Method for processing half frame on upper portion of helicopter body and vacuum sucking clamp

A vacuum adsorption and processing method technology, applied in the field of mechanical processing, can solve the problems of large deformation of parts, difficulty in ensuring wall thickness and web size, etc., to solve large deformation, improve processing efficiency, improve processing pass rate and process efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The processing method of the upper half frame of a certain type of helicopter fuselage, the processing steps are:

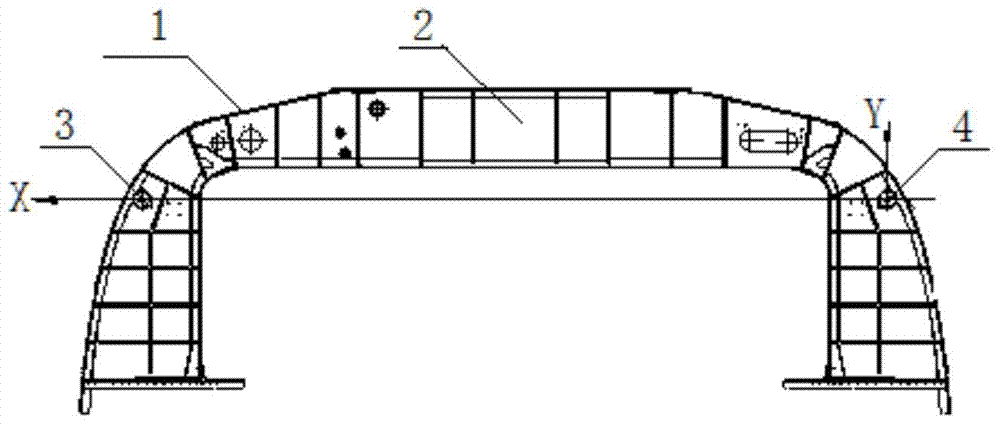

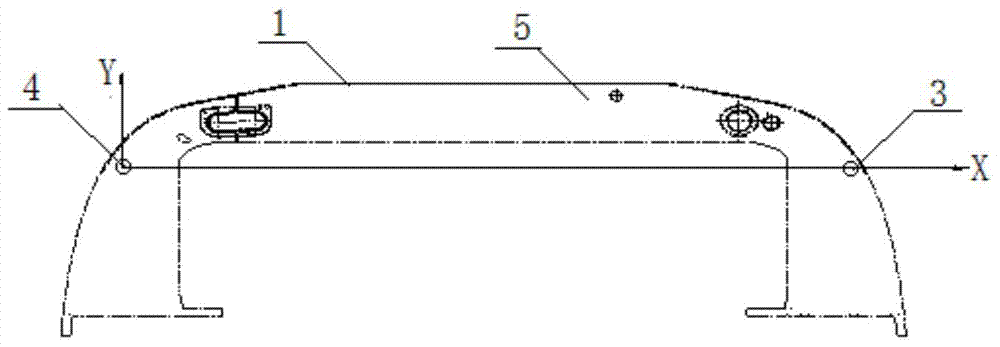

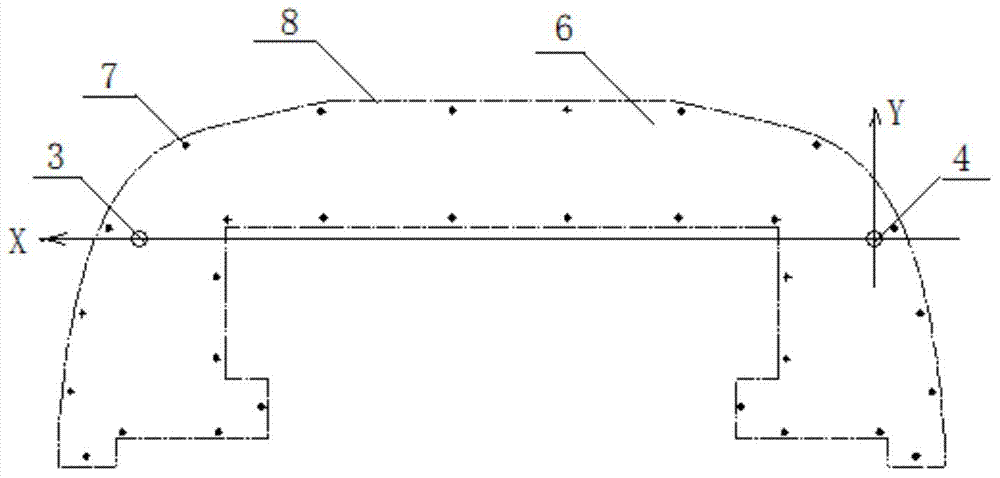

[0024]1. Manufacture the blank of the upper half frame of the fuselage: use sheet blanking to form a rectangular wool, process the left positioning hole 3 and the right positioning hole 4 at both ends of the wool length direction, establish a three-dimensional coordinate system, and use the right positioning hole 4 The center point is the origin, the straight line passing through the center points of the left positioning hole 3 and the right positioning hole 4 is the X axis, the positive direction is toward the left positioning hole 3, the positive direction of the Y axis is backward, and the positive direction of the Z axis is upward; The outline of the side 8 of the blank is processed from the top view of the upper half frame, and the outline of the side 8 of the blank is extended by 70mm according to the theoretical outline of the upper half frame of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com