Tempered glass cooling device

A cooling device and a technology for tempered glass, which are applied in glass tempering, glass transportation equipment, glass manufacturing equipment, etc., can solve the problems of insufficient high-pressure cold air, insufficient cooling, waste of high-pressure cold air, etc., to reduce the waste of cold air, The effect of increasing the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

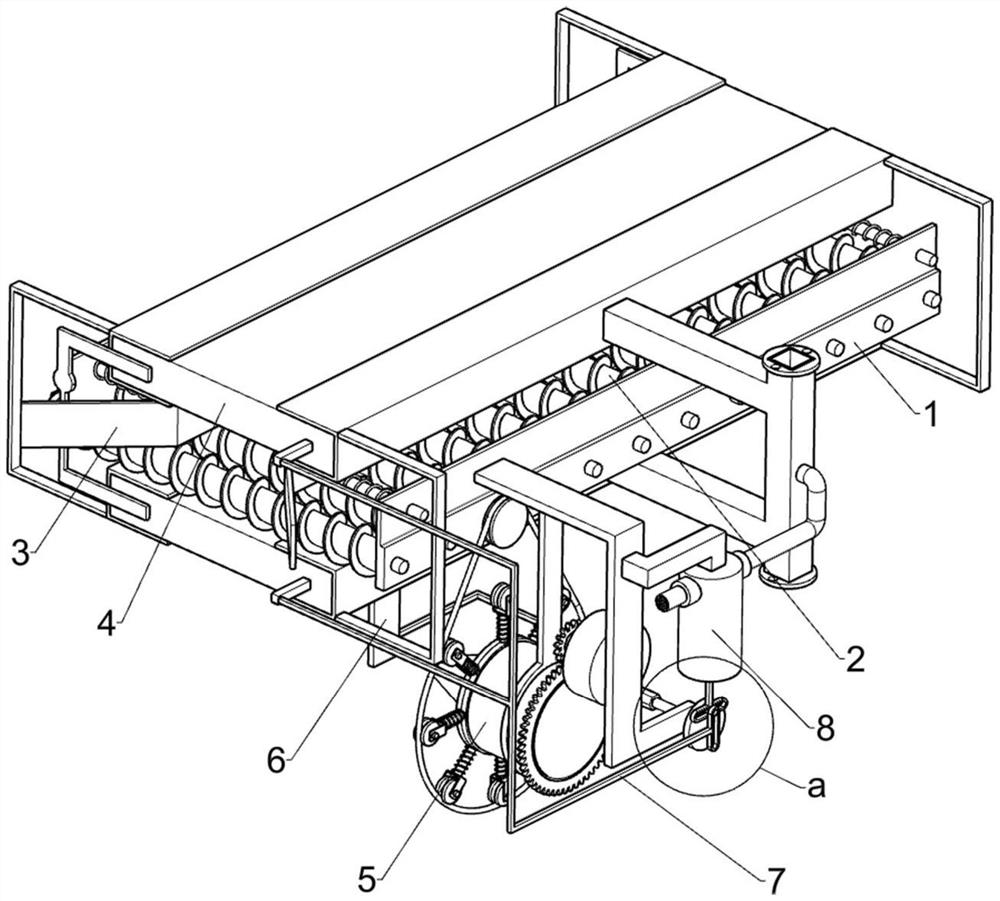

[0031] A tempered glass cooling device, such as Figure 1-9 As shown, it includes a long mounting plate 1, a conveying part 2, a glass width detecting part 3, an exhaust part 4, a driving speed adjusting part 5 and an adjusting part 6, the long mounting plate 1 is provided with a conveying part 2, and the conveying part The function of 2 is to transport the glass. The conveying part 2 is provided with a glass width detection part 3 and an exhaust part 4. The glass width detection part 3 can control the displacement of cooling air according to the width of the glass, and the exhaust part 4 can discharge The cold air cools the glass, the glass width detection part 3 is connected with the exhaust part 4, the long mounting plate 1 is provided with a driving speed adjusting part 5, and the driving speed adjusting part 5 can adjust the conveying speed of the glass according to the width of the glass. For adjustment, the driving speed adjusting member 5 is connected to the conveying ...

