A kind of alloy material with negative thermal expansion property and preparation method thereof

A technology of negative thermal expansion and alloy materials, which is applied in the field of alloy materials with negative thermal expansion properties and its preparation, can solve the problems of limited performance and application, narrow temperature range, small expansion coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

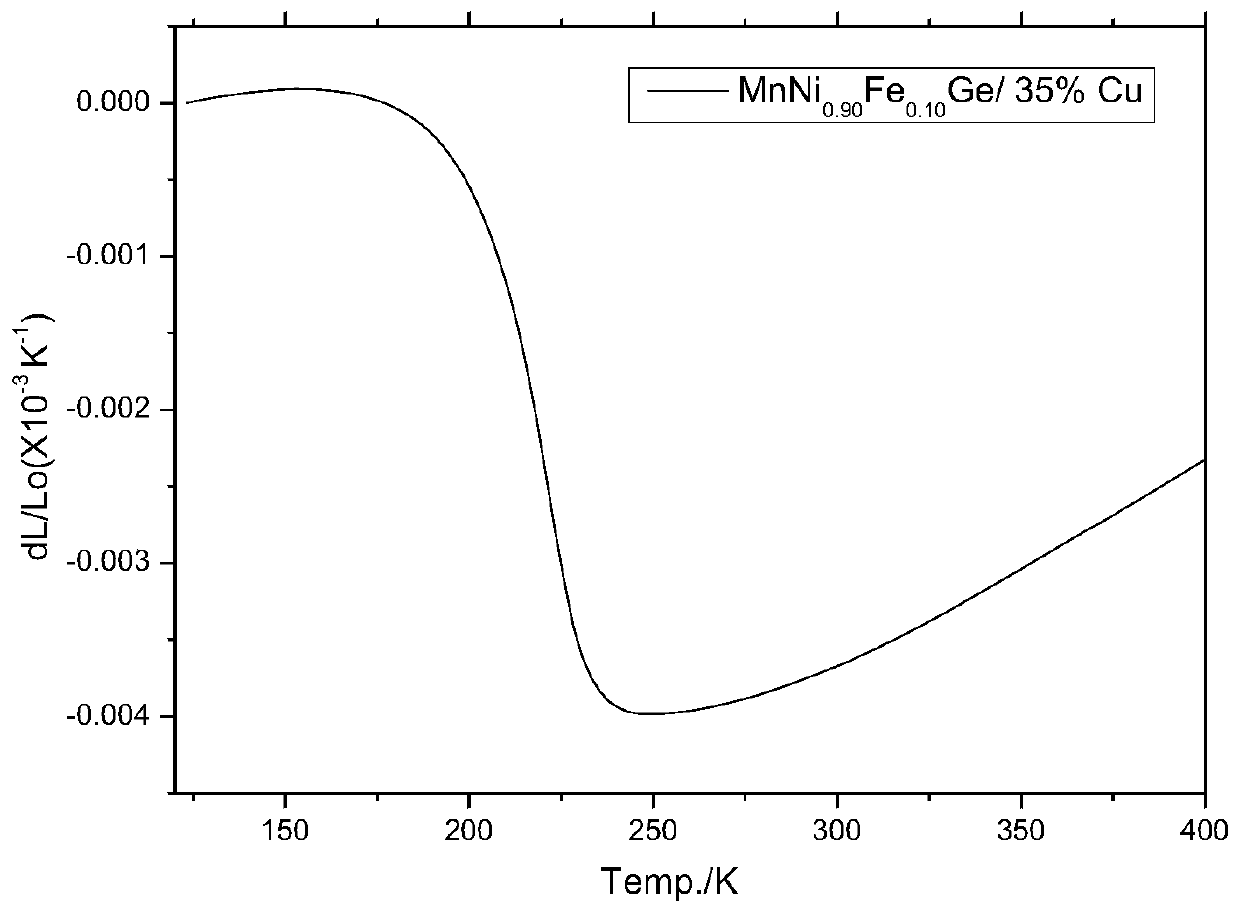

[0027] MnNi 0.90 Fe 0.10 The preparation of Ge / 35wt% Cu is illustrated as an example, and is only used to illustrate the present invention, not to limit the present invention.

[0028] The invention relates to a metal composite material with negative thermal expansion properties, which is prepared by a solid phase sintering method. The base material is MnNi 0.90 Fe 0.10 Ge, its preparation process is as follows:

[0029] Step 1: According to the stoichiometric ratio of Mn:Fe:Ni:Ge=1:0.90:0.10:1, use an electronic balance to weigh 3.5446g Mn powder, 3.4082g Ni powder, 0.3603g Fe powder and 4.6868g Ge powder and place them in an agate mortar In the middle, fully grind for 1.5h to make the powder mix evenly;

[0030] Step 2: Press the uniformly mixed metal powder into a cylindrical block with a height of about 2.5 mm using a common cylindrical mold with a diameter of 15 mm and a tablet press;

[0031] Step 3: Seal the above-mentioned cylindrical metal block into a vacuum qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com