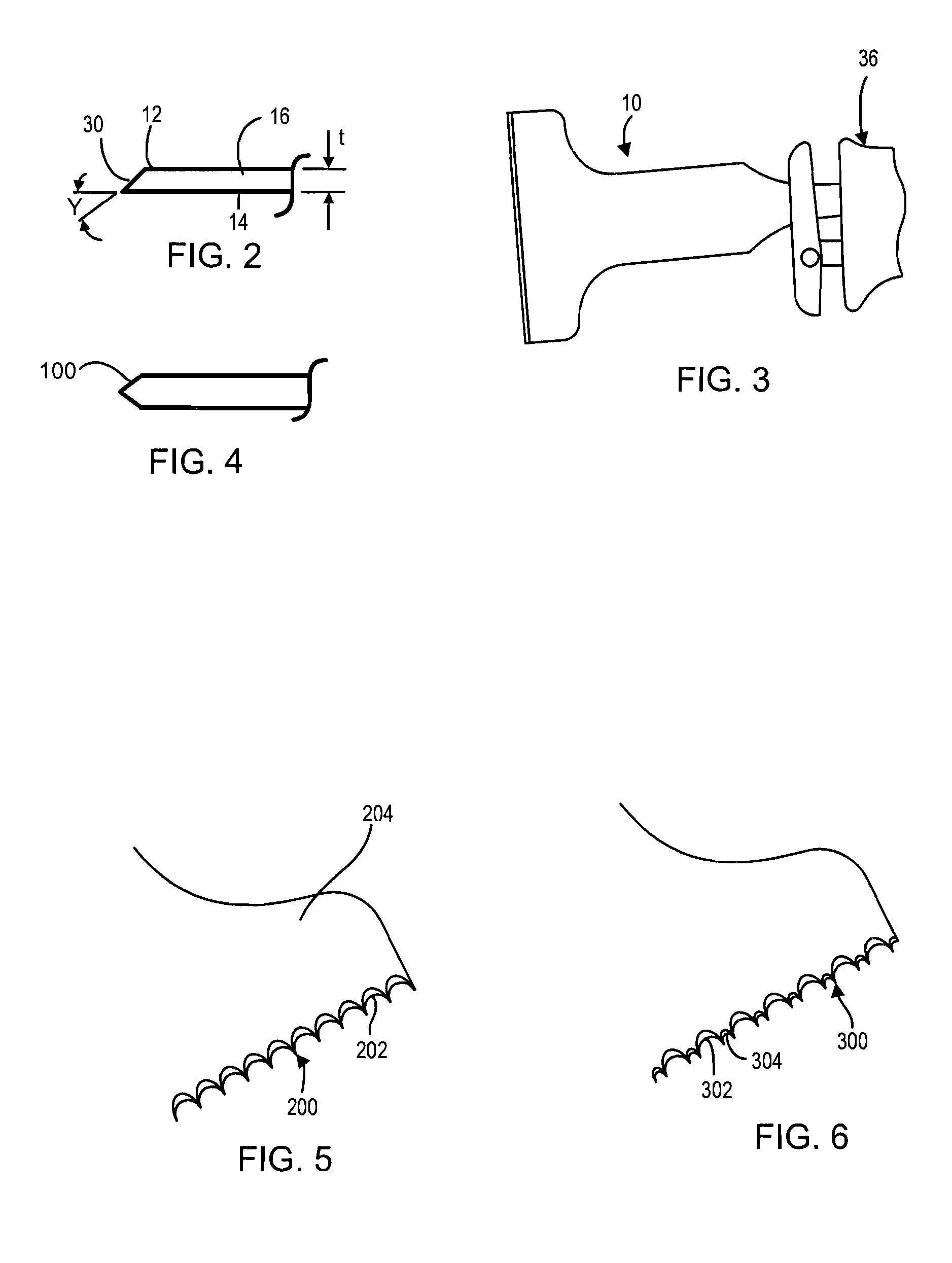

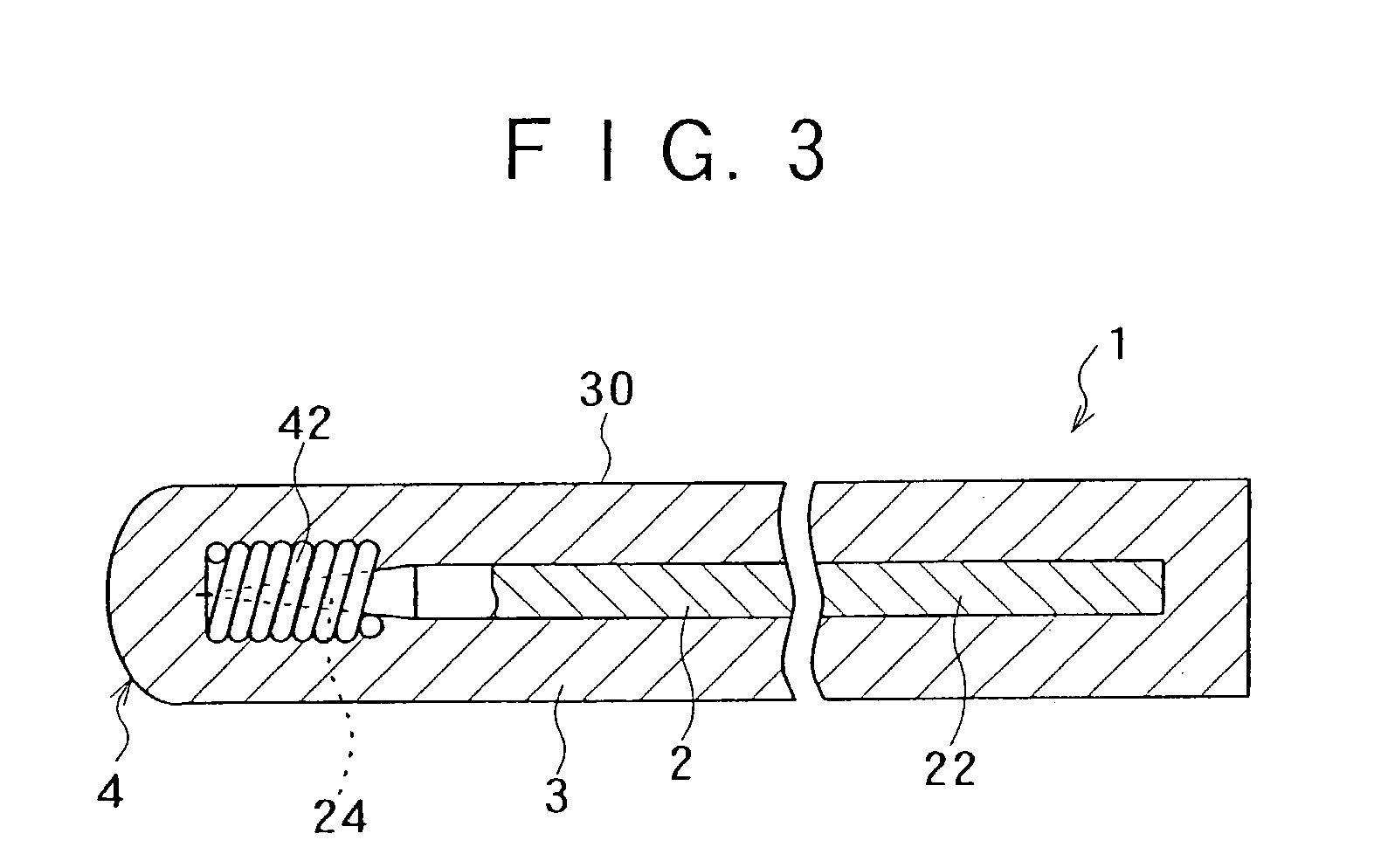

Endcap for use with an endoscope

A guide system for use with an endoscope, and a method of use is disclosed. The guide system can include a track, in the form of a rail, and a mating member for engaging the rail. The guide system can also include an accessory, such as an accessory guide tube through which a medical instrument can be carried external of the endoscope. An end cap can be provided to support the track relative to the distal end of the endoscope.

Owner:ETHICON ENDO SURGERY INC

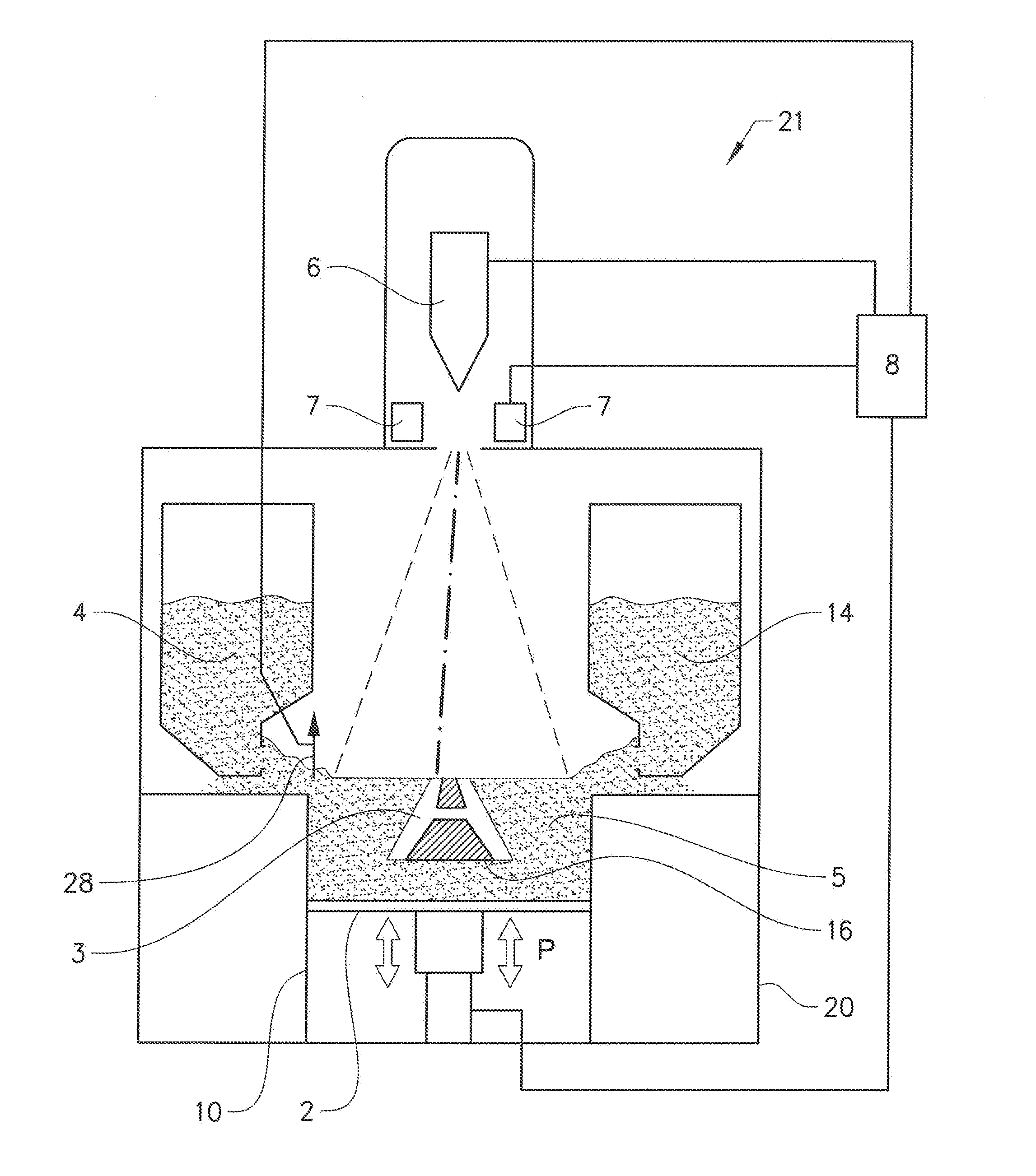

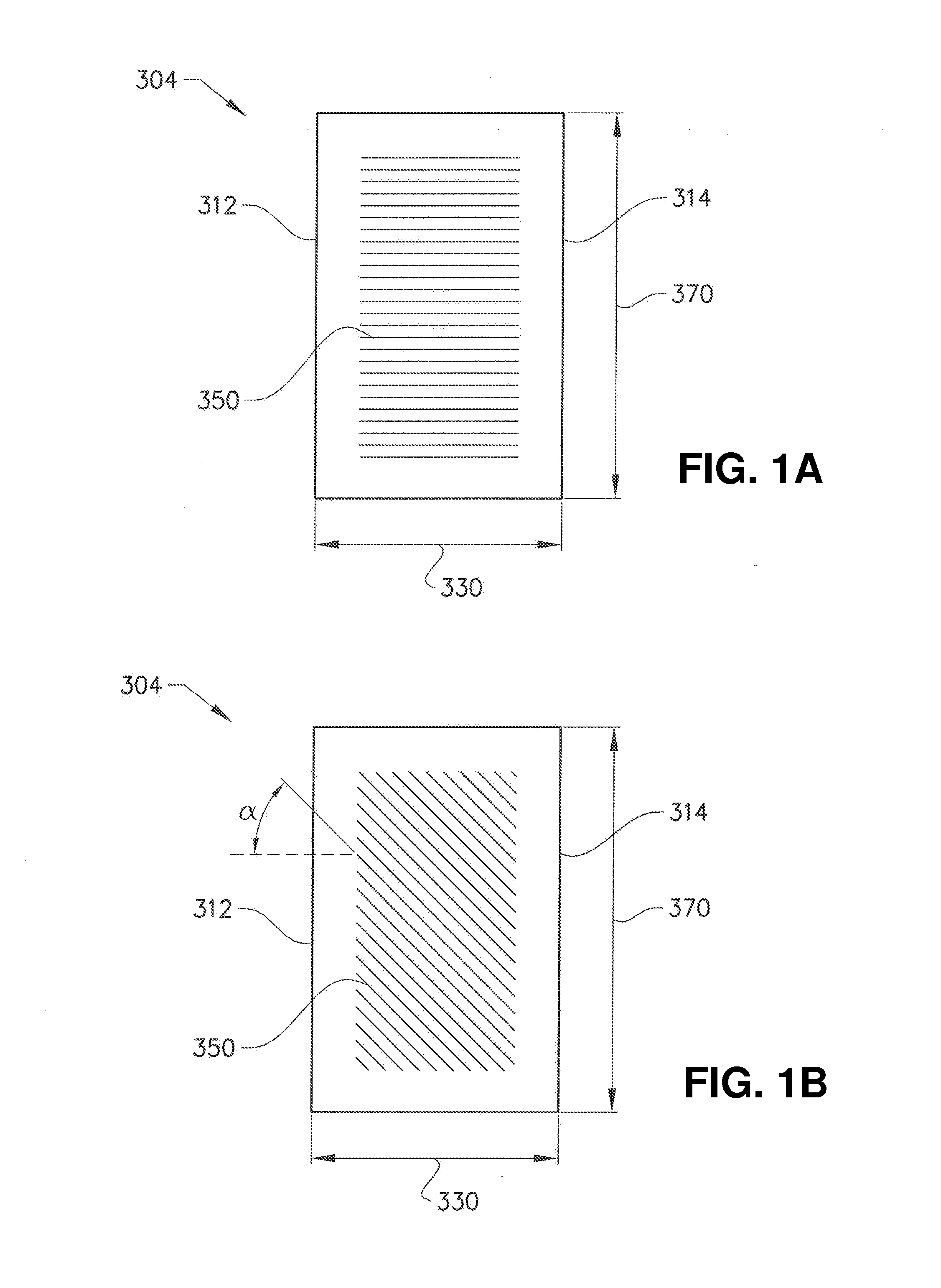

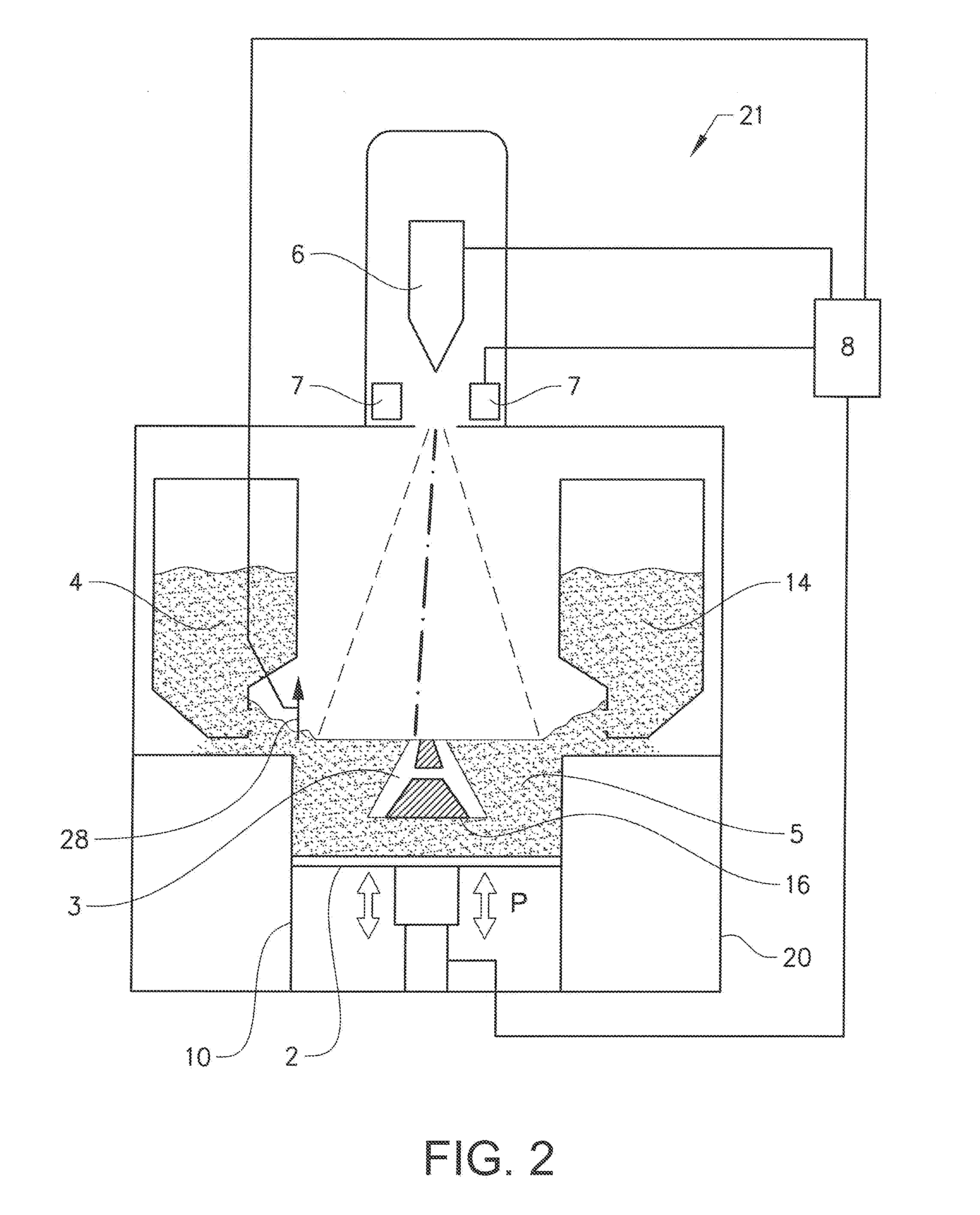

Method and apparatus for forming a three-dimensional article

ActiveUS20140314609A1Improve compactionIncrease flexibilityAdditive manufacturing apparatusElectric discharge tubesMetallurgyDistributor

An apparatus for forming at least one three-dimensional article by fusing parts of a powder bed layer-wise. The apparatus comprising a powder distributor and an energy beam for fusing the powder layer. Said powder distributor comprises a first part being an elongated rod provided movable at a predetermined distance above the powder bed and with its central axis in parallel with a top surface of said work table and second part being a metal foil having at least a first and a second opposite edge portions. Said metal foil is provided between said elongated rod and said work table, said first and second opposite edge portions are attached to said elongated rod so that a distance between said first and second edge portions is smaller than the distance between said first and second edge portions of said metal foil when said metal foil is in a flat position.

