Peanut coat removing device

A peanut skin tank technology, applied in the field of peanut peeling devices, can solve the problems of unfavorable peanut integrity and separation of two cotyledons, and achieve the effect of continuous peeling process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

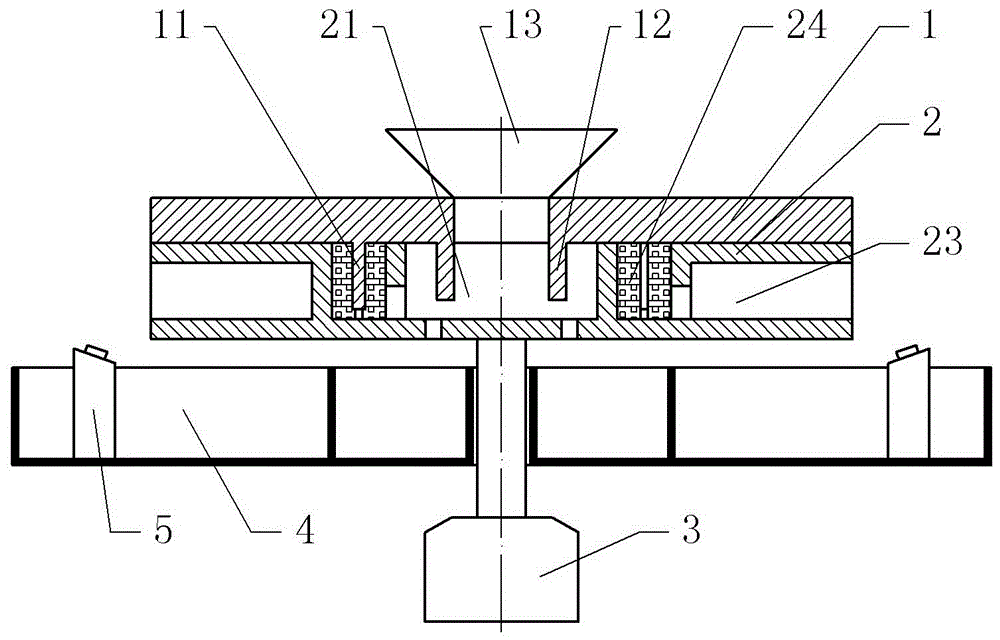

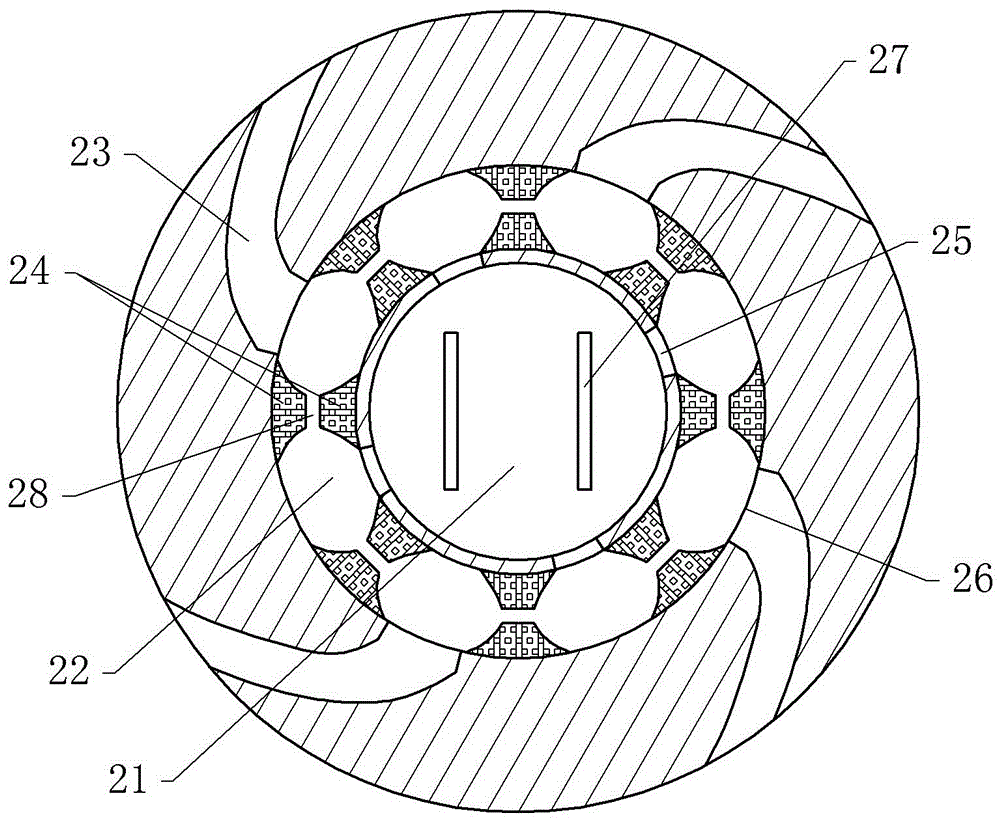

[0024] The reference signs in the accompanying drawings of the description include: upper grinding disc 1, extrusion shaft 11, stirring shaft 12, feed hopper 13, lower grinding disc 2, collecting tank 21, peeling tank 22, discharge tank 23, air bag 24, Material inlet 25, material outlet 26, material selection slit 27, peeling slit 28, motor 3, hopper 4, fan 5.

[0025] The embodiment is basically as figure 1 , figure 2 Shown:

[0026] The peanut peeling device of the present embodiment comprises a frame, an upper millstone 1, a lower millstone 2 and a motor 3, the upper millstone 1 is fixed on the frame, the lower millstone 2 is connected to the frame in rotation, and the motor 3 drives the lower millstone 2 to rotate .

[0027] The center of the lower grinding disc 2 is provided with a collecting tank 21, the outer periphery of the collecting tank 21 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com