Polarizing film, polarizing film with adhesive layer, and image display device

An adhesive layer, polarizing film technology, applied in the direction of film/sheet adhesive, adhesive, polarizing element, etc., can solve the problems of cracks, difficult to completely suppress shrinkage, unavoidable shrinkage of optical film laminates, etc. The effect of reducing shrinkage and improving deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0124] Production example 1 (manufacture of polarizing film (1))

[0125] Corona treatment was performed on one side of an amorphous isophthalic acid-copolyethylene terephthalate (IPA-co-PET) film (thickness: 100 μm) with a water absorption rate of 0.75% and a Tg of 75°C. Coating on the corona-treated surface at 25°C contains polyvinyl alcohol (polymerization degree: 4200, saponification degree: 99.2 mol%) and acetoacetyl modified PVA (polymerization degree: 1200, acetoacetyl group) in a ratio of 9:1. Modification rate: 4.6%, saponification degree: 99.0 mol% or more, Nippon Synthetic Chemical Industry Co., Ltd., trade name "GOHSEFIMER Z200") aqueous solution was dried to form a PVA-based resin layer with a thickness of 11 μm, and a laminate was produced.

[0126] The obtained laminate was stretched 2.0 times in the longitudinal direction (longitudinal direction) between rollers with different circumferential speeds in an oven at 120° C. (assisted stretching treatment in gas at...

manufacture example 2

[0136] Production example 2 (manufacture of polarizing film (2))

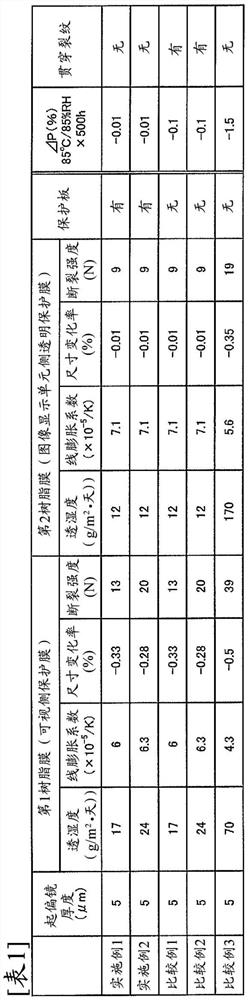

[0137] The ultraviolet curable adhesive produced in Example 1 was coated on the surface of the polarizer (thickness: 5 μm) of the optical film laminate obtained in Production Example 1 so that the thickness of the adhesive layer after curing became 0.1 μm. At the same time, a transparent protective film on the visible side (cycloolefin film with a thickness of 27 μm (trade name: ZD12-099063-C1300UHC, manufactured by Zeon Co., Ltd. in Japan), moisture permeability at 40°C and 92% R.H.: 24g / (m 2 days), linear expansion coefficient: 6.3×10 -5 / K, dimensional change rate: -0.28%, breaking strength: 20N), and then irradiate ultraviolet rays as active energy rays to cure the adhesive. Gallium-encapsulated metal halide lamp was used for ultraviolet irradiation, irradiation device: LightHAMMER10 manufactured by Fusion UV Systems, Inc., valve: V valve, peak illuminance: 1600mW / cm 2 , cumulative exposure 1000 / mJ / cm ...

manufacture example 3

[0138] Production example 3 (manufacture of polarizing film (3))

[0139]The surface of the polarizer (thickness: 5 μm) of the optical film laminate obtained in Production Example 1 was coated with a polyvinyl alcohol-based adhesive so that the thickness of the adhesive layer became 0.1 μm, and the visible side was bonded. Transparent protective film (acrylic film with a thickness of 40 μm (trade name: HX-40UC-1330, manufactured by Kaneka Co., Ltd.), moisture permeability at 40° C., 92% R.H.: 70 g / (m 2 days), linear expansion coefficient: 4.3×10 -5 / K, dimensional change rate: -0.5%, breaking strength: 39N), and then dried at 50° C. for 5 minutes. Next, the amorphous PET substrate was peeled off, and a polyvinyl alcohol-based adhesive was applied on the peeled surface so that the thickness of the adhesive layer became 0.1 μm, and at the same time, a transparent protective film on the side of the image display unit was pasted. (Acrylic film with a thickness of 20 μm (trade na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com