Method for detecting position of leakage point of underground concrete continuous wall

A detection method and technology of leakage point, which can solve the problem of incomplete detection of the leakage point position of the diaphragm wall by detecting the appearance of fluid at the leakage point, protection device, buoy liquid level indicator, etc., and achieve improved sealing performance, ensuring comprehensiveness, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

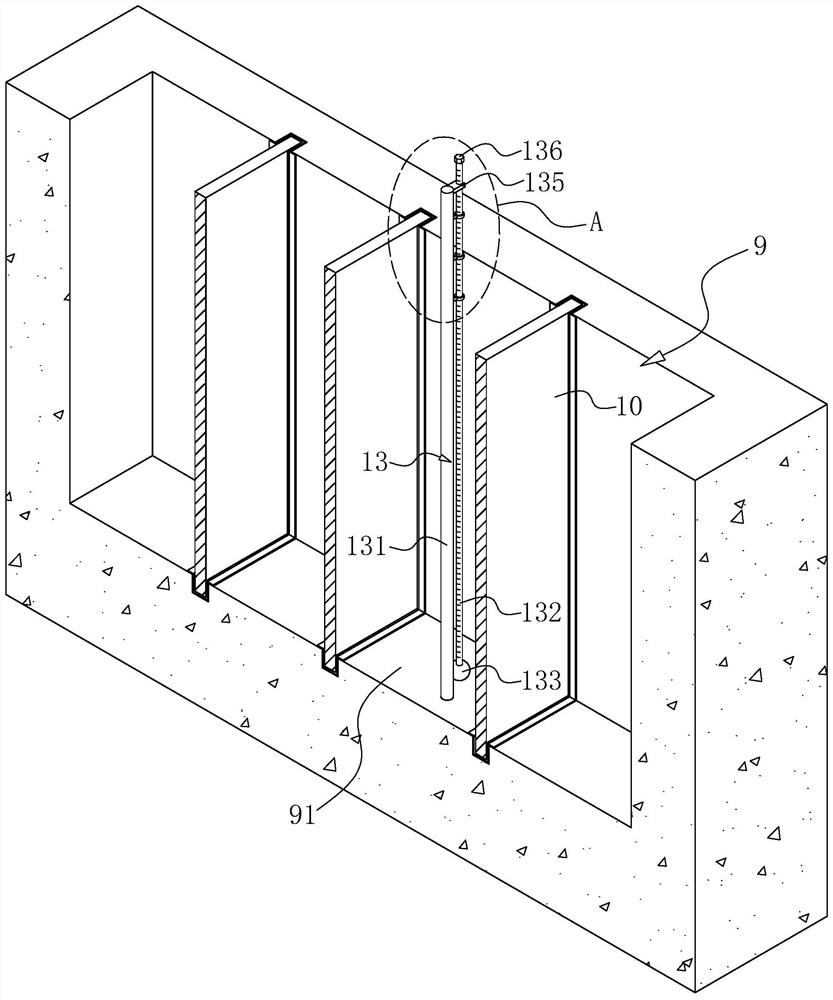

[0044] The following is attached Figure 1-4 The application is described in further detail.

[0045] The embodiment of the present application discloses a method for detecting the position of a leakage point of an underground concrete continuous wall.

