Consecutive wrapping welding drawing production line for railway subgrade through ground wires

A technology of penetrating ground wire and cladding welding, which can be used in the manufacture of circuits, electrical components, cables/conductors, etc., and can solve problems such as inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

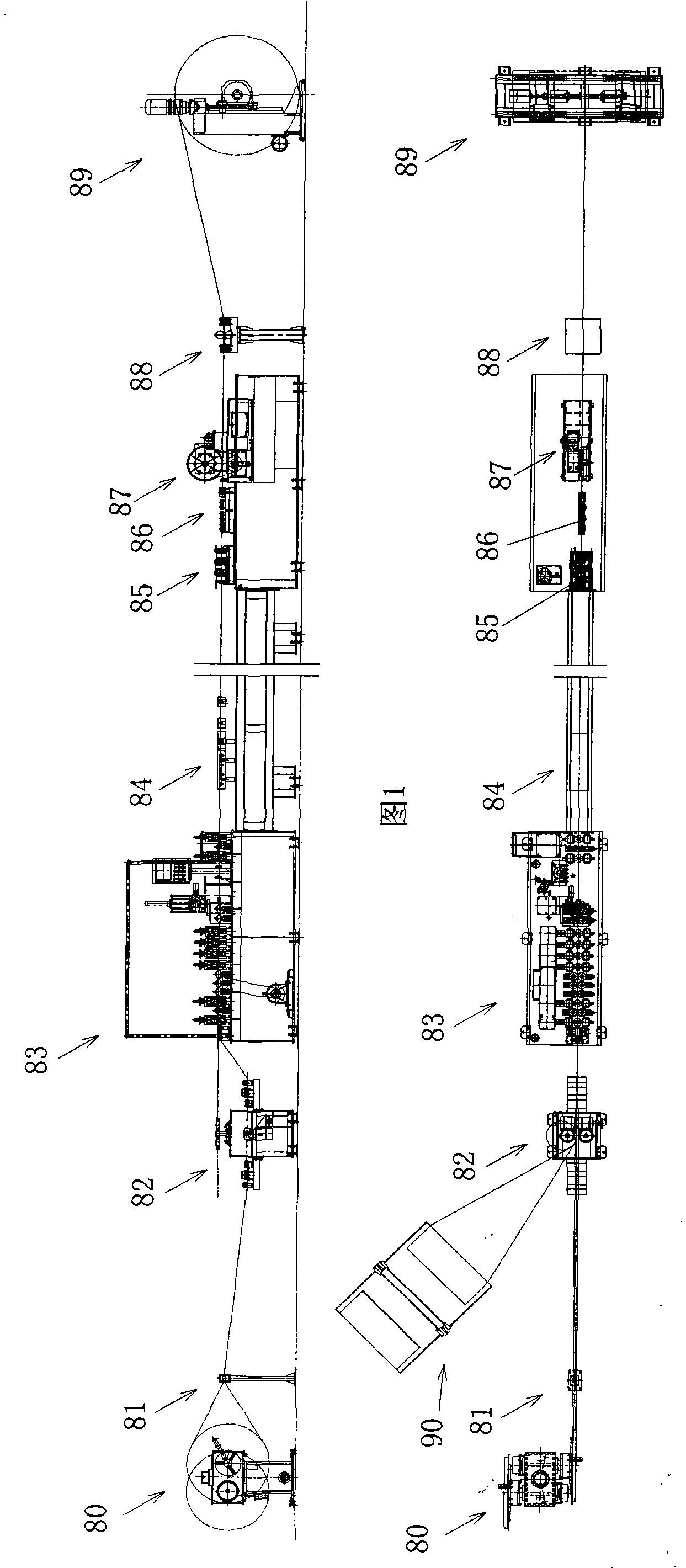

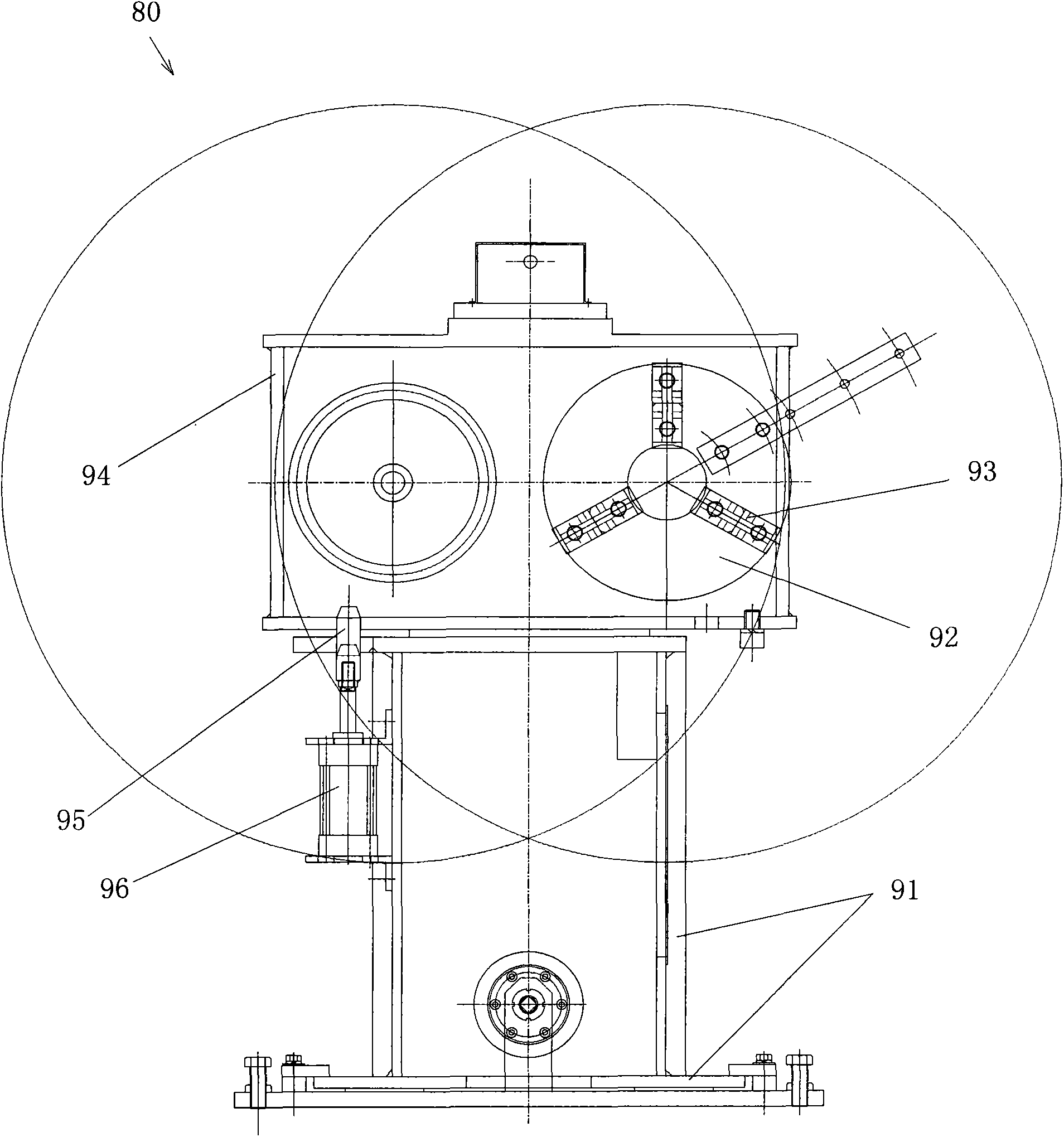

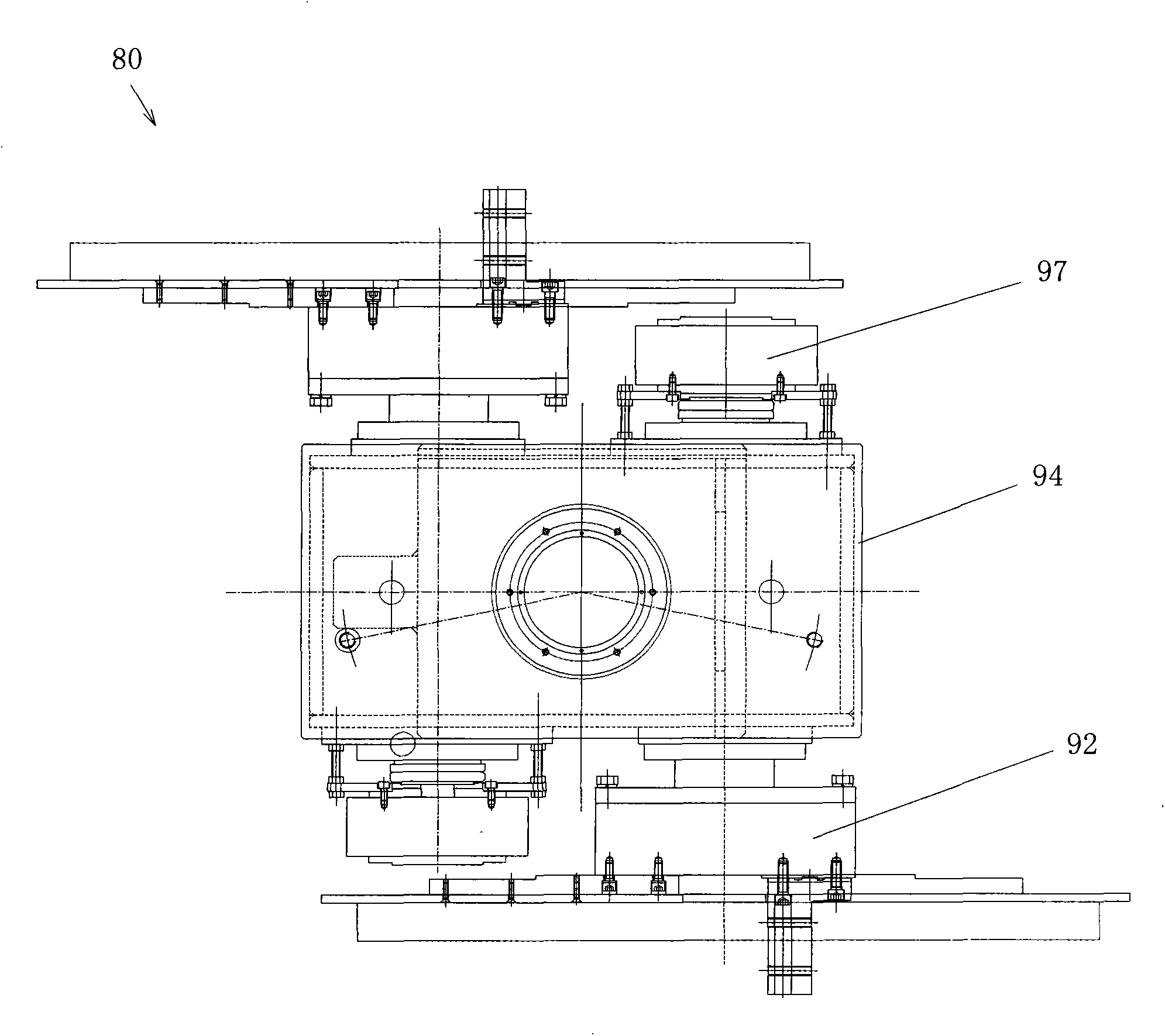

[0044] Such as figure 1 , 2 Shown: the production line of the present invention sequentially includes a strip unwinding machine 80, a copper strip edging cleaning machine 82, a continuous cladding welding device 83, a cooling tank 84, a drawing die seat device 85, a traction machine 87, a wire take-up machine 89 and Core wire pay-off machine 90; a detection mechanism 81 is provided between the tape unwinder 80 and the copper strip edging cleaning machine 82; a cleaning and drawing mechanism 86 is provided between the drawing die seat device 85 and the tractor 87; the tractor A meter counter 88 is provided between 87 and the take-up machine 89.

[0045] Such as Figure 5 , 6 , 7, 8, 9: the specific structure of the copper belt edging cleaning machine 82 is as follows: 14 is the frame, which can be made of section steel and metal plates. A sliding seat 13 is fixedly installed on the frame 14 transversely by bolts, and two sliding blocks, namely a front sliding block 12 and a rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com