A method for forging the inner and outer rings of fan variable speed bearings

A fan speed change, inner and outer ring technology, applied in the field of steel forging, can solve the problems of difficult to guarantee the quality of forgings, coarse grains of forgings, prone to cracks, etc., and achieve the effects of shortening forging time, strong toughness and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

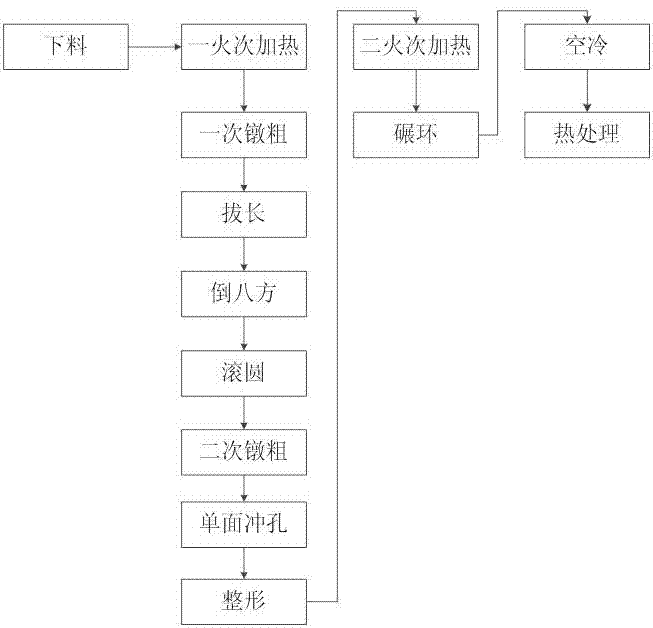

[0030] Such as figure 1 As shown, a forging method for the inner and outer rings of a variable speed bearing of a fan includes the following steps:

[0031] Step 1) blanking: blanking according to the required thickness of the inner and outer rings of the variable speed bearing of the fan to make a blank;

[0032] Step 2) Heating for the first time: heating the billet in the heating furnace to 1260±10°C and keeping it warm;

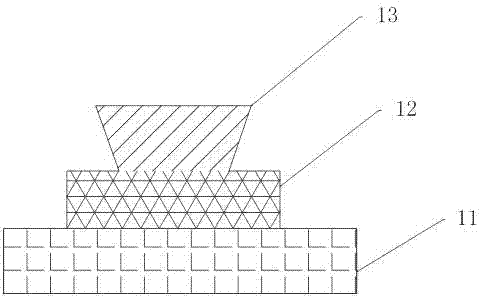

[0033] Step 3) Cylindrical billet production: take out the billet in the furnace, use the forging anvil to perform an overall upsetting on the billet, take out the forging billet and stretch it to the technical size, and then perform inversion and rounding on the drawn forging billet. made into a cylindrical billet;

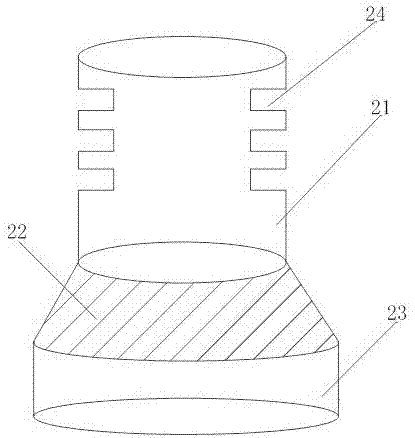

[0034] Step 4) Making ring blanks: after taking out the round blanks, put them on the forging anvil again, carry out secondary overall upsetting, then punch holes with punches to make ring blanks, and shape the ring blanks;

[0035] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com