Owner:ARCAM AB

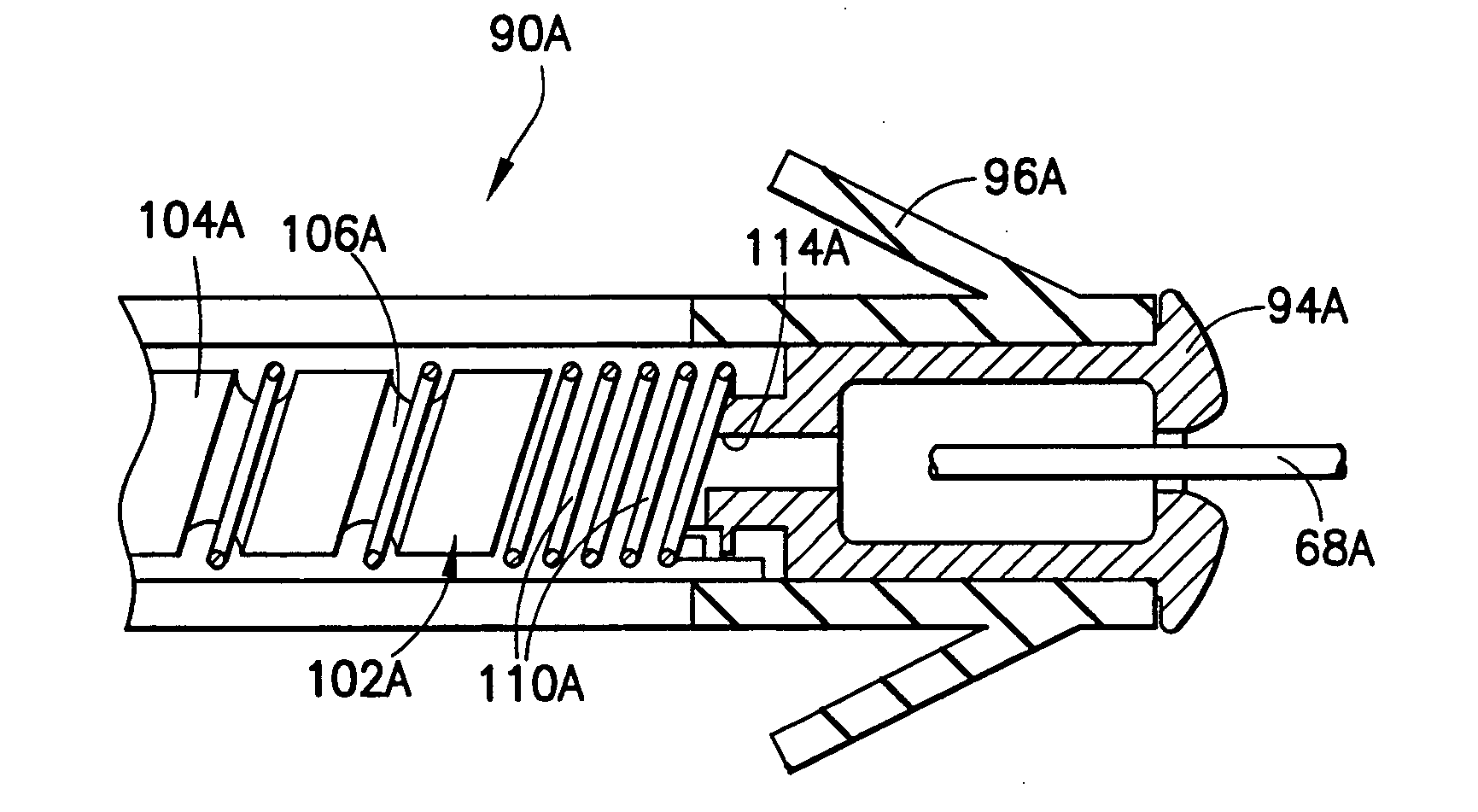

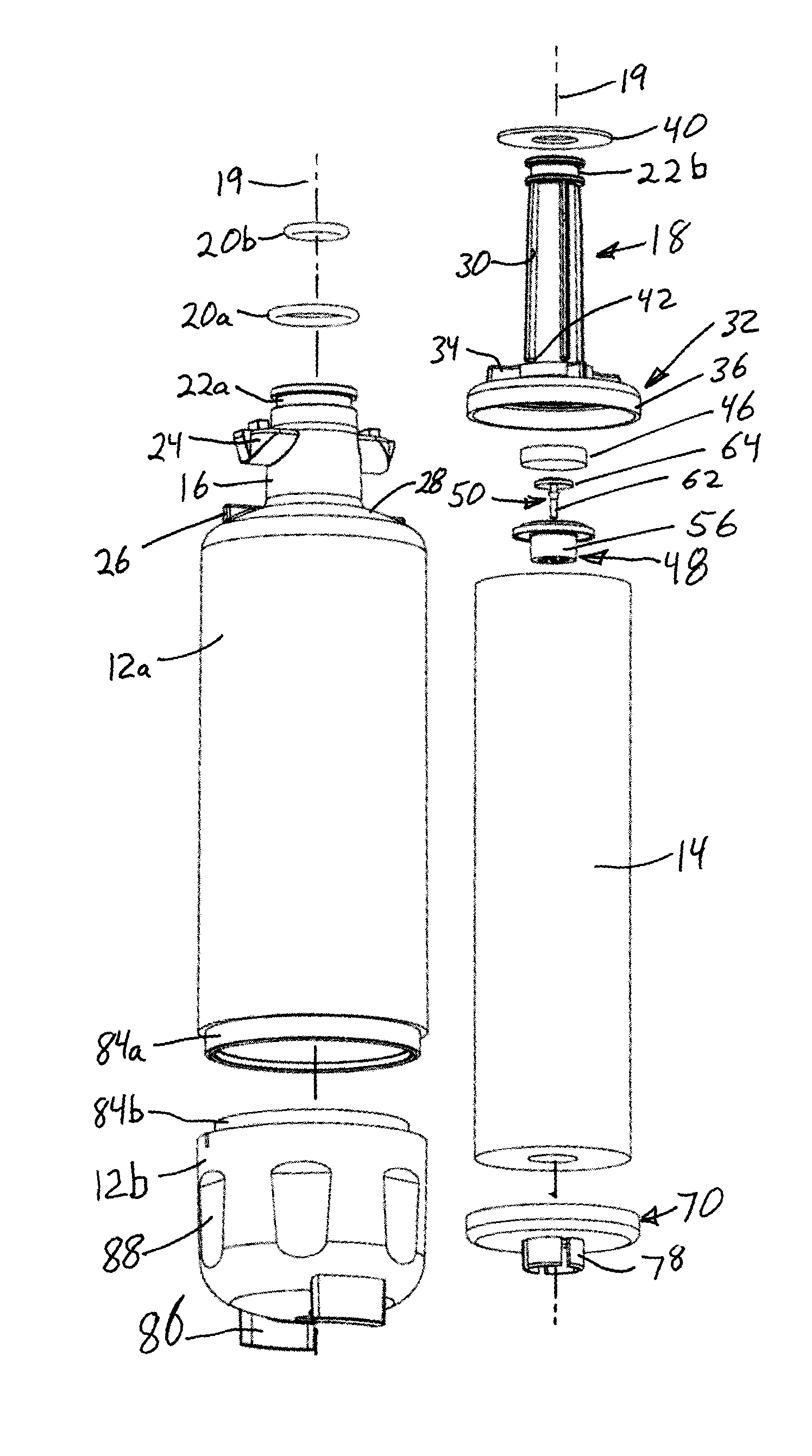

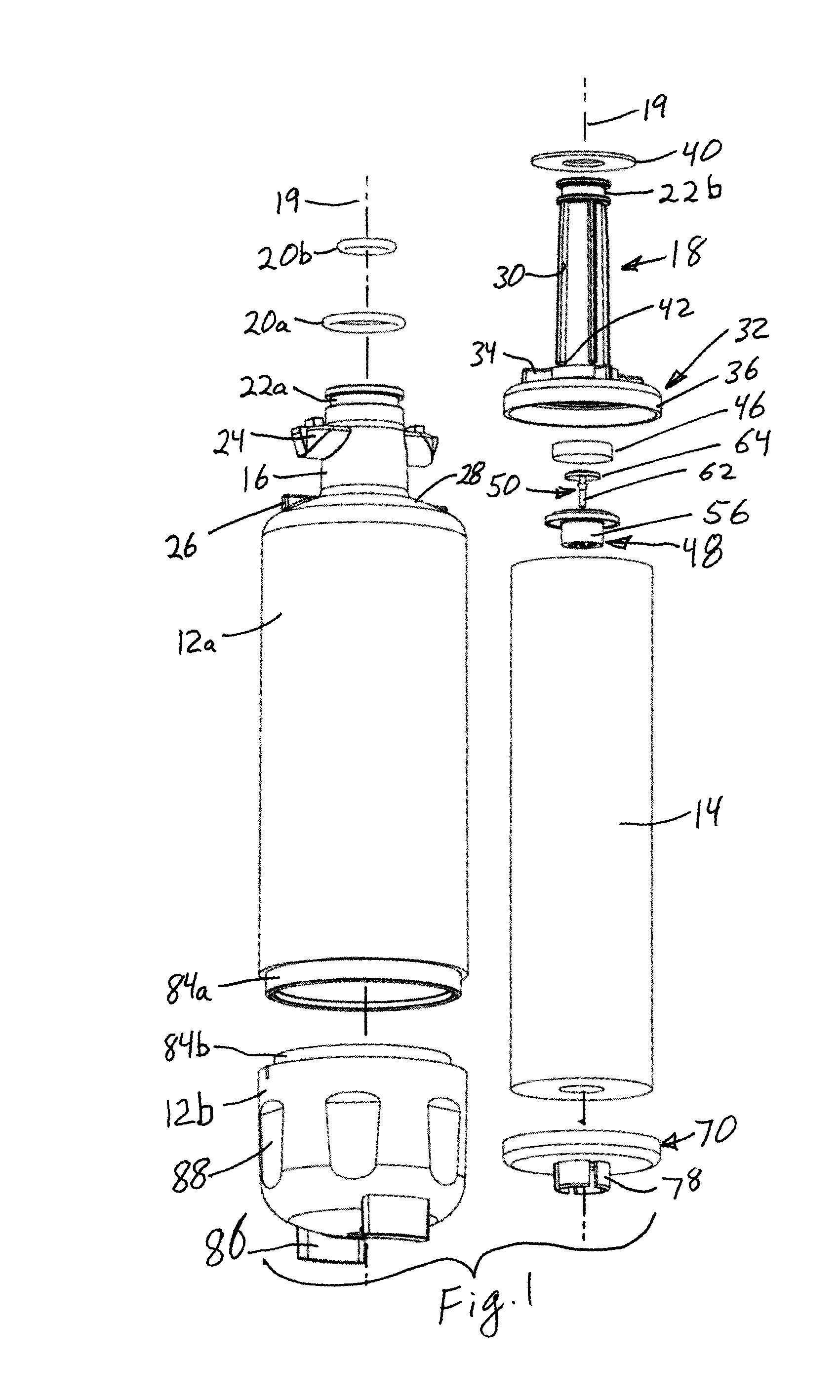

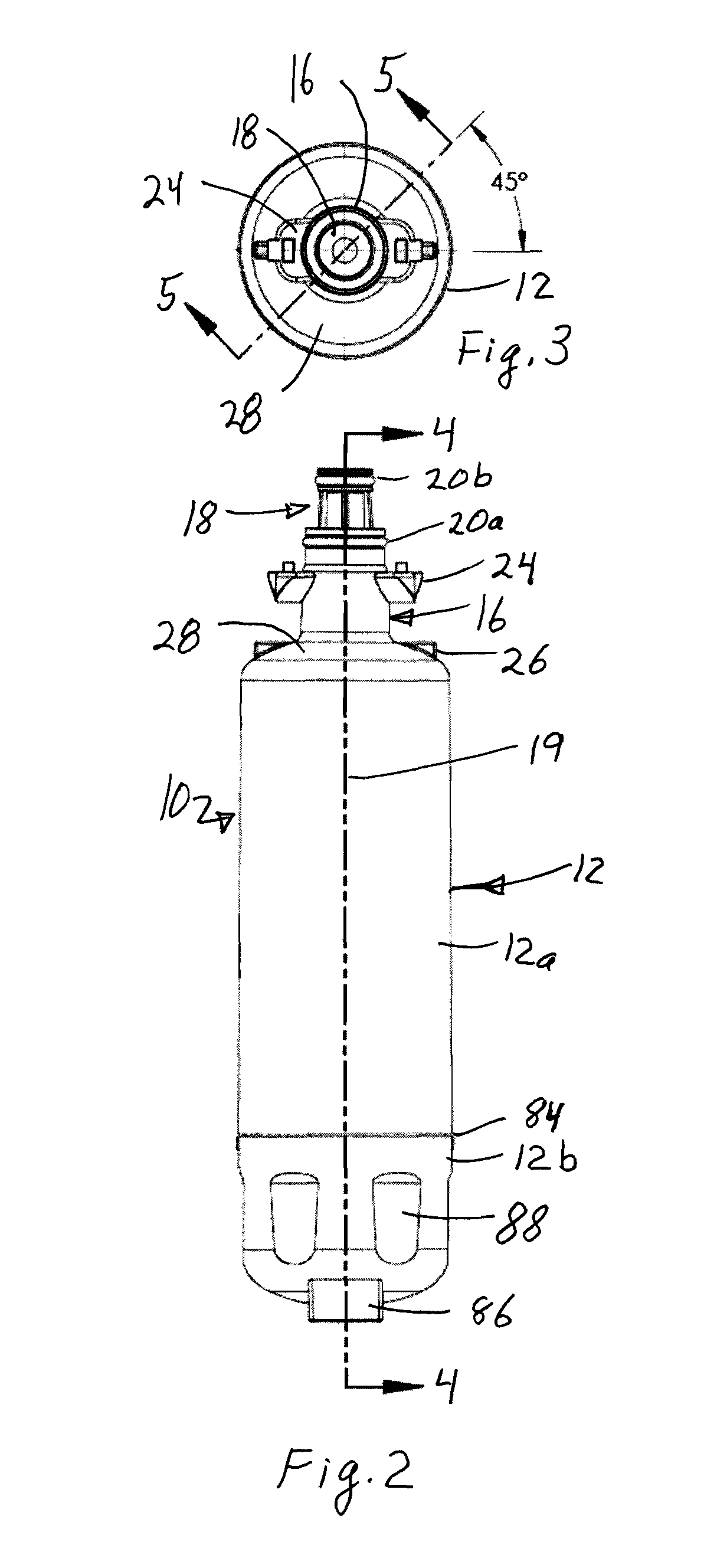

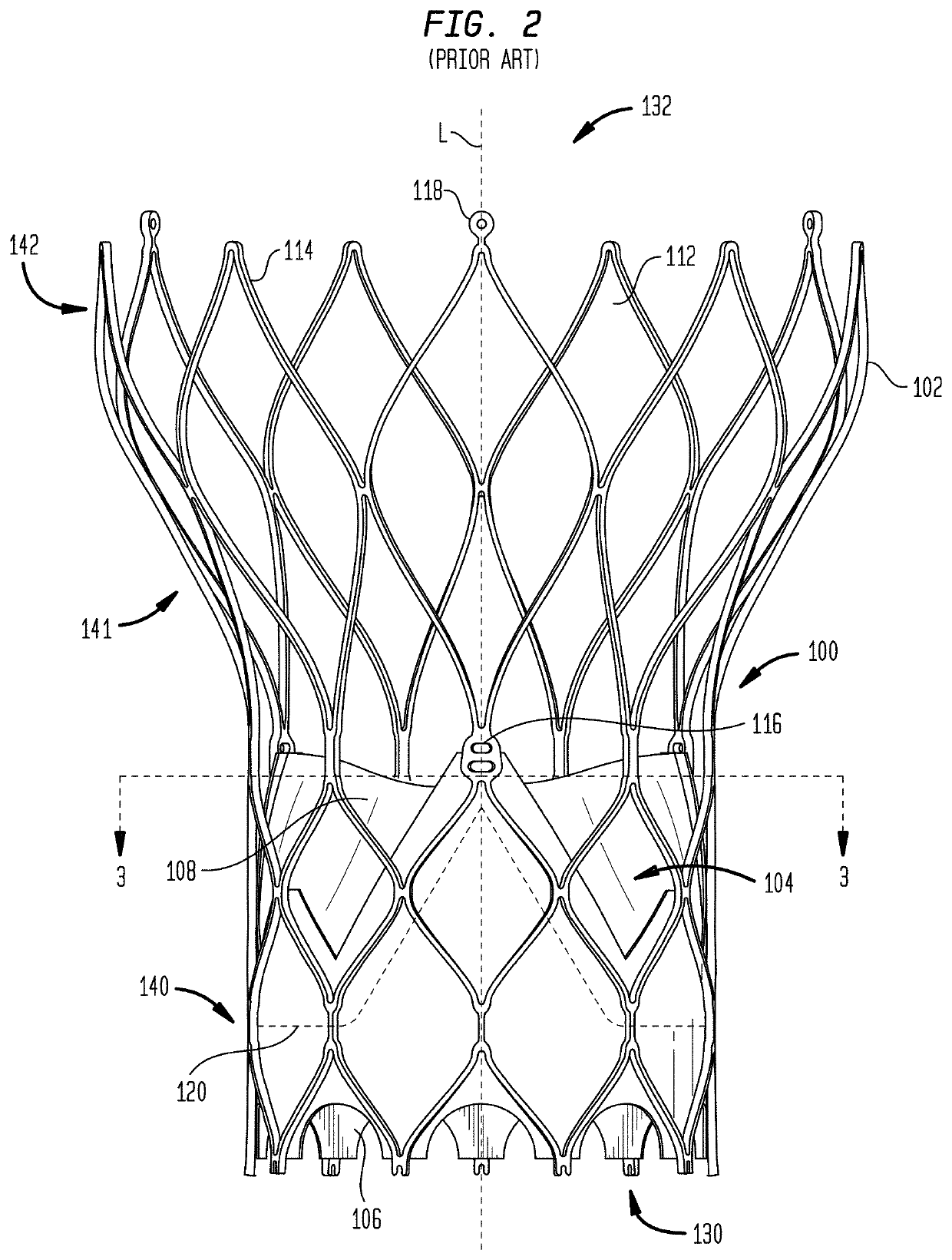

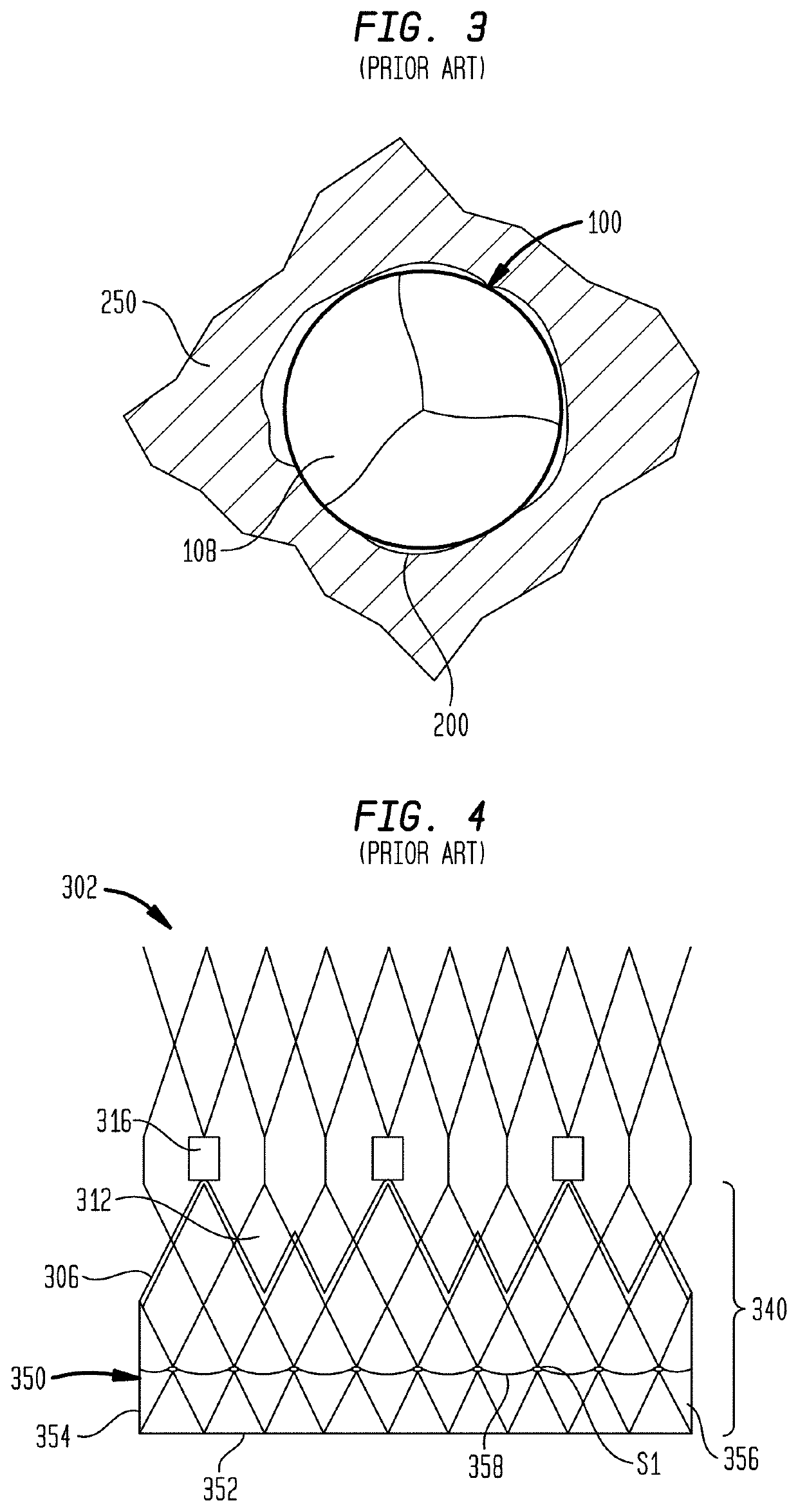

Medical apparatus for use with an endoscope

InactiveUS7615005B2Change flexibilityFlexible and/or relatively short accessory medical instrumentsSurgeryEndoscopesEngineeringGuide tube

A guide system for use with an endoscope, and a method of use is disclosed. The guide system can include a track, in the form of a rail, and a mating member for engaging the rail. The guide system can also include an accessory, such as an accessory guide tube through which a medical instrument can be carried external of the endoscope. An end cap can be provided to support the track relative to the distal end of the endoscope.

Owner:ETHICON ENDO SURGERY INC

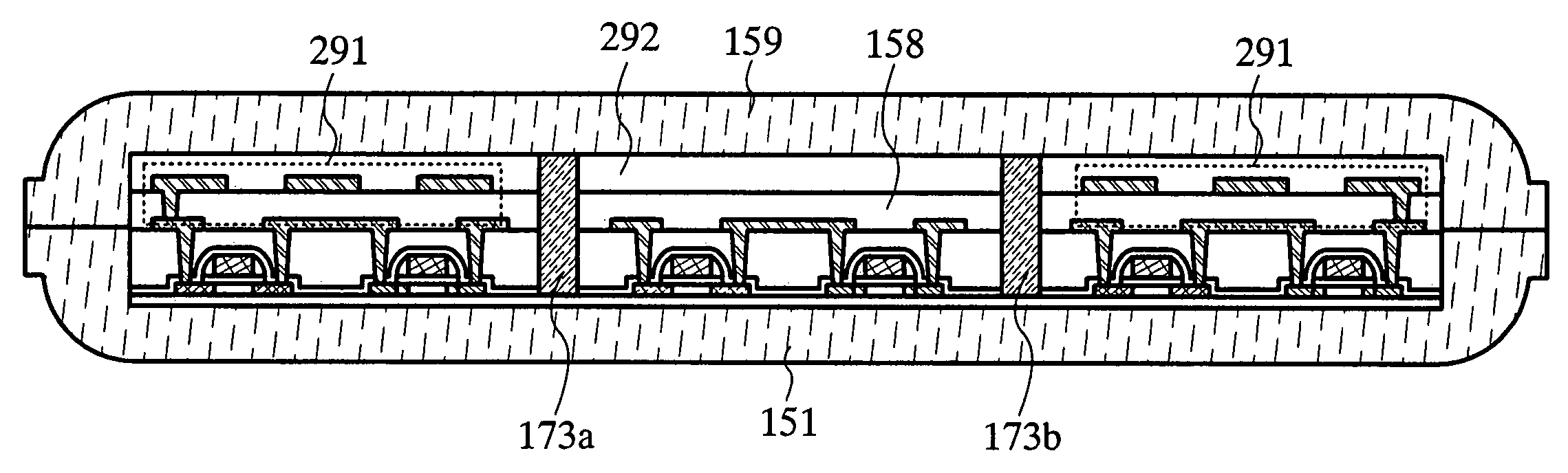

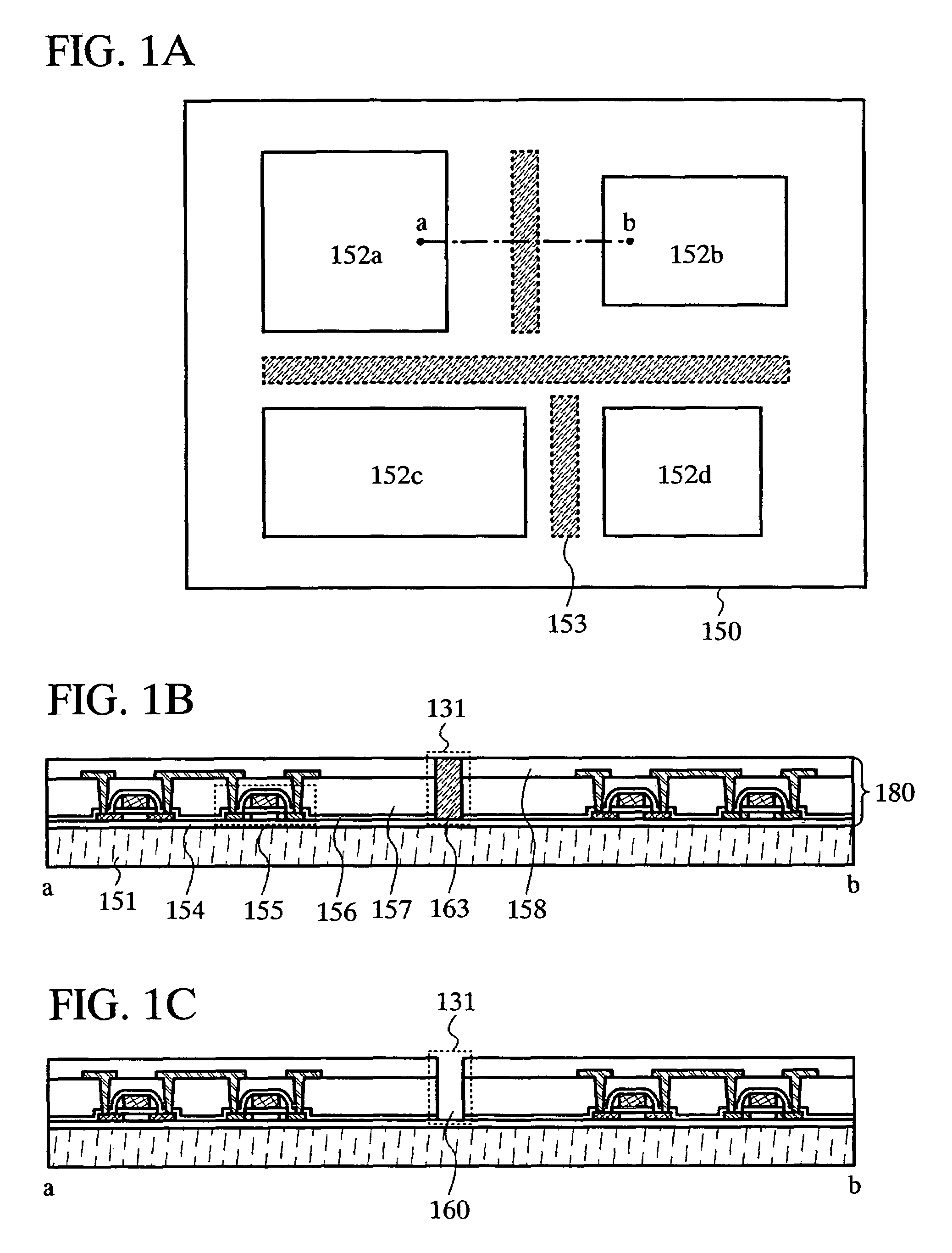

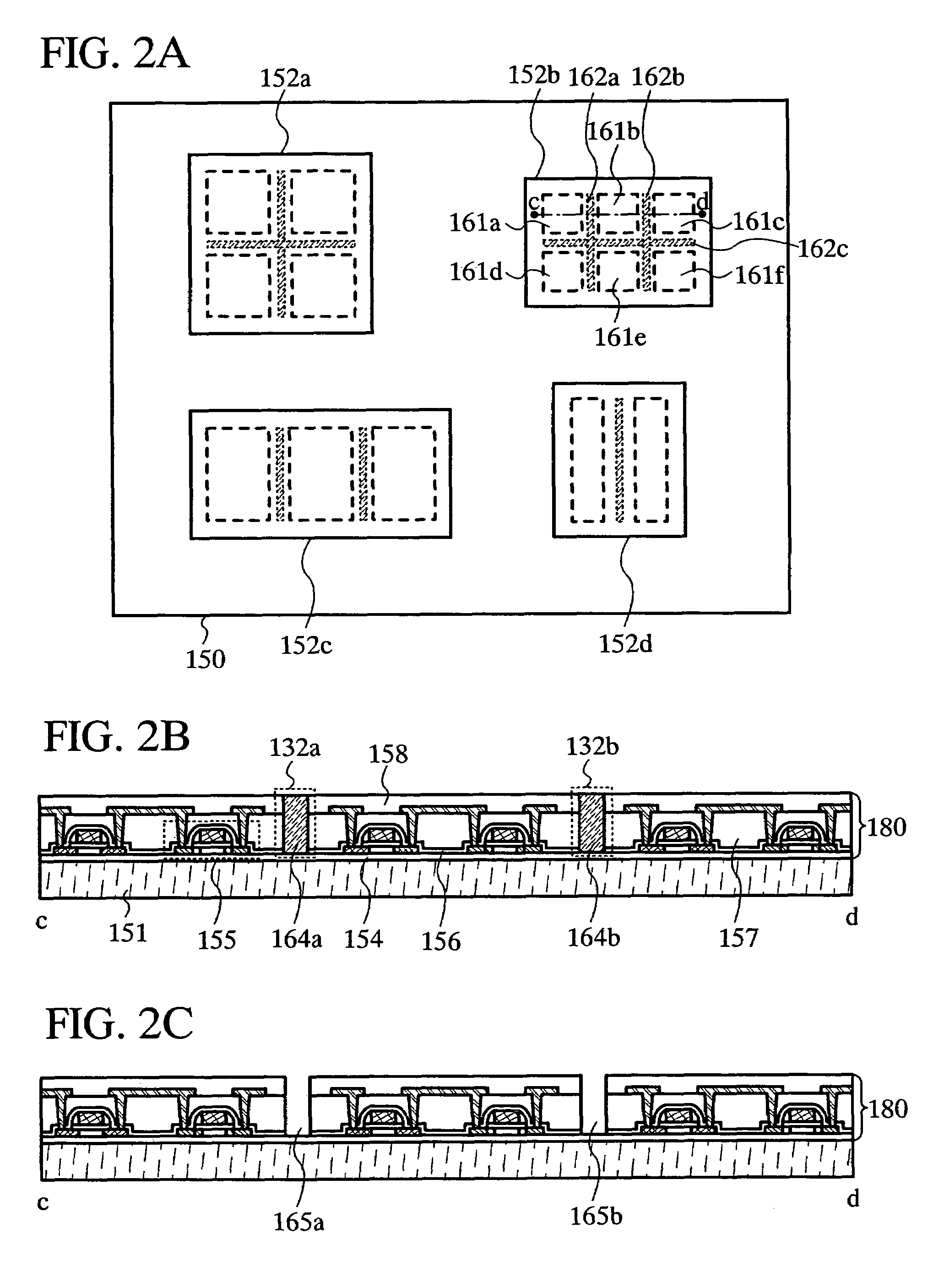

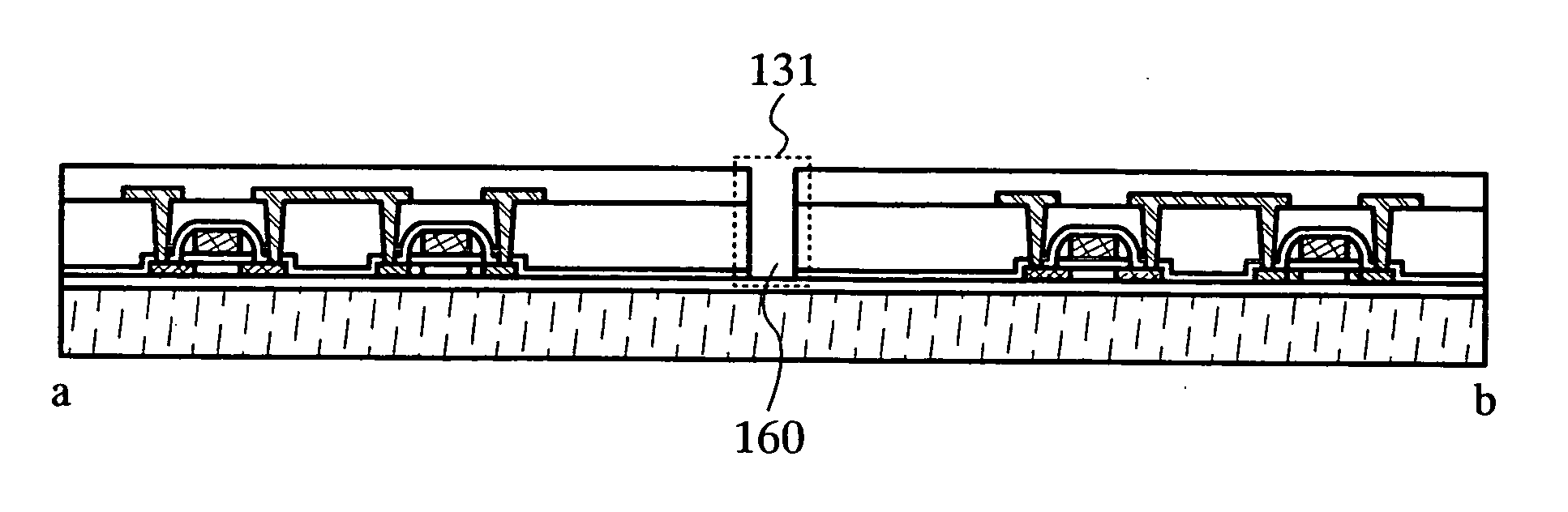

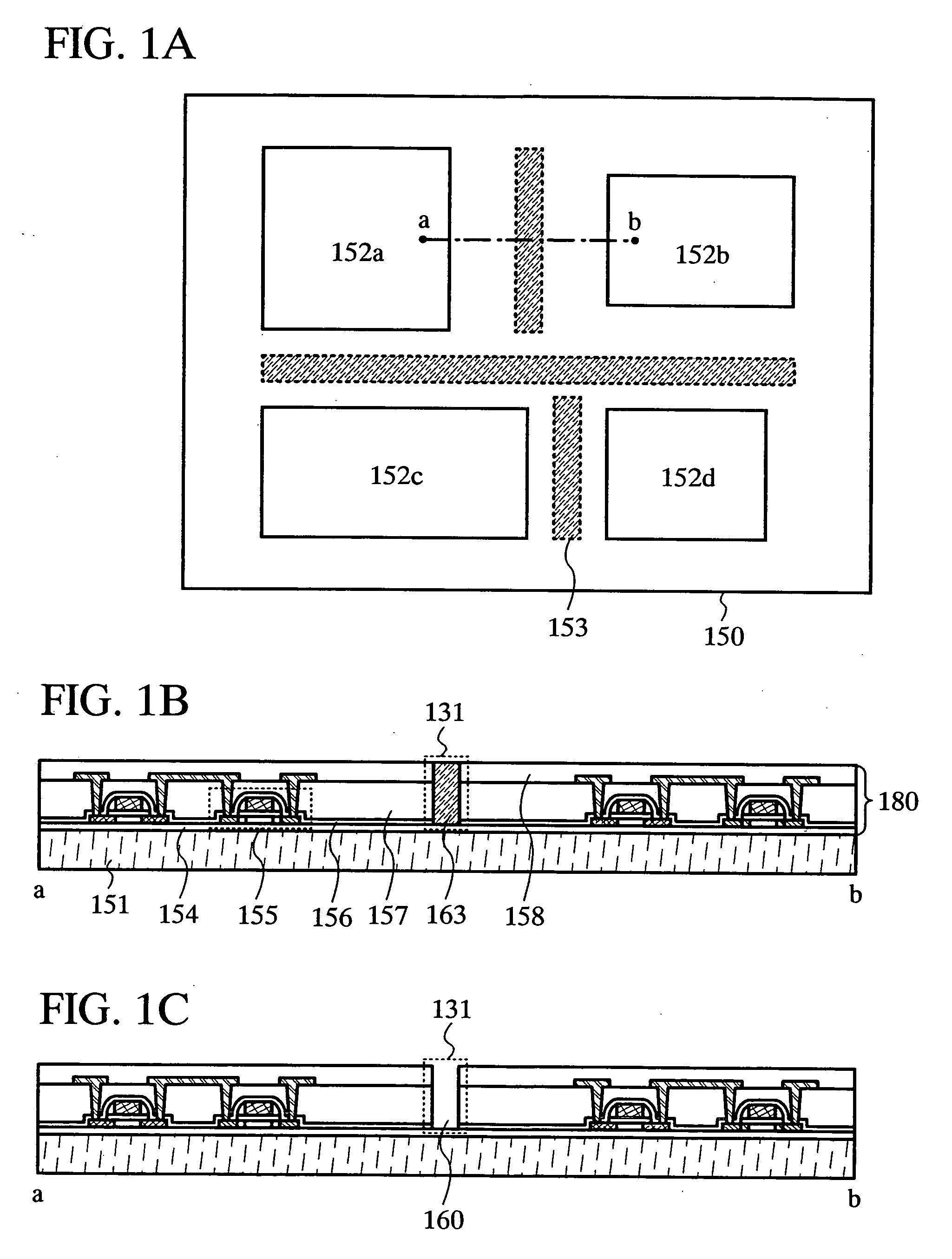

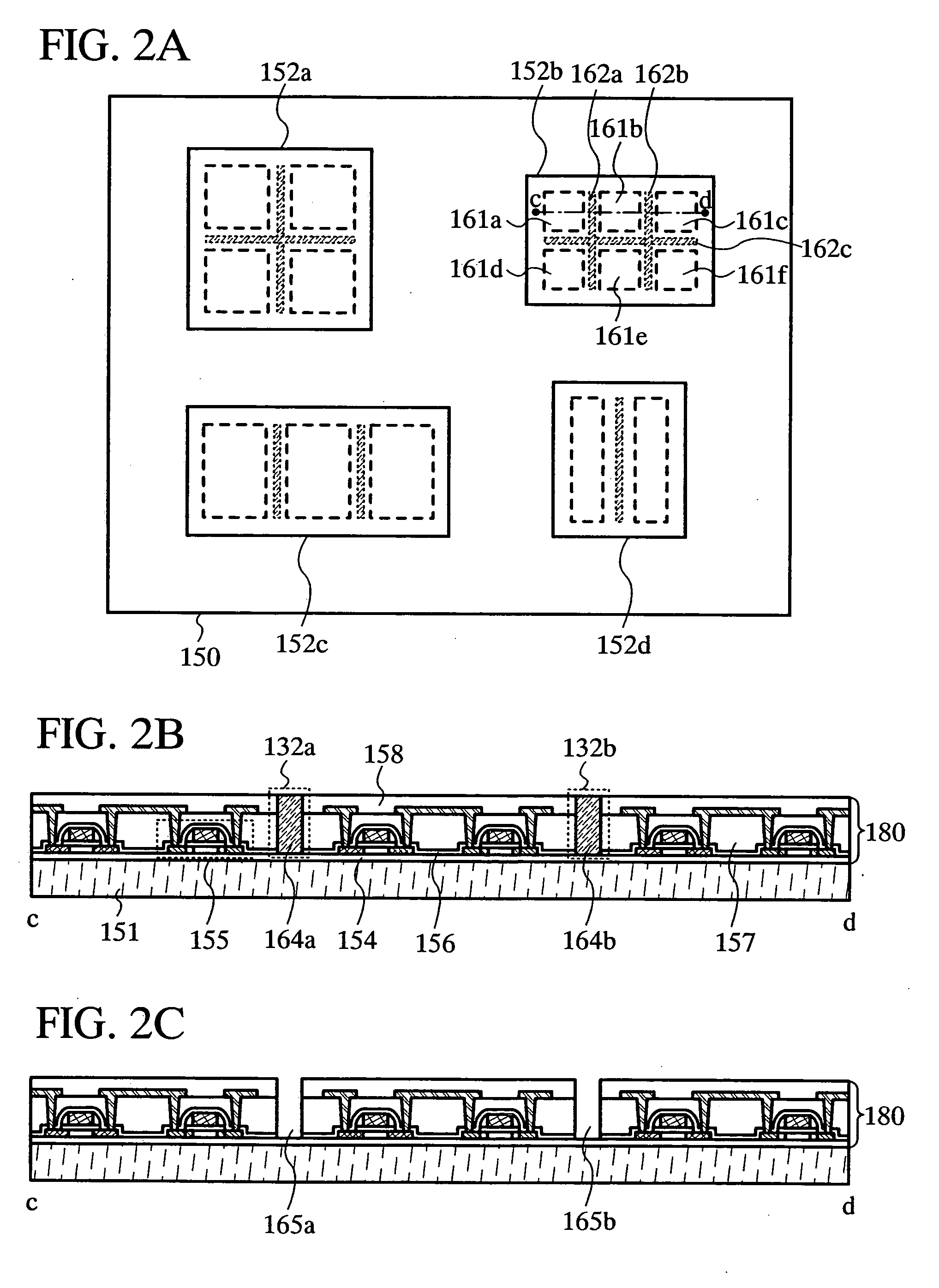

Semiconductor device and method for manufacturing the same

InactiveUS7566633B2Change flexibilityChange resistanceFinal product manufactureSolid-state devicesEngineeringGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

