Application of a kind of adhesion promoter for rubber

A technology of adhesion promoter and rubber adhesive, applied in the application field of adhesion promoter for rubber, can solve the problems of poor thermal stability of formaldehyde carrier, increasing the dosage of vulcanization system, affecting the vulcanization speed of rubber compound, etc. The effect of simplifying rubber process design, simplifying formulation design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

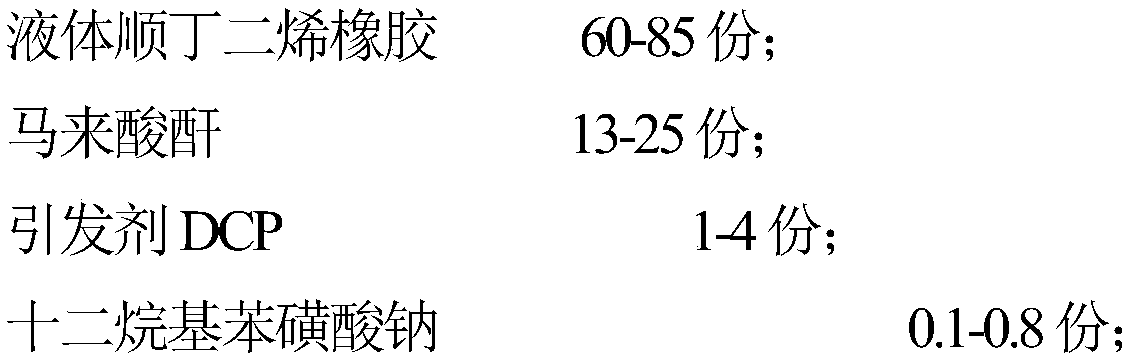

[0036] 1. The raw material components of the adhesion promoter are as follows (parts by weight):

[0037] 80.8 parts of liquid butadiene rubber;

[0038] 18 parts of maleic anhydride;

[0039] Initiator DCP 1.2 parts.

[0040] 2. Preparation of adhesion promoter

[0041] (1) Inject liquid butadiene rubber into the reaction kettle, stir and heat to 135±3°C;

[0042] (2) Maleic anhydride is dropped into the reactor, and under stirring condition, it is incubated for 10 ± 1 minute;

[0043] (3) adding initiator DCP;

[0044] (4) Continue to stir and keep warm for 15-20 minutes to obtain the adhesion promoter.

[0045] 3. The application of this adhesion promoter in general-purpose fabric core conveyor belts. The product implements the national standard GB / T7984—2001 "Conveyor belt with rubber or plastic covering layer for general purpose fabric core conveyor belt", in which the requirement for bonding strength is not less than 4.5N / mm, and this application example can reach ...

Embodiment 2

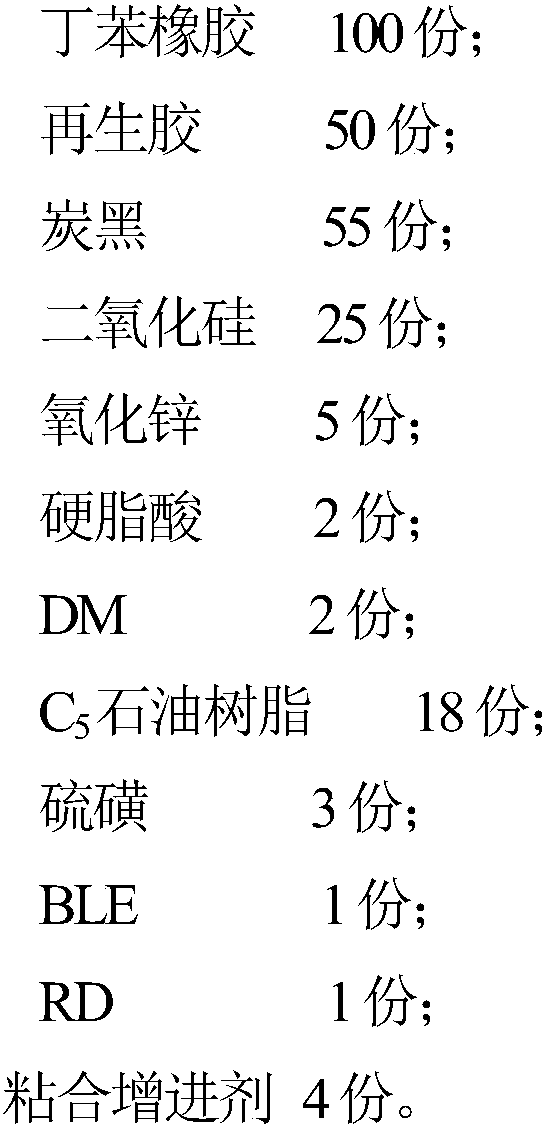

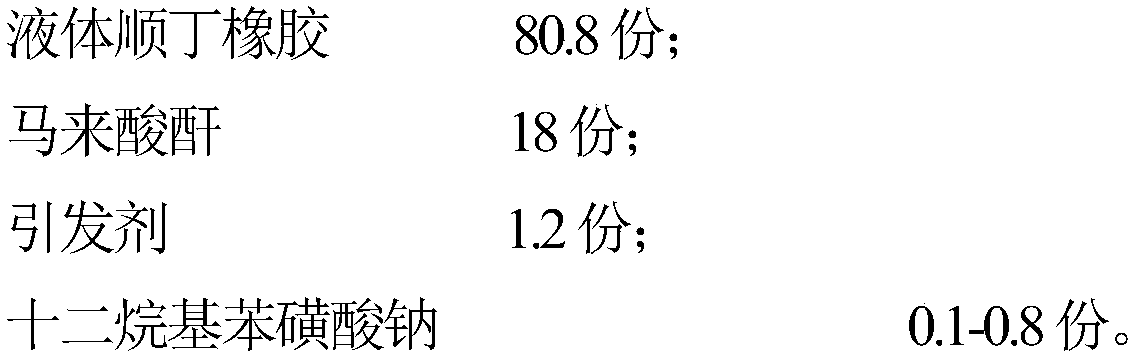

[0051] 1. The raw material components of the adhesion promoter are as follows (parts by weight):

[0052]

[0053] The dispersant is sodium dodecylbenzenesulfonate.

[0054] 2. Preparation of adhesion promoter

[0055] (1) Inject liquid butadiene rubber into the reaction kettle, stir and heat to 135±3°C;

[0056] (2) Maleic anhydride is dropped into the reactor, and under stirring condition, it is incubated for 10 ± 1 minute;

[0057] (3) Add initiator DCP and dispersant;

[0058] (4) Continue to stir and keep warm for 15-20 minutes to obtain the adhesion promoter.

[0059]3. The application of this adhesion promoter in tubular fabric core conveyor belts. The basic requirements of this product are the same as those of Example 1, but because its use environment is much harsher than that of Example 1, it is required to have a bonding strength of more than 13.0 N / mm, which is much higher than the requirements of GB / T7984-2001, and the difficulty is relatively high. This a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com