Light guide plate full-automatic numerical control polishing apparatus

A light guide plate, fully automatic technology, applied in the direction of grinding/polishing equipment, grinding automatic control device, metal processing equipment, etc., can solve the problems of small dust collection area, affecting product quality, easy deviation of light guide plate, etc., to achieve Improve the final accuracy, improve efficiency, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

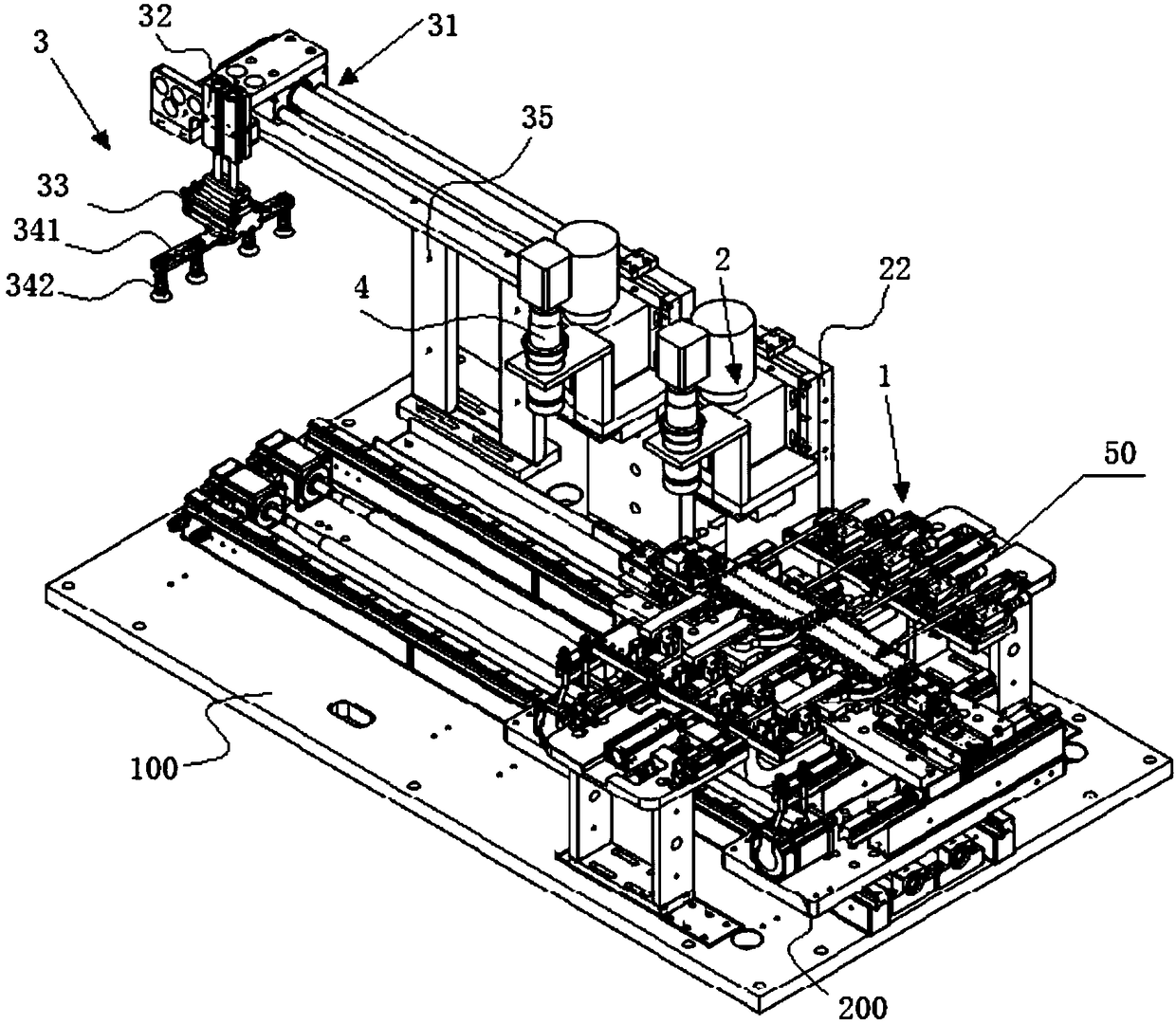

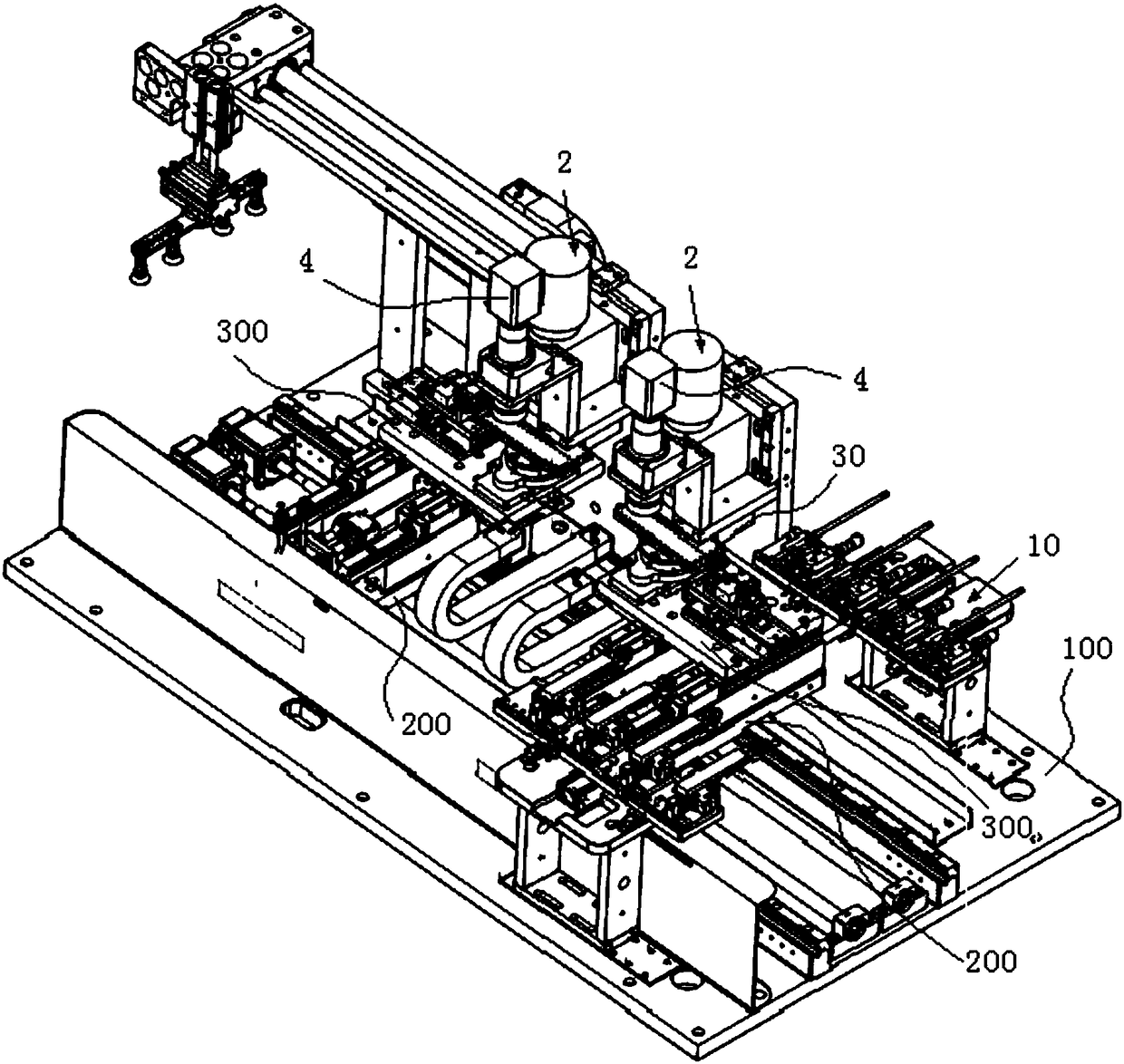

