Processing method of aramid fiber reinforced polytetrafluoroethylene holder

A polytetrafluoroethylene and processing method technology, applied in the field of bearing processing, can solve the problems of insufficient product qualification rate, high stress, unable to meet the production and processing of aramid reinforced polytetrafluoroethylene cages, etc. The effect of improving the accuracy of card loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention relates to a processing method of an aramid-reinforced polytetrafluoroethylene cage. The processing method adds stabilization treatment ①, semi-finishing outer diameter end face, semi-finishing inner diameter end face and stabilization treatment on the basis of combining traditional processing procedures. ②, At the same time, corresponding requirements are put forward for the processing ambient temperature, so the processing method of the present invention is also applicable to the processing of other non-metallic cages.

[0024] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

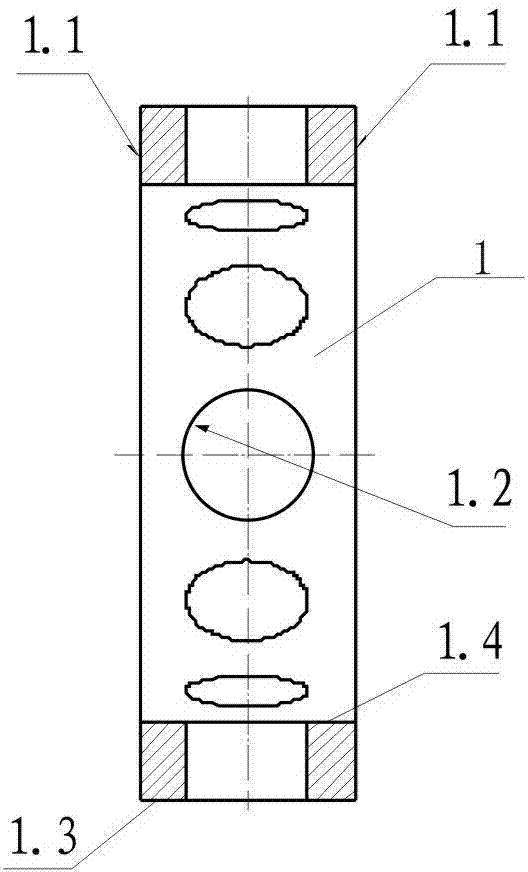

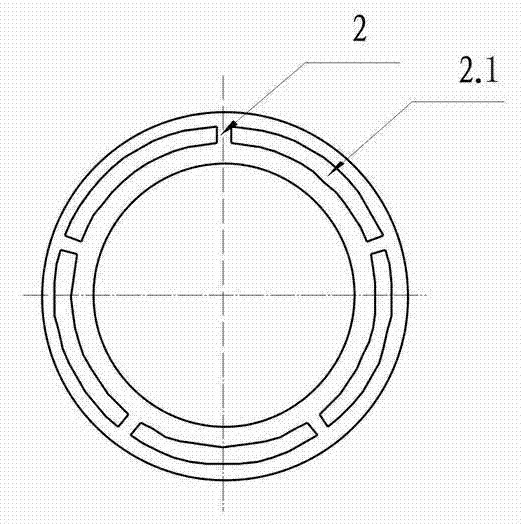

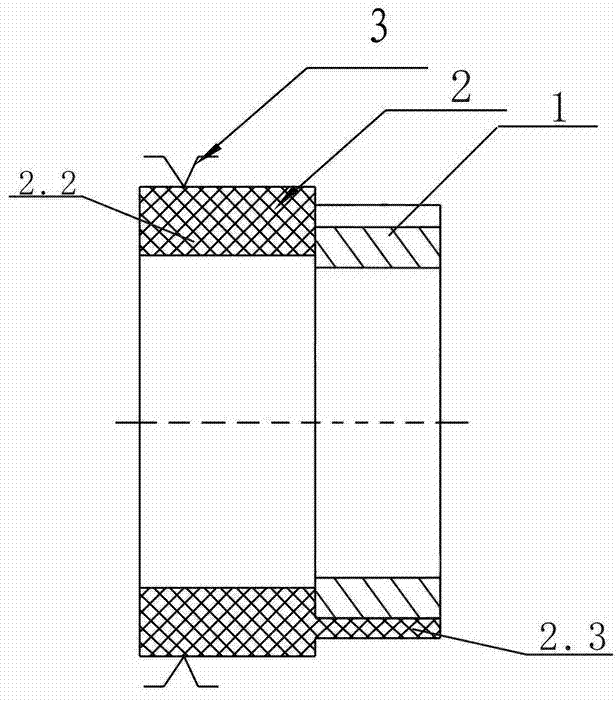

[0025] combine figure 1 First, the aramid reinforced PTFE cage 1 has two side end faces 1.1, pockets 1.2, outer diameter end faces 1.3 and inner dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com