Method for manufacturing hollowed-out embossed hollow stone column through computer

A computer and embossing technology, which is applied in the field of making hollowed-out embossed hollow stone pillars by computer, can solve problems such as not being able to meet its requirements, and achieve the effects of easy assembly, strong pertinence, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

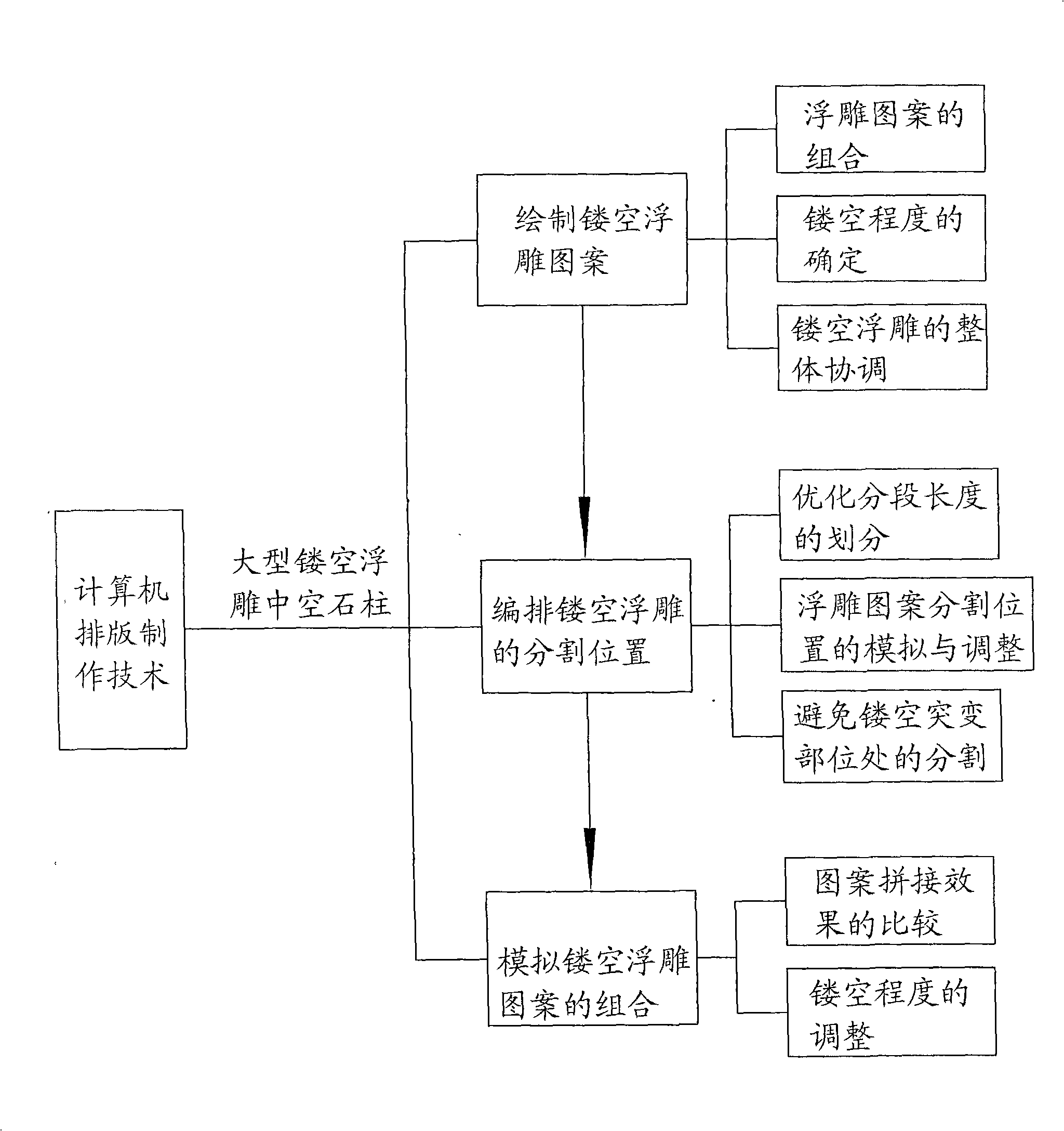

[0010] Such as figure 1 Shown, the present invention is a kind of method utilizing computer to make hollow relief hollow stone column, and it comprises the following steps:

[0011] 1. The computer draws hollow relief patterns. (1) The overall coordination of hollow relief. Using computer simulation technology, it can simulate the three-dimensional overall effect of large-scale hollow relief stone pillars, and can also express the depth of stone carving hollowing out. (2) Determination of the degree of hollowing out. The degree of hollowing out of the relief pattern can be simulated by computer, which can not only further optimize the hollowing pattern before the engraving operation, but also ensure the quality of the hollowing out of the relief; (3) combination of relief patterns. The three-dimensional effect of the large stone pillar hollow relief is simulated by computer, which provides an intuitive reference for the overall coordination of the hollow relief, and is bene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com