acupuncture needles

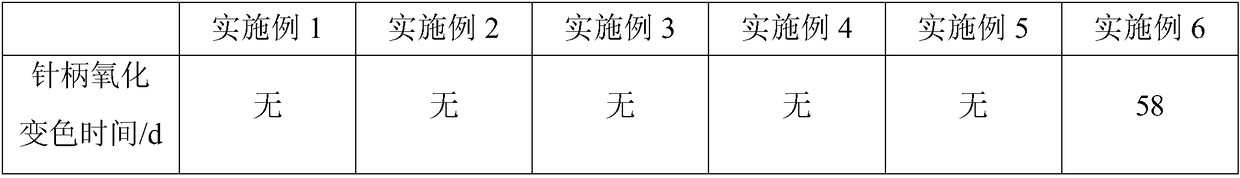

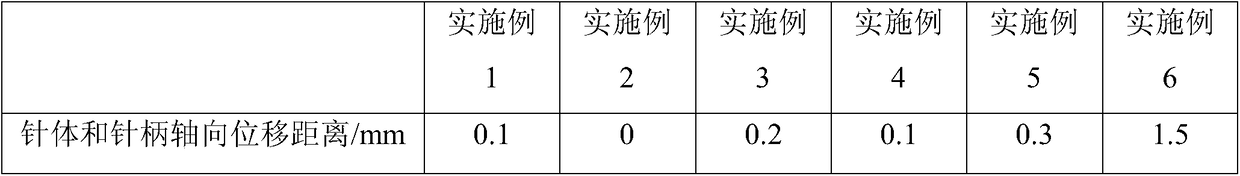

An acupuncture needle and needle body technology, applied in the field of acupuncture needles, can solve the problems of oxidative discoloration of plastic handle needles, and achieve the effects of outstanding aging resistance, improved rheological properties, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

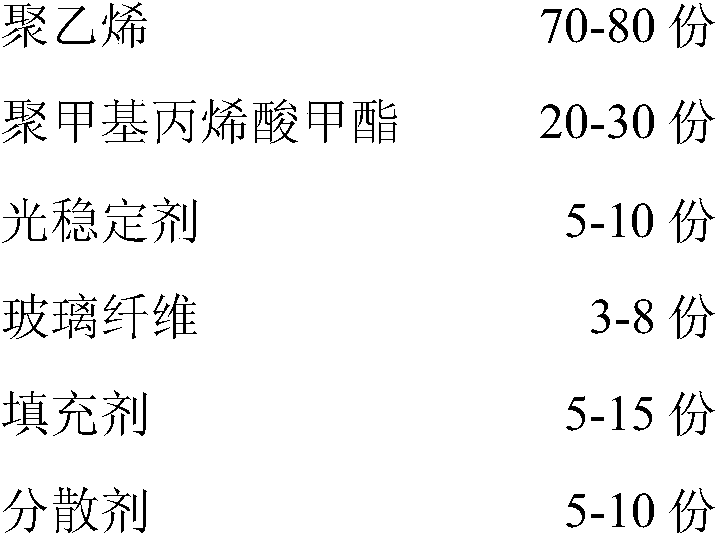

[0037] Step1: Weigh 70 parts of polyethylene, 30 parts of polymethyl methacrylate, 5 parts of light stabilizer (weight ratio of nano titanium dioxide: nano zinc oxide = 1:0.5), 15 parts of filler (weight ratio of nano calcium carbonate: nano Silicon dioxide=1:5), 10 parts of zinc stearate, 0.05 parts of titanate coupling agent, 10 parts of BHT, all the components obtained by weighing were added to a high-speed mixer and stirred;

[0038] Step2: Add the mixture to the twin-screw extruder, weigh 3 parts of glass fiber and add it by side feeding, the twin-screw extruder melts and extrudes, one-time molding, the length of the needle handle is 1 of the total length of the needle body and the needle tip / 3;

[0039] Step3: After evenly applying 1% cyanoacrylate of the total weight of the needle body and the needle tip on the back end of the needle body, put the needle handle into the back end of the needle body, make the needle handle rotate 5 times relative to the needle body, and ...

Embodiment 2

[0041] Step1: Weigh 72 parts of polyethylene, 20 parts of polymethyl methacrylate, 8 parts of light stabilizer (weight ratio of nano titanium dioxide: nano zinc oxide = 1: 1), 10 parts of filler (weight ratio of nano calcium carbonate: nano Silicon dioxide=1:2), 5 parts of zinc stearate, 0.1 part of titanate coupling agent, 5 parts of BHT, add all the obtained components into a high-speed mixer and stir and mix;

[0042] Step2: Add the mixture to the twin-screw extruder, weigh 7 parts of glass fiber and add it by side feeding, the twin-screw extruder melts and extrudes, one-time molding, the length of the needle handle is 1 of the total length of the needle body and the needle tip / 2;

[0043] Step3: After evenly applying 2% cyanoacrylate of the total weight of the needle body and needle tip on the back end of the needle body, put the needle handle into the back end of the needle body, make the needle handle rotate 5 times relative to the needle body, and let it stand Until t...

Embodiment 3

[0045] Step1: Weigh 80 parts of polyethylene, 22 parts of polymethyl methacrylate, 6 parts of light stabilizer (weight ratio of nano titanium dioxide: nano zinc oxide = 1: 2), 5 parts of filler (weight ratio of nano calcium carbonate: nano Silicon dioxide=1:3), 7 parts of zinc stearate, 0.75 parts of titanate coupling agent, 8 parts of BHT, add all the components obtained by weighing into a high-speed mixer and stir and mix;

[0046] Step2: Add the mixture to the twin-screw extruder, weigh 8 parts of glass fiber and add it by side feeding, the twin-screw extruder melts and extrudes, one-time molding, the length of the needle handle is 1 of the total length of the needle body and the needle tip / 3;

[0047] Step3: After evenly applying 3% cyanoacrylate of the total weight of the needle body and needle tip on the back end of the needle body, put the needle handle into the back end of the needle body, make the needle handle rotate 5 times relative to the needle body, and let it s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com