Rotor Slot Liner Bending Tool for Wet Winding Motors

A motor rotor and winding technology, applied in the field of wet winding motor rotor slot lining bending tools, can solve the problems of copper strip deformation, increased cost, loss of protective effect of copper strip, etc., and achieves the effect of improving efficiency and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

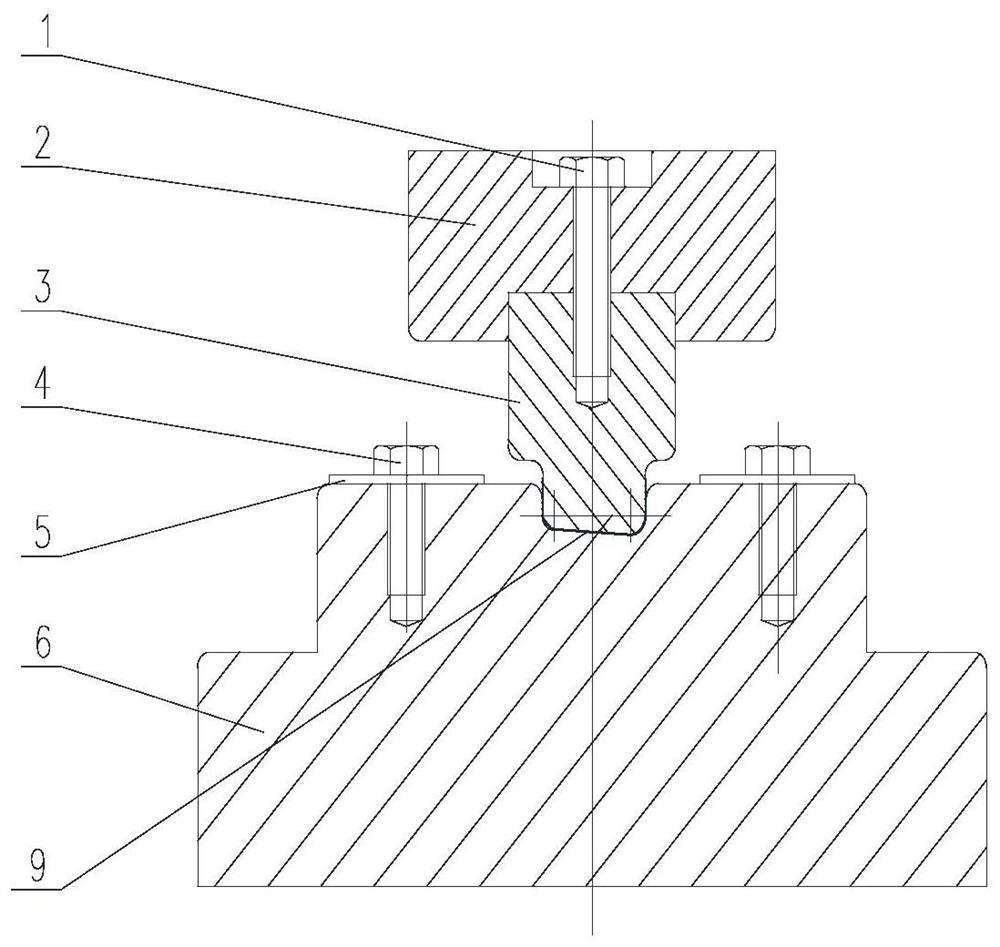

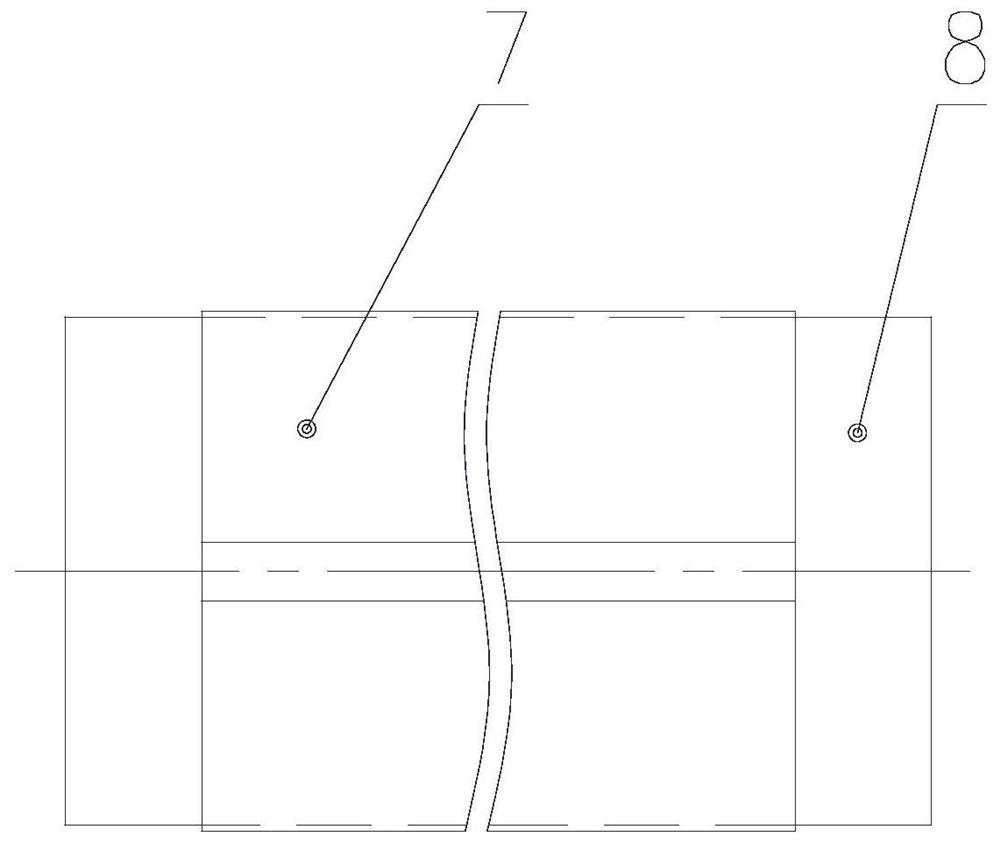

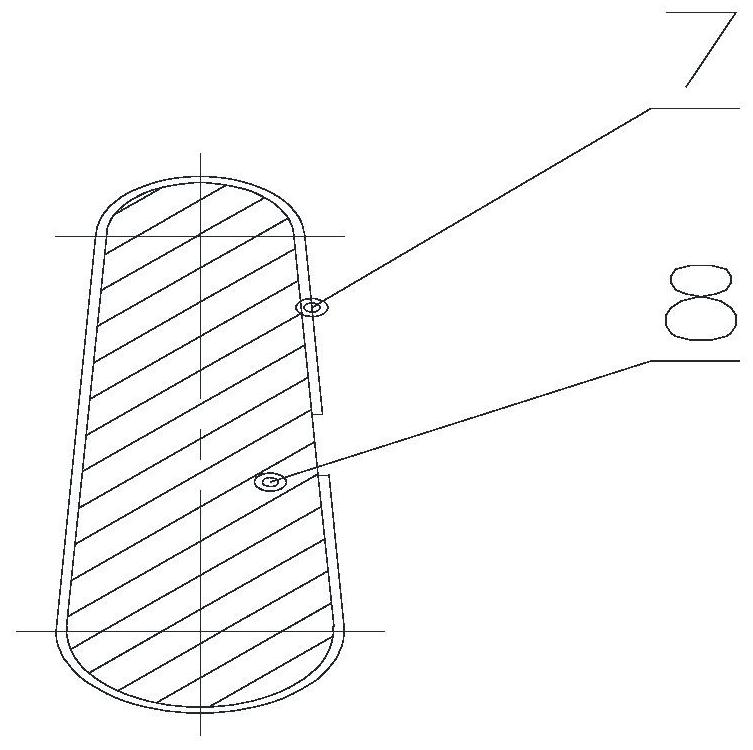

[0014] Such as figure 1 The desired wet winding motor rotor slot is thin, the tool consists of a lower mold 6, a positioning plate 5, a bolt 4, a upper mold 3, a upper mold 2, a bolt 1, and a lower mold 6 with a limit slot. 9, the positioning plate 5 is fixed to the lower mold 6, and the standard bolt 4 is fixed; the upper mold 3 is assembled with the upper mold 2, and the bolt 1 is assembled, the bolt 1 is a fully threaded bolt. The upper mold 3 is composed of a plurality of pieces, and the threaded holes are fixed on each piece; and the lower groove liner 7 is placed on the lower mold 6, and the groove liner is fixed by adjusting the positioning plate 5. Good, the coated copper strip 8 is placed on the slot, and the limit slot 9 of the lower mold 6 is correct, and the mounted upper mold 3 and the copper strip 8 are correct, by tightening multiple bolts. 1. Press the copper strip 8 into the groove lining 7 to achieve a seamless bonding of the groove liner 7 and the copper strip 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com