Shaft assembly for lithium battery material production and combination method thereof

A technology of lithium battery materials and shaft components, which is applied in the direction of couplings, conveyor objects, rigid shaft couplings, etc., can solve the problem that metal materials cannot meet production needs well and affect the quality of lithium battery raw material sintering, equipment Cost rises and other issues, to avoid processing, save production costs, and ensure the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

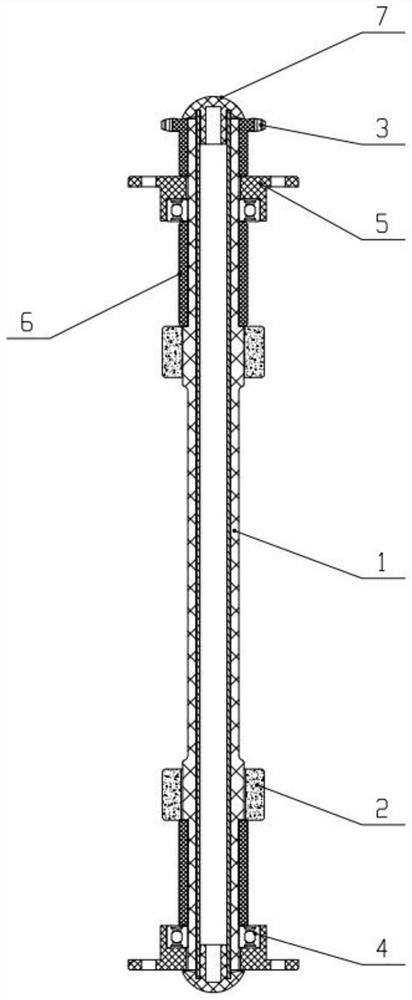

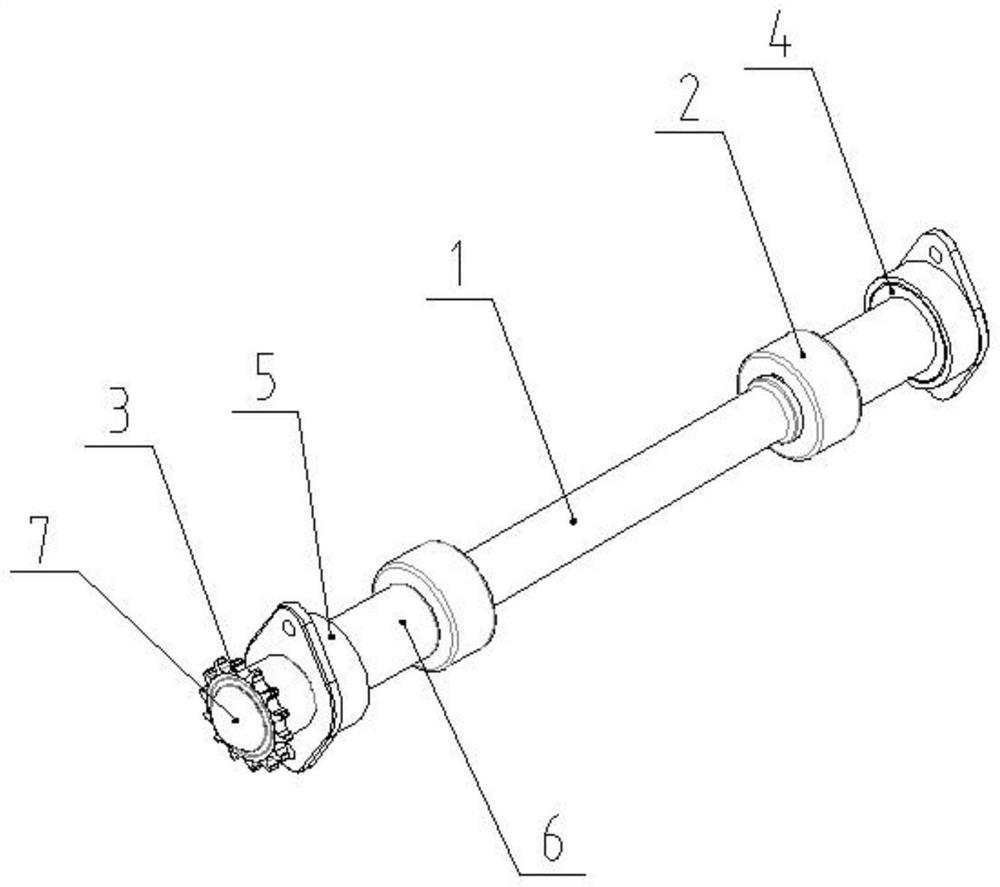

[0018] Attached below Figure 1-4 The technical scheme of the present invention will be further described.

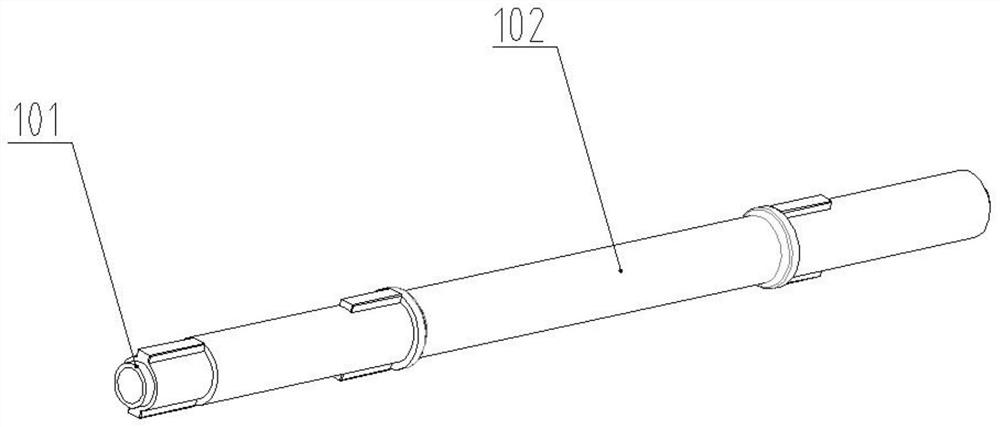

[0019] As shown in the figure, a shaft assembly for lithium battery material production includes a transmission shaft 1 for transporting lithium battery production materials. The transmission shaft 1 includes a hollow support shaft 101 and a cladding layer 102 wrapped on the outer surface of the support shaft.

[0020] The cladding layer 102 contains 20%-50% high temperature resistant polyamide and 10%-40% glass fiber.

[0021] The transmission shaft 1 is sheathed with two rollers 2, which are used for direct contact with the transported items and transmission of power.

[0022] One end of the transmission shaft 1 is covered with a transmission wheel 3 that drives the overall movement of the transmission shaft 1 , a bearing 4 is arranged between the transmission wheel 3 and the roller 2 , and a bearing seat 5 cooperating with it is provided outside the bearing 4 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com