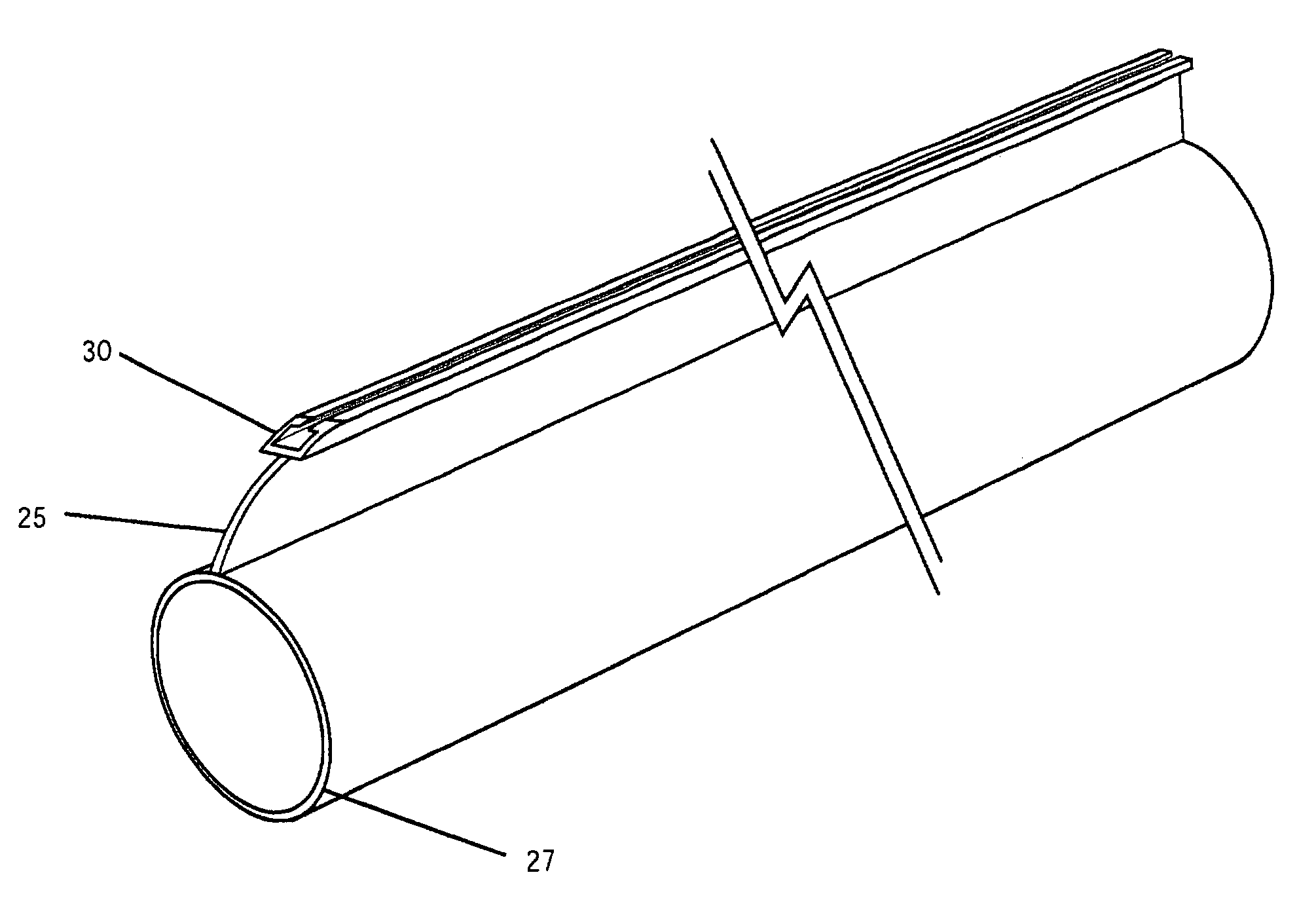

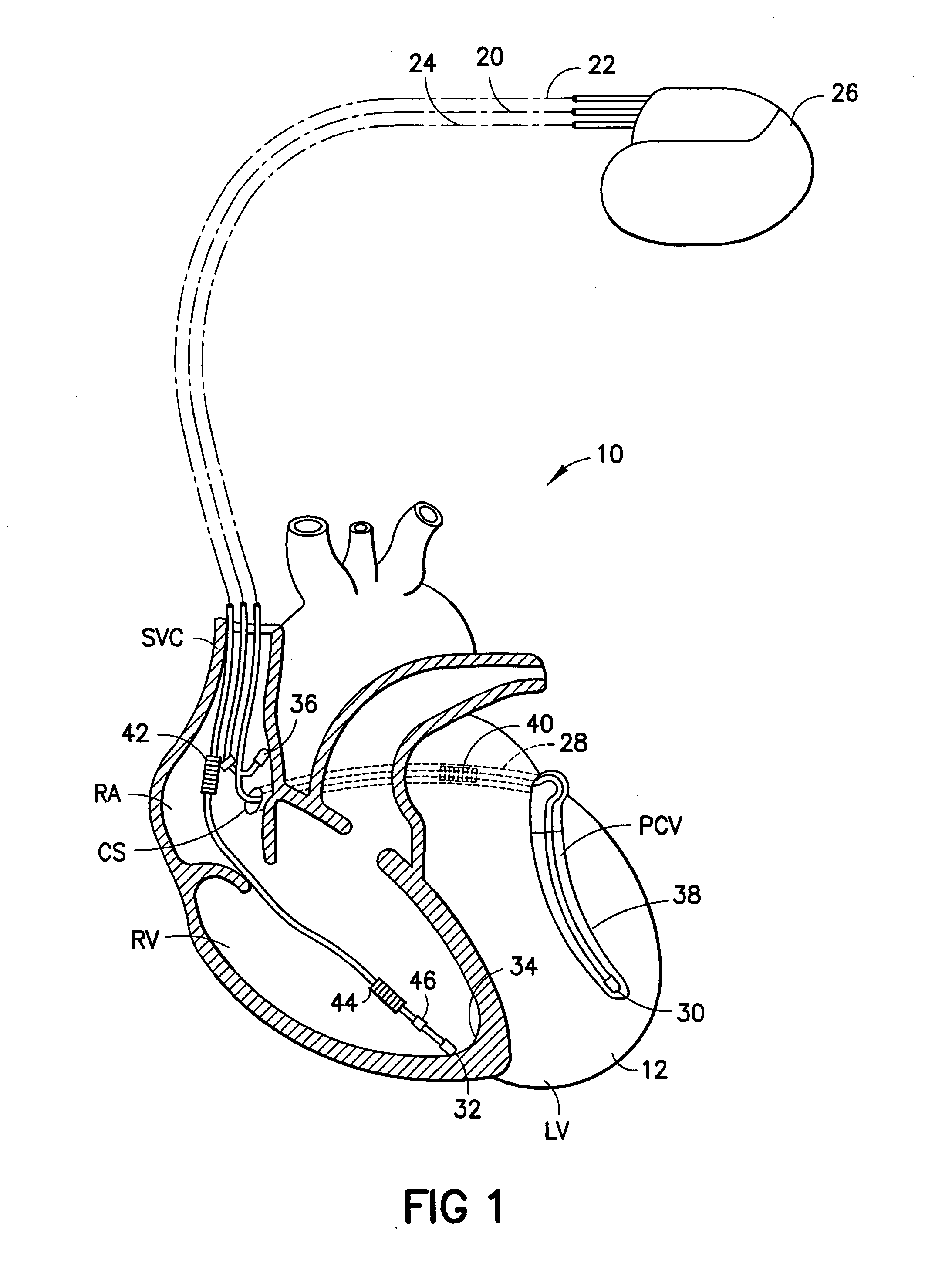

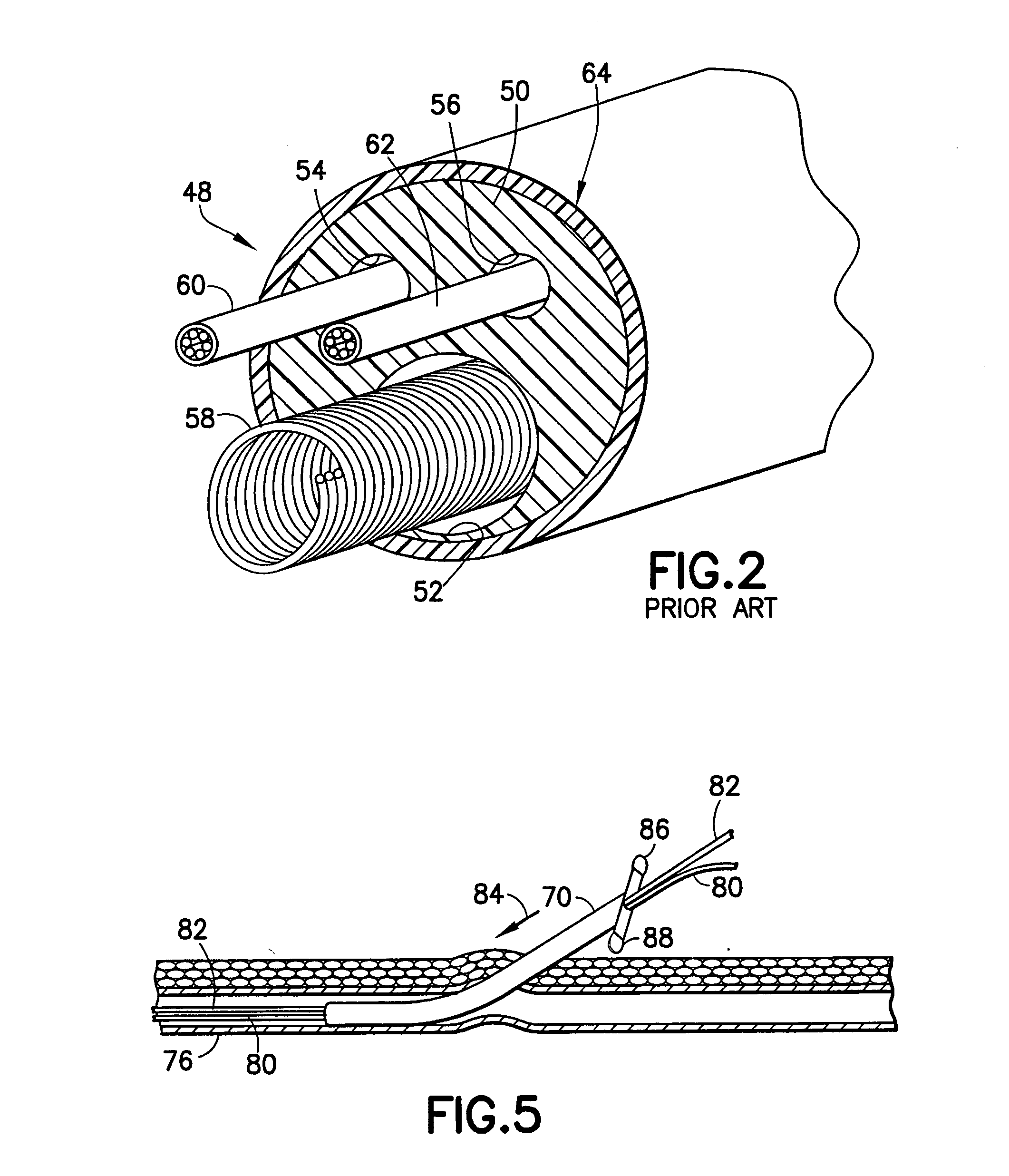

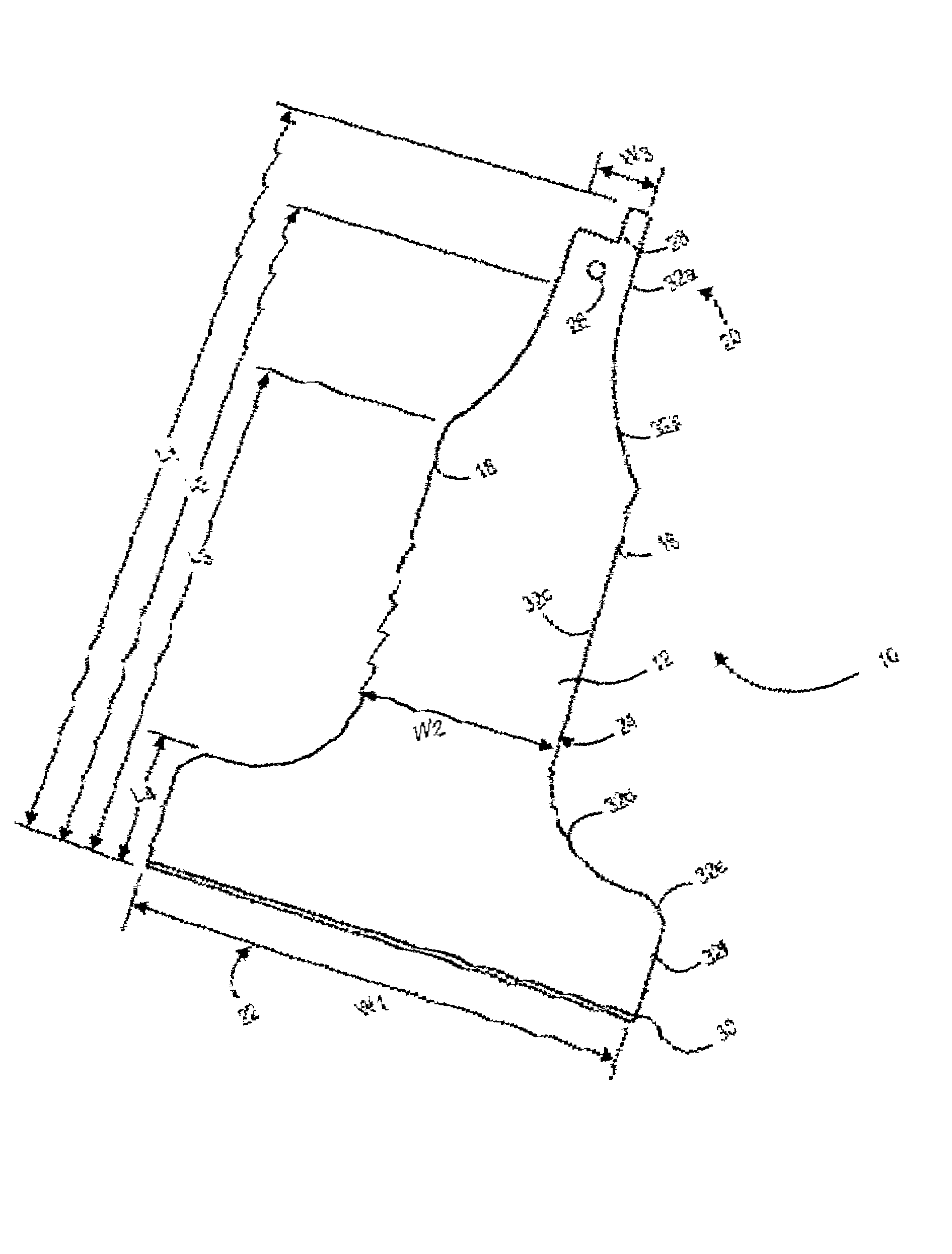

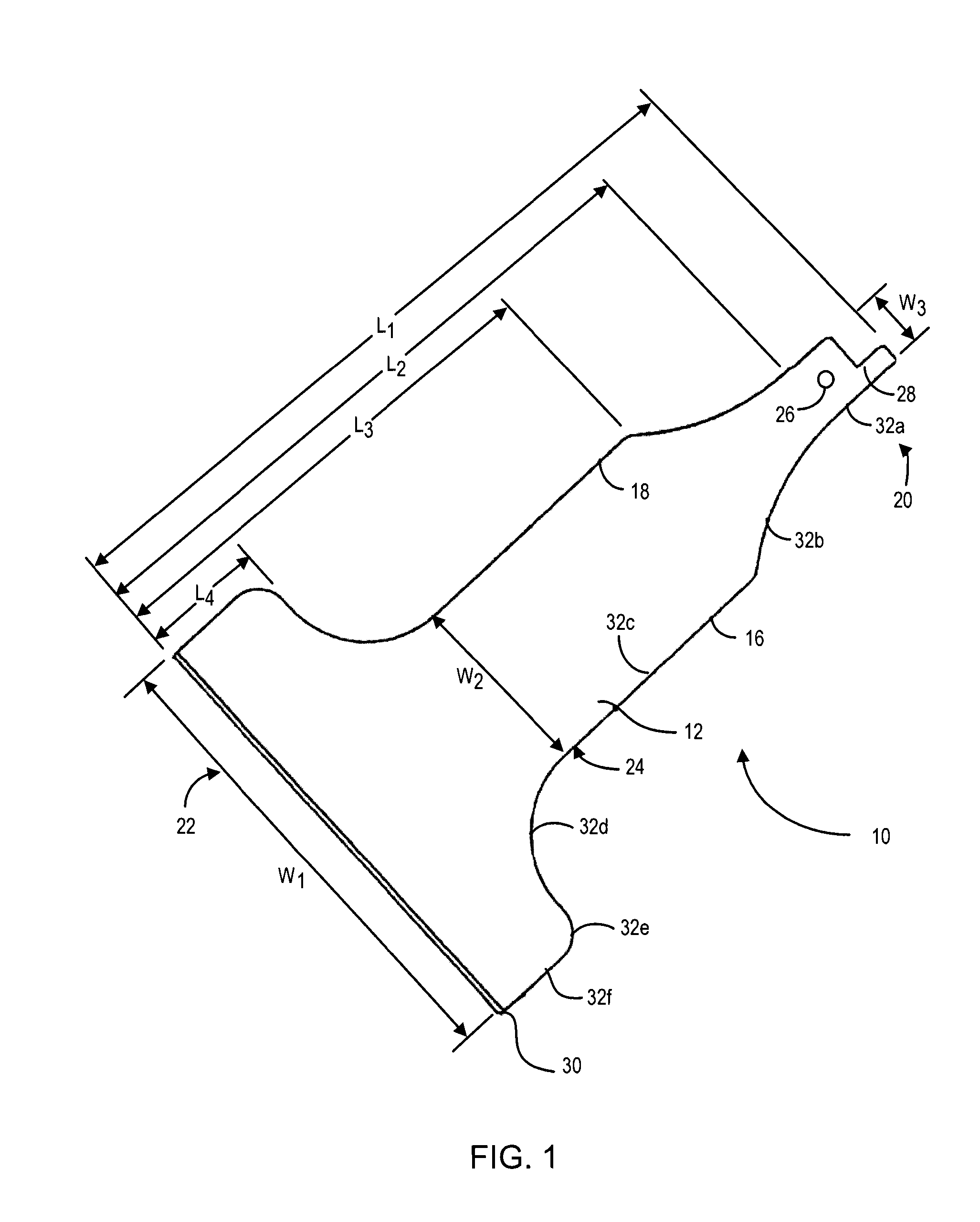

Lead body construction

InactiveUS20050080471A1Alleviate “ whip-like ” actionStiffnessTransvascular endocardial electrodesExternal electrodesElectrical conductorYoung's modulus

An implantable cardiac stimulation lead system for use with a stimulation device includes a lead body preferably having an outer diameter of less than 4 French and formed of a biocompatible material having a Young's modulus of at least 20,000 pounds per square inch. In the lead body, an inner insulator is composed of a suitable polymer such as PTFE or ETFE with an outer peripheral surface formed with a helical groove containing a conductor extending between a proximal connector and a distal tip electrode, and an outer insulator composed of polyurethane or silicone rubber or a combination thereof is positioned around the inner insulator. The lead system may be formed with a lumen for receiving a guidewire longitudinally through the lead body. A pair of insulated conductors may be received in the helical groove, one extending to the distal tip electrode, the other extending to a ring electrode proximally spaced from the distal tip electrode.

Owner:PACESETTER INC

Semiconductor device and method for manufacturing the same

InactiveUS20060202206A1Less forceReduce stress exertedFinal product manufactureSolid-state devicesDevice materialGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

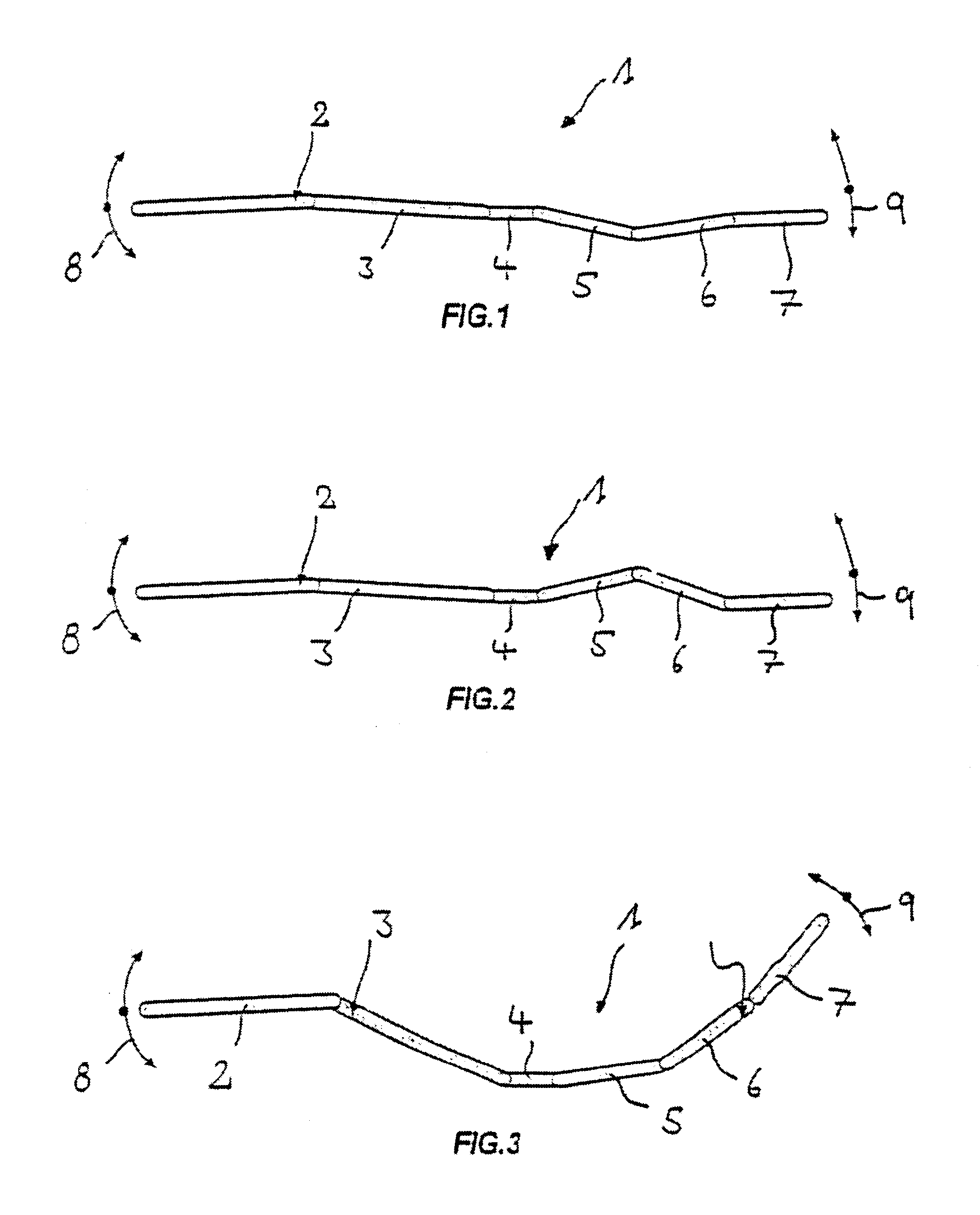

Scraper Blade

InactiveUS20090320299A1Easy to convertLow costCleaning using toolsOther artistic work equipmentsManganeseHardness

A scraper blade preferably configured for use with a reciprocating saw. The blade has a first end comprising a mounting structure, and a second end with a cutting edge. The second end is coupled with and spaced apart from the first end. Preferably, the first end is configured to be mounted in a reciprocating saw chuck and the first and second ends are integral. Further, the first and second ends are preferably manufactured from heat treated steel comprising between approximately 0.45 to 1.05% carbon and between approximately 0.3 to 1.0% manganese. Preferably, the steel has a yield tensile strength of between approximately 150,000 to 250,000 pounds per square inch, a modulus of elasticity of between approximately 20,000 to 40,000 kilopounds per square inch, and a hardness on the Rockwell C scale of between approximately 30 to 60.

