Flat-surface milling machine

A technology of plane milling machine and milling head, which is applied in the direction of processing machines for manufacturing flat surfaces, rotary cutting tools, fine planers, etc. It can solve the problems of poor surface quality and the inability to achieve the efficiency of plane milling machines, etc., and achieve installation/adjustment or The effect of simple tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

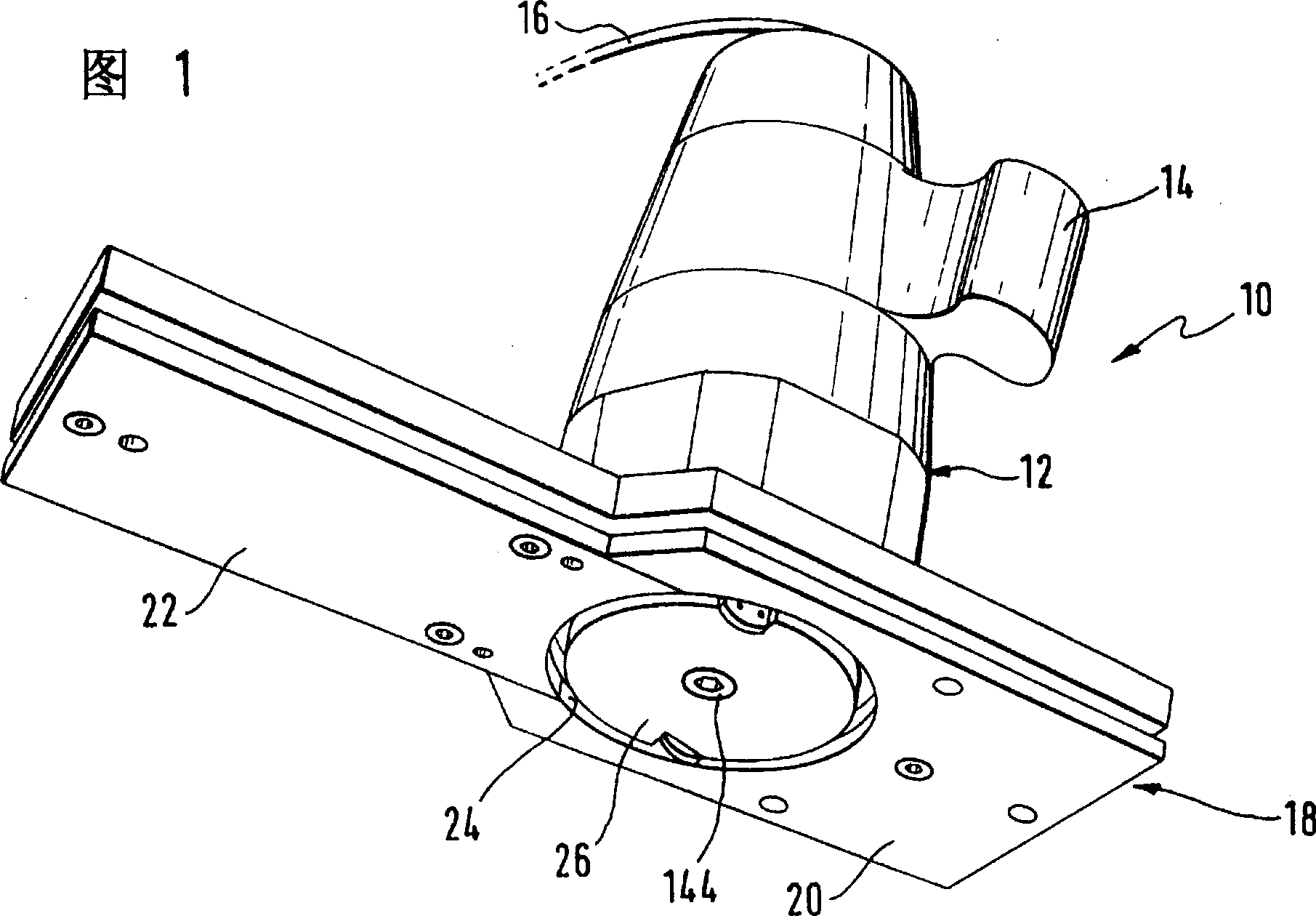

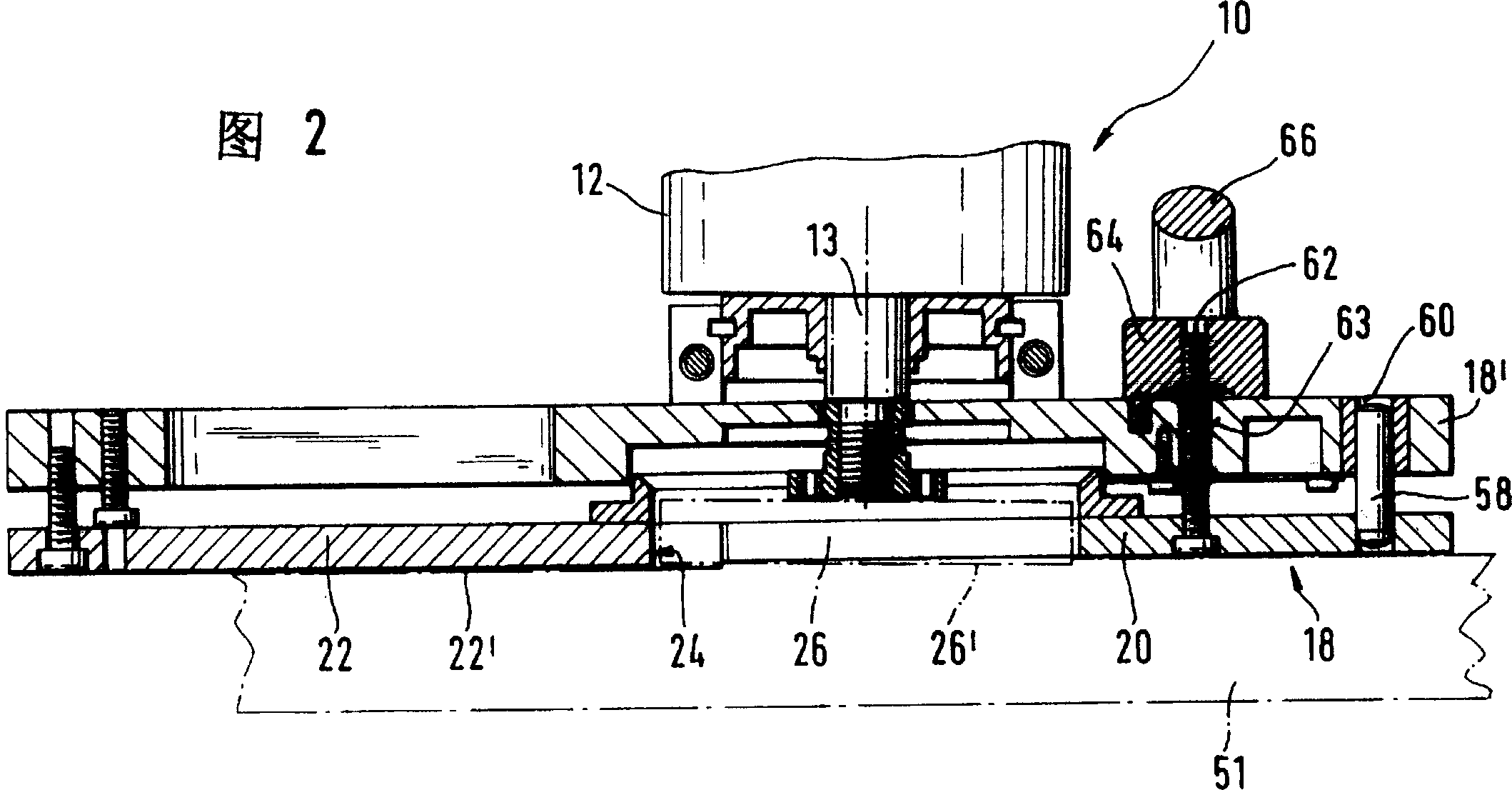

