Micron-sized particle stacking compactness testing device and testing method thereof

A particle accumulation and testing device technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve problems such as the inability to accurately measure the packing density of small particle size particles, the inability to completely eliminate the influence of particle clusters, and the prediction of rheological properties of mixtures, etc. , to achieve the effect of guaranteeing the final quality, increasing the maximum stress, and predicting the rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

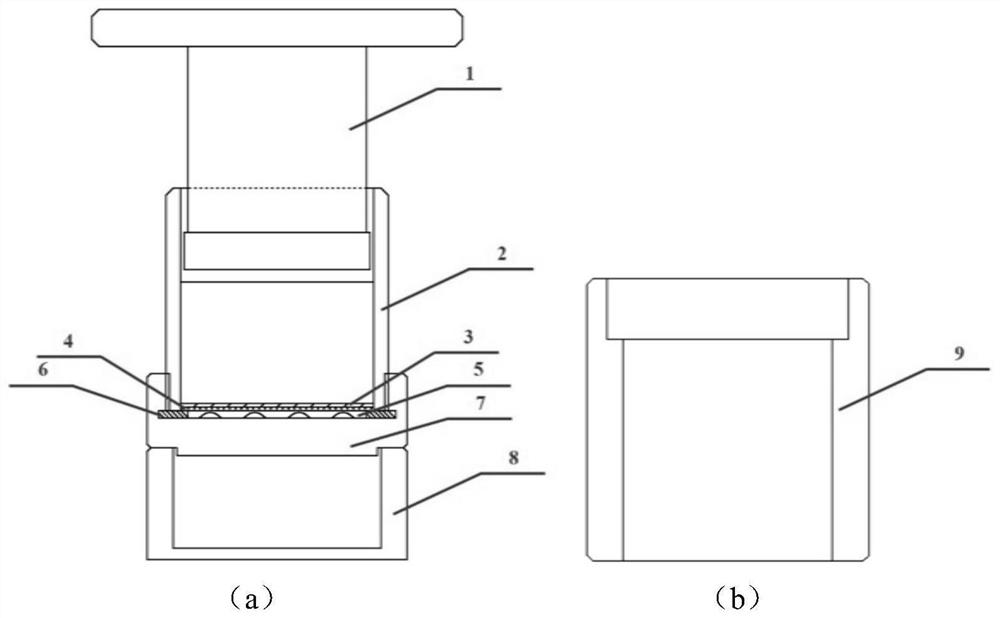

[0061] The test method for the packing density test device of micron-sized particles includes the following steps:

[0062] 1) Take the P·I 42.5 type reference cement as the particle to be tested, mix it with water and stir evenly to obtain a test slurry with a water-cement ratio of 0.3;

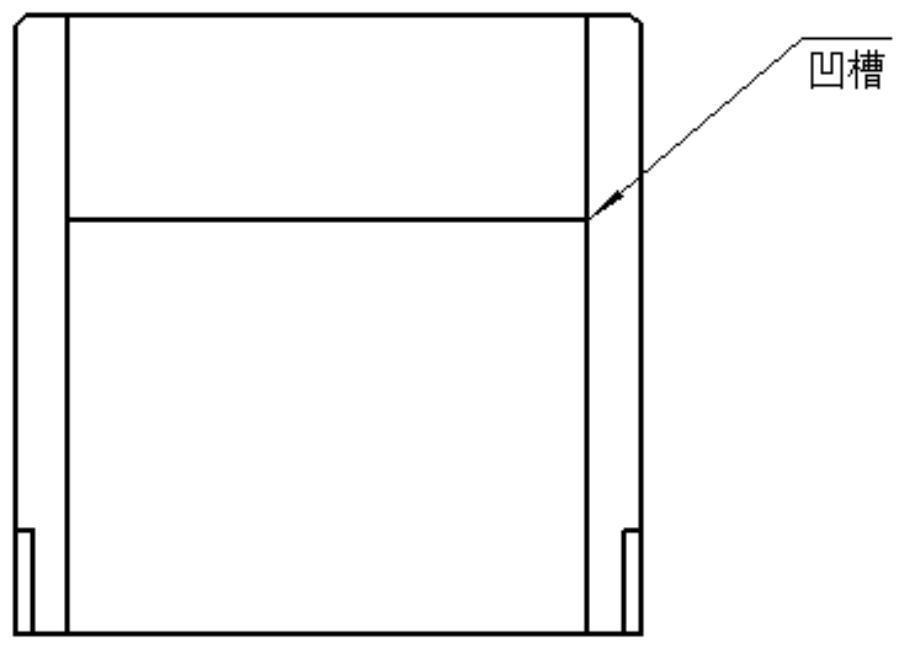

[0063] 2) Assemble a test device for packing density of micron-sized particles, pour the test slurry into the storage bin, so that the liquid level is located at the groove on the inner surface of the outer sleeve 2;

[0064] 3) Appropriately vibrate the test device to discharge the air bubbles introduced during the sample loading process;

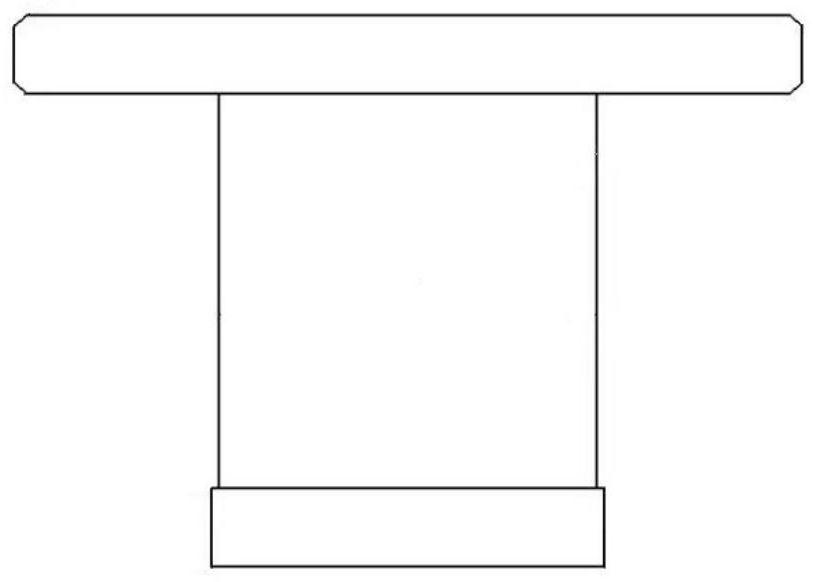

[0065] 4) Put the piston 1 into contact with the surface of the test slurry, and place the test device on the loading platform of the universal testing machine;

[0066] 5) Edit the loading program so that the upper pressure head of the universal testing machine drops at a rate of 0.01-0.2mm / s first, and when the applied pressure reaches 90% of the set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com