Micro-nano scale wave structure in macroscopic composite material and preparation method thereof

A wave structure, micro-nano-scale technology, applied in nanotechnology, chemical instruments and methods, nano-carbon, etc. for materials and surface science, can solve difficult-to-control, complex preparation process of micro-nano-scale wave structure, and orientation and other issues to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment is a composite material with a micro-nano size wave structure formed by assembling two-dimensional transition metal oxide nanosheets. 3 Take nanosheets as an example, the specific steps are as follows:

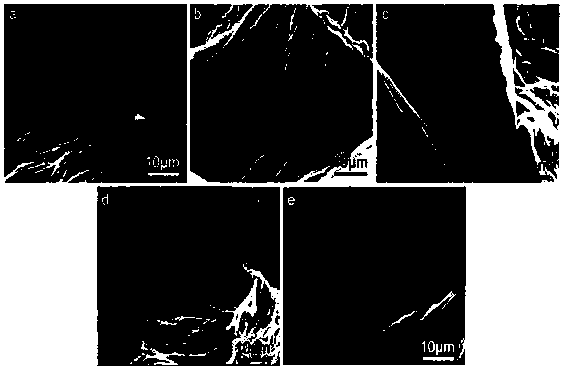

[0039] 1. Equipped with saturated dicyandiamine aqueous solution (40mg / ml, 80°C insulation); scanning electron microscope photos of molybdenum oxide nanosheets prepared by chemical vapor deposition method are as follows figure 1 (a), the smooth surface can be seen; the molybdenum oxide nanosheets synthesized by chemical vapor deposition (CVD) are ground to make the cross-sectional size smaller, and then ultrasonicated with 80% power for 10-20 minutes to disperse to a concentration of 2 -10mg / ml emulsion;

[0040] 2. Measure 3ml of saturated dicyandiamine aqueous solution according to the mass ratio of 5:4 and inject 30ml of molybdenum oxide emulsion with a concentration of 5mg / ml, oscillate and sonicate for 10-30 minutes to obtain uniformly dispersed molybdenu...

Embodiment 2

[0044] This embodiment is a method for preparing a boron nitride-based composite material with a micro-nano-scale wave structure, which is specifically carried out according to the following steps:

[0045] 1. Configure saturated dicyandiamide aqueous solution (40mg / ml, 80℃ insulation); boron nitride nanosheets such as figure 1 (c) The surface is smooth; the boron nitride powder is dispersed into an emulsion with a concentration of 2-10 mg / ml with 80% power ultrasound for 10-30 minutes;

[0046] 2. Measure 2.25ml of saturated dicyandiamine aqueous solution according to the mass ratio of 5:3 into 30ml of boron nitride emulsion with a concentration of 5mg / ml, shake and sonicate for 10-30 minutes to obtain a relatively uniform nitrogen Boron-dicyandiamine mixture;

[0047] 3. Measure 9ml of the boron nitride-dicyandiamide mixed dispersion and pour it into a 10ml cylindrical ceramic crucible, precool it at -40-0℃ for 2-4 hours to form interconnected ice crystals, and then at -100~ Freez...

Embodiment 3

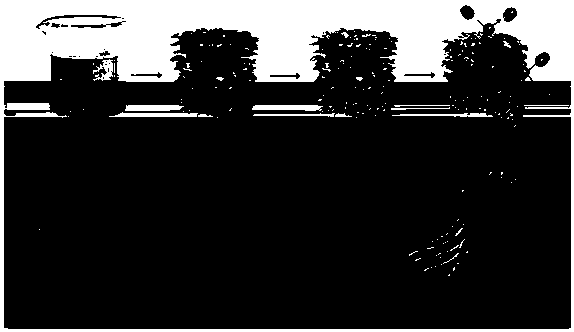

[0050] This embodiment is a method for preparing graphene-based porous composite foam with micro-nano-scale wave structures with different deformation degrees and different densities. The preparation process and the micro-wave structure change process are as follows figure 2 ; The specific steps are as follows:

[0051] 1. Configure saturated dicyandiamine aqueous solution (40mg / ml, 80℃ insulation), while ultrasonic concentration of 2-8mg / ml neutral graphene oxide solution, ultrasonic 10-120 minutes to obtain few or single layer graphite oxide Ene nanosheet solution;

[0052] 2. According to the mass ratio of 5:1, 5:2, 5:3, 5:4 and 5:8, measure 0.25, 0.5, 0.75, 1 and 2 ml of dicyandiamide solution and inject 10 ml of dicyandiamide solution with a concentration of 5mg / In ml of graphene oxide solution, shake and sonicate for 15-60 minutes to mix well;

[0053] 3. Take out 0.9 ml of the mixed solution of step 2 and pour it into a 1 ml cylindrical ceramic crucible, pre-cool at -40-0°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com