Owner:SM PRODS

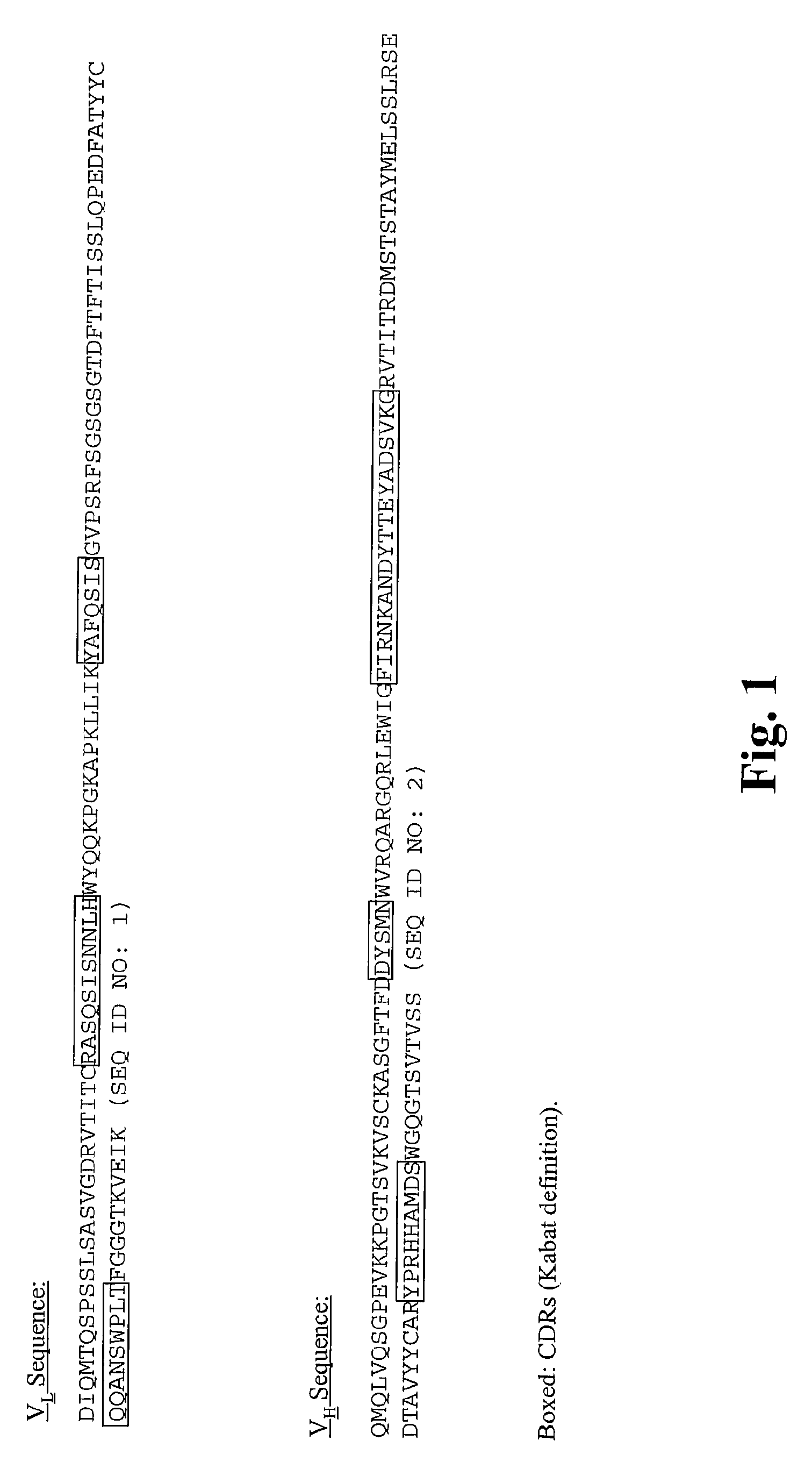

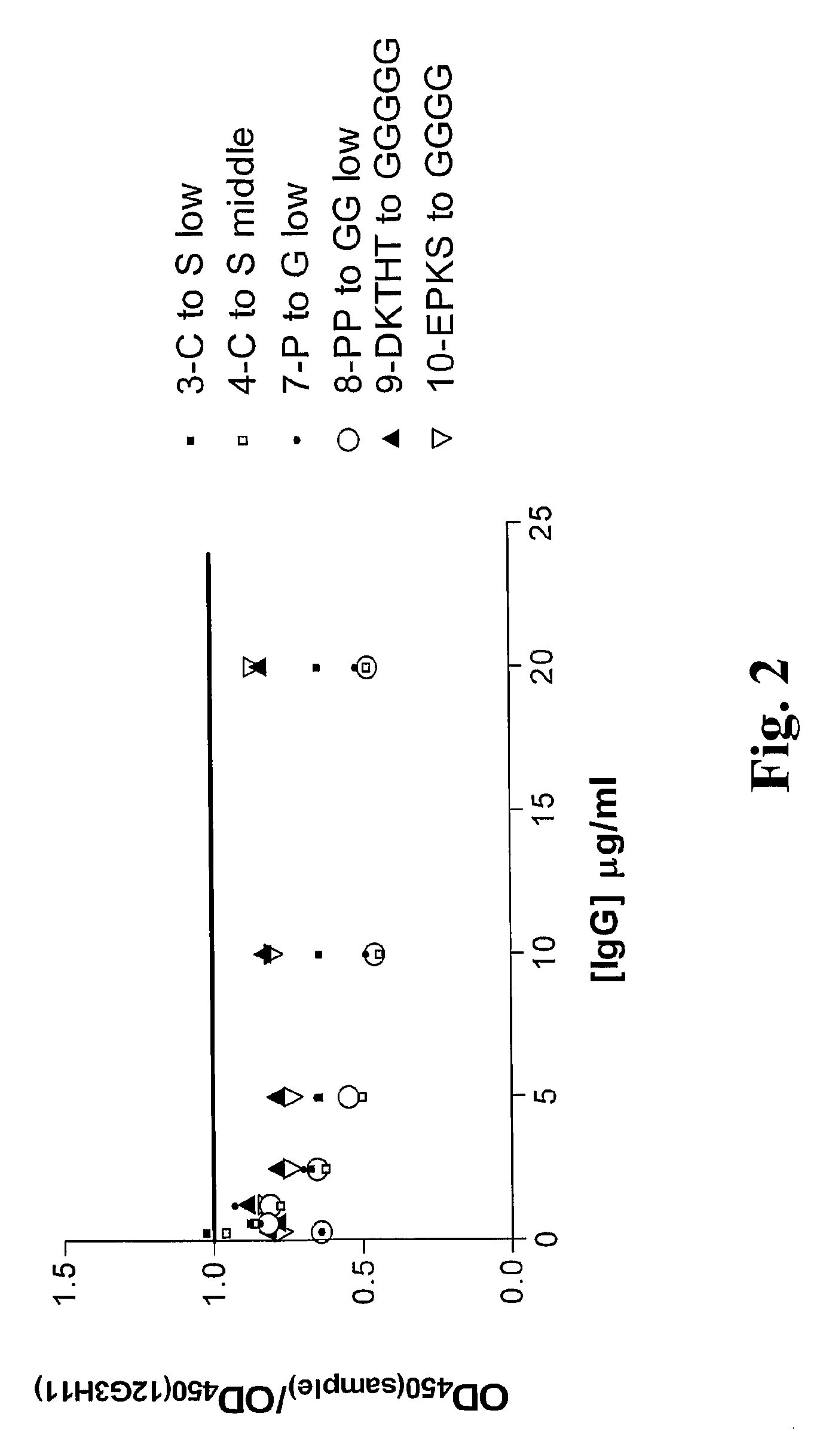

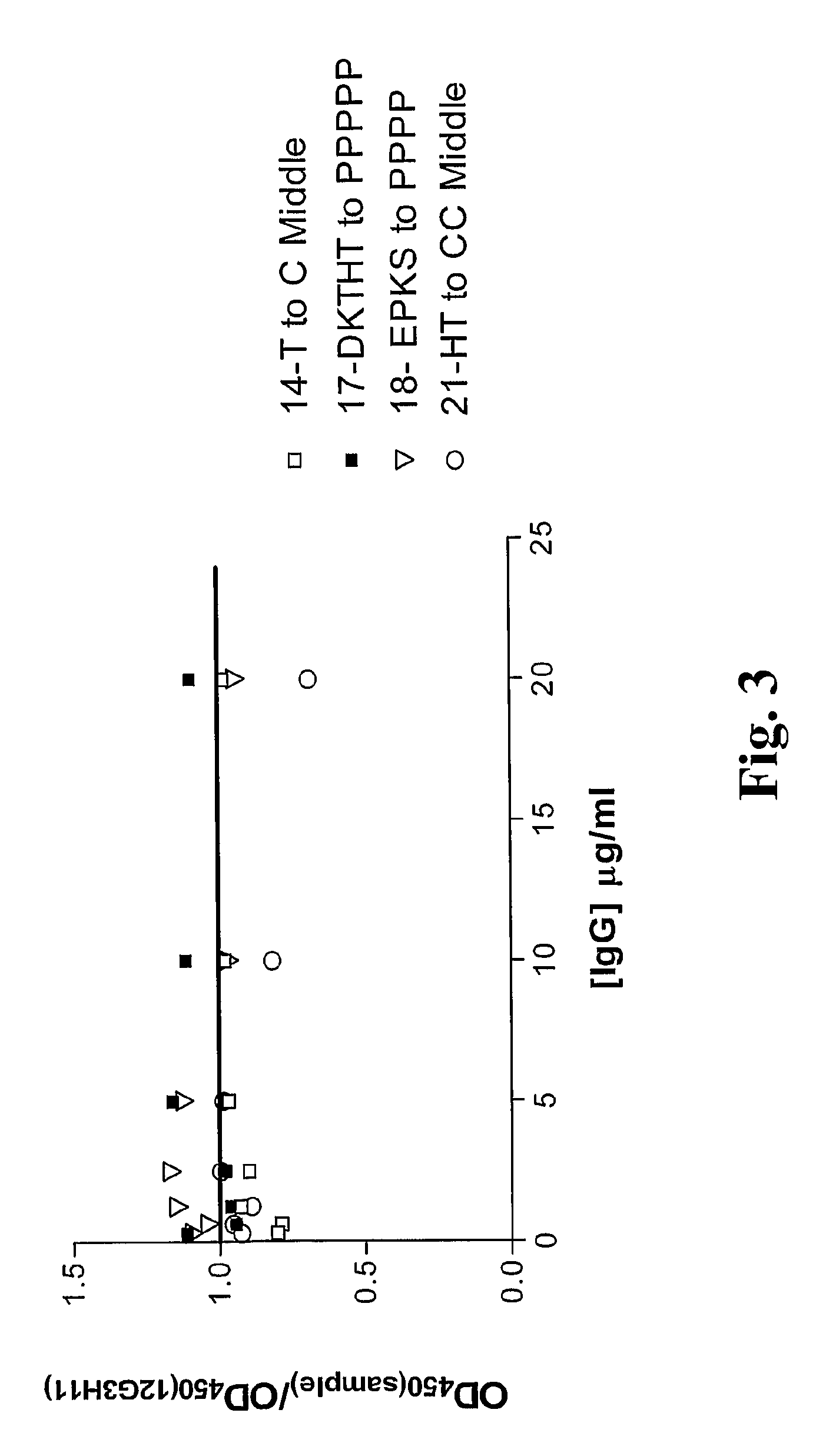

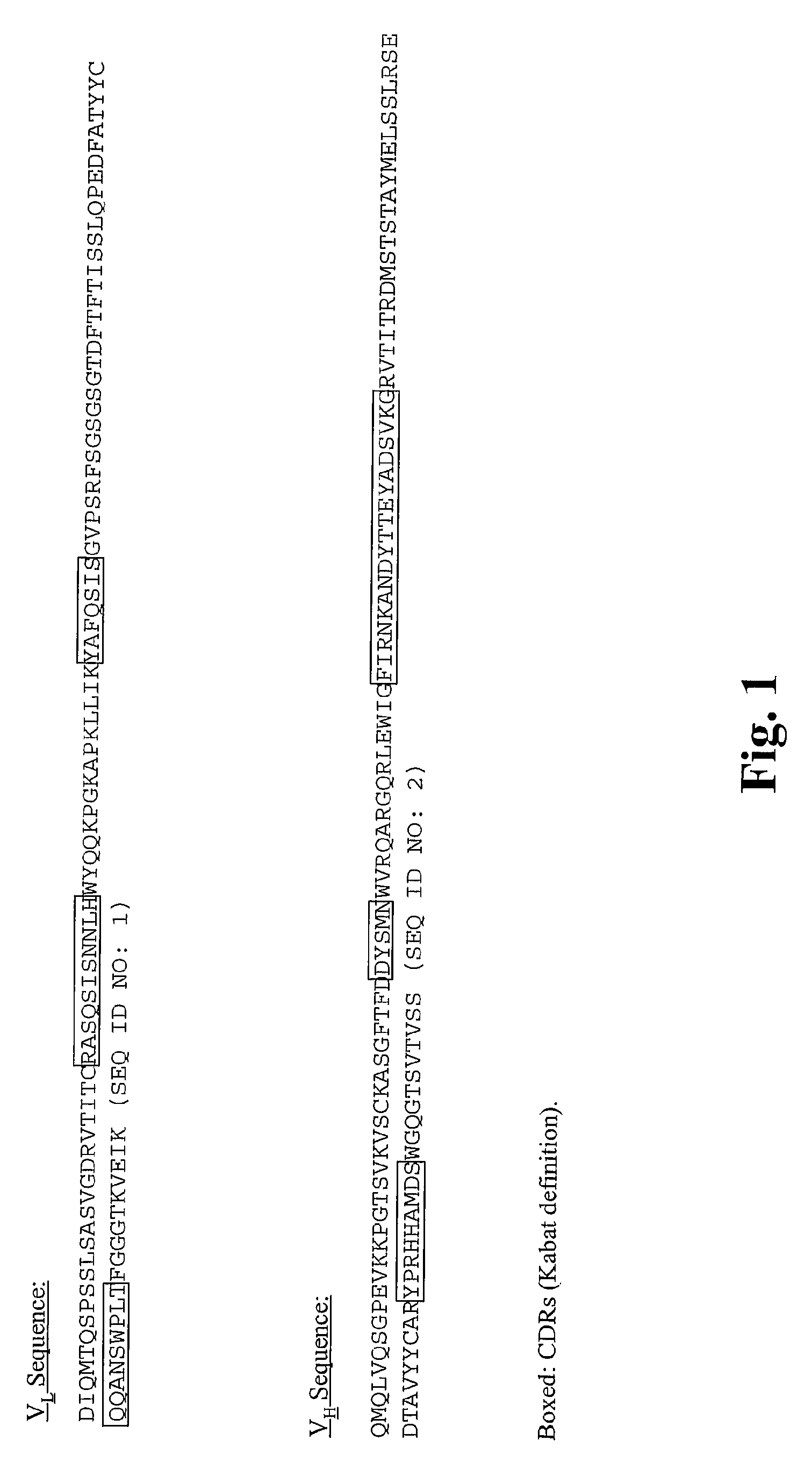

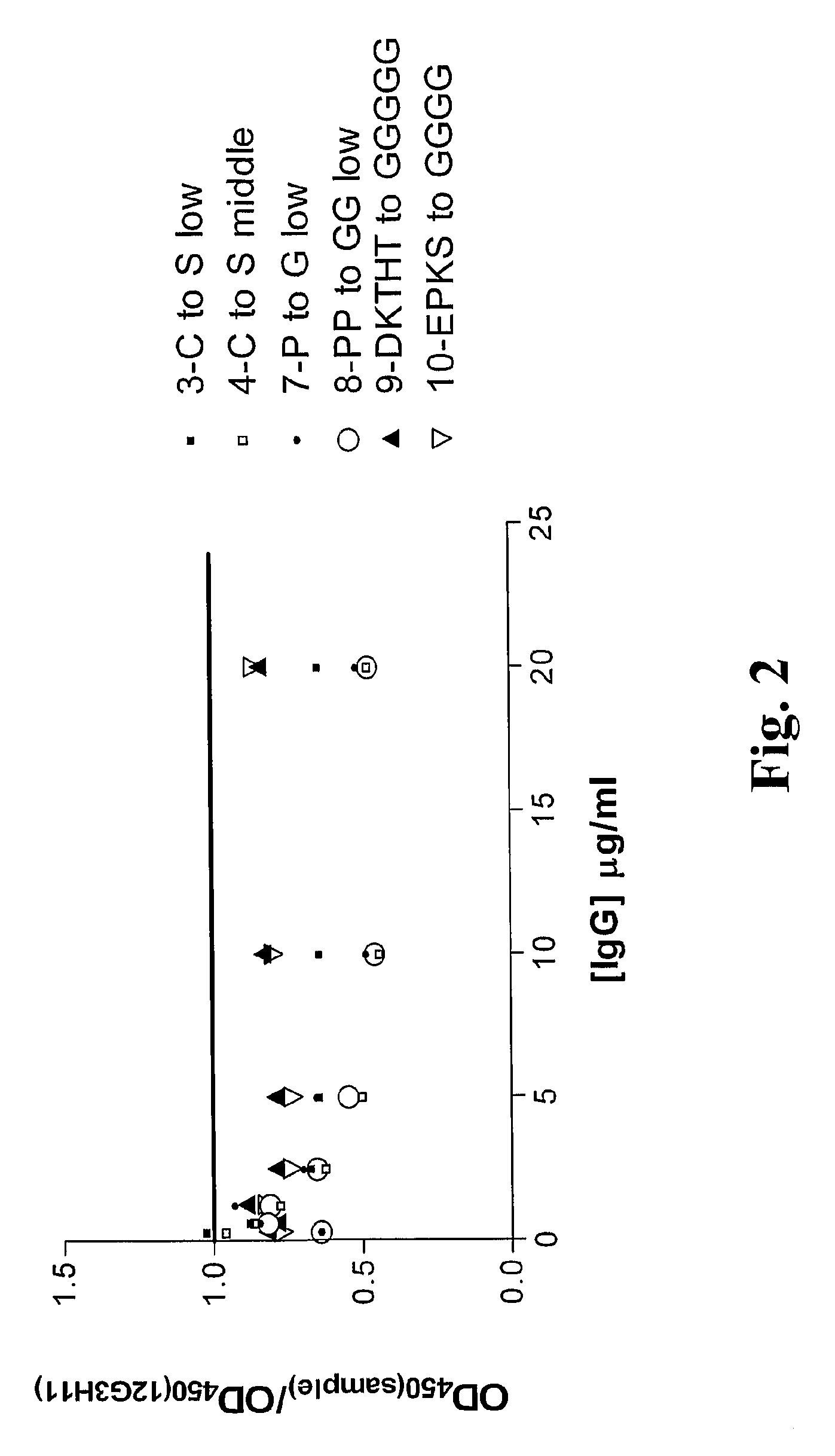

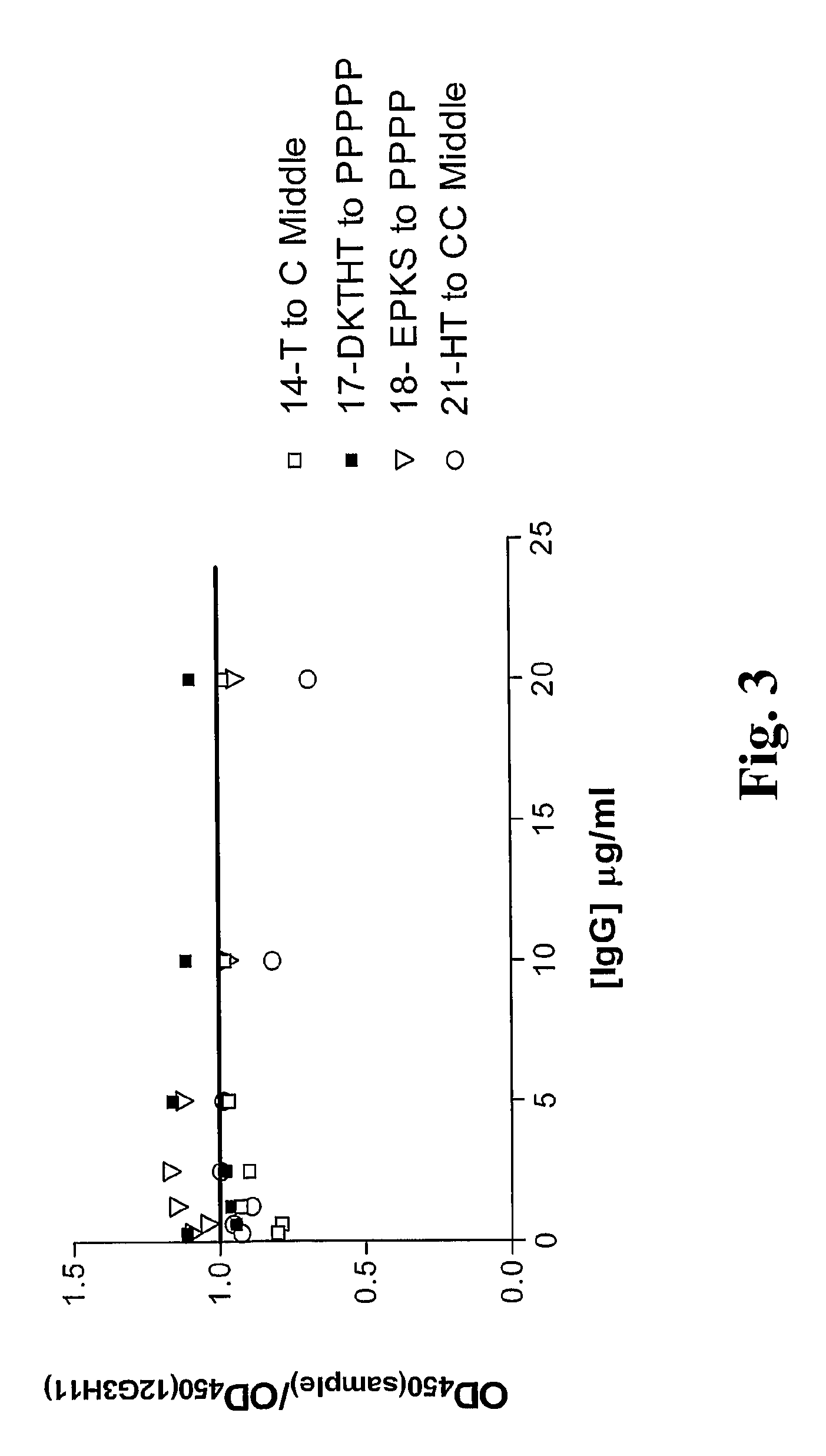

Modulation of antibody effector function by hinge domain engineering

ActiveUS20090221803A1Enhance prophylacticGood treatment effectAntibacterial agentsSenses disorderComplement-dependent cytotoxicityAntigen binding

The present invention relates to novel molecules (Fc variants) comprising at least one antigen binding region and an Fc region that further comprises a modified hinge which alters the binding of Fc to one or more Fc ligand (e.g., FcγRs) and / or modulates effector function. More specifically, this invention provides Fc variants that have modified binding affinity to one or more FcγR and / or CIq. Additionally, the Fc variants have altered antibody-dependent cell-mediated cytotoxicity (ADCC) and / or complement dependent cytotoxicity (CDC) activity. The invention further provides methods and protocols for the application of said Fc variants particularly for therapeutic purposes.

Owner:MEDIMMUNE LLC

Water filter cartridge with valves

InactiveUS20140110331A1Reduce leakageChange flexibilityTreatment involving filtrationMembrane filtersWater filterEngineering

A water filter cartridge having a housing with an inlet nozzle with a concentric, smaller outlet nozzle extending through the inlet nozzle with a space therebetween defining an inlet to a flow path passing through a filter and through the outlet nozzle. A diaphragm valve mounted to the outlet nozzle blocks upstream flow out of the inlet when the cartridge is not in use. An umbrella valve mounted on the end of the filter blocks downstream flow out of the outlet nozzle when the cartridge is not in use, thus reducing leakage when the cartridge is removed from the appliance.

Owner:BAIRD MICHAEL T

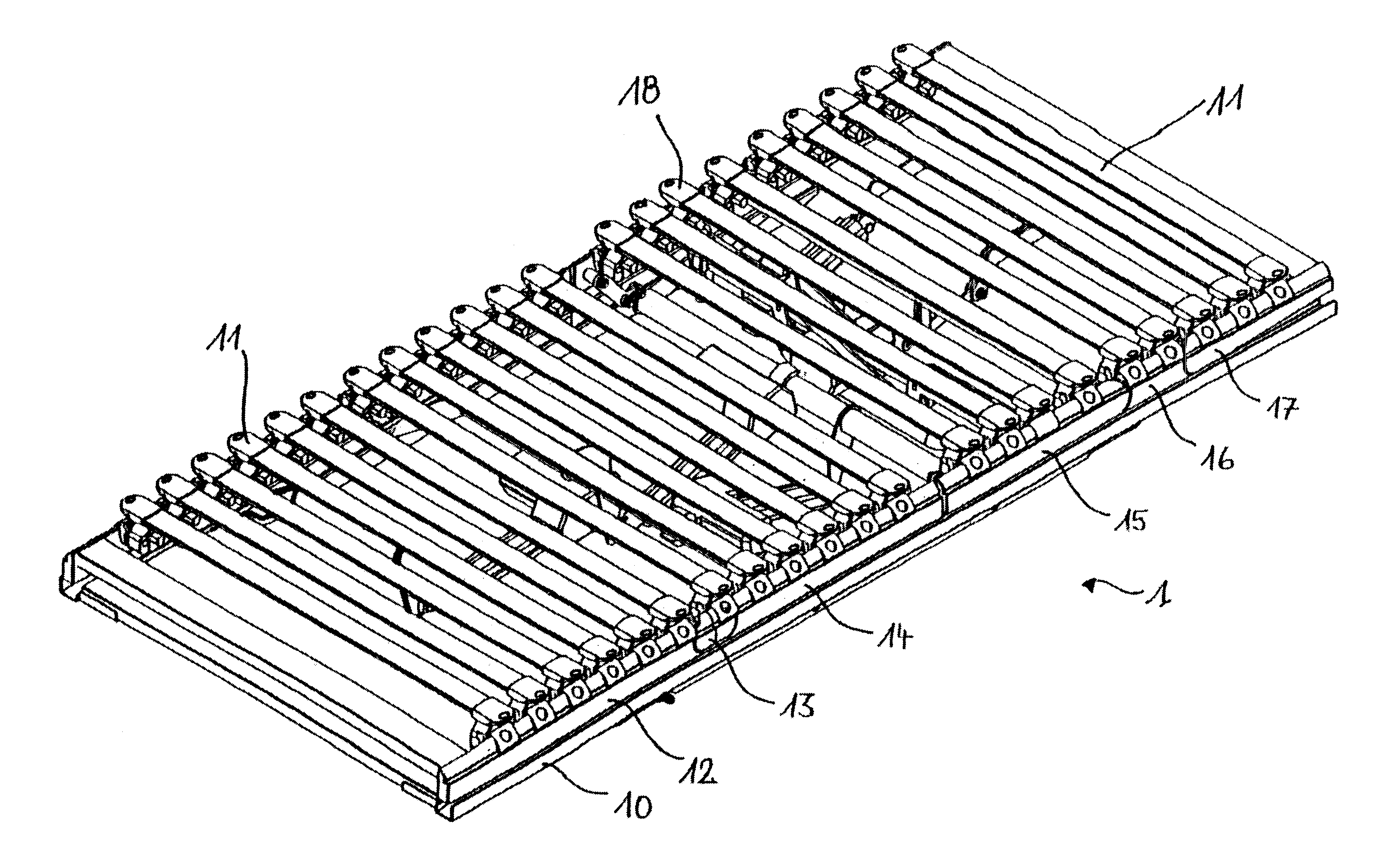

Bed

InactiveUS6986180B1Increase the curvatureQuality improvementChiropractic devicesSofasSpinal columnEngineering

A reclining device (1) is described having a support (10) which can be moved back and forth between different positions automatically and continuously, so that the spinal column and other joints, for example of the hip, knee, leg, can be moved and exercised specifically.

Owner:WILKE HANS JOACHIM

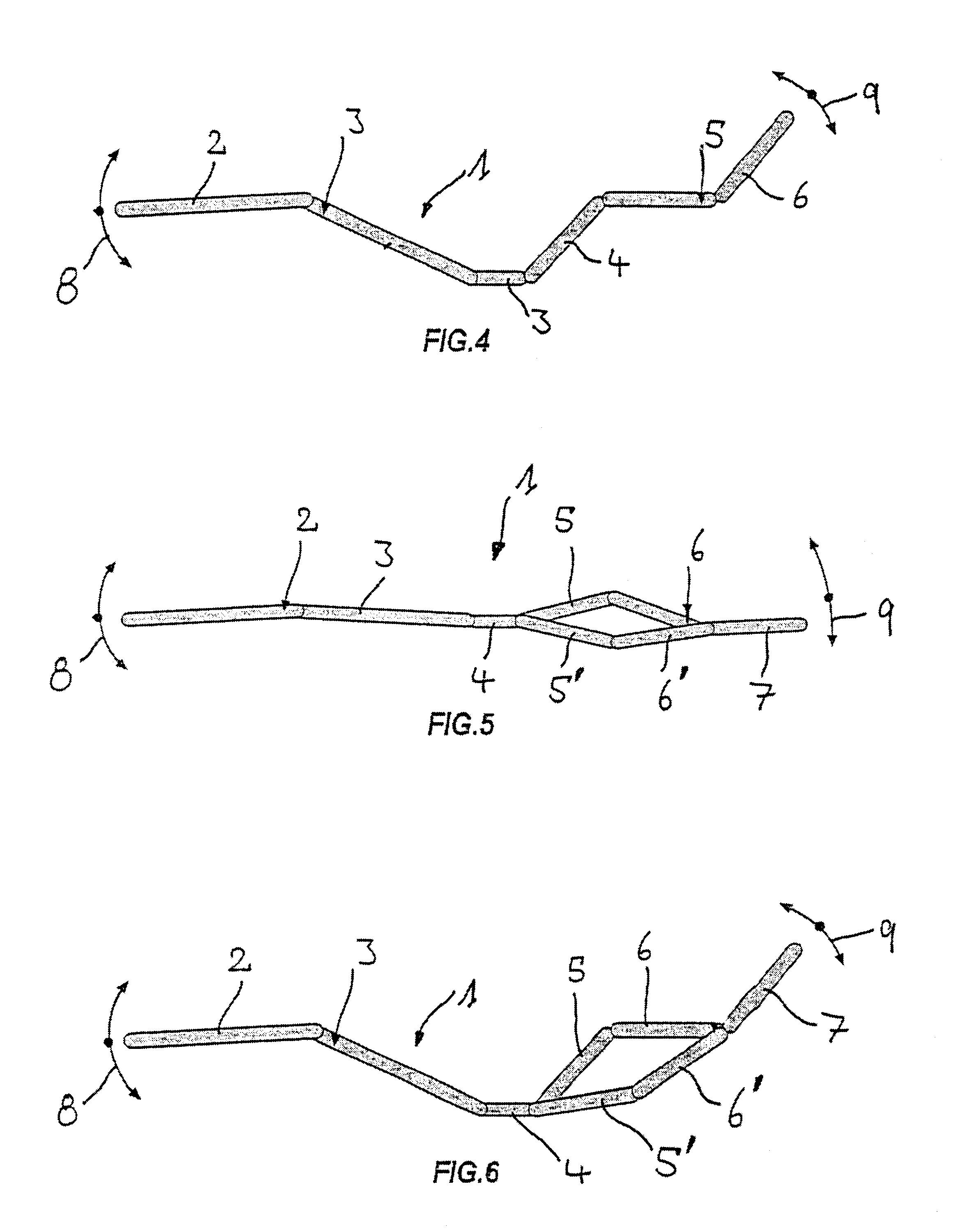

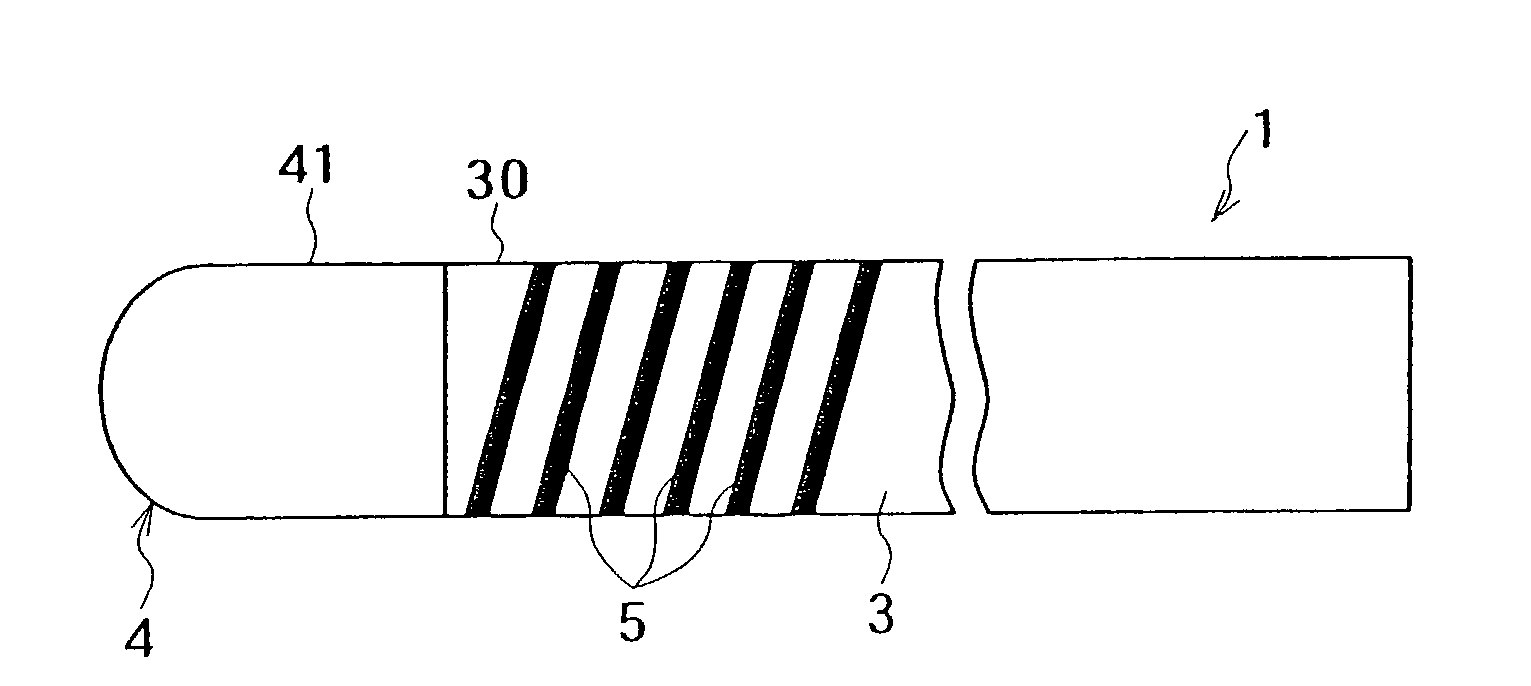

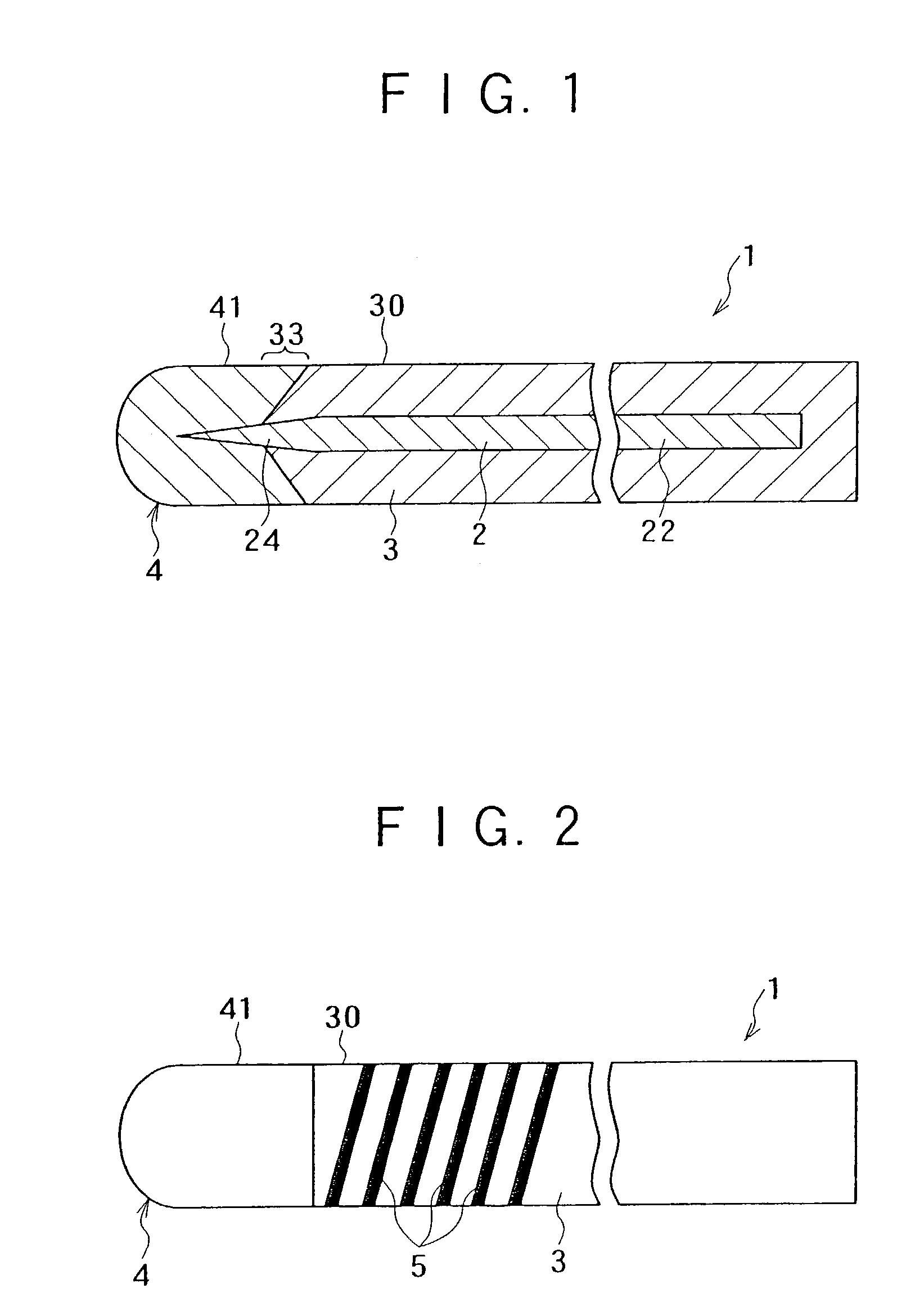

Guide wire

ActiveUS7278973B2Increase awarenessImprove visibilityGuide wiresDiagnostic recording/measuringEngineeringLaser light

A guide wire is configured to have a less lossy marker formed at a desired position and providing a relatively high degree of contrastability under X-ray fluoroscopic guidance or the like. The guide wire includes a linear core member, a resin layer covering a main body portion of the core member, and a contrasting portion covering the distal end portion of the core member. The resin layer contains a color developing agent which develops color by laser light irradiation, and a contrast agent composed of a metal oxide powder. The contrasting portion is made from a resin containing a contrast agent composed of a metal powder and has a contrasting function higher than the resin layer. A visible marker is formed on the outer surface of the resin layer through color development of the color developing agent by irradiating the surface of the resin layer with laser light.

