Method of preparing bromobisphenol S diene propyl ether

A technology of bisallyl ether and tetrabromobisphenol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large solvent loss, difficult application, large energy consumption, etc., and achieves manufacturing cost The effect of reducing and saving production costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

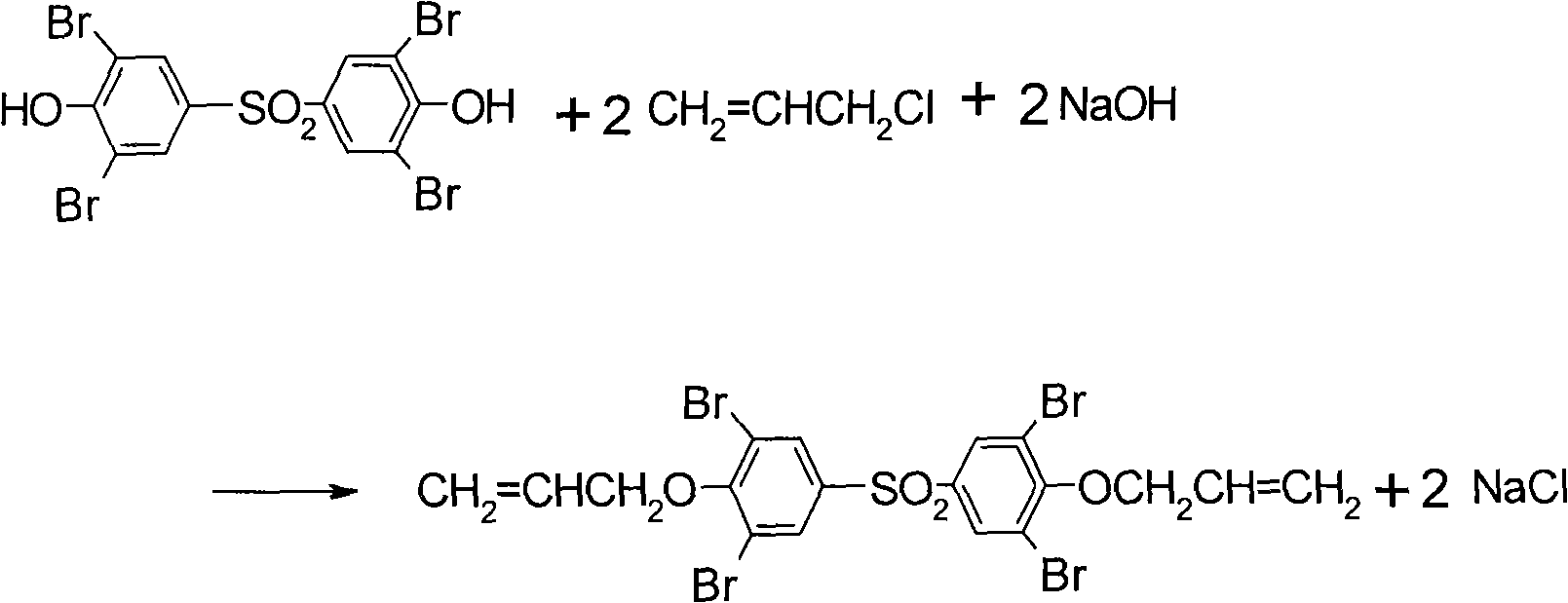

Image

Examples

Embodiment 1

[0018] Add 30g of tetrabromobisphenol S, 40ml of isopropanol, 60ml of water, 5ml of chlorobenzene, 4.5g of sodium hydroxide, and 0.5g of tetraethylammonium bromide into a 500ml four-necked bottle equipped with a stirrer, a thermometer, and a condenser. , put 9g of allyl chloride into the pear-shaped addition funnel, heat the solution to 80°C, add allyl chloride dropwise, and keep the reaction solution alkaline during the reaction. If the pH value is less than 8, NaOH can be added appropriately and kept warm After reacting for 10 hours and cooling, white crystals were obtained, which were centrifuged and dried to obtain the product tetrabromobisphenol S diallyl ether with a melting point of 183° C. and a yield of 95%.

Embodiment 2

[0020] Add 60ml of isopropanol, 30g of tetrabromobisphenol S, 40ml of water, and 4.5g of NaOH into a 250ml three-necked flask equipped with a stirrer, a thermometer, and a condenser, stir to dissolve, and then add 0.5g of tetraethylammonium bromide , 20ml of chlorobenzene, 9g of chloropropene, heated to 65°C, kept warm for 9 hours, cooled to obtain white crystals, centrifuged, and dried to obtain the product tetrabromobisphenol S diallyl ether with a melting point of 184°C. The rate is 92%.

Embodiment 3

[0022] Add 30g of tetrabromobisphenol S, 25ml of isopropanol, 30ml of water, 4ml of chlorobenzene, 5g of sodium hydroxide, and 1g of tetraethylammonium bromide in a 500ml four-necked bottle equipped with a stirrer, a thermometer, and a condenser tube. Put 10g of allyl chloride into the pear-shaped addition funnel, heat the solution to 70°C, add allyl chloride dropwise, and keep the reaction solution alkaline during the reaction. If the pH value is less than 8, NaOH can be added appropriately, and the reaction time is 8 After cooling for one hour, white crystals were obtained, which were centrifuged and dried to obtain the product tetrabromobisphenol S diallyl ether with a melting point of 184° C. and a yield of 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com