rail fixed frame

A technology of fixing frame and rail row, applied in the direction of track, laying track, track maintenance, etc., can solve the problems of increasing workload and material input, changing the optimal stress state of track and track plate, increasing operation and maintenance work, etc. Easy to fix and ensure the effect of construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

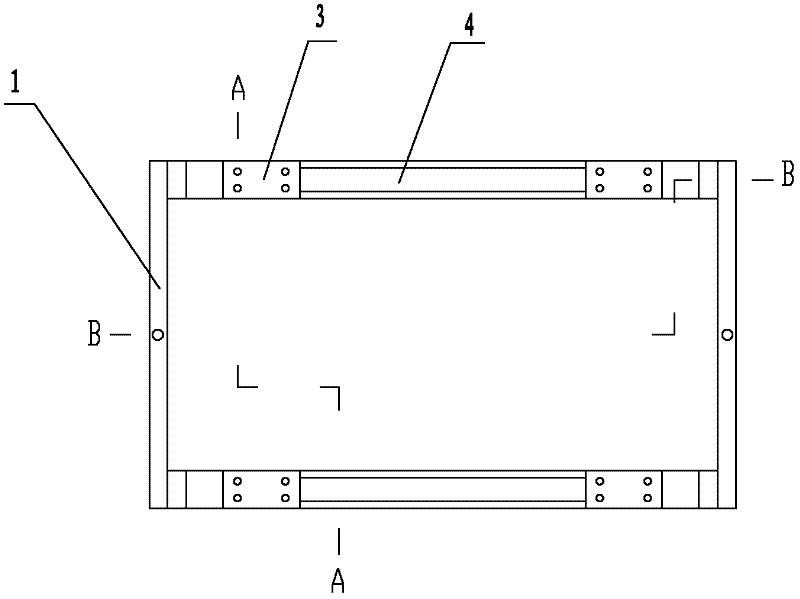

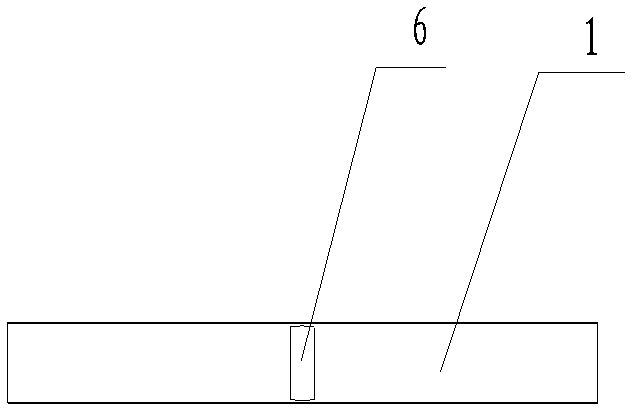

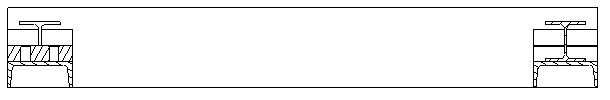

[0026] Such as Figure 1-Figure 5 As shown, the rail row fixing frame of the present invention includes a longitudinal beam 1, a cross beam 2, a rail bottom slope fixing plate 3, a cross beam reinforcing rib 4, a longitudinal and cross beam connecting reinforcing rib 5 and a nut cover 6. Two longitudinal beams 1 and two cross beams 2 form a frame structure, which may be welded. A crossbeam reinforcing rib 4 is arranged in the middle of the two crossbeams 2, and rail bottom slope fixing plates 3 are arranged on both sides of the crossbeam reinforcing rib 4, and a total of four rail bottom slope fixing plates 3 are arranged on the two crossbeams 2, and two Two symmetrical. A pressure plate connection hole 15 is processed on the rail bottom slope fixing plate 3 , a longitudinal beam connection reinforcing rib 5 is arranged between the longitudinal beam 1 and the cross beam 2 , and a nut sleeve 6 is arranged in the middle of the longitudinal beam 1 .

[0027] Install the two wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com