Owner:TERUMO KK

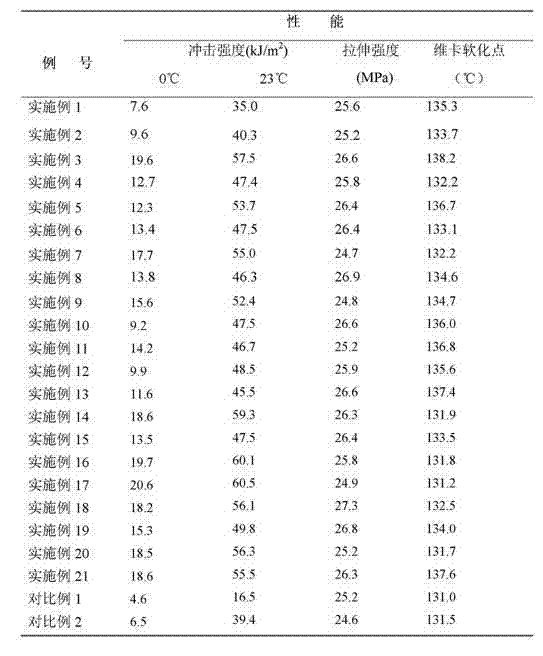

Random-copolymerization polypropylene toughening modified material and preparation method thereof

The invention discloses a random-copolymerization polypropylene toughening modified material which is formed by carrying out melt blending modification on the following components in parts by weight: 100 parts of random-copolymerization polypropylene, 0-15 parts of polypropylene homopolymer, 5-20 parts of ethylene copolymer, 2.5-12 parts of modifying master batch and 0.1-0.4 part of antioxidant. The tensile strength of the material is 24.7-27.3MPa, the notch impact strength at 23 DEG C is 35.0-60.5 kJ / m<2>, the notch impact strength at 0 DEG C is 7.6-20.6 kJ / m<2>, and the Vicat softening point is 131.2-138.2 DEG C. The invention also discloses a preparation method of the random-copolymerization polypropylene toughening modified material. The random-copolymerization polypropylene toughening modified material disclosed by the invention has favorable rigidity / toughness balance performance and heat resistance, can be widely used in the industries of construction materials, furniture, automobiles, electric appliances, electronics, electric appliances and the like, and can be used for preparing various profiles, tubes, films, sheets, plates, injection molding parts and the like. Besides, the preparation method is simple, can shorten the molding processing time, and can also lower the energy consumption and the production cost, thereby having high practicality.

Owner:SICHUAN UNIV

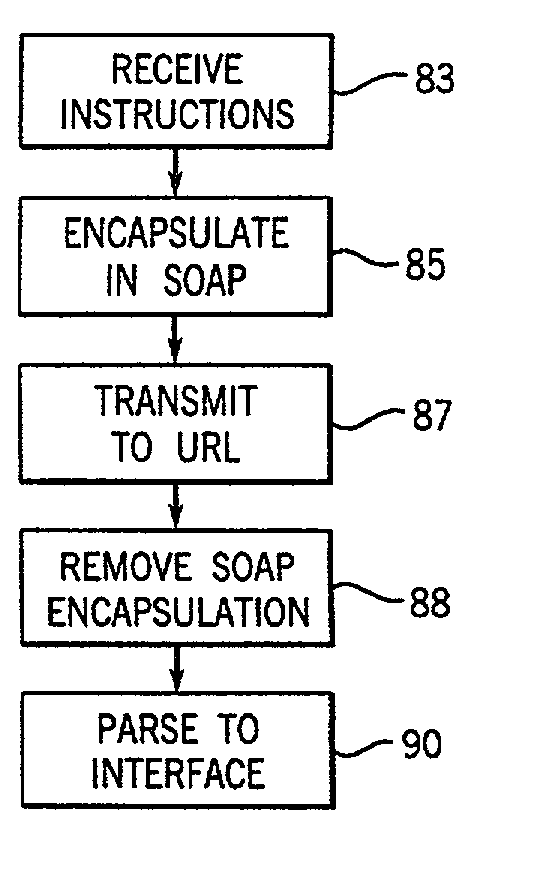

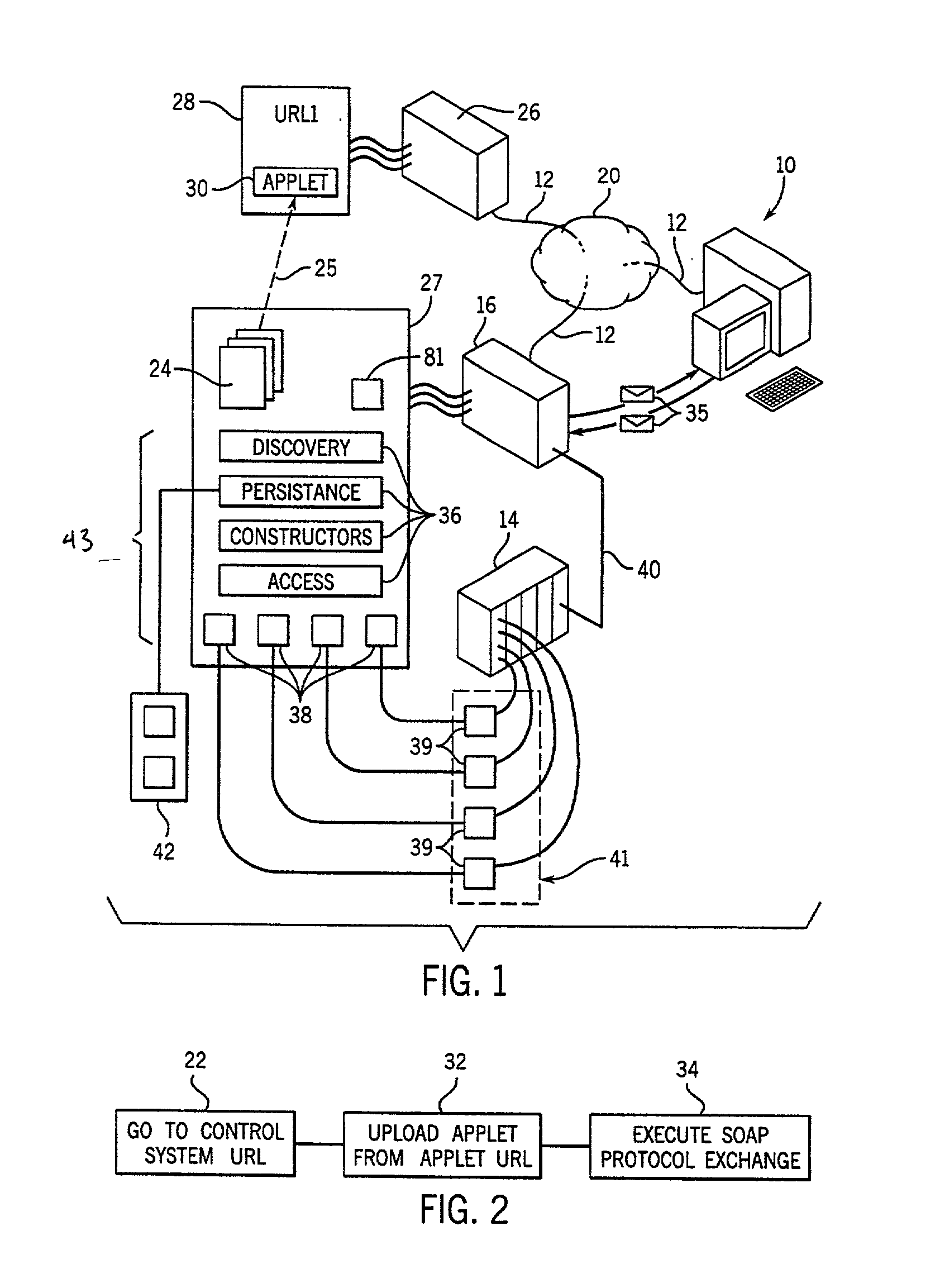

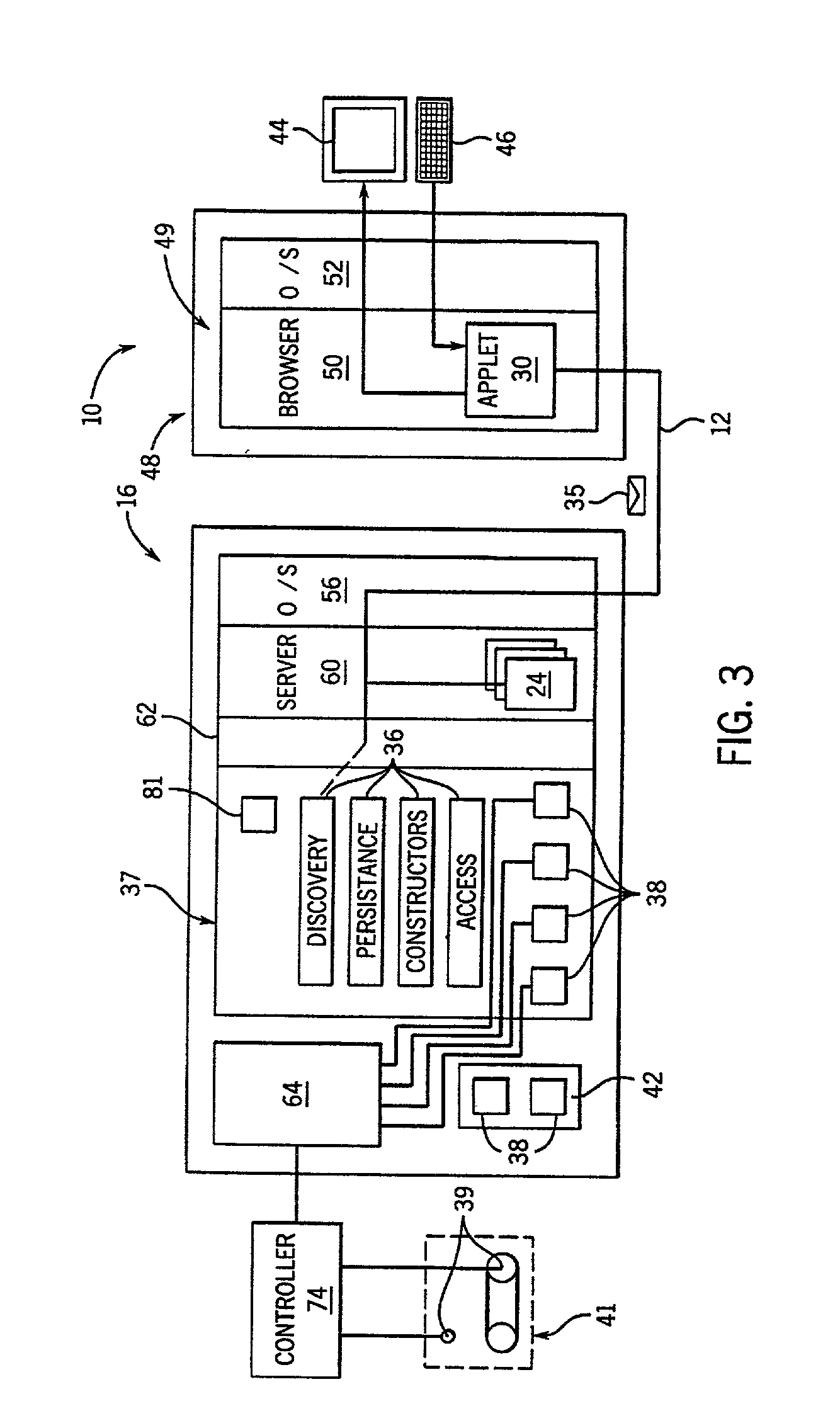

Industrial controller interface providing standardized object access

InactiveUS20030084201A1Change flexibilityComputer controlSimulator controlIndustrial control systemServer-side

An interface for an industrial control system provides, at a server side, a set of objects for programmer use. Instances of object provider objects, linked to each of the software objects, provide a uniform interface for the software objects allowing software objects from different vendors to be used while preserving a common programmer interface.

Owner:ROCKWELL SOFTWARE +1

Modulation of antibody effector function by hinge domain engineering

ActiveUS8008443B2Altered binding affinityHigh binding affinityAntibacterial agentsSenses disorderComplement-dependent cytotoxicityAntigen binding

The present invention relates to novel molecules (Fc variants) comprising at least one antigen binding region and an Fc region that further comprises a modified hinge which alters the binding of Fc to one or more Fc ligand (e.g., FcγRs) and / or modulates effector function. More specifically, this invention provides Fc variants that have modified binding affinity to one or more FcγR and / or CIq. Additionally, the Fc variants have altered antibody-dependent cell-mediated cytotoxicity (ADCC) and / or complement dependent cytotoxicity (CDC) activity. The invention further provides methods and protocols for the application of said Fc variants particularly for therapeutic purposes.

Owner:MEDIMMUNE LLC

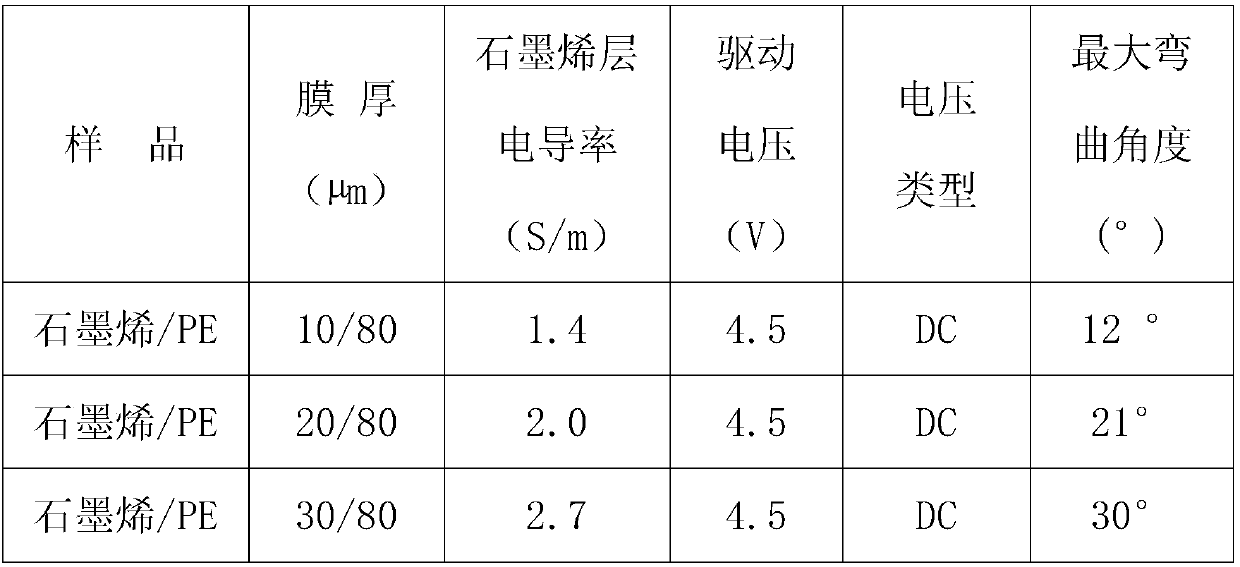

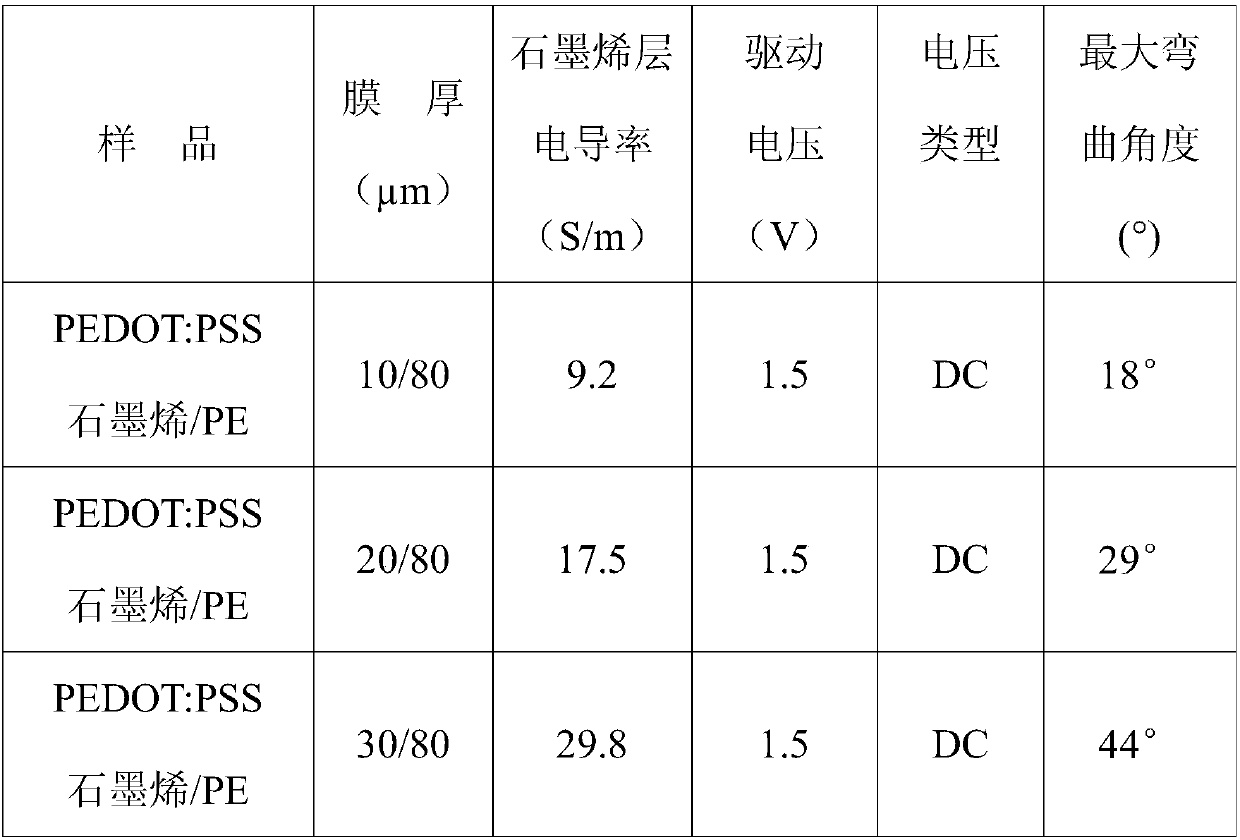

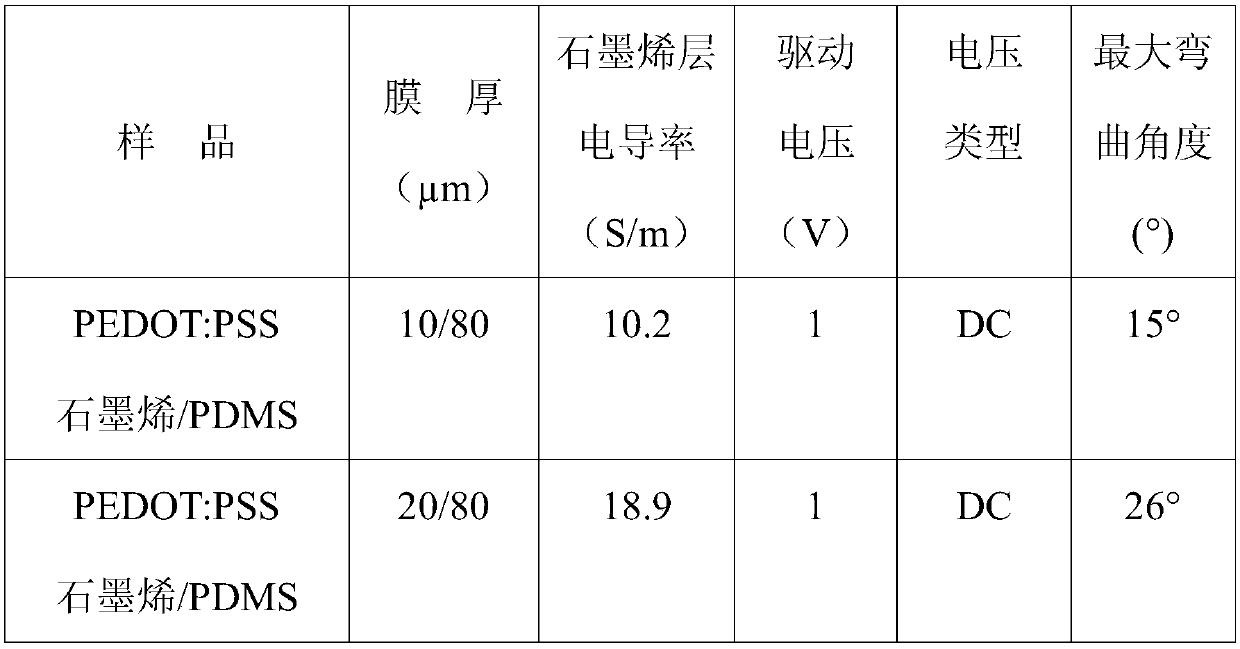

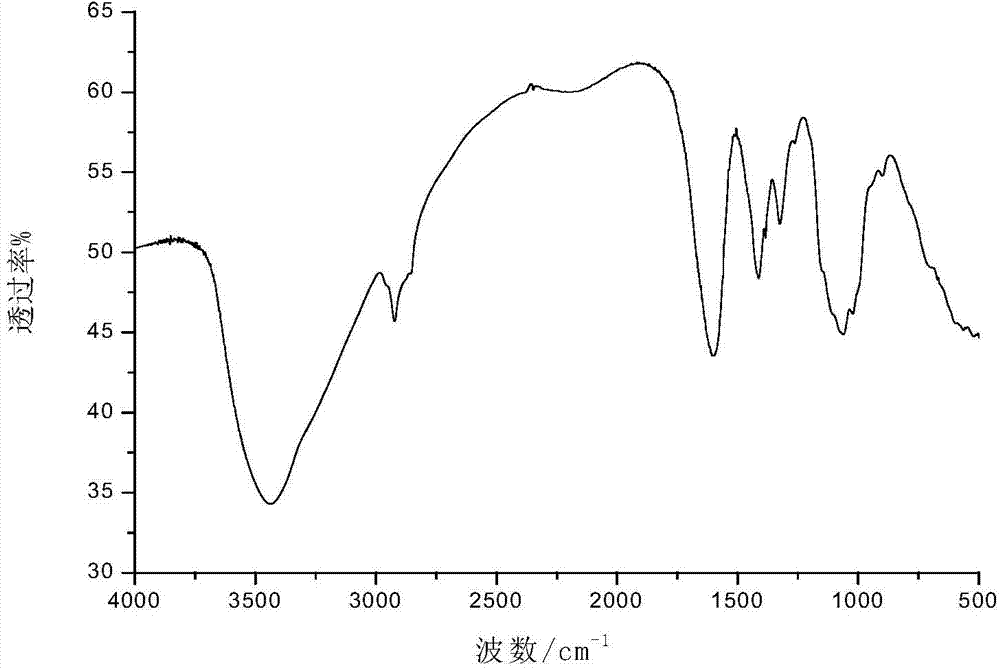

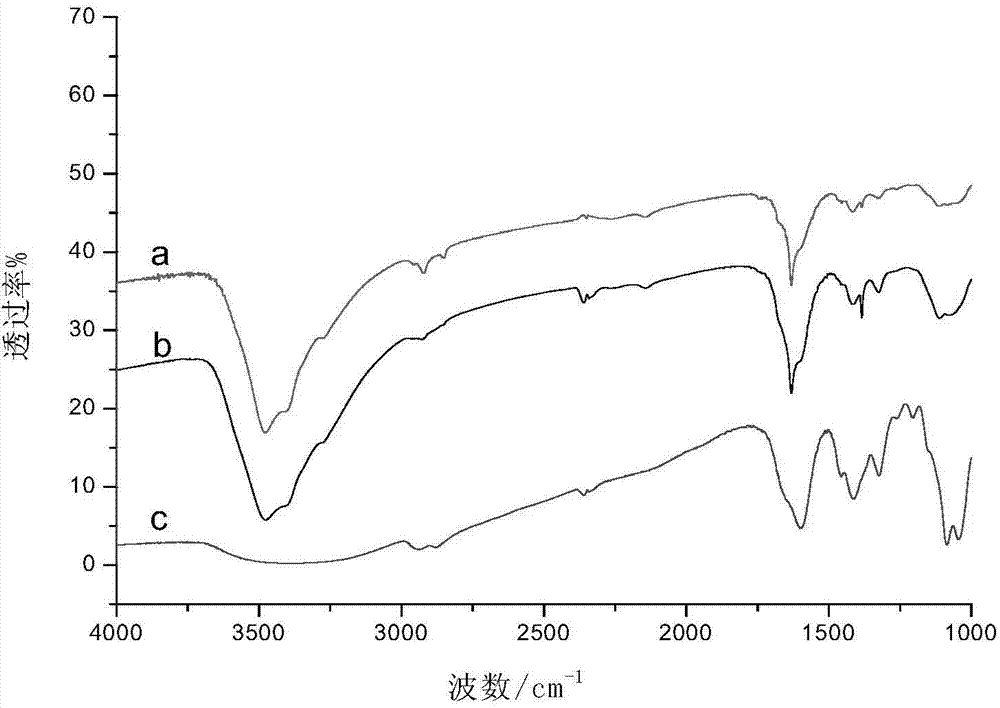

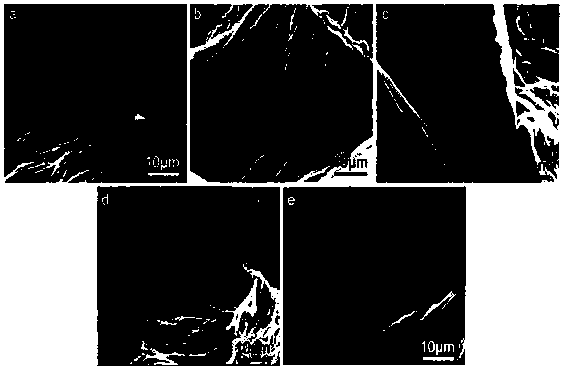

Graphene double-layer electroactive membrane and preparation method thereof

InactiveCN107778514AImprove flexibilityLarge coefficient of linear expansionGrapheneElectrically-conductive paintsPolymer thin filmsActuator

The invention discloses a graphene double-layer electroactive membrane and a preparation method thereof. The graphene double-layer electroactive membrane is composed of a flexible conducting layer anda flexible polymer layer. The preparation method comprises mixing and reacting flake graphite powder, NaNO3, sulfuric acid, KMnO4 and deionized water, and performing washing and drying processes to obtain graphene oxide; mixing and ultrasonic-dispersing the graphene oxide, hydrazine hydrate, ammonium hydroxide and deionized water for reaction to obtain reduced graphene oxide dispersion liquid; dropwise or rotatingly applying the reduced graphene oxide dispersion liquid onto a flexible polymer layer-polymer membrane and performing a drying process to form the flexible conducting layer onto thepolymer membrane to obtain the graphene double-layer electroactive membrane. The graphene double-layer electroactive membrane has the advantages of high responsiveness, low power, broad pressure range and the like when being electrically driven, and can be applied to the fields of flexible wearable equipment, micro motor actuators and micro-robots.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of dialdehyde carboxymethyl chitosan

The invention relates to a preparation method of dialdehyde carboxymethyl chitosan and belongs to the technical field of chitosan preparation. Through dissolution, oxidation reaction, standing, aftertreatment and drying, the dialdehyde carboxymethyl chitosan is prepared. Compared with the existing p-carboxymethyl chitosan modification research technology, the preparation method utilizes periodic acid and its sodium salt as oxidizing agents, under strong selective oxidation effects of the oxidizing agents, carboxymethyl chitosan is oxidation-modified by opening of a pyranoid ring on a molecular chain and then generation of the novel dialdehyde group so that a relatively-high molecular weight oxidation product can be obtained, the oxidation product molecular structure can be changed, reaction activity can be improved and molecular chain rigidity can be reduced. The preparation method has important effects of improving carboxymethyl chitosan polymer crystallinity, molecular chain flexibility and gel performances.

