Random-copolymerization polypropylene toughening modified material and preparation method thereof

A technology of random copolymerization and toughening modification, applied in the field of random copolymerization polypropylene toughening modified materials and preparation, can solve problems such as difficulty in realizing industrialization, increase production cost, increase annealing equipment, etc., to reduce energy consumption, The effect of improving performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

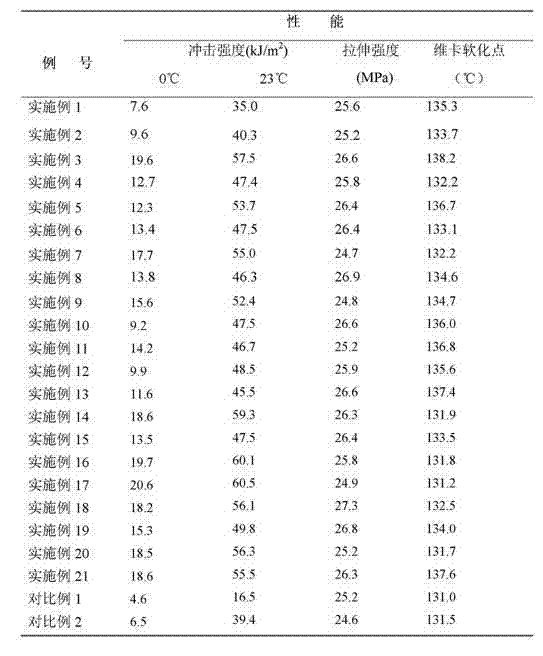

Examples

Embodiment 1

[0031] 1) Disperse molecular sieves in absolute ethanol solution for surface wetting, then add silane coupling agent, heat to 50°C in a water bath, stir for 30min at a speed of 1200r / mim; then add deionized water with a volume ratio of 1:3 Water / absolute ethanol solution, after stirring for 1 hour, add stearic acid, continue stirring for 30 minutes, suction filter while hot, and dry at 70°C for later use, wherein the mass ratio of silane coupling agent to molecular sieve is 1:50, stearic acid to molecular sieve The mass ratio is 1:10;

[0032] 2) After premixing 100 parts of random copolymerized polypropylene with ethylene content <5%, 0.5 parts of polypropylene β-nucleating agent TMB-5 and 25 parts of surface-activated molecular sieve 13X, it is passed through a twin-screw at 180~200°C The modified masterbatch is obtained by melt blending, extrusion, cooling and pelletizing by the extruder;

[0033] 3) Copolymerize 100 parts of random copolymerized polypropylene with ethylen...

Embodiment 2

[0035] 1) In this step, except that molecular sieve 4A is treated with silane coupling agent KH550, other conditions are the same as in Example 1, so the description is omitted here.

[0036] 2) After premixing 100 parts of random copolymerized polypropylene with ethylene monomer content <5%, 0.5 parts of polypropylene β-nucleating agent TMB-5 and 25 parts of surface-activated molecular sieve 4A, it was heated at 180~200°C Twin-screw extruder melt blending extrusion, cooling, pelletizing to obtain modified masterbatch;

[0037] 3) After premixing 100 parts of random copolymerized polypropylene with ethylene monomer content <5%, 10 parts of ethylene-propylene block copolymer, 8 parts of modified masterbatch, and 0.2 parts of antioxidant B215, add it to the twin-screw extruder In the extruder, melt blending and extruding at 180~200°C, cooling and pelletizing. The prepared random copolymerized polypropylene modified pellets were injection molded into products; the properties of ...

Embodiment 3

[0039] 1) After premixing 100 parts of random copolymerized polypropylene with ethylene monomer content <5% and 2 parts of polypropylene β-nucleating agent TMB-5, melt blending and extruding through a twin-screw extruder at 180~200 °C The modified masterbatch can be obtained after discharging, cooling and pelletizing;

[0040] 2) 100 parts of random copolymerized polypropylene with ethylene monomer content <5%, 10 parts of modified masterbatch, 5 parts of polypropylene homopolymer (brand YD50G, MFR: 0.3g / 10min, Liaoning Huajin), 5 parts 1 part of ethylene-propylene block copolymer, 10 parts of ethylene-propylene copolymer elastomer, 0.1 part of antioxidant B215, pre-mixed, added to the twin-screw extruder, melt blended and extruded at 180~200 ° C, cooled , Diced into pieces. The prepared random copolymerized polypropylene modified pellets were injection molded into products; the properties of the products were placed at room temperature for 24 hours and tested in the attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com