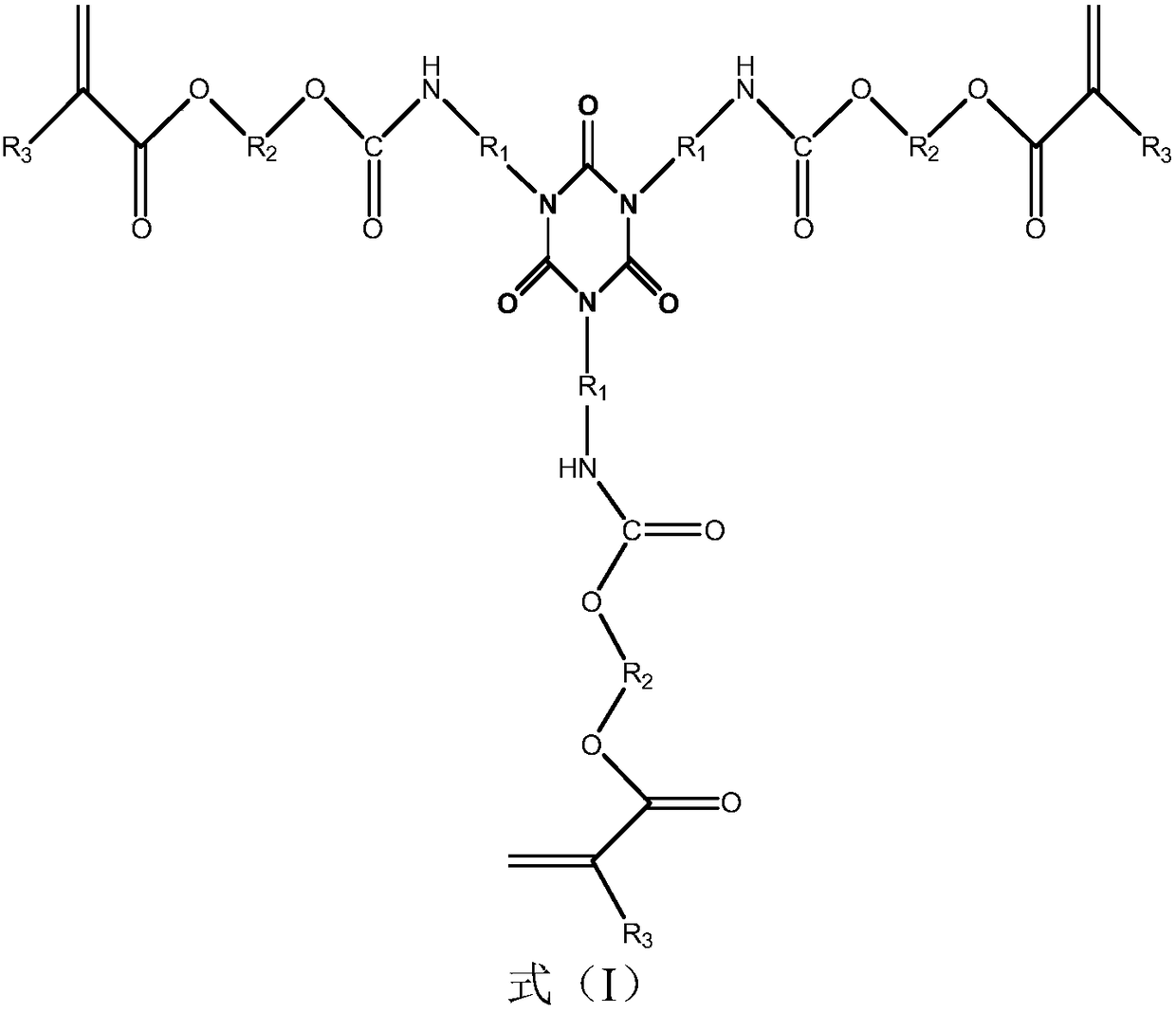

Ultraviolet light curing composition, and preparation method and application thereof

A technology of ultraviolet light and composition, applied in the direction of organic chemistry, additive processing, etc., can solve the problem of low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