Owner:JIANGNAN UNIV

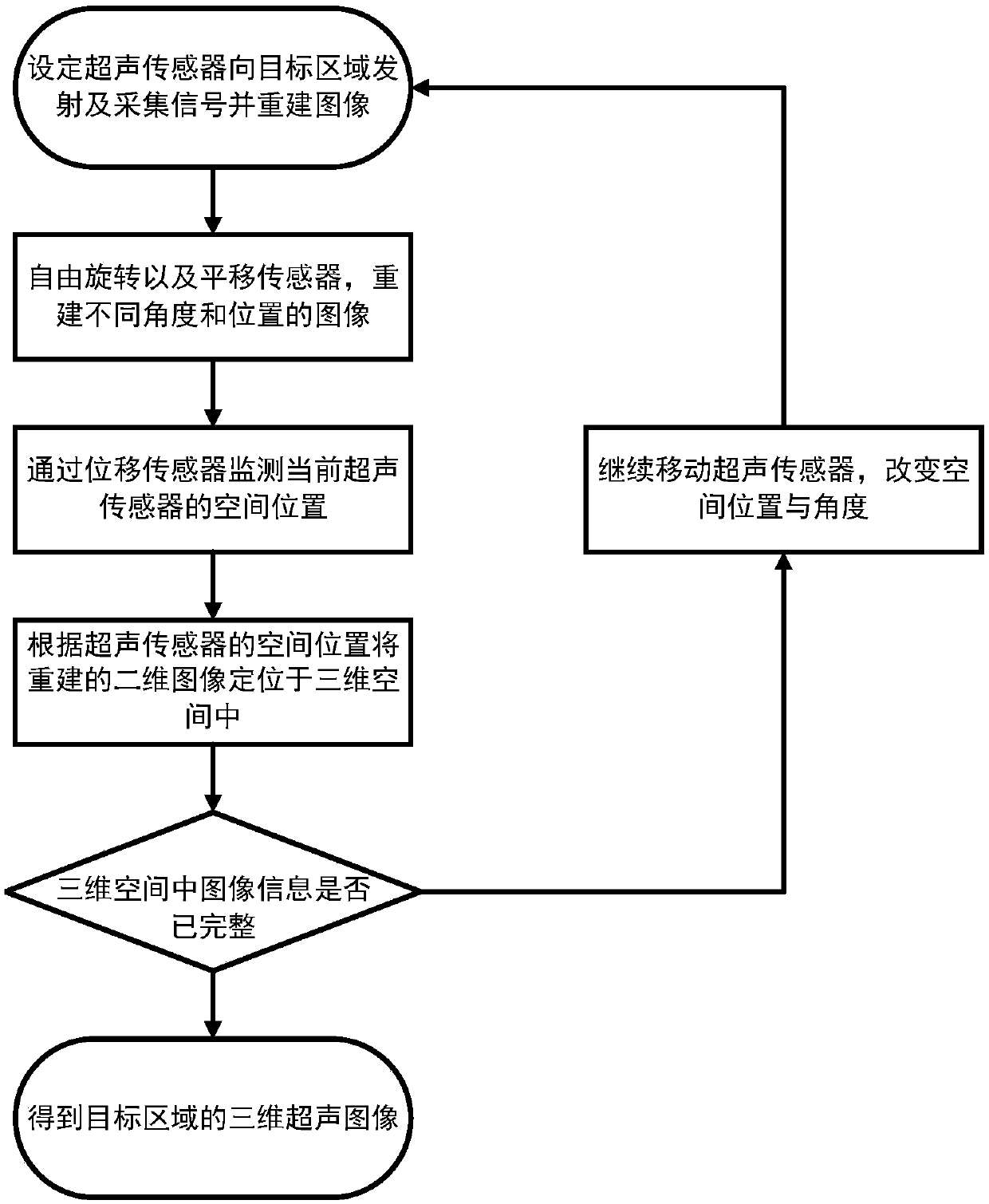

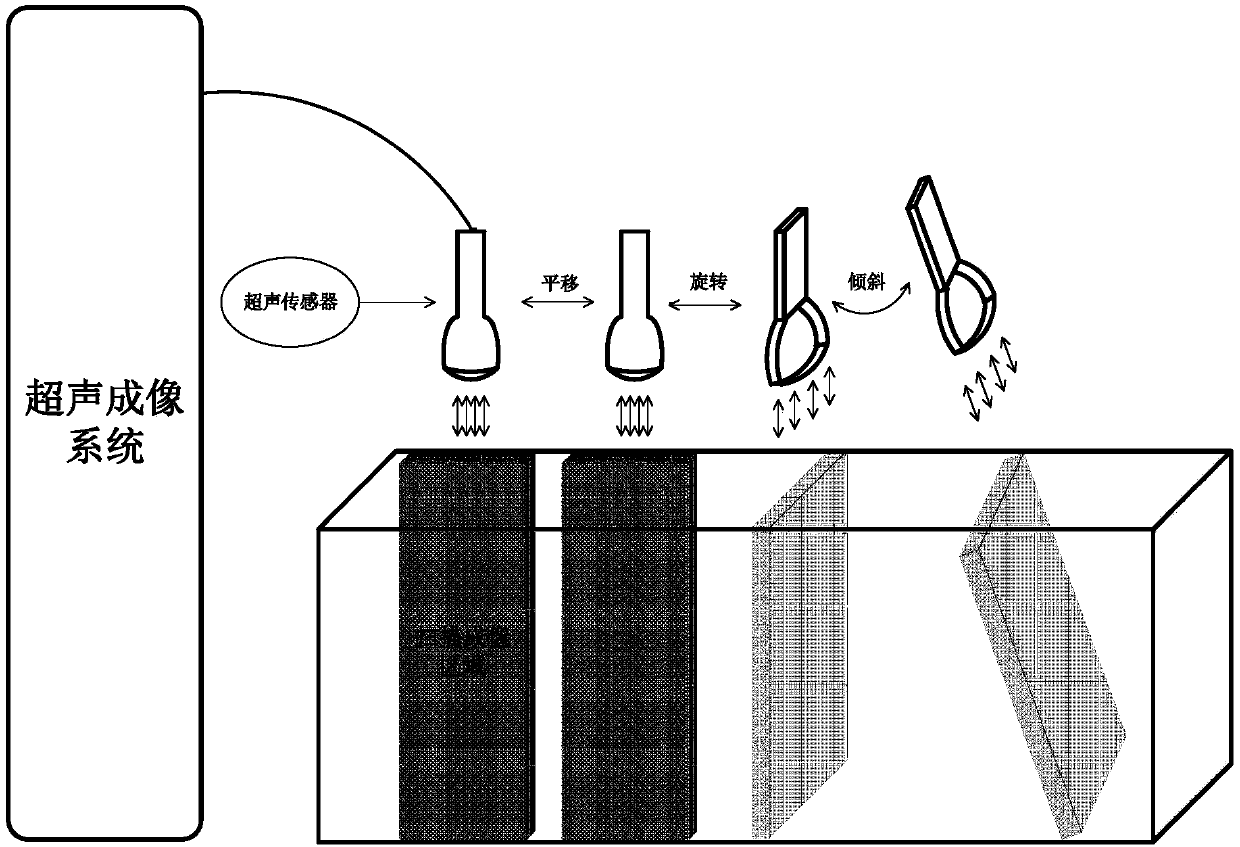

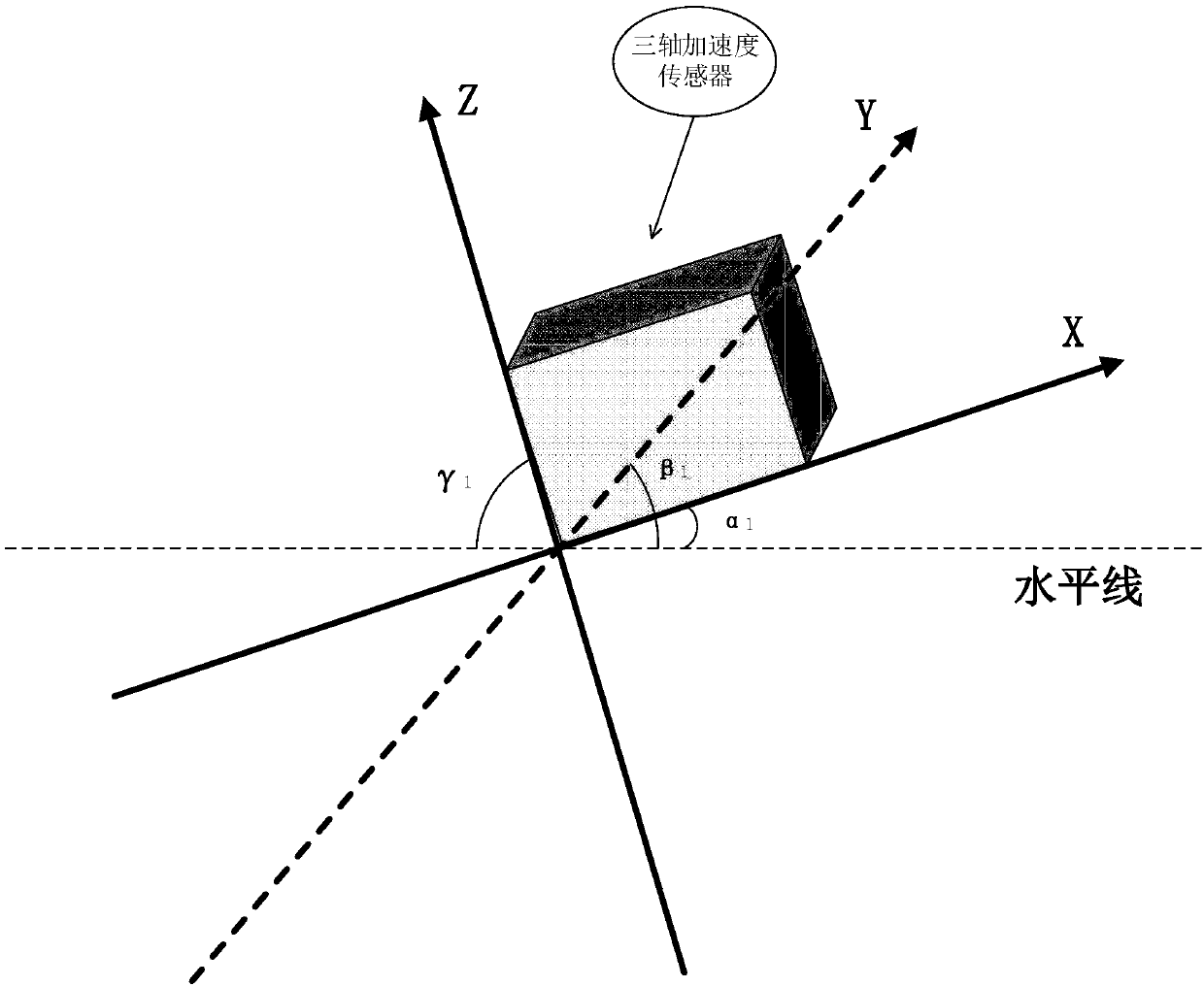

Three-dimensional ultrasonic imaging method for two-dimensional ultrasonic image set reconstruction

ActiveCN107582098AChange flexibilityUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsThree-dimensional spaceUltrasonic imaging

The invention discloses a three-dimensional ultrasonic imaging method for two-dimensional ultrasonic image set reconstruction. The method comprises the following steps that a linear array ultrasonic sensor is used for emitting ultrasonic signals to a target three-dimensional space, collecting the ultrasonic signals and reconstructing two-dimensional ultrasonic images of the target three-dimensional space; an ultrasonic sensor is rotated freely and moves horizontally, and the two-dimensional ultrasonic images of the target three-dimensional space at different angles and in different positions are reconstructed; the position and angle information of the ultrasonic sensor in the moving and rotating processes is detected through a displacement sensor and an angle sensor; in combination with the position and angle information of the ultrasonic sensor, the corresponding two-dimensional ultrasonic images are positioned in the three-dimensional space; a three-dimensional ultrasonic image is reconstructed through a two-dimensional ultrasonic image set.

Owner:NANJING UNIV +1

Micro-nano scale wave structure in macroscopic composite material and preparation method thereof

InactiveCN108298585AEasy to operateEasy to controlMaterial nanotechnologyGrapheneWave structureMicro nano

The invention discloses a micro-nano scale wave structure in a macroscopic composite material and a preparation method thereof, and belongs to the technical field of functional composite materials. Atwo-dimensional nano-material dispersion solution is self-assembled to form a macroscopic structure including a thin film, gel and the like; a carbon-nitrogen compound is generated by utilizing thermal chemical reaction and the state of a two-dimensional composite material is regulated and controlled to form the micro-nano scale wave structure. The micro-nano scale wave structure disclosed by theinvention has the characteristics that a preparation technology is simple, the size and shape of the composite material are easy to regulate and control, the mechanical elasticity, an electronic structure or a surface state of the material is adjustable and the like; a foundation is laid for researches and application of an assembled macroscopic material to the fields including flexible conductors, micromechanical electronics and flexible energy storage devices, catalytic carriers and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

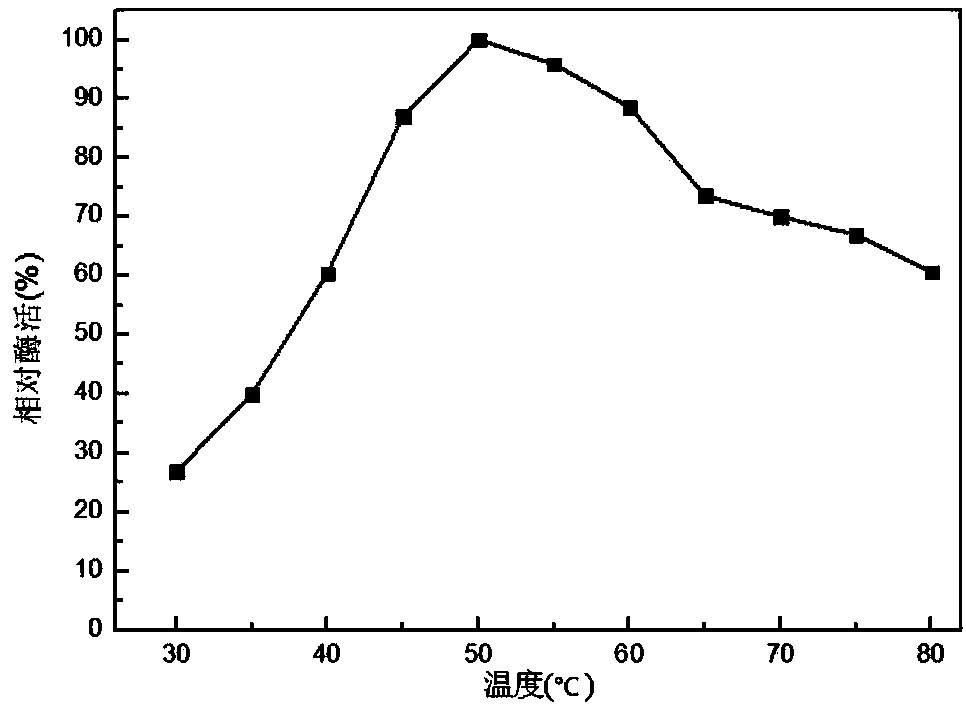

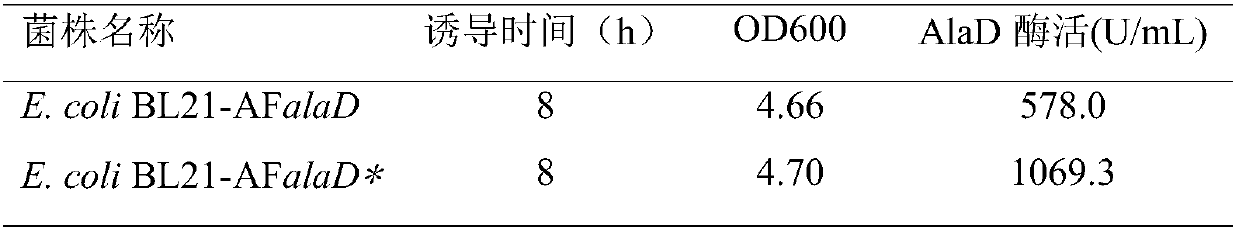

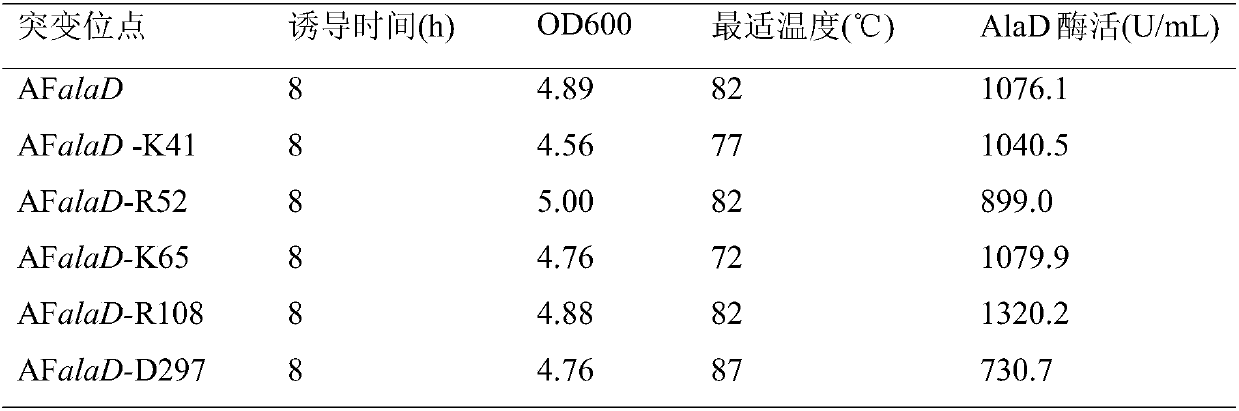

Alanine dehydrogenase mutant and application thereof

ActiveCN107937361AChange flexibilityEfficient productionBacteriaMicroorganism based processesEscherichia coliBacteroides

The invention discloses an alanine dehydrogenase mutant and application thereof, and belongs to the technical field of biological engineering. According to the alanine dehydrogenase mutant, archaeoglobus fulgidus derived alanine dehydrogenase is modified through protein engineering; an optimal enzyme-activity temperature of the alanine dehydrogenase is decreased from 82 DEG C to 50 DEG C; a key gene on a synthetic competitive route of L-alanine is cancelled in bacillus coli K12; the generation of by-products is reduced; an alaD gene and an alanine racemase dadX gene for coding the L-alanine dehydrogenase in a recombinant strain are replaced with modified archaeoglobus fulgidus derived alanine dehydrogenase genes; the two-stage fermentation is carried out by utilizing the recombinant strain; the fermentation is carried out for 42h; a yield of the L-alanine reaches 153.9g / L, and a sugar-acid conversion ratio is 81.0 percent.

Owner:金华利家园生物工程有限公司 +1

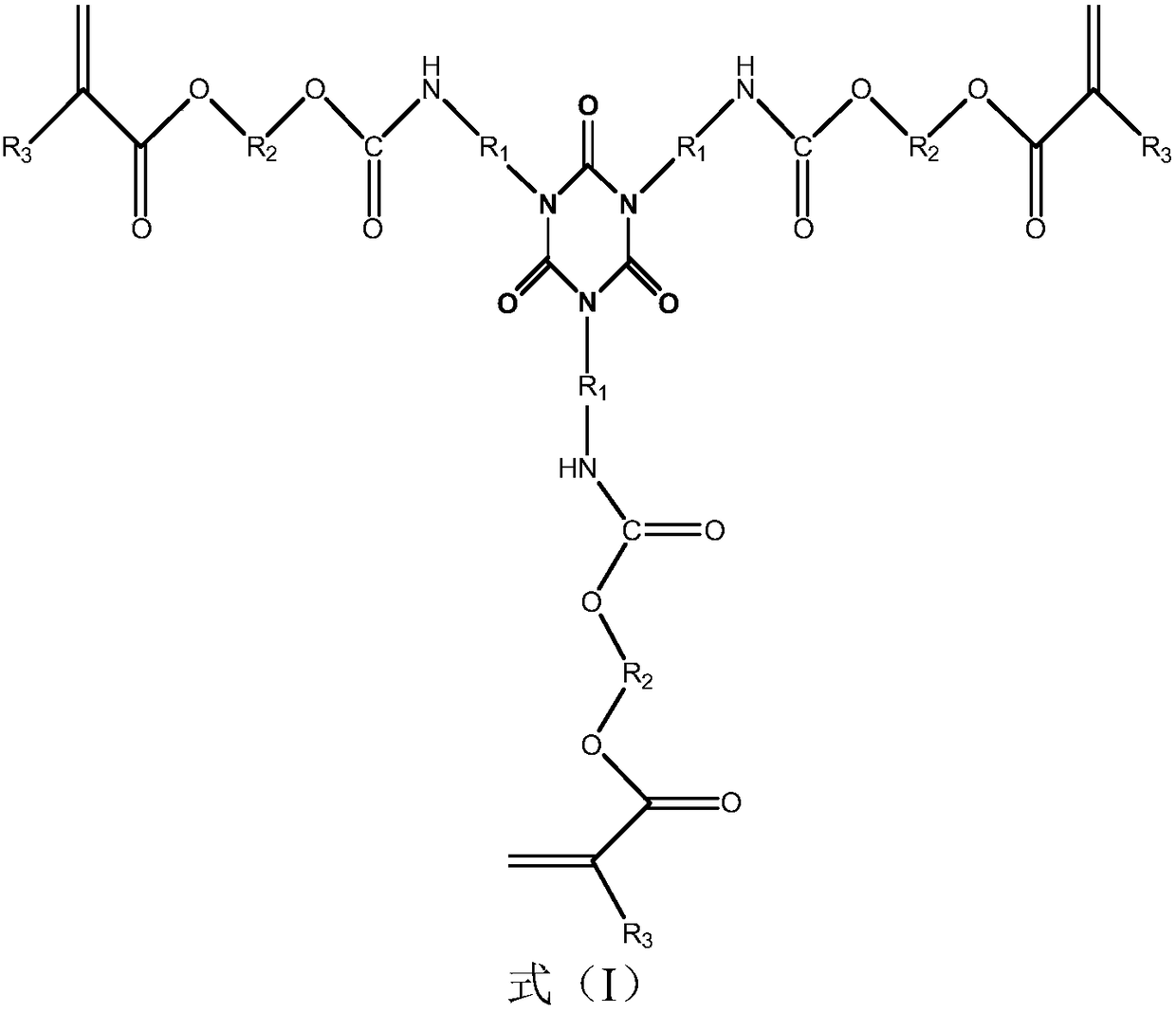

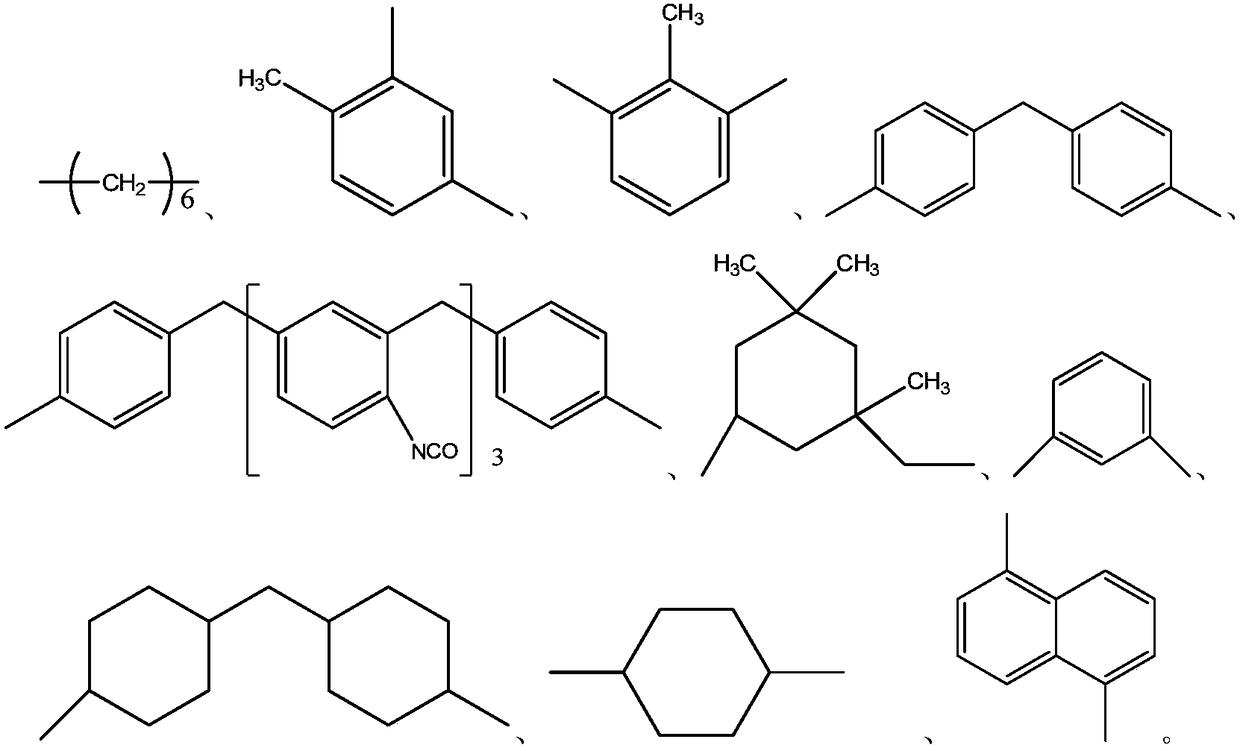

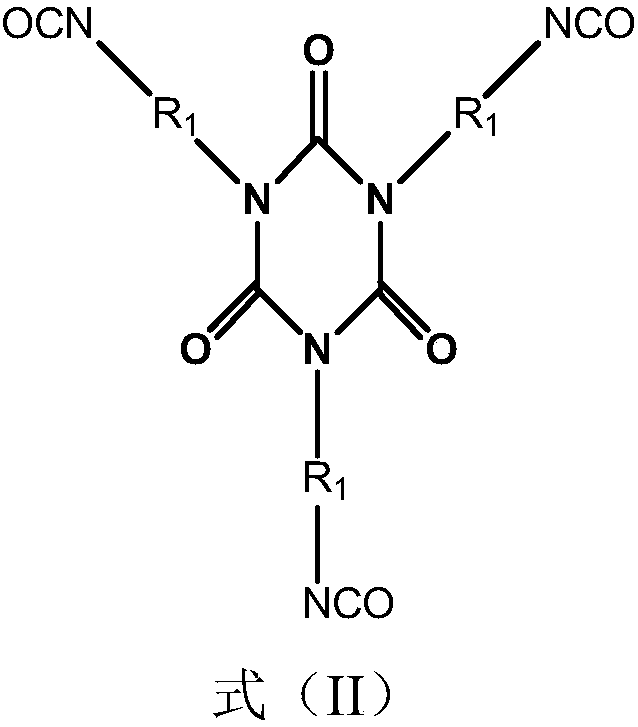

Ultraviolet light curing composition, and preparation method and application thereof

ActiveCN108359053ALow viscosityHigh functionalityAdditive manufacturing apparatusOrganic chemistryUltraviolet lightsTemperature resistance

The invention provides an ultraviolet light curing composition used for 3D printing, and a preparation method and an application thereof. The composition comprises an ultraviolet light curing prepolymer as shown in a formula (I) which is described in the specification, wherein the usage amount of the ultraviolet light curing prepolymer accounts for 55 wt% or more of the total weight of the composition. The ultraviolet light curing composition provided by the invention has the advantages of high tensile strength, etc., and can be used as a 3D printing material and a light curing material; curedresin prepared from the composition provided by the invention has the advantages of low shrinkage rate, high-temperature resistance, fast curing speed, etc., and is applicable to curing through a manner of 3D printing.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

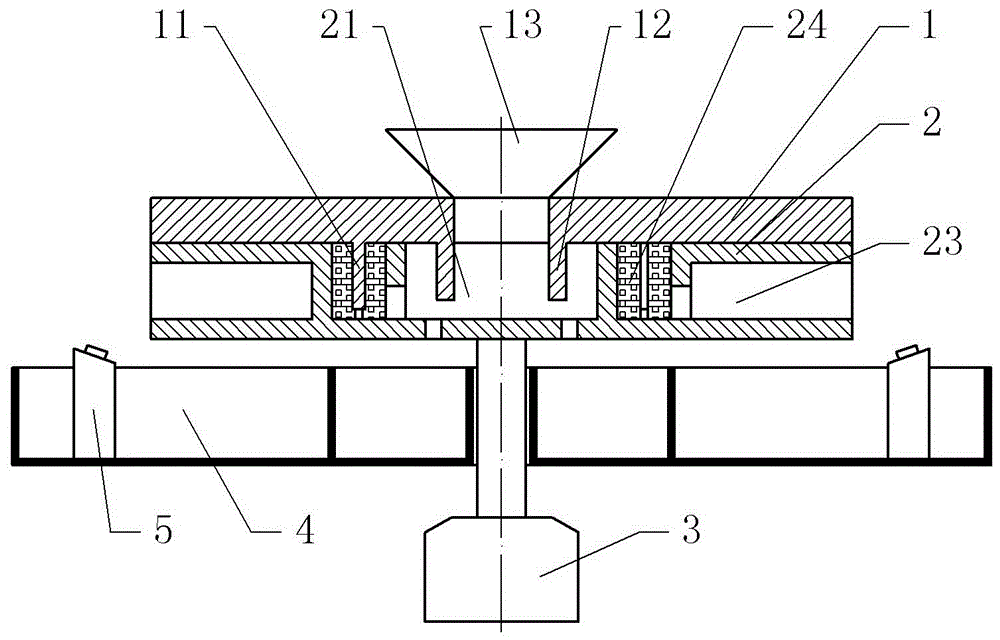

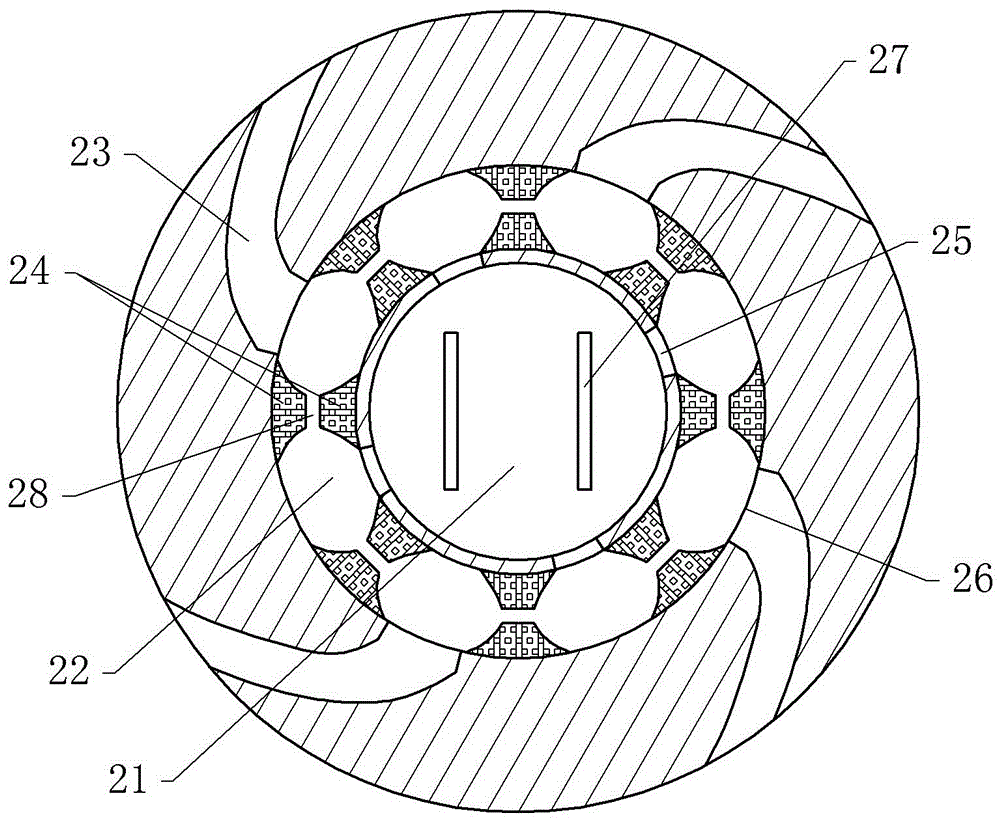

Peanut coat removing device

InactiveCN106820174AHas a wrapping effectAvoid separationHuskingHullingMotor drivePulp and paper industry

The invention discloses a peanut coat removing device and relates to a food processing device. The peanut coat removing device comprises a rack, an upper grinding disc, a lower grinding disc and a motor, wherein the upper grinding disc is fixed to the rack, the lower grinding disc is rotatably connected to the rack, and the motor drives the lower grinding disc to rotate. A material collecting groove is formed in the center of the lower grinding disc, the periphery of the material collecting groove is provided with a coat removing groove, a discharging groove is formed in the periphery of the coat removing groove, a plurality of elastic blocks are arranged in the coat removing groove, and the middles of the elastic blocks are provided with coat removing slots. The coat removing groove is provided with a feeding port and a discharging port, the feeding port is communicated with the material collecting groove, the discharging port is communicated with the discharging groove, and the feeding port and the discharging port are formed between two elastic blocks and are arranged in a spaced mode. The upper grinding disc is provided with an extruding shaft corresponding to the coat removing groove, a feeding hopper corresponding to the material collecting groove and a stirring shaft. A hopper and a fan are arranged below the lower grinding disc. The device can keep the integrity of peanuts without coats at 95% or above.

