Three-dimensional ultrasonic imaging method for two-dimensional ultrasonic image set reconstruction

A technology of ultrasonic image and three-dimensional ultrasound, which is applied in the directions of ultrasonic/sonic/infrasonic diagnosis, ultrasonic diagnosis, infrasonic diagnosis, etc., which can solve the problems of lack of flexibility and freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

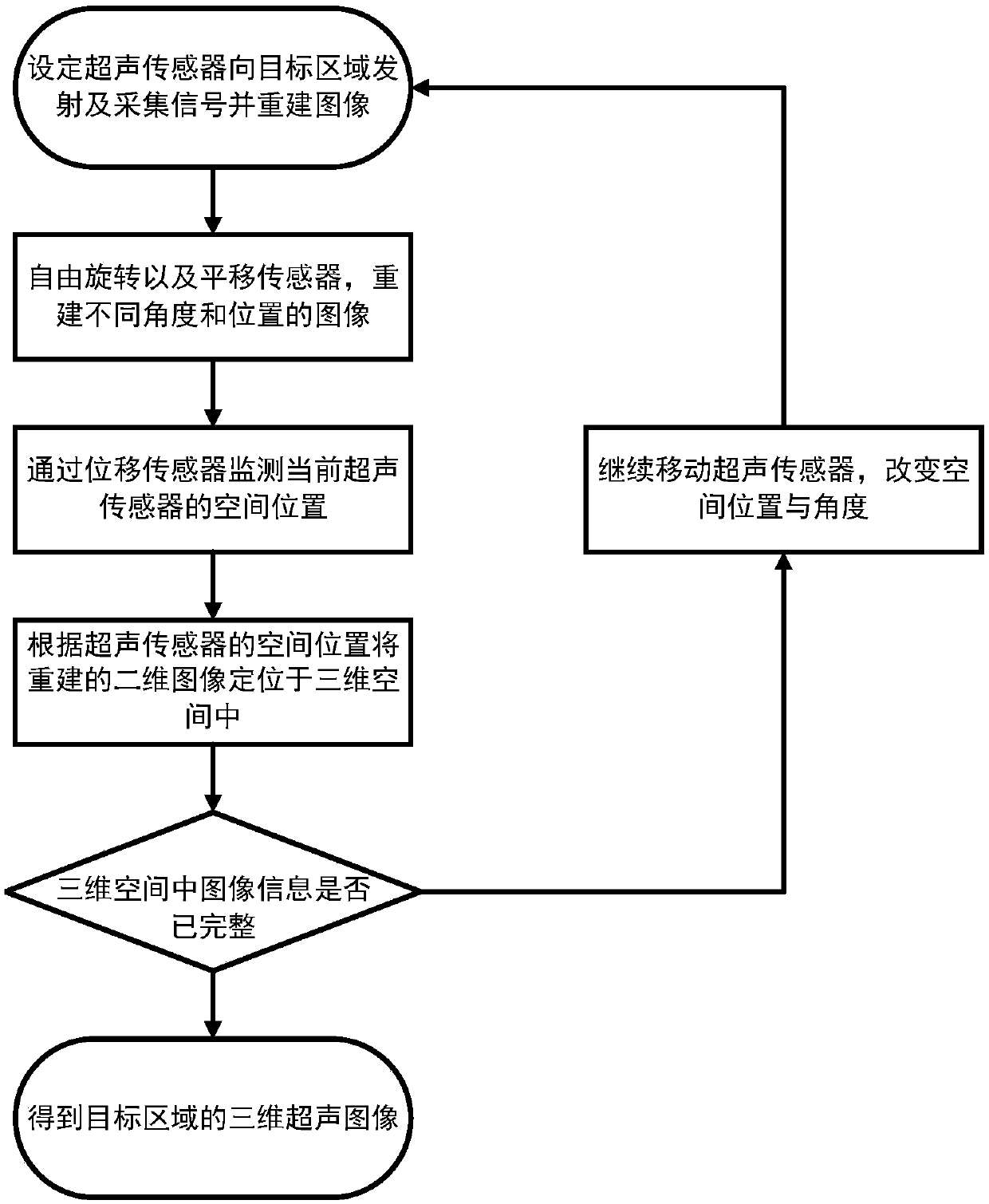

[0056] Such as figure 1 As shown, the present invention discloses a three-dimensional ultrasonic imaging method for reconstructing a set of two-dimensional ultrasonic images, comprising the following steps:

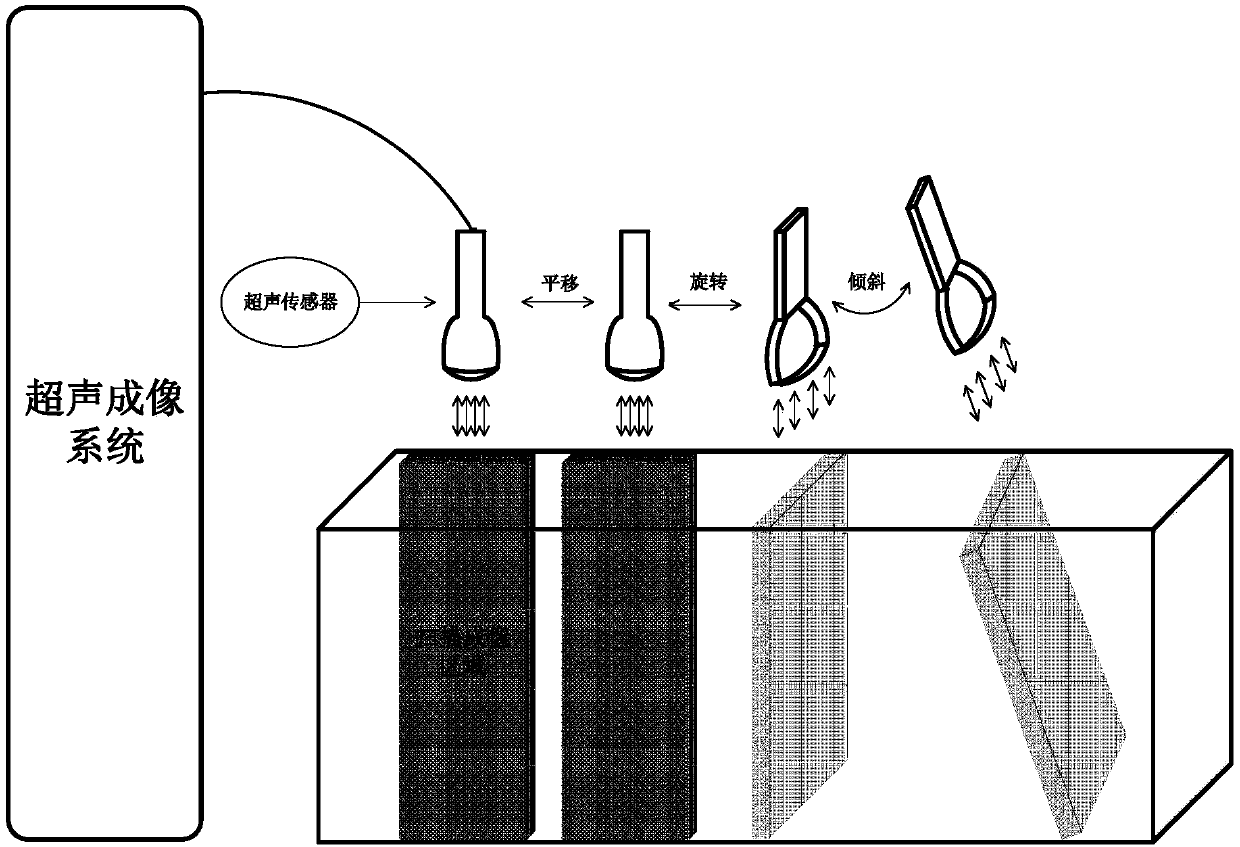

[0057] Step 1: Use the linear array ultrasonic sensor to transmit and collect ultrasonic signals to any section in the target three-dimensional space, reselect the section in the target three-dimensional space by freely rotating and translating the ultrasonic sensor, and repeatedly transmit and collect ultrasonic signals to reconstruct 2D ultrasound images in all sections;