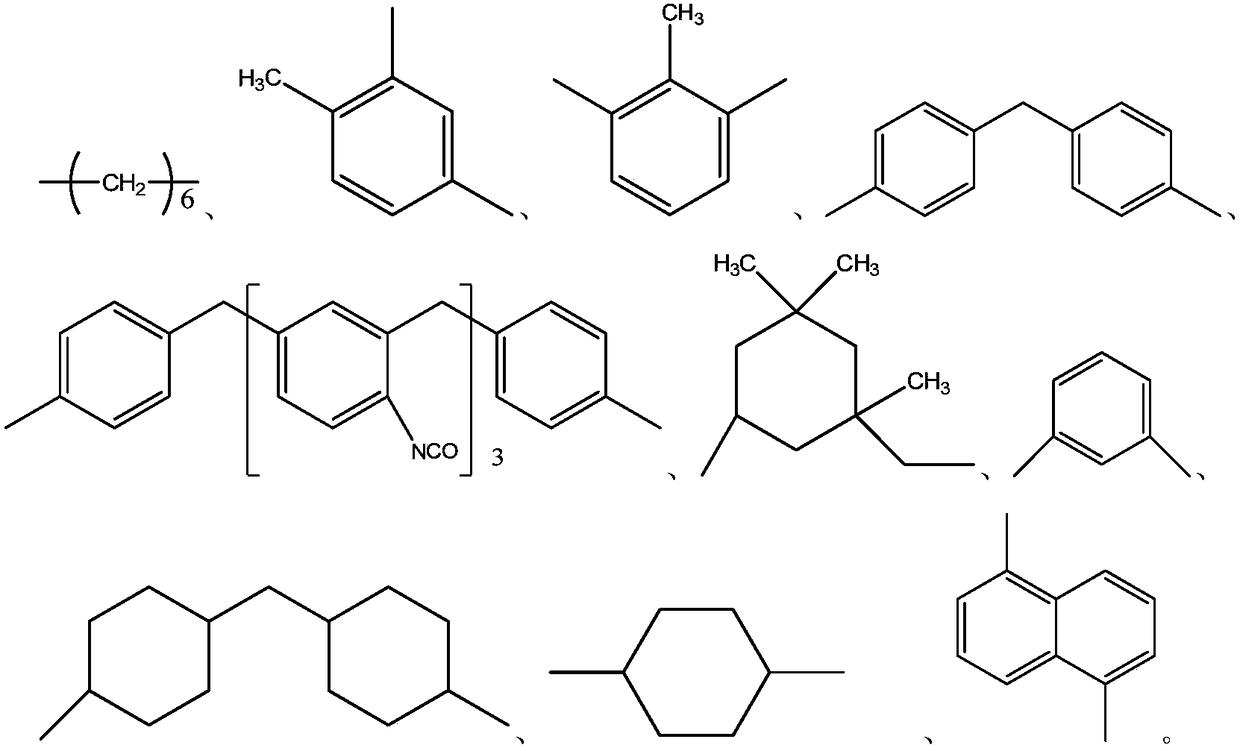

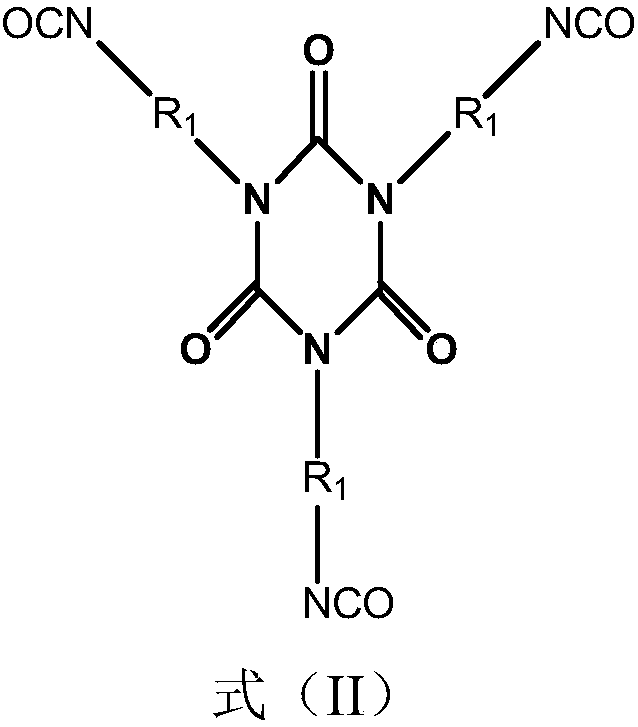

Method used

Image

Examples

Embodiment

[0070] 1. In a 500ml four-necked flask with mechanical stirring, temperature control thermocouple and condensing tube, add diisocyanate trimer (HDI trimer), catalyst (dilaurel Dibutyltin acid, stannous octoate) and polymerization inhibitors (p-hydroxyanisole, hydroquinone), and the commercial product of HDI trimer is Bayer's N3600 or N-3300. Heat and stir, keep the temperature at 65°C for 30min. Add hydroxyacrylates (hydroxyethyl methacrylate, hydroxyethyl acrylate, hydroxypropyl acrylate) dropwise to the dropping funnel. After the addition is complete, titrate the -NCO content with di-n-butylamine until the -NCO is completely reacted.

[0071] 2. Take by weighing the photocurable prepolymer in the above step 1 in a beaker according to Examples 1-9 in Table 2, and add a photoinitiator (1-hydroxycyclohexyl phenyl ketone, 2, 4,6 (trimethylbenzoyl) diphenylphosphine oxide) and diluents (hydroxyethyl methacrylate, tripropylene glycol diacrylate, trimethylolpropane triacrylate), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com