Owner:CHONGQING SHUNTAI FOOD

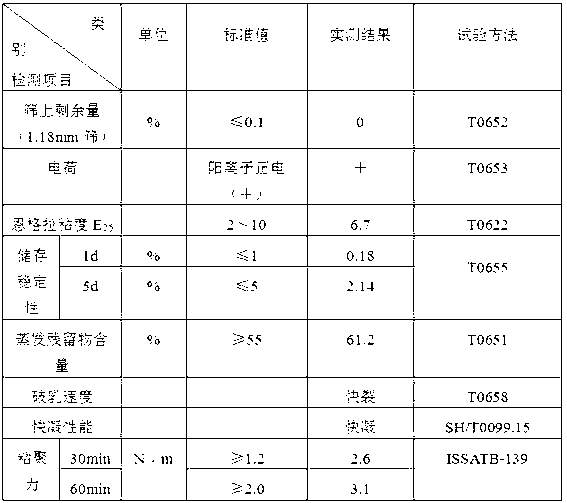

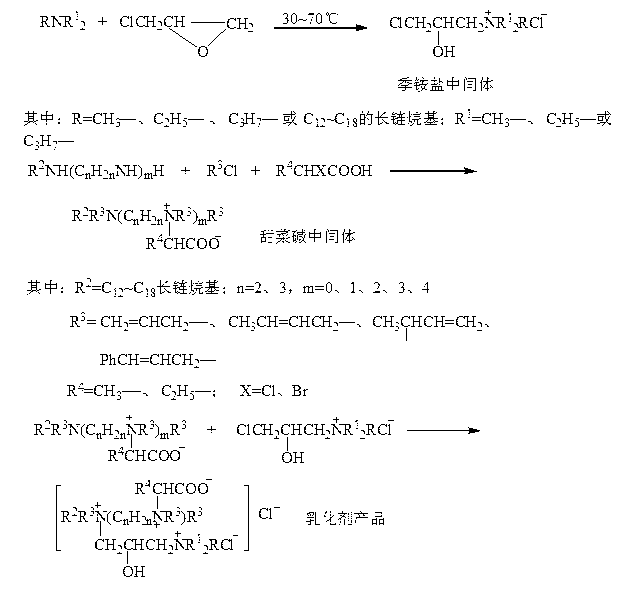

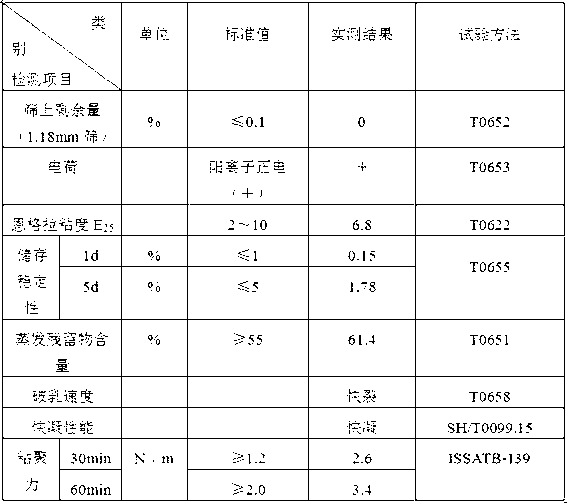

Quick-breaking and quick-curing type asphalt emulsifier preparation method

InactiveCN102936206AGood storage stabilityGood emulsificationOrganic compound preparationAmino-carboxyl compound preparationQuaternary ammonium cationFatty amine

The present invention relates to a quick-breaking and quick-curing type asphalt emulsifier preparation method, which comprises the following specific steps: adding a reaction mixture comprising a long chain fatty amine, chlorinated olefin and halogenated fatty acid to a reaction vessel, adding an alcohol solvent, and carrying out a stirring reaction to obtain an alkyl substituted betaine type intermediate solution; adding aliphatic tertiary amine, water and hydrochloric acid to the reaction vessel to obtain a tertiary amine hydrochlorate solution, then adding epichlorohydrin to the tertiary amine hydrochlorate solution, and carrying out a stirring reaction to obtain a quaternary ammonium salt intermediate solution; and adding the quaternary ammonium salt intermediate solution to the alkyl substituted betaine type intermediate solution in a dropwise manner, and carrying out a stirring reaction to obtain the quick-breaking and quick-curing type asphalt emulsifier. According to the present invention, the quick-breaking and quick-curing type asphalt emulsifier has the following beneficial effects that: an excellent emulsifying property is provided, and petroleum asphalts with different production places and different types can be emulsified; and advantages of uniform and fine asphalt emulsion, good storage stability, strong adaptability to aggregate, good adhesion, and flexible emulsifier molecule structure design, and the like are provided.

Owner:WUHAN UNIV OF TECH

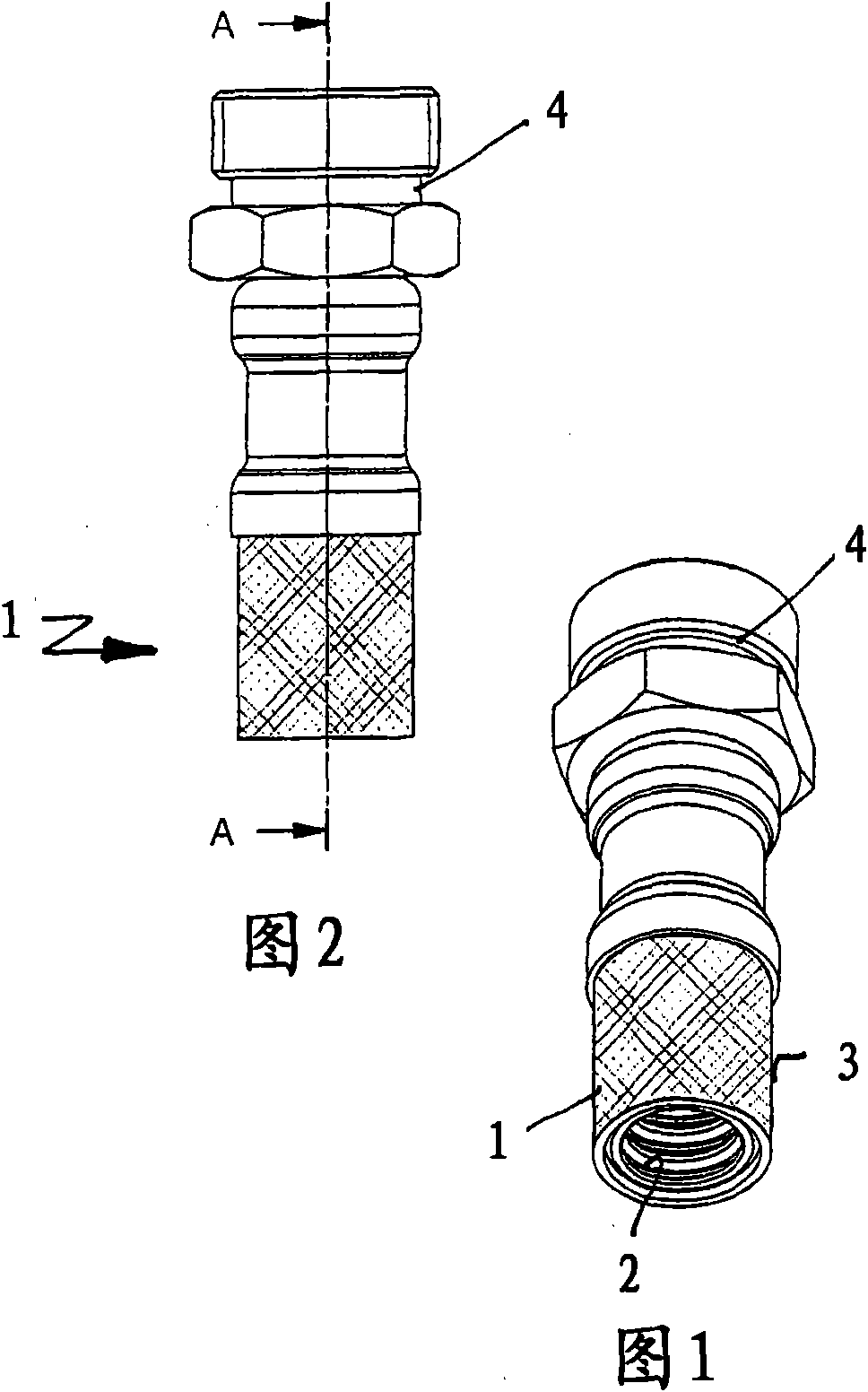

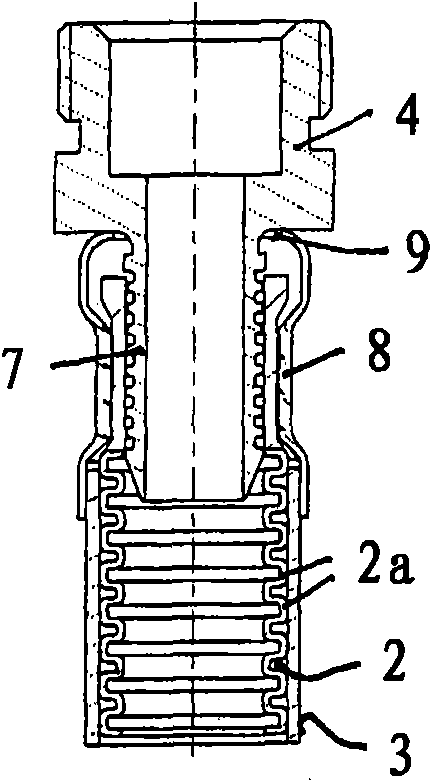

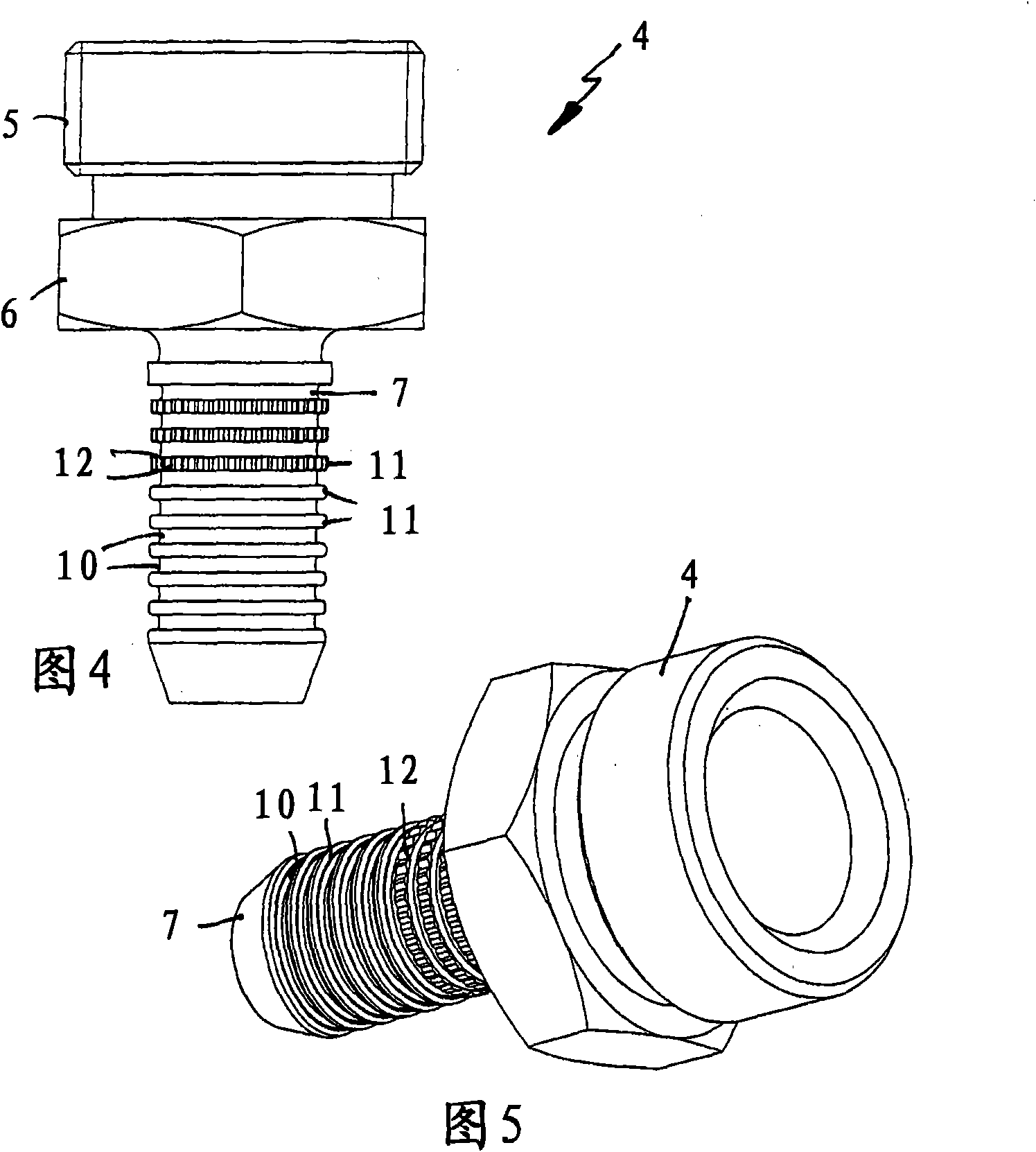

Pressure hose for use in water-guiding system

ActiveCN101660637AGuaranteed anti-twist protectionImprove flexibilityDomestic plumbingFlexible pipesEngineeringUltimate tensile strength

The invention relates to a functional pressure hose for a water-carrying system, which has an inner hose made of plastic and an outer jacket made of a braided material extended in the whole pressure hose length. At least one pressure hose end is provided with a connector piece having a tubular connector, onto which the pressure hose end is pressed to the connector from exterior by means of a pressing sleeve. The hose demonstrates great flexibility while maintaining the required pressure strength, but at the same time guarantees great bending protection. The inner hose is formed by a corrugated hose which has parallel corrugations and is extended in the whole pressure hose length, the corrugated hose is directly surrounded by the outer jacket, and the tubular connector has circumferential ring beads that are adapted to the inner contour of the corrugated hose. At least some of the ring beads are provided with notches that run axially. The inner hose is surrounded by the pressing sleeve and is pressed into a groove of the connector formed by the ring beads by means of the pressing sleeve.

Owner:联益管材系统股份有限公司

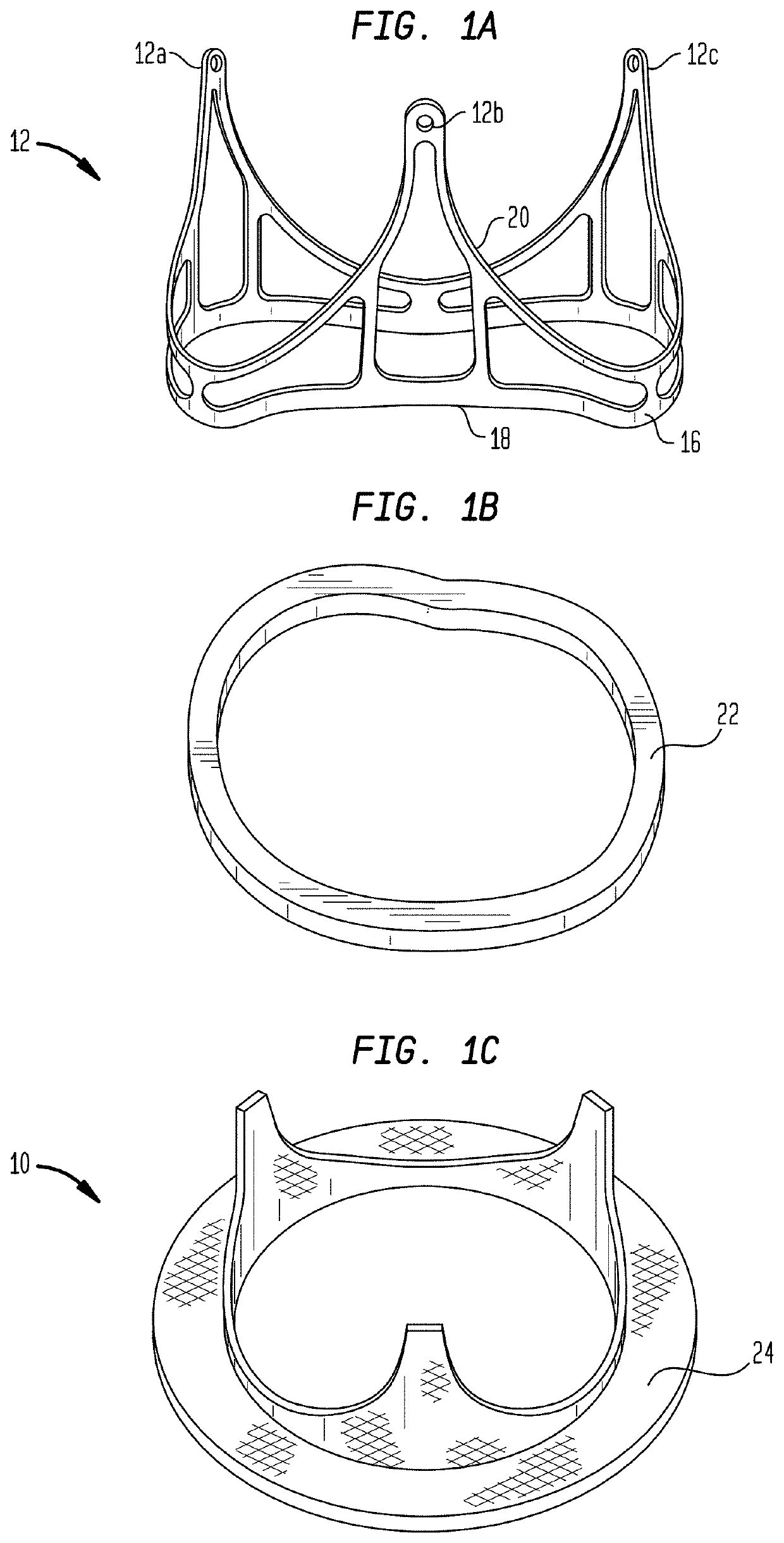

Fabric Material For Medical Devices

PendingUS20200188098A1Adjusting surface roughnessAltering lubricityAdditive manufacturing apparatusHeart valvesMedicineEngineering

At least a portion of fabrics for use in medical devices is formed from polymeric materials. The fabrics may be uncoated, partially coated or fully coated with one or more layers of a polymer. The fabrics may be used for the leaflets and / or cuffs of prosthetic heart valves and as a component of other medical devices.

Owner:ABBOTT LAB INC

Production technology of contrast-effect automobile seat cushion leather

ActiveCN103667542AFlexibleImprove viewabilityTanning treatmentPre-tanning chemical treatmentFolding enduranceRoom temperature

The invention relates to a production technology of contrast-effect automobile seat cushion leather. The protection technology comprises the steps of liming: dissolving Na2S, NaHS and lime into water in a mass ratio of 1:1:2 to form a liming alkali liquor, reacting fur with the liming alkali liquor in a liquor ratio of 100:100 for 6 h, adding the liming alkali liquor step by step to enable the liquor ratio to increase to 100:200, and continuously reacting for 12 h; retanning: for every 100 parts of fur, adding 100 parts of water, 1 part of a pre-fatting agent and 3 parts of a chrome tanning agent or a chrome-free tanning agent, reacting at the normal temperature for 1 h, adding 2 parts of sodium formate, reacting at the temperature of 40 DEG C for 1 h, and controlling the pH in a range of 3.6-4.0; and finishing: the finishing comprises the steps of roller coating of a bottom layer, embossing, spraying of a color layer, roller coating of an effect layer and spraying of a top layer. The leather produced through the technology is soft, fine in grain side, full in hand feeling, elastic, safe and environment-friendly and has characteristics of wear resistance, folding endurance, light resistance, color migration resistance and the like; and ornamental and pleasant characteristics of the leather are added due to roller coating of the effect layer, and the rigid and non-flexible appearance of ordinary automobile seat cushion leather is changed.

Owner:HAINING SENDE LEATHER

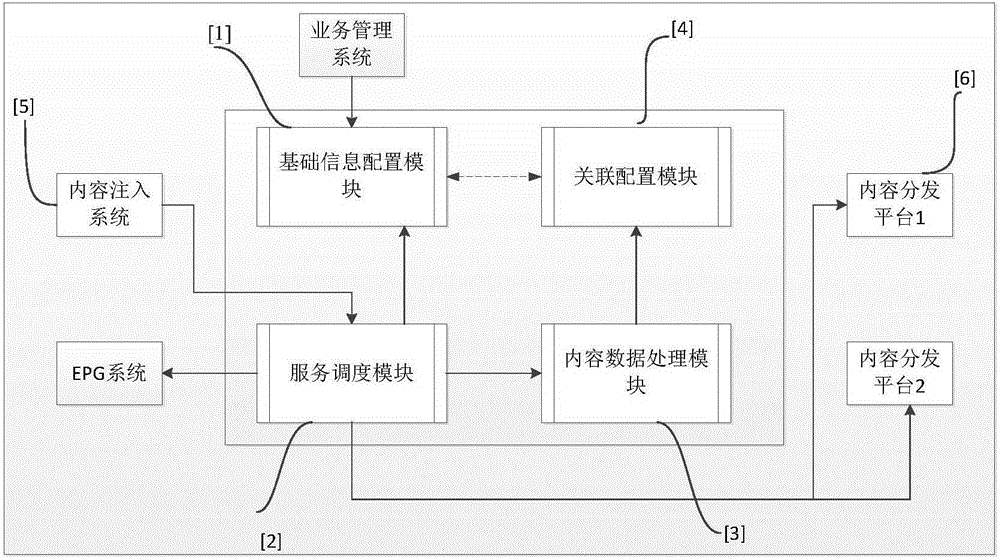

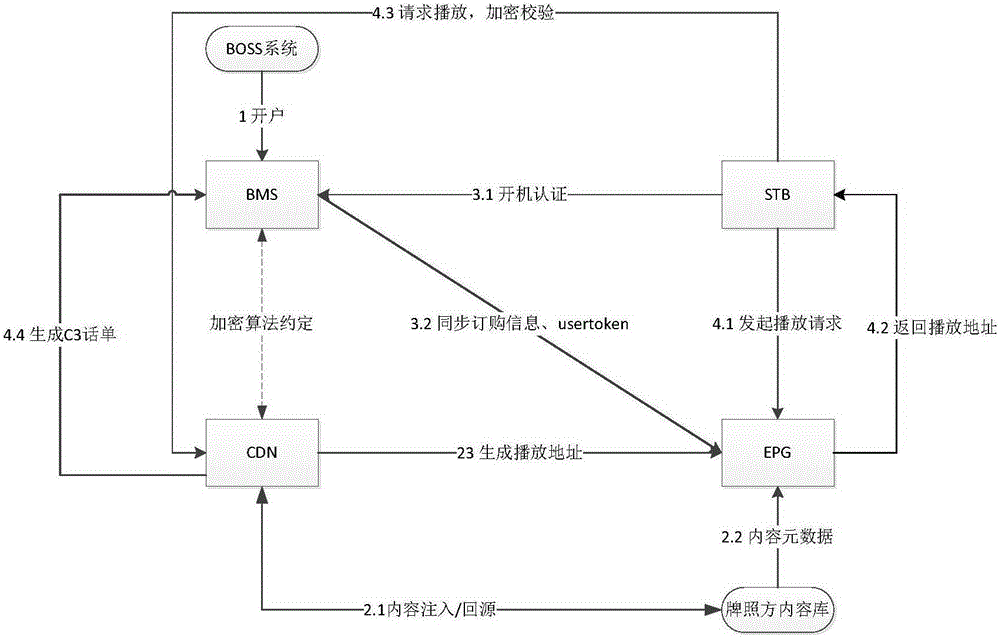

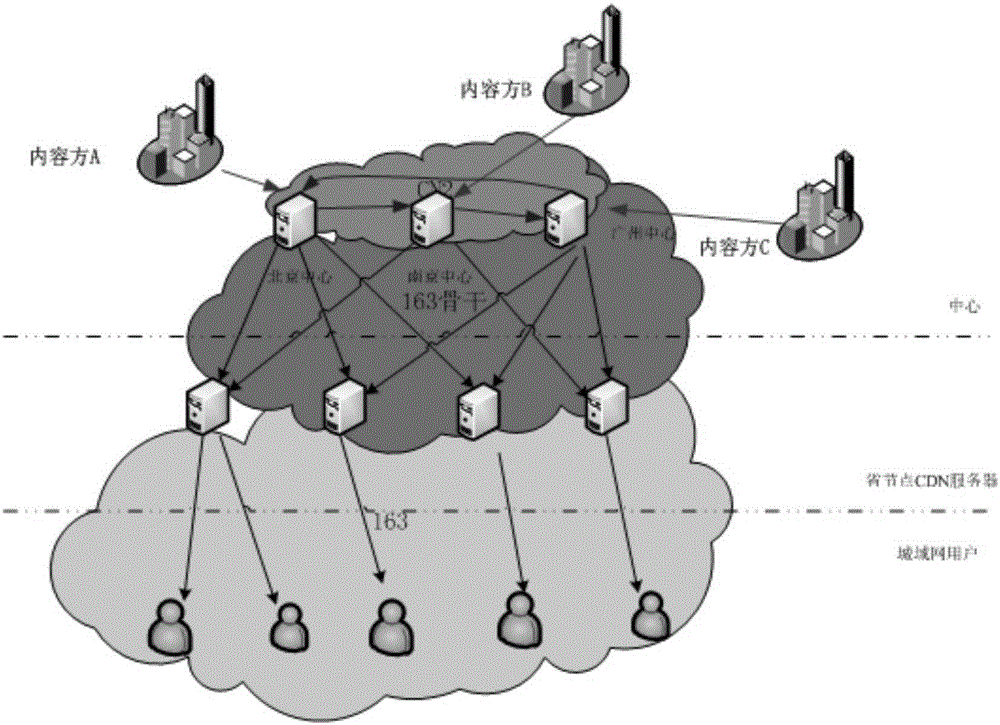

Video content distributed issuing method

ActiveCN105208414AMeet localized loading requirementsConvenient and fast docking methodSelective content distributionGlobal schedulingButt joint

The invention discloses a video content distributed issuing method, which comprises the steps of issued video-on-demand content injection, live broadcast playback on-line procedure and localization channel support. According to the invention, one-point access and global scheduling can be realized based on media asset issuing systems nationwide, service localization loading requirements are met at the same time, and a butt-joint method, which is unified in standard, convenient and efficient, is provided for each party of an industry chain; an original technical framework of an IPTV system is reserved, defects of decentralized information and poor flexibility among existing systems are changed through determination of interconnecting and interworking standard and processing procedures, and the processing efficiency and the service supporting capacity can be significantly improved; and a current situation of repeated investment caused by independent construction of each area of the IPTV system at present is changed, loose coupling among the systems can be realized based on cloud technologies, and the hardware cost of a server is greatly reduced.

