Large-scale hollowed-out embossed hollow stone column construction method

A construction method and technology of stone pillars, applied in the field of stone processing, can solve the problems that small and medium-sized stone carving crafts cannot meet its requirements, and achieve the effects of easy assembly, good earthquake resistance and typhoon resistance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

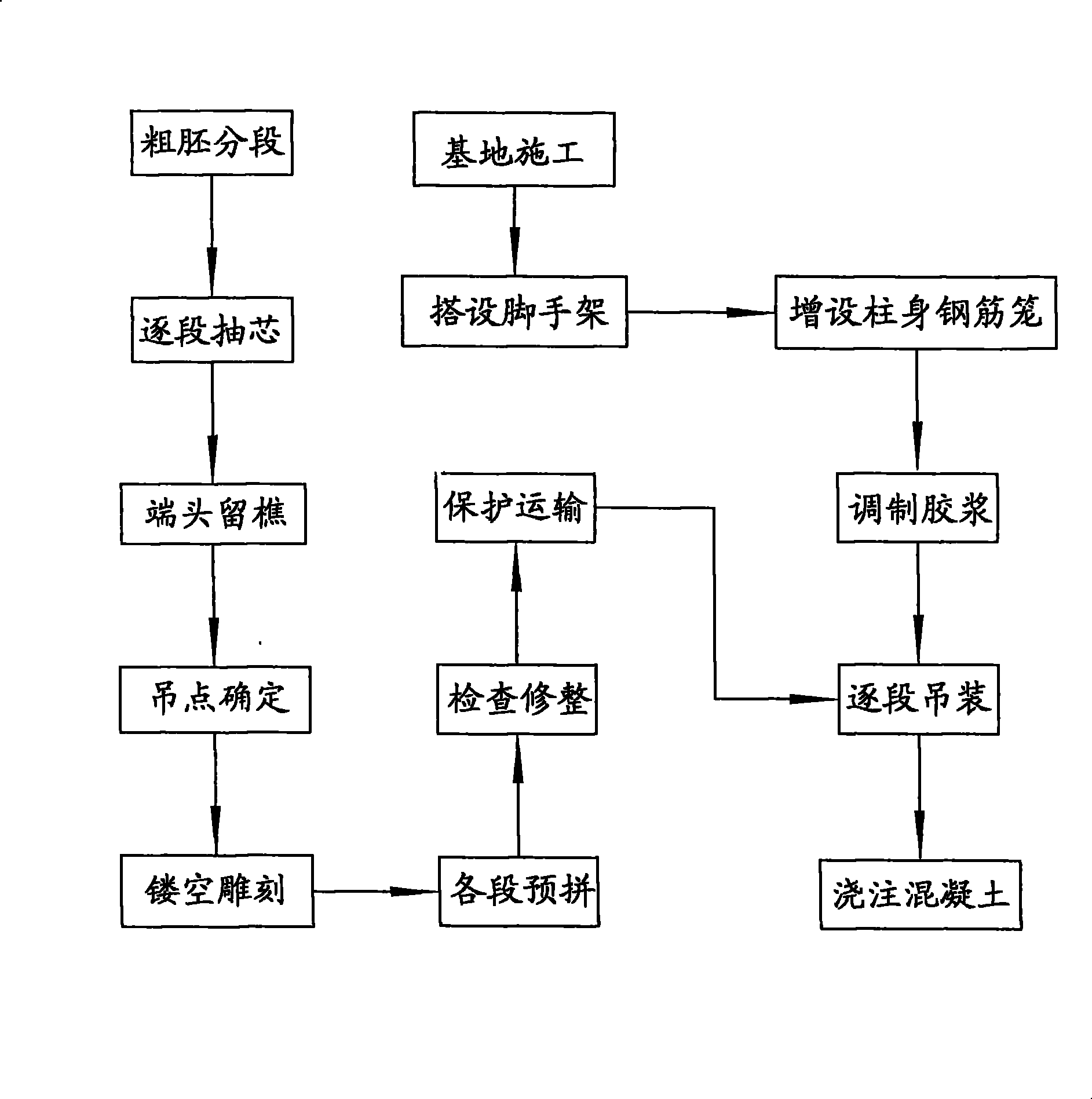

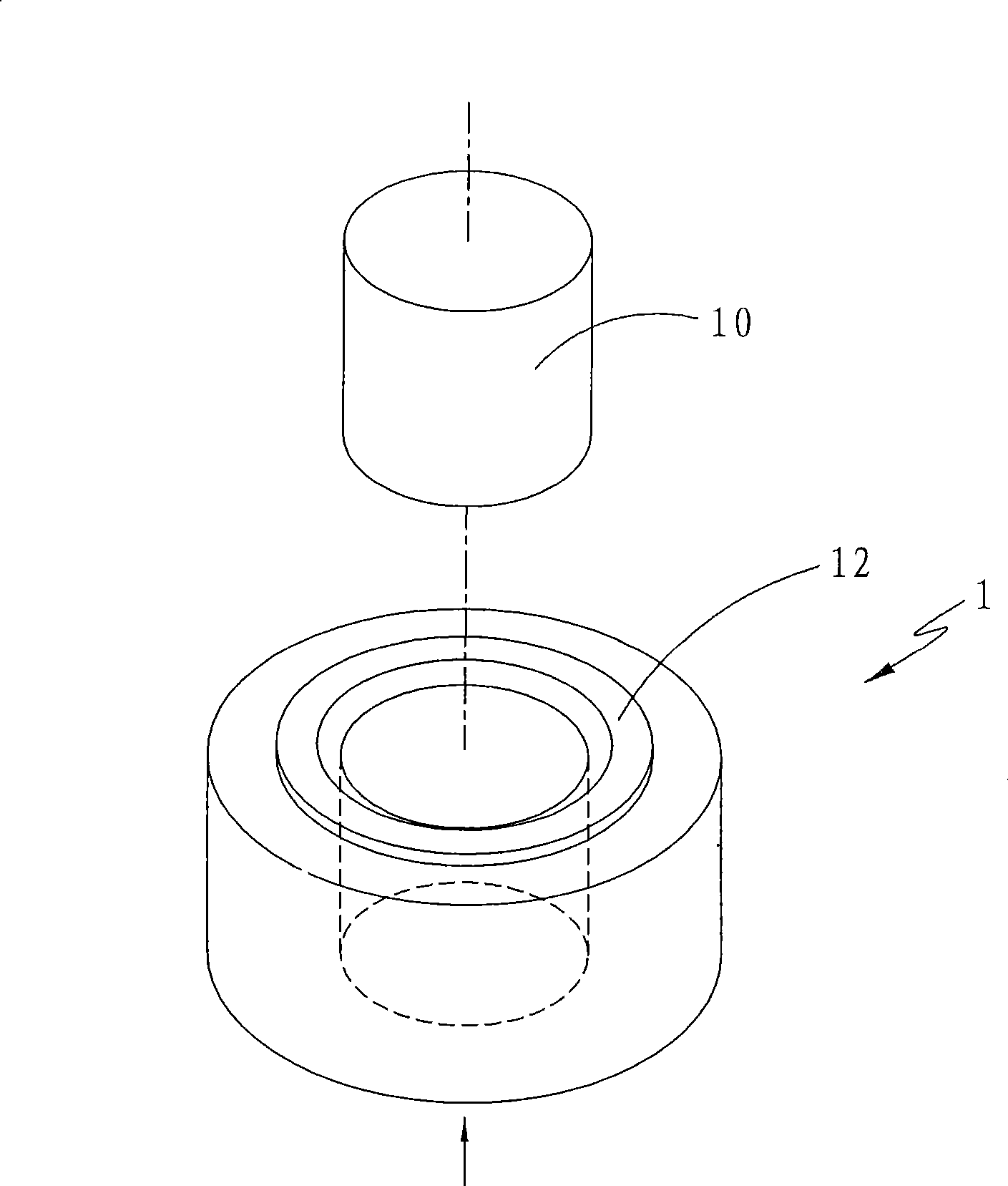

[0031] Such as figure 1 refer to Figure 4 As shown, the invention discloses a construction method of a large-scale hollow relief hollow stone column, which comprises the following steps:

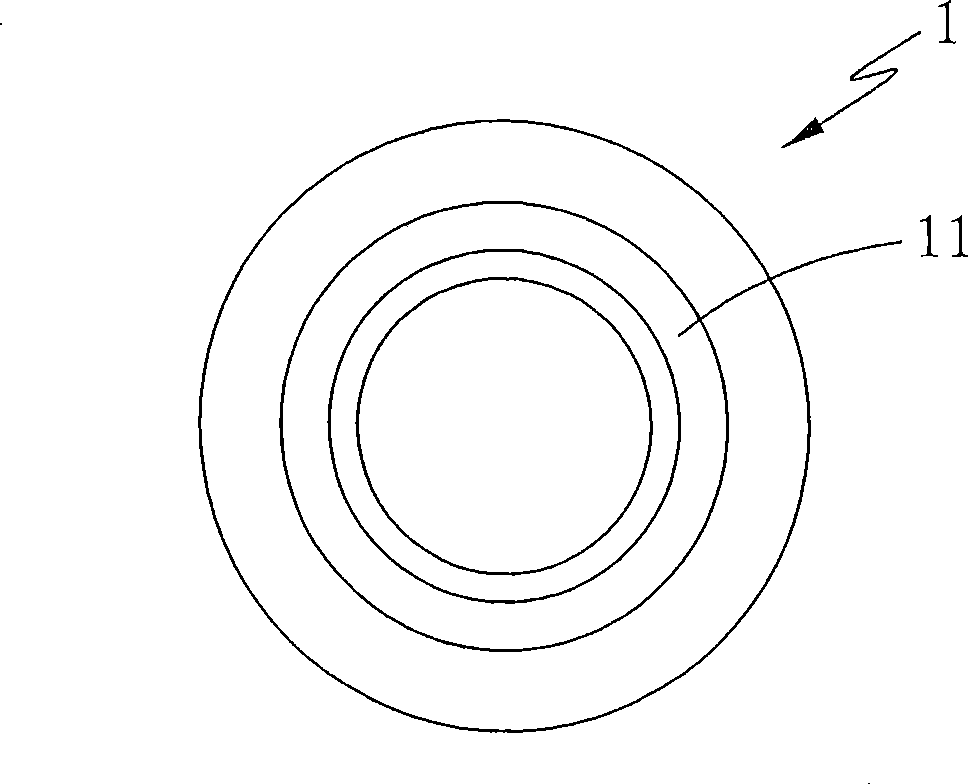

[0032] (1) Segmentation of rough embryos: Since the large stone pillar 1 has its own characteristics of large length, volume and weight, its manufacturing method is different from the overall molding method used for small and medium-sized stone pillars. Computer typesetting is required to divide the large stone pillar 1 into several parts. Sections are processed and manufactured separately with each section of the stone pillar 1 as a unit. The determination of the section length mainly considers the operability of the large stone column 1 in the transportation and hoisting links, especially the influence of factors such as the layout of the lifting points and the lifting load. length) is controlled between 1.0m and 2.0m, and the section length decreases with the increase of the outer dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com