Method for processing magic cube box

A Rubik's Cube and carton technology, which is applied in box making operations, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc. It can solve the problems of overlapping surfaces, difficulty in wrapping paper, and uneven surfaces, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

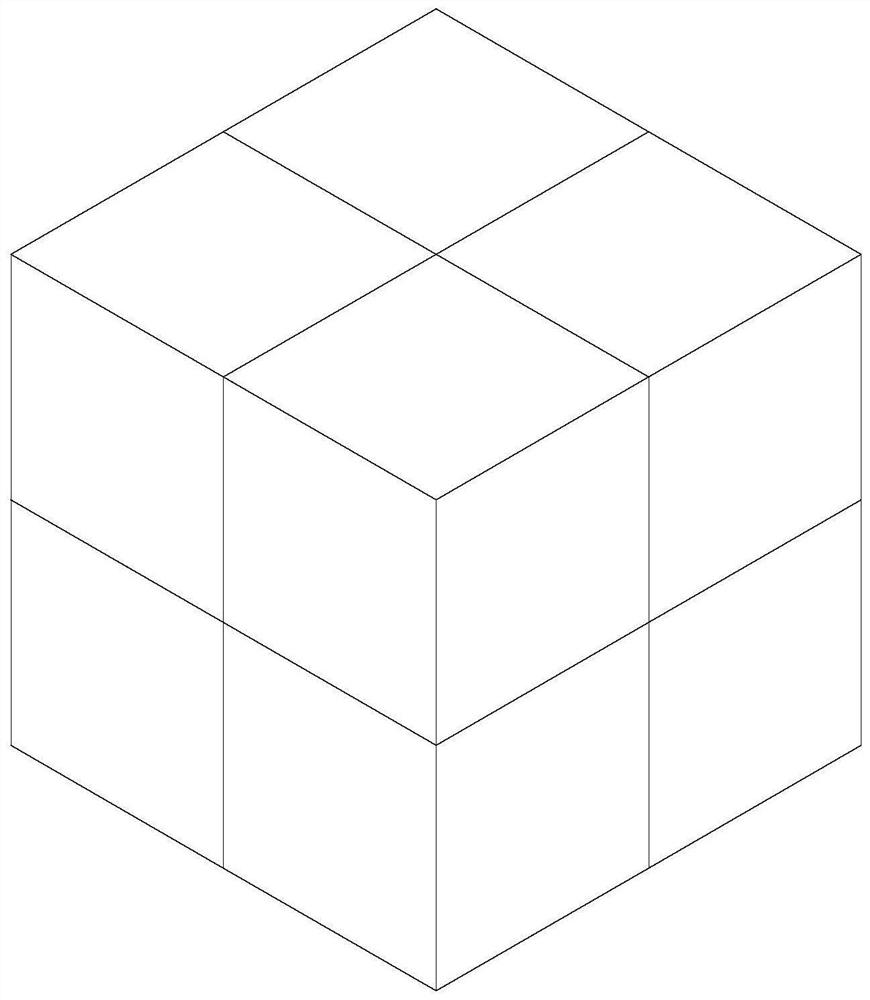

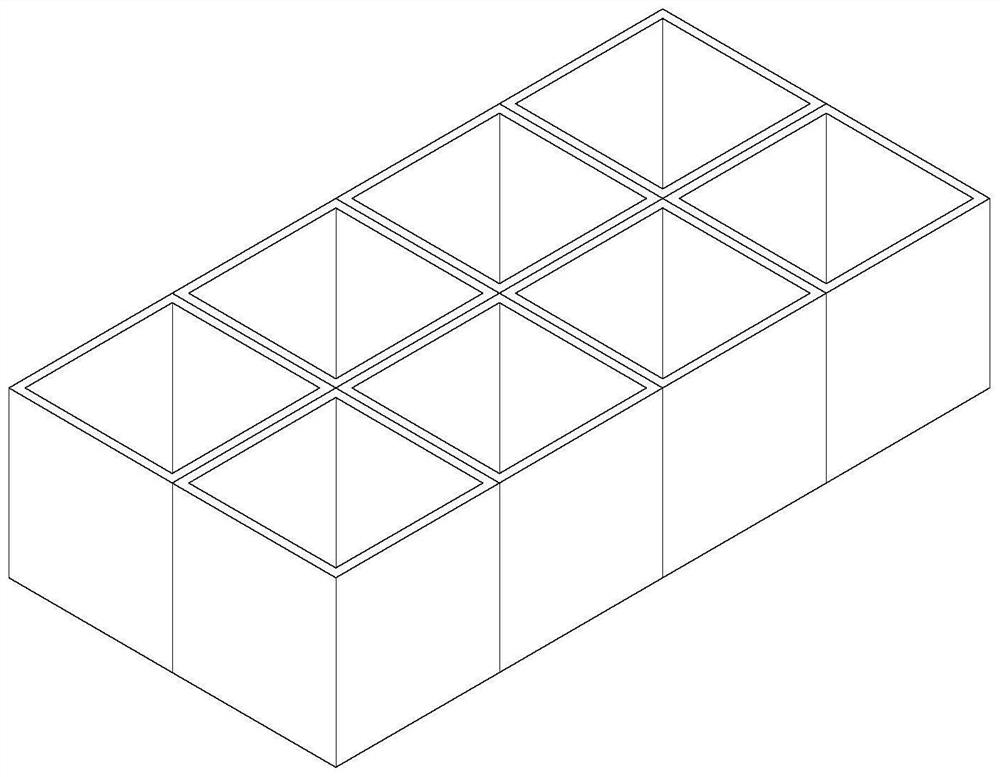

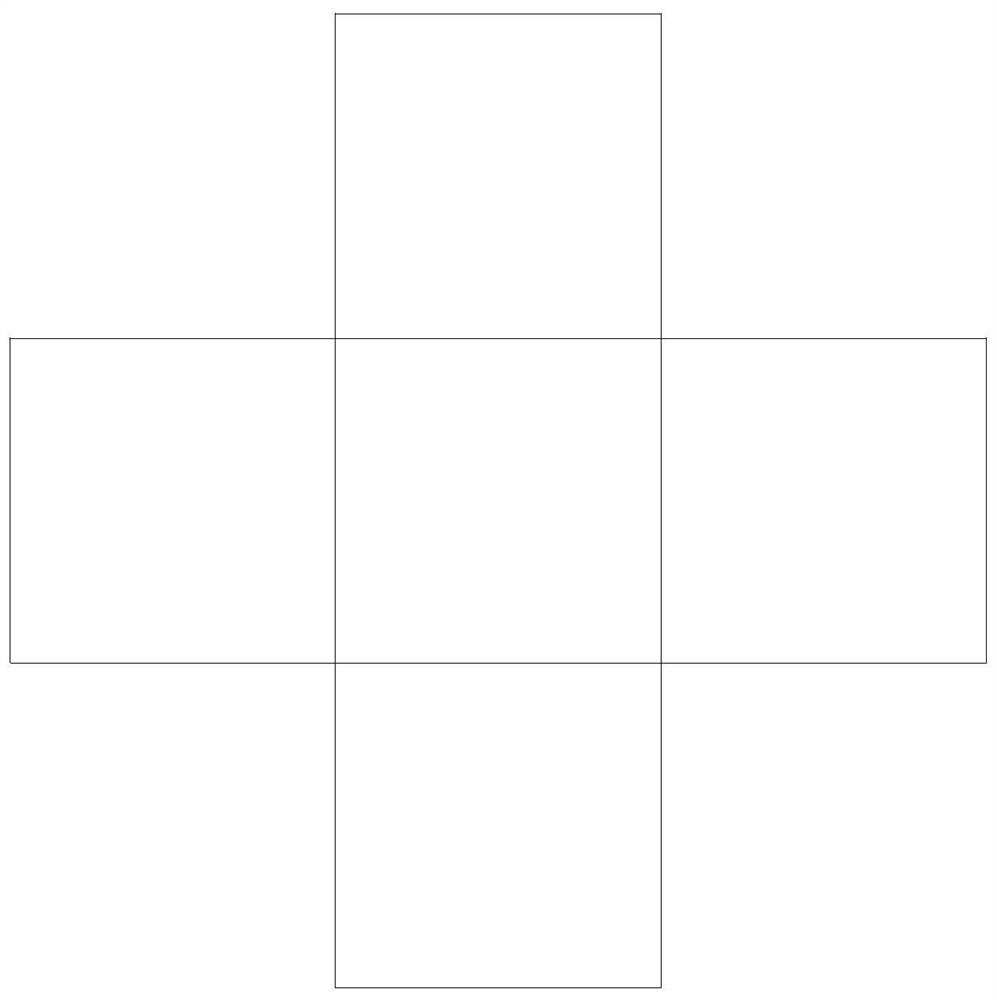

[0041] Such as Figure 1-20 Shown, a kind of method that is used for Rubik's Cube box processing, process steps are as follows:

[0042] (1) Cutting: Use carton cutting equipment to cut gray boards and various wrapping papers used to decorate gray boards;

[0043] (2) Pressing line: Use a slotting machine to roll the required slot line according to the pattern required by the product design, and die-cut the half-through depth on the cut gray board and packaging paper, so that the carton can be subsequently bent according to the predetermined position ;

[0044] (3) Pretreatment: Fold the gray board into a box shape through the magic cube packaging device, and paste the packaging paper used to decorate the outer wall of the box on the gray board to fix the gray box to form a structurally stable inner box;

[0045] (4) Complete packaging: add bottom wrapping paper and inner wrapping paper for the fixed inner box;

[0046] (5) Arrangement: Arrange the packaged inner box indivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com