Owner:天翼智慧家庭科技有限公司

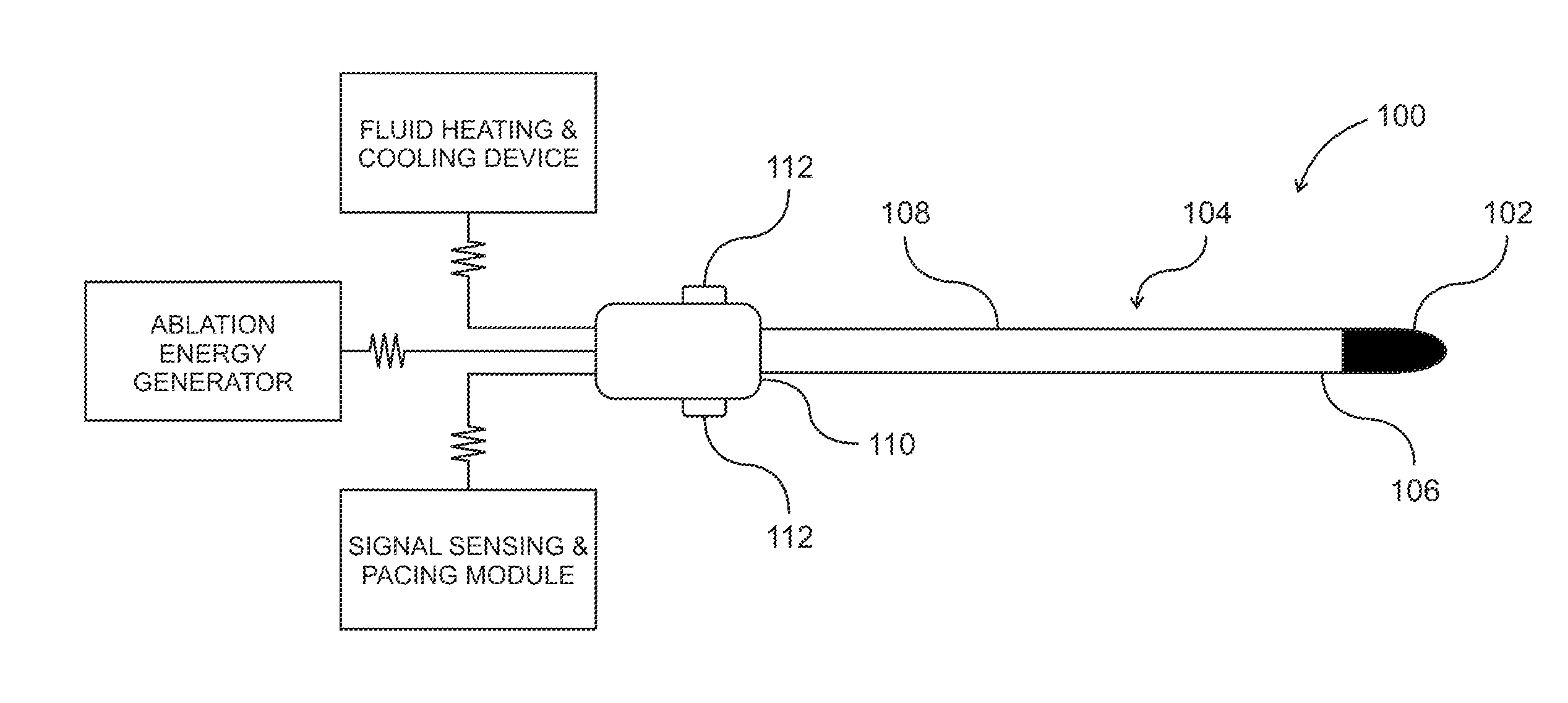

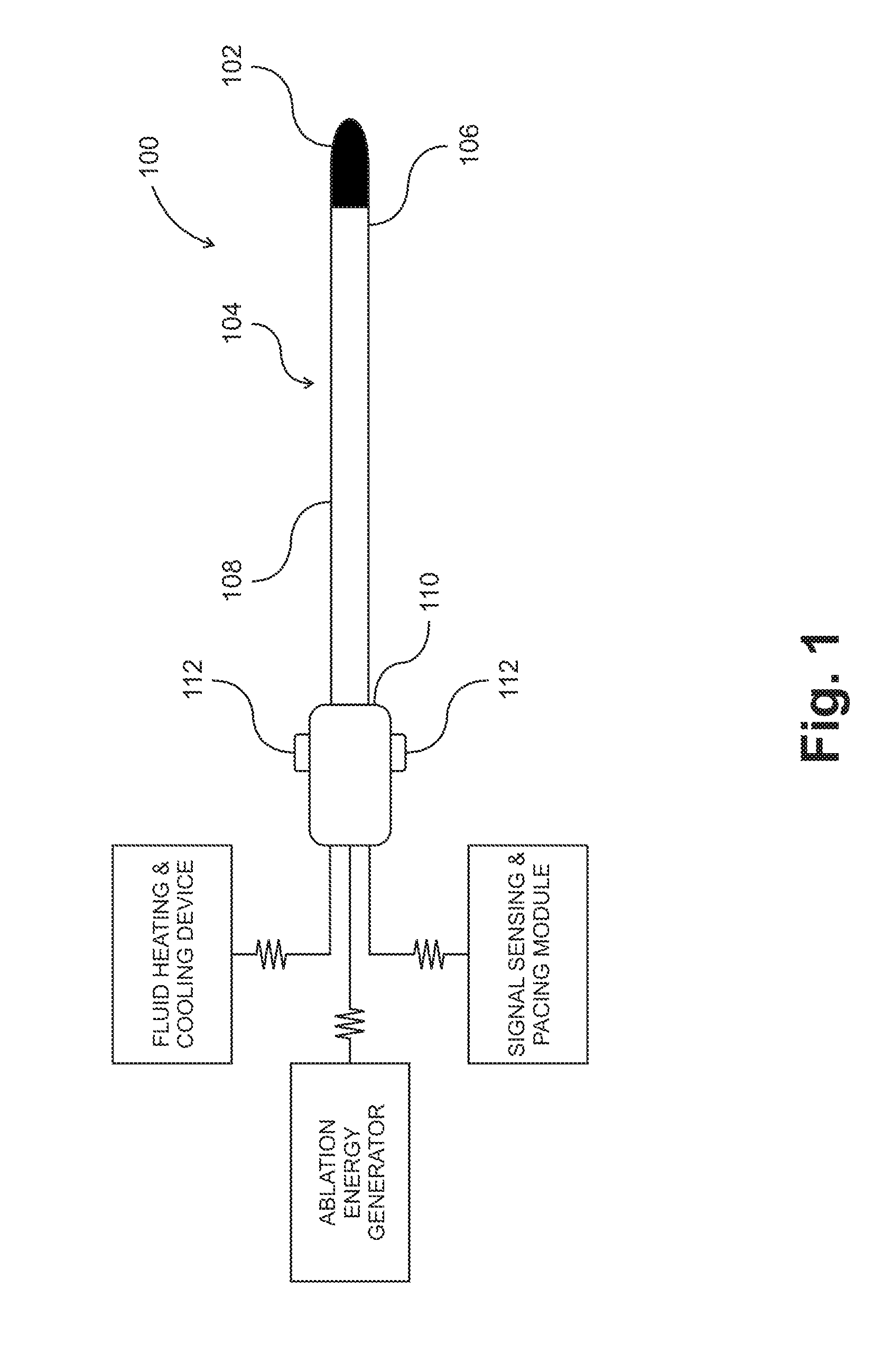

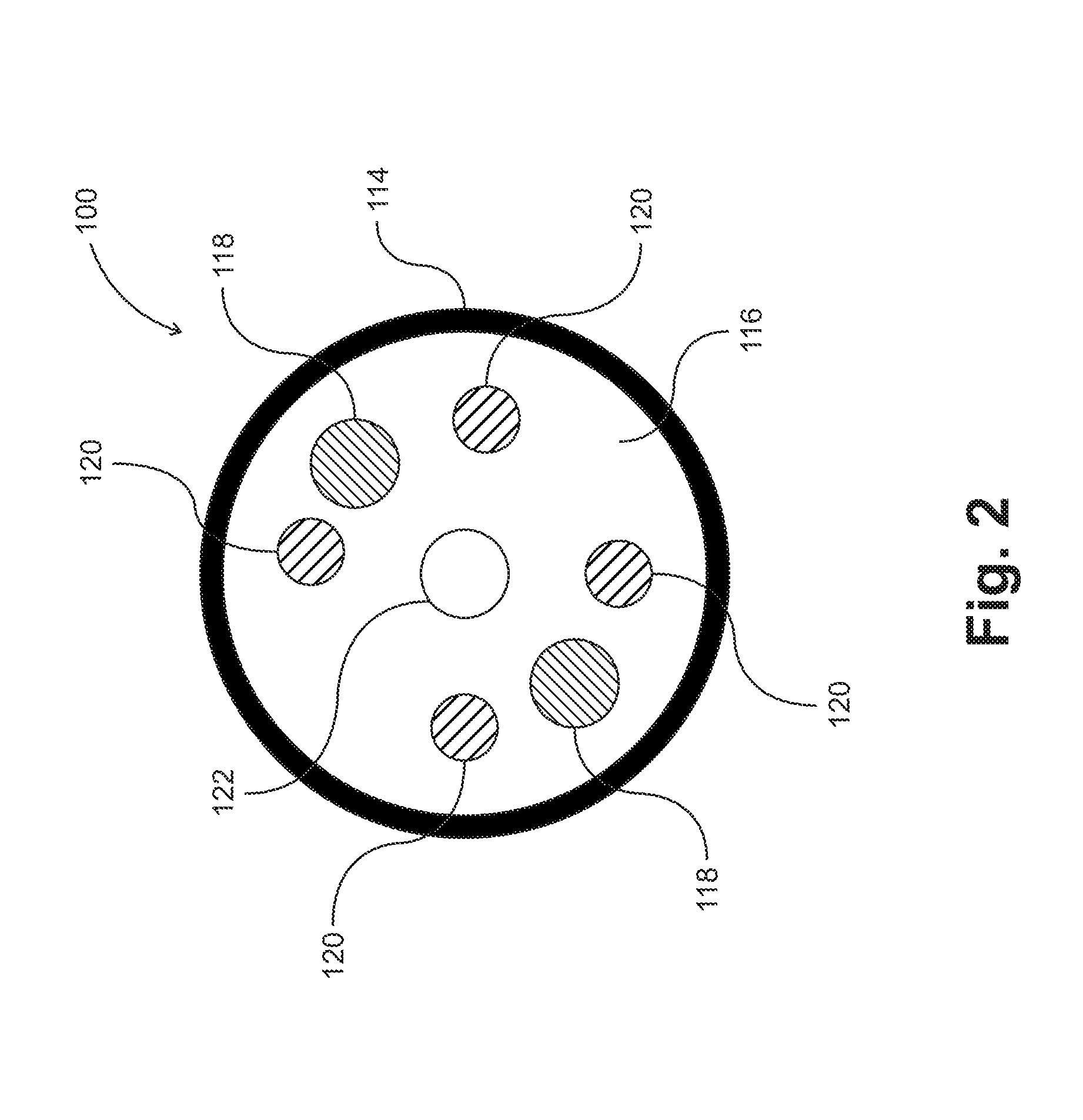

Variable Stiffness Catheter

InactiveUS20140378945A1Variable stiffnessReduce chanceMedical devicesCatheterVariable stiffnessAlloy

A device and method for inserting a variable stiffness catheter into a subject with a catheter body being in relatively stiff state at a first temperature and a more flexible state at a second temperature. A temperature sensitive polymer is incorporated into the catheter that varies in stiffness depending on the temperature. The stiffness of the catheter is regulated by being in thermal contact with a circulating fluid within the catheter, or by being connected to resistive members in thermal contact with temperature sensitive alloys or polymers. The variable stiffness catheter can therefore be guided through the vasculature while in a relatively flexible state, but be changed into a relative stiff state during ablation procedures.

Owner:BERI ABHIMANYU

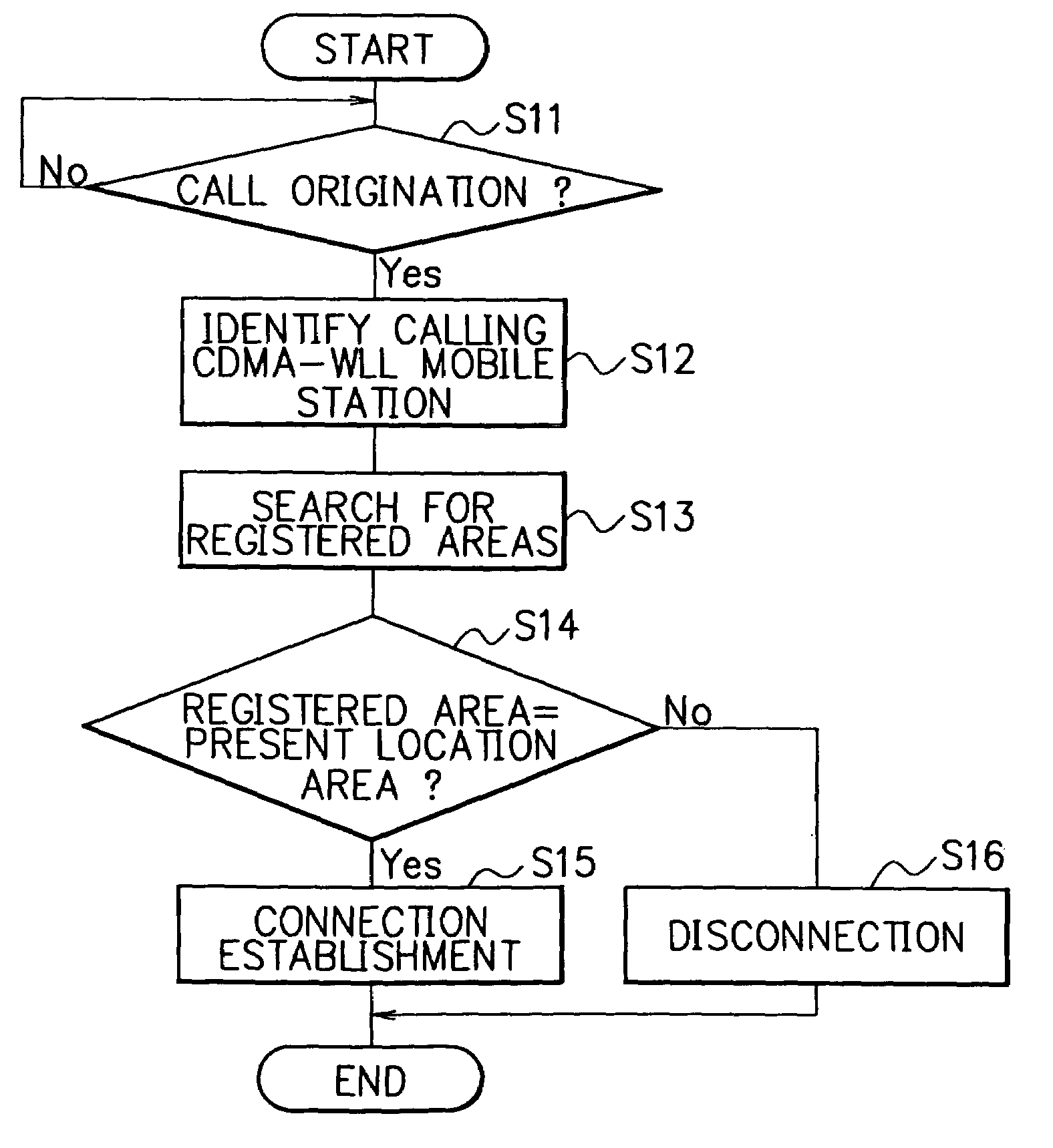

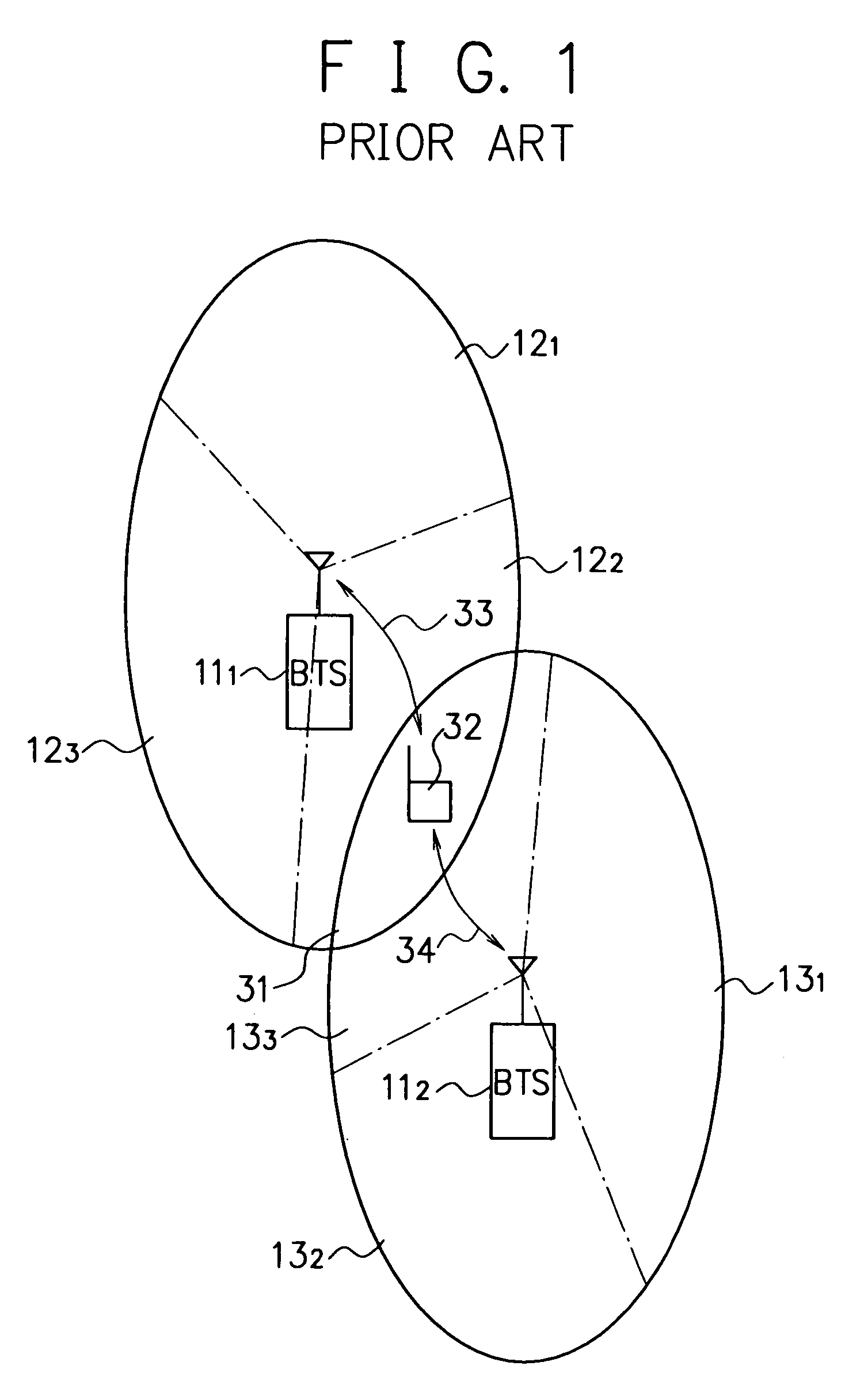

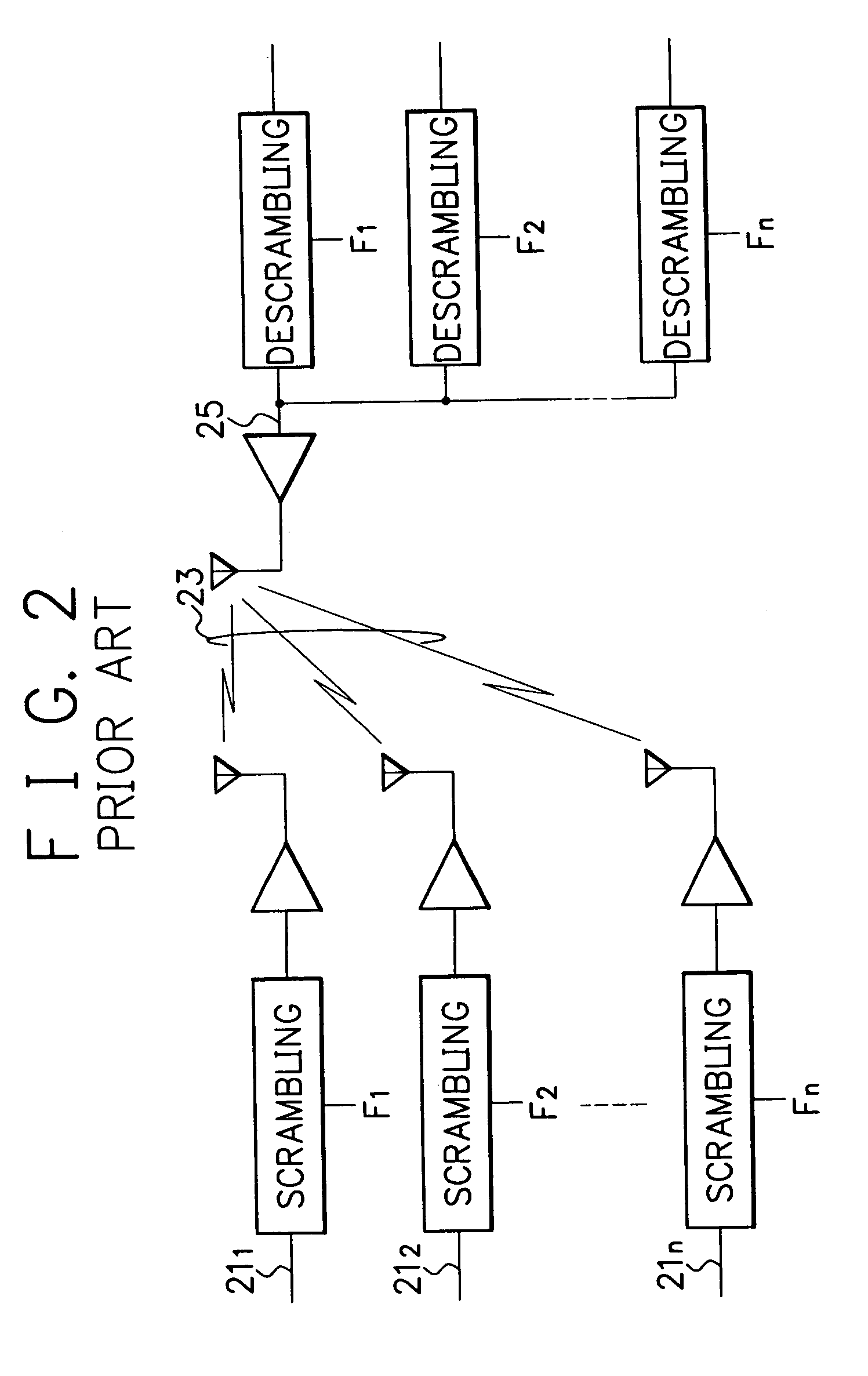

System, method and record medium for mobile radio communication employing location-limited mobile stations

InactiveUS6947745B1Maintain balanceChange flexibilityNetwork topologiesSubstation equipmentMobile businessCall origination

The use (call origination, call reception and / or communication (handoff)) of a CDMA-WLL (Wireless Local Loop) mobile station (location-limited mobile station) outside its registered areas is functionally prohibited. The registered areas are determined with regard to each CDMA-WLL mobile station and information concerning the registered areas is stored in a CDMA-WLL controller. For example, when a CDMA-WLL mobile station originated a call, a mobile services switching center refers to the CDMA-WLL controller and thereby searches for the registered areas of the CDMA-WLL mobile station, compares the registered areas with present location areas of the CDMA-WLL mobile station, and executes a connection establishment process for the CDMA-WLL mobile station if a match occurred in the comparison. By such functional location limitation of the CDMA-WLL mobile station, the differentiation between the CDMA-WLL mobile stations and ordinary (location-unlimited) mobile stations can be made properly, and the balance between the CDMA-WLL mobile stations and fixed (wired) telephone sets can be maintained appropriately.

Owner:NEC CORP

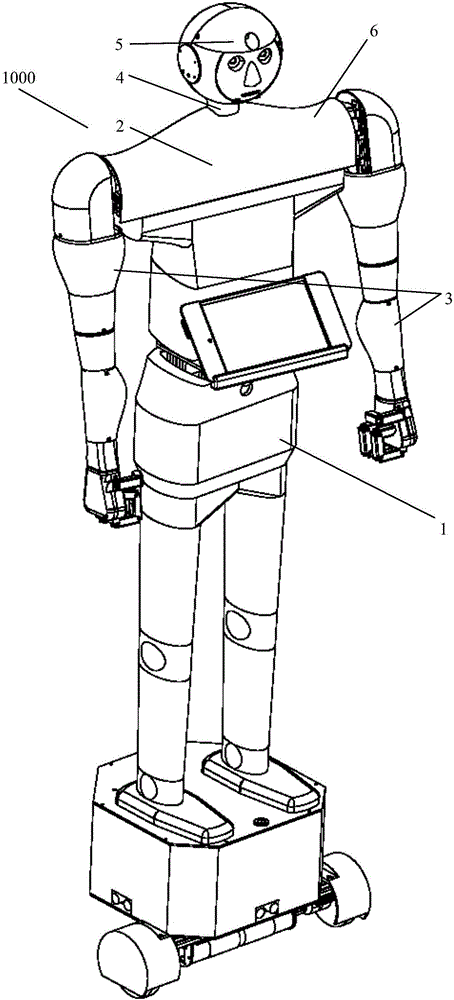

Modular robot

InactiveCN106078720AEasy to replaceEasy to assembleProgramme-controlled manipulatorJointsResource consumptionModularity

The invention discloses a modular robot. The modular robot comprises a base plate, a trunk, mechanical arms, a neck portion, a head portion and a shell, wherein the trunk comprises a shoulder skeleton, a chest portion and a waist portion. Each portion of the robot is modularized and provided with multiple modules with different structures. Each portion is obtained through combination of different modules, so that robots which have different freedom degrees and can be applied to different application occasions are obtained. By the adoption of the modular structure, modularization of robot components is achieved, combination is convenient, function scalability is realized, and movement is flexible. One modular robot can replace multiple robots with fixed functions and freedom degrees, and resource consumption and waste can be reduced. Freedom degree number can be changed, so that the flexibility of the robot can be changed according to actual needs. The modular robot can be widely applied to the fields including industry, service and education.

Owner:许志林

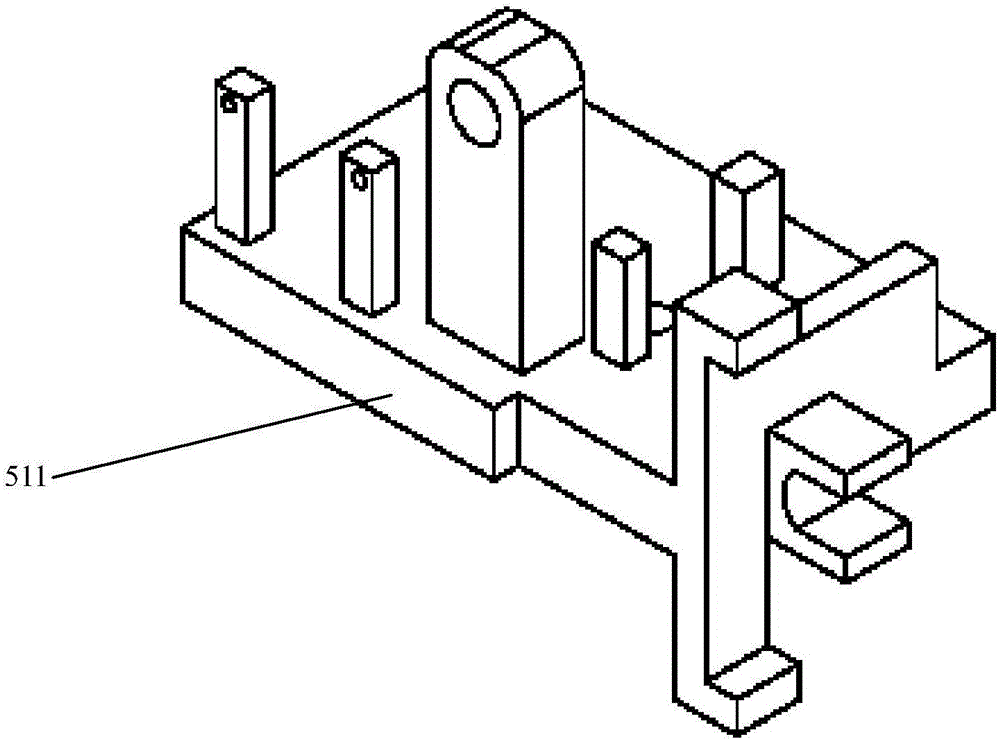

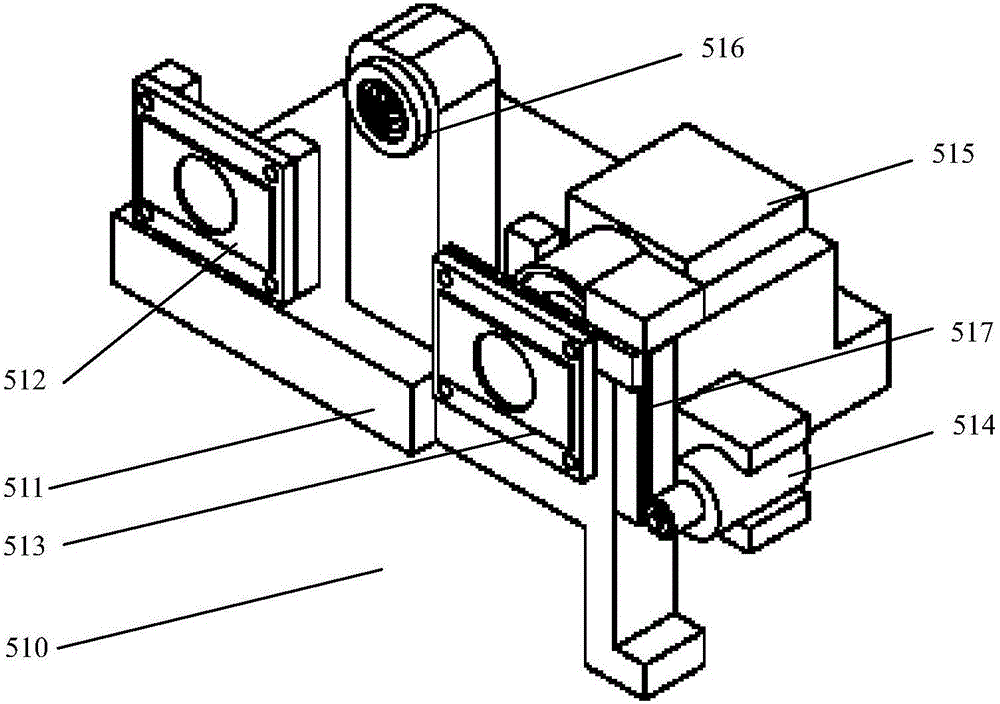

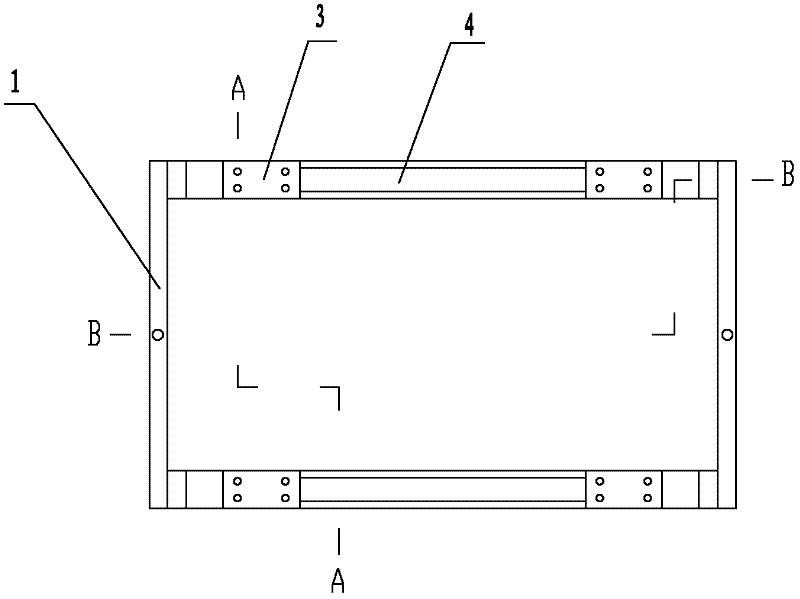

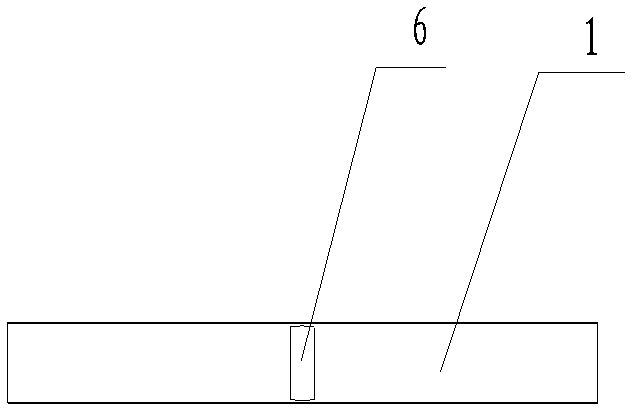

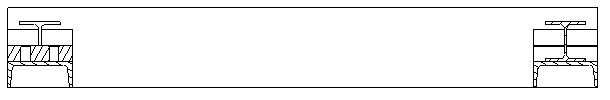

rail fixed frame

The invention provides a ballastless track construction device easy to fix the tight alignment result and insusceptible to external interference and a construction method thereof. The ballastless track construction device comprises working tracks, a dual-block sleeper and a track panel fixing frame of a framework structure, wherein the two working tracks are mounted on the track panel fixing frame to form a track panel framework; the two working tracks are parallel; and the track panel framework is mounted on the dual-block sleeper to form the framework type track panel. According to the invention, the track panel framework construction method is adopted, the conventional construction method is changed that the track panel is replaced by a track board; and then a mature board type adjusting process is adopted to adjust the track panel so that the tight alignment result is easy to fix, the device is insusceptible to external interference and the construction precision can be guaranteed.

Owner:成都十九号极速文化传播股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com