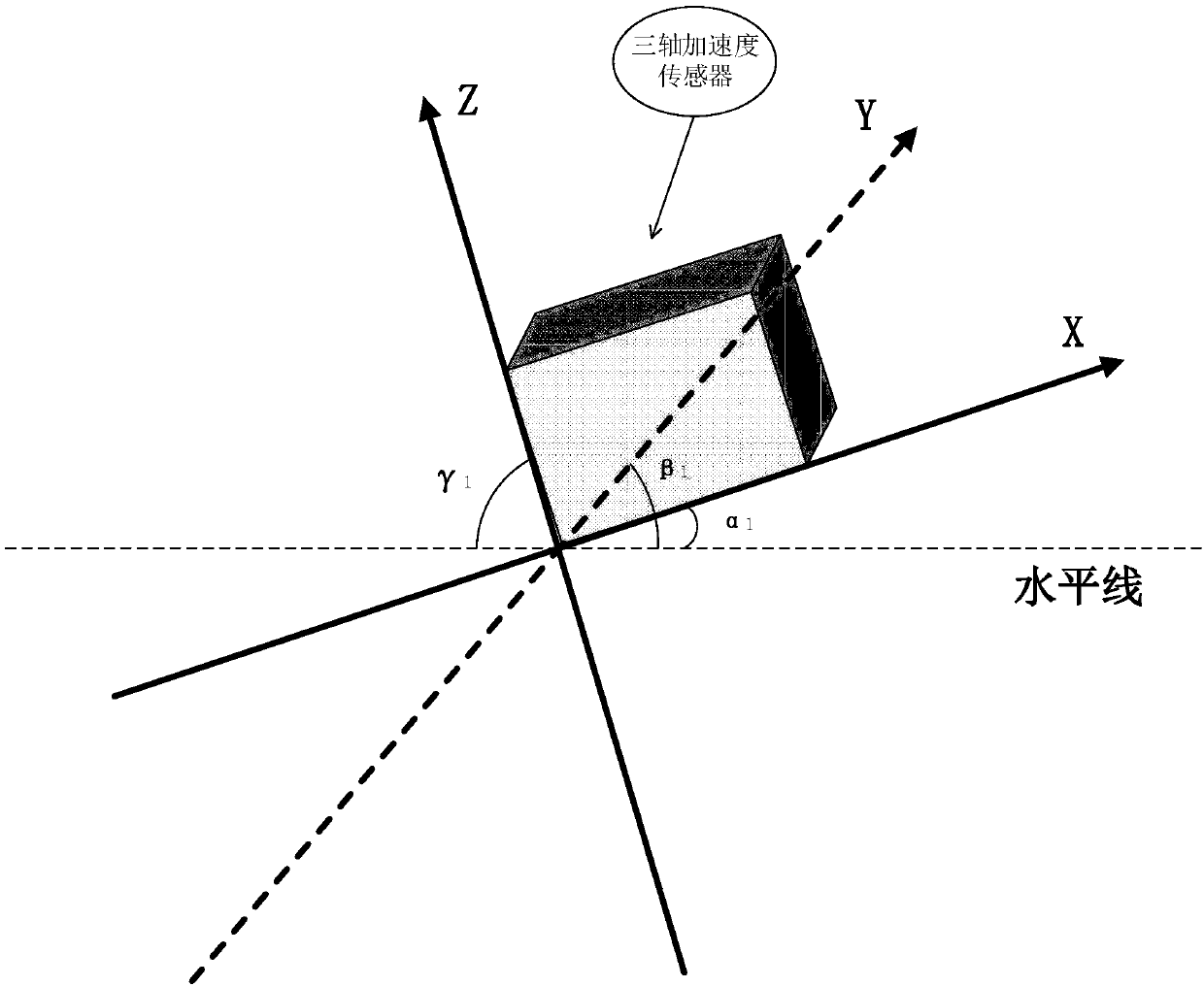

[0058] Step 2, setting a displacement sensor and an angle sensor outside the ultrasonic sensor, using these sensors to detect the spatial position and angle information of the ultrasonic sensor during movement and rotation;

[0059] Step 3, combining the spatial position and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com