Two-sided milling fixture for blank forming molds

A technology of double-sided milling and initial molding, which is applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of unstable parts size, inaccurate positioning, and low production efficiency, so as to ensure production accuracy and easy operation , The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

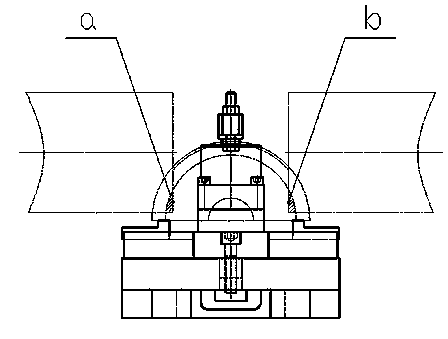

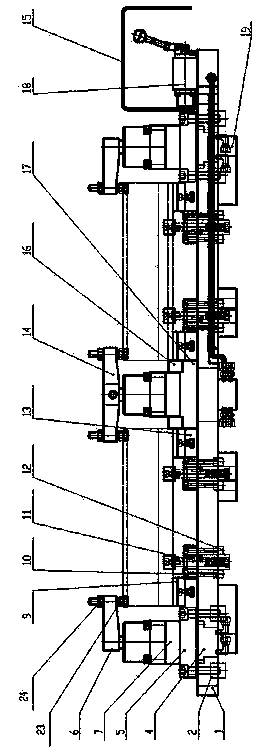

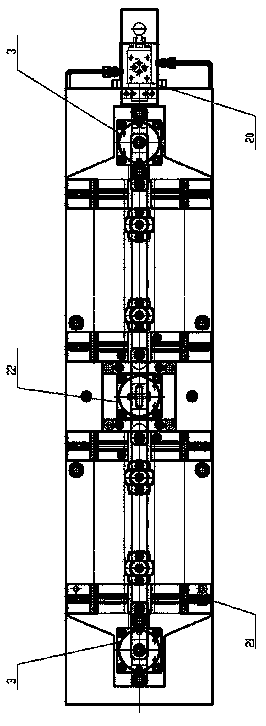

[0028] Such as Figure 1 to Figure 5 Shown are the schematic diagrams of the front view, top view, and left view after the parts are installed by the double-sided milling fixture of the blank mold of the present invention, and the situation of using different heights of oil cylinder pads 7 and different pin heads 8 to process different parts.

[0029] A double-sided milling fixture for forming a blank mold, including a base, a movable support clamping mechanism, a movable centering mechanism, and an intermediate fixed support clamping mechanism, wherein the intermediate fixed support clamping mechanism is installed in the middle of the base, and the two ends of the base are installed There is a mobile support clamping mechanism, and a mobile centering structure is installed between the fixed mechanism and the moving mechanism on the base.

[0030] The base includes a bottom plate 1 , a switch valve 18 and an oil block 20 , wherein the switch valve 18 is mounted on the oil bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com