Ring crane corbel for nuclear power station and manufacturing method thereof

A manufacturing method and technology for nuclear power plants, which are applied to load hanging components, supporting structures, buildings, etc., can solve the problems of large welding workload, easy cracking of welds, large welding stress and welding deformation, etc., and achieve weld quality. Control, ensure the final quality, the effect of welding deformation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

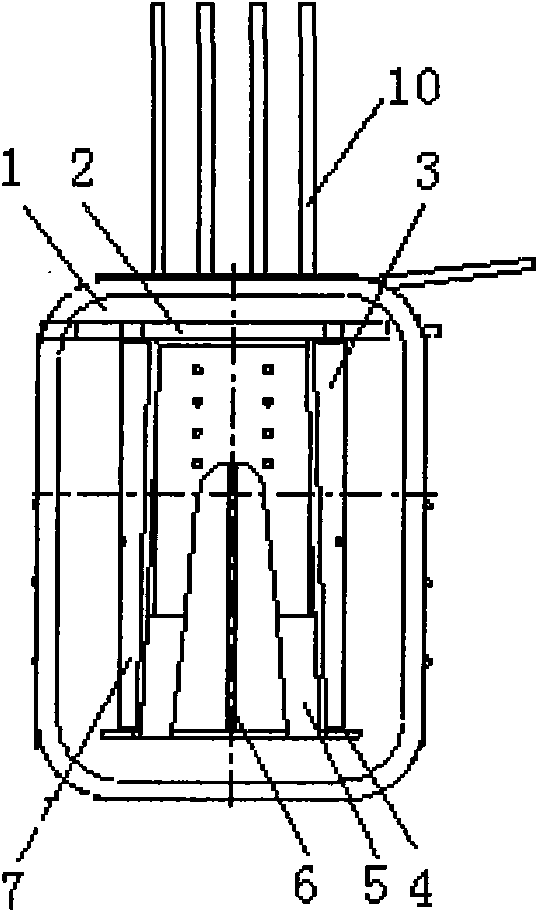

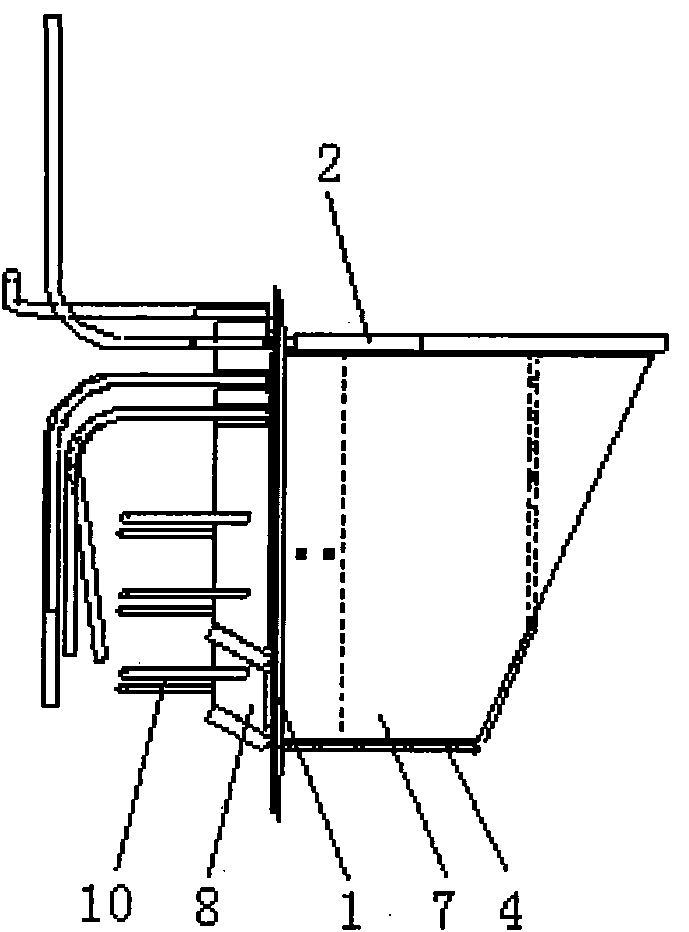

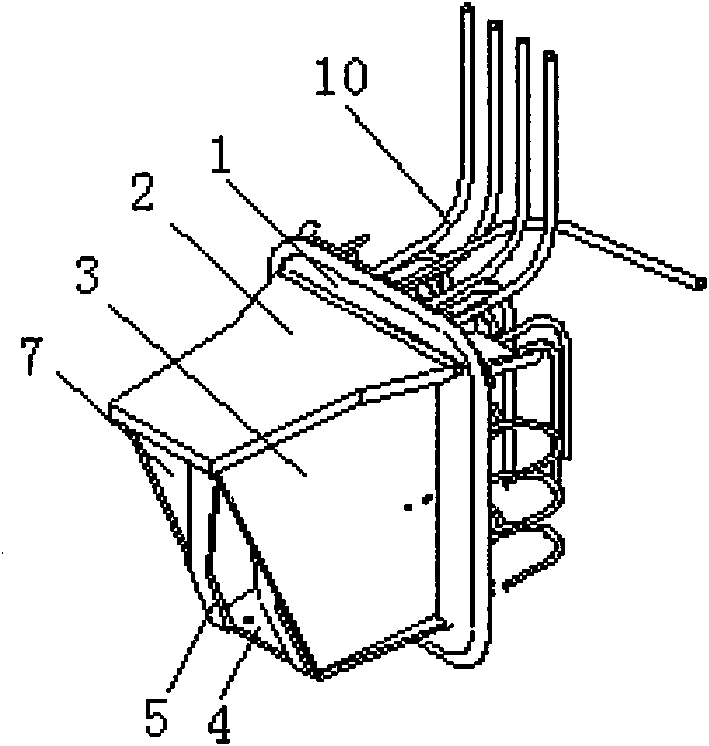

[0025] The basic structure of a ring-hanging corbel of a nuclear power plant in this embodiment is as follows: Figure 1 to Figure 4 As shown, the box frame body comprises rectangular thickened body panels 1 . One side of the main body plate 1 is adjacent to the upper and lower edges, and the upper cover plate 2 and the lower cover plate 4 perpendicular thereto are respectively welded and fixed, wherein the upper cover plate 2 is longer than the lower cover plate 4 . The trapezoidal left and right side plates 7 and 3 and the rectangular middle rib 6 are welded between the upper and lower cover plates, and the edges of the left and right side plates and the middle rib plate adjacent to the main body plate 1 are fully welded to the main body plate . The two ends of the side of the lower cover plate 4 away from the main body plate are welded to the two bottom edges of the door-shaped external baffle plate 5. After being folded, it is perpendicular to the upper cover plate 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com