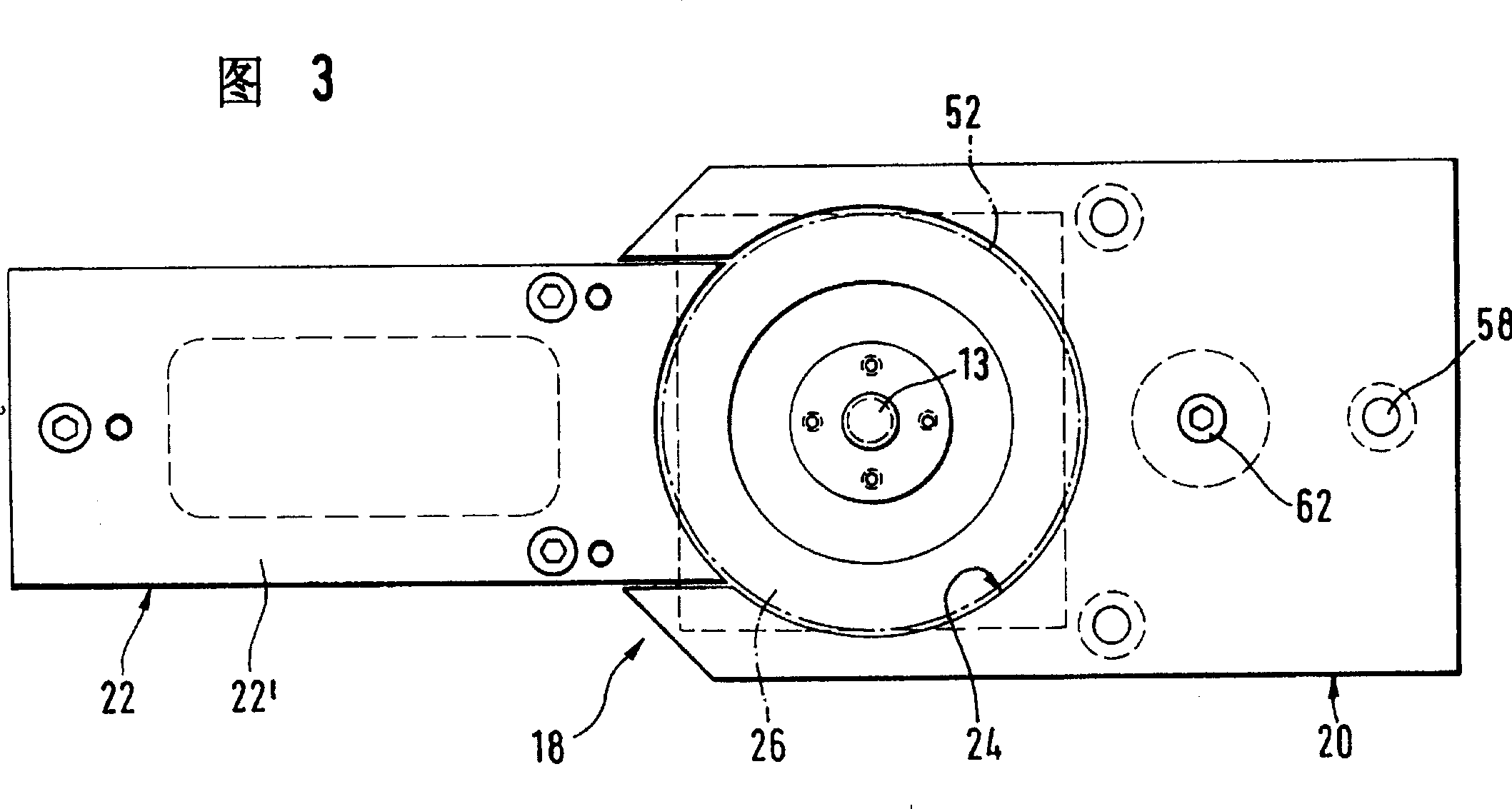

[0029] The plane milling machine ( 10 ) shown in perspective in FIG. 1 has an approximately cylindrical housing 12 extending axially from top to bottom in the viewing direction. The housing has a power supply cable 16 emerging from above and two handles 14 projecting radially laterally, only one of which is shown here, for operating the surface milling machine 10 on a workpiece not shown.

[0030] The lower part of the housing 12 is connected to a base plate 18 for being supported on a workpiece, which base plate consists of a front, axially adjustable, wide part 20 and a rear, fixed narrow part 22 . The base plate 18 is provided in the axial extension of the housing 12 with a circular through-opening 24 for passing through a disk-shaped milling head 26 for cutting into a workpiece (not shown). The through hole 24 is placed between the parts 20, 22 of the base plate 18, wherein a relatively small part of this hole 24 - viewed to the left - is formed by the narrow, fixed edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com