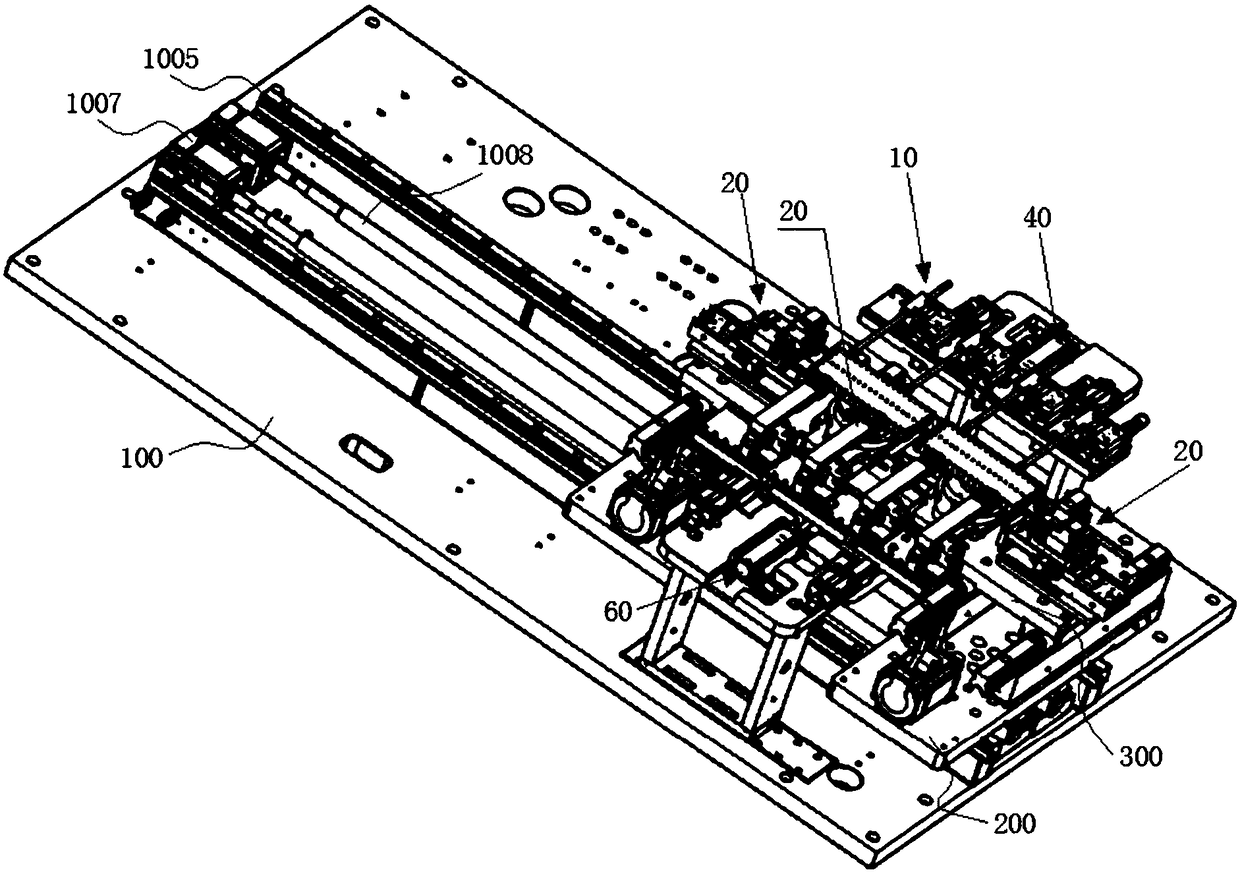

[0060] Embodiment: a kind of light guide plate automatic numerical control polishing equipment, such as Figure 1 to Figure 18 As shown, it includes a workbench and a positioning device 1 located on the workbench, a polishing device 2 and a retrieving device 3, and the retrieving device is located downstream of the polishing device; the workbench is equipped with at least one for The rotating platform 50 that fixes the light guide plate is connected with a rotating drive mechanism that drives the rotating platform to rotate horizontally, and the workbench is also equipped with an X-axis drive that can drive the rotating platform to reciprocate and translate along the X-axis direction. mechanism and a Y-axis drive mechanism capable of driving the rotating platform to reciprocate and translate along the Y-axis direction;

[0061]The polishing equipment is also provided with a control system, and the positioning device, the polishing device, the retrieving device, the rotation dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com