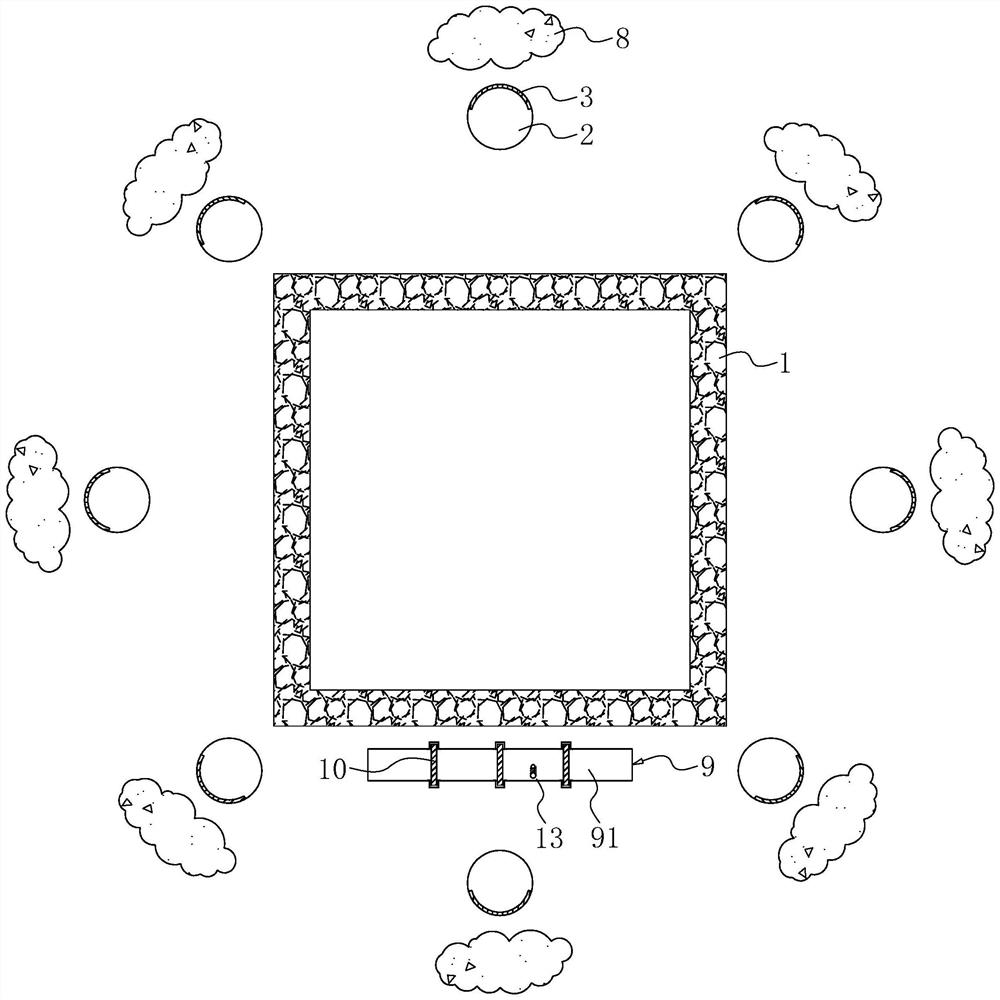

[0046] refer to figure 1 , a method for detecting the location of a leak point in an underground concrete diaphragm wall, comprising the following steps:

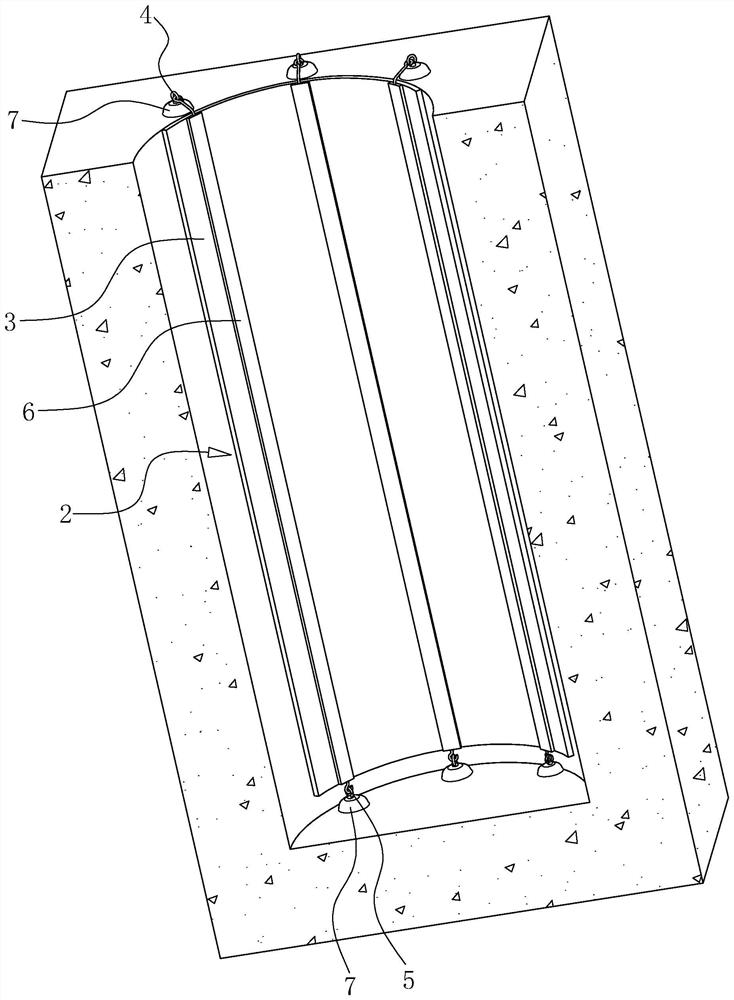

[0047] Step S1: Dig some preliminary survey wells 2 at equal intervals on the periphery of the diaphragm wall 1, and then lay a layer of waterproof coiled material 3 on the inner wall of these preliminary survey wells 2 facing away from the diaphragm wall 1, and then lay a layer of waterproof coiled material 3 in the initial survey wells 2. Inject polyurethane 8 into the periphery of the side facing away from the diaphragm wall 1 to seal the water source for a short time, then pour water into these initial survey wells 2, and mark the highest water level;

[0048] Step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com