Embodiment 2

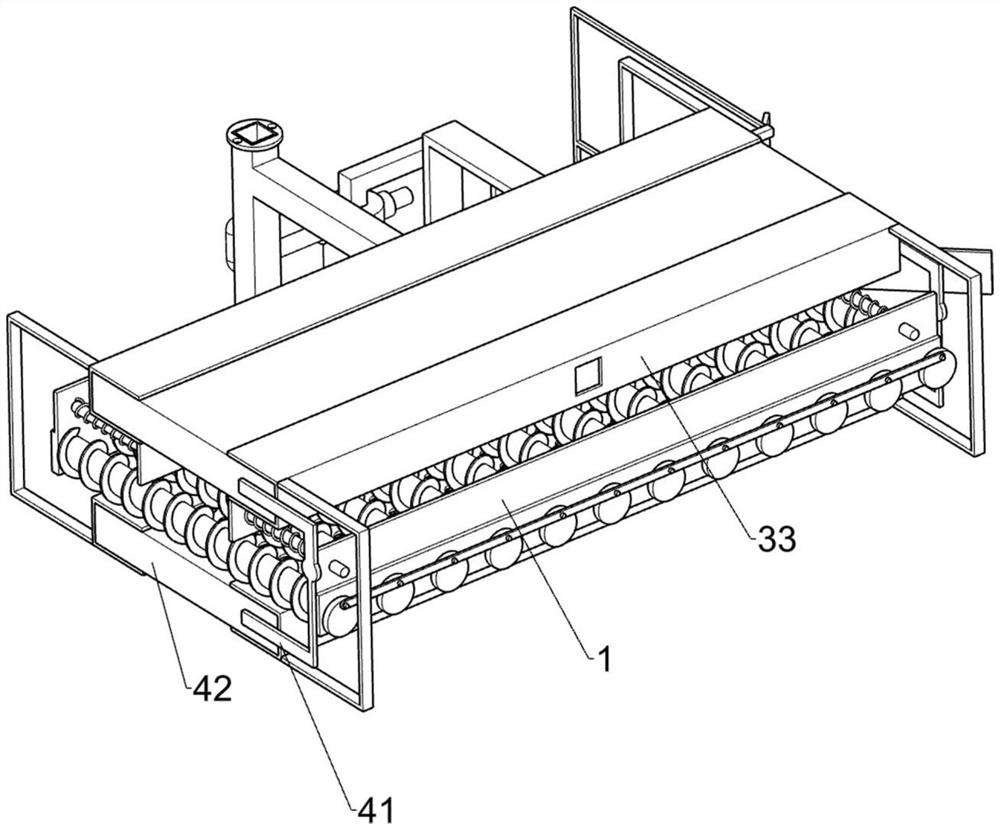

[0033] On the basis of Example 1, as Figure 1-9 As shown, the conveying member 2 includes a conveying roller 21, a rotating disc 22 and a connecting rod 23. A plurality of conveying rollers 21 are rotatably mounted on the long mounting plate 1. The conveying roller 21 can transmit the glass. One end of the conveying roller 21 Several rotating disks 22 are fixedly installed, and connecting rods 23 are rotatably connected to the rotating disks 22 .

[0034]The glass width detection component 3 includes an inclined surface driven plate 31, a compression spring 32, a limit frame 33 and a U-shaped link 34. Two inclined surface driven plates 31 are slidably mounted on the two long mounting plates 1 and are symmetrical Installation, a compression spring 32 is connected between the inclined surface driven plate 31 and the long installation plate 1, a limit frame 33 is fixedly installed on the inclined surface driven plate 31, and a U-shaped connecting rod 34 is welded on one side of ...

Embodiment 3

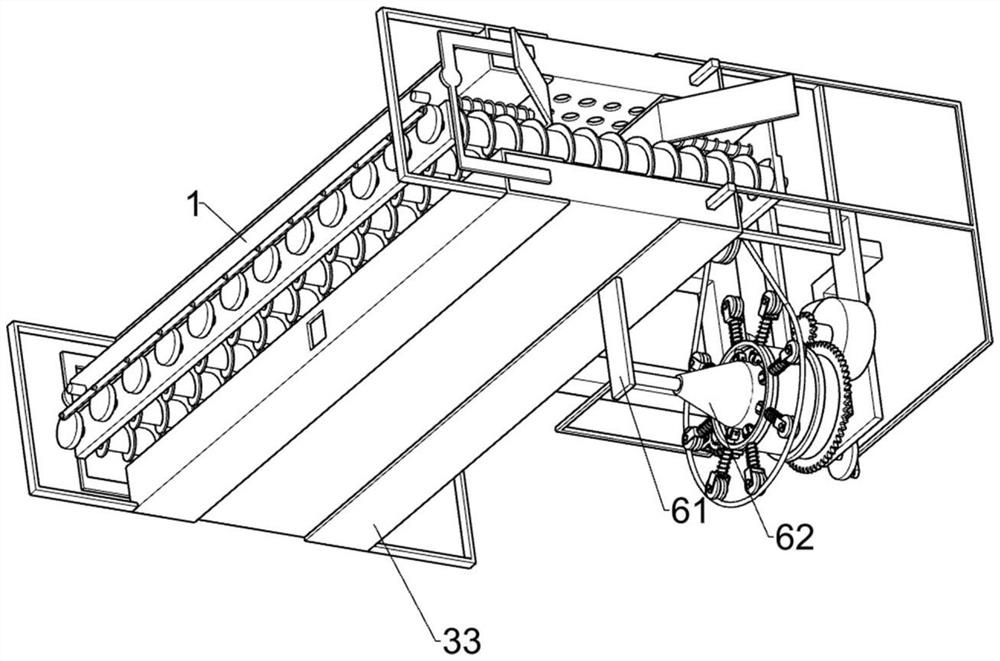

[0037] On the basis of Example 2, as Figure 1-9 As shown, the drive speed adjusting part 5 includes an L-shaped support plate 51, a servo motor 52, a drive gear 53, a support strip 54, a rotating frame 55, a ring gear 56, a fixed ring 57, a movable strut 58 with a pulley, and a return spring 59. Friction support wheel 510, pulley 511 and elastic belt 512, L-shaped support plate 51 is fixedly installed on the long mounting plate 1, servo motor 52 is fixedly installed on the L-shaped support plate 51, and the output shaft of the servo motor 52 is fixed on A drive gear 53 is installed, a support strip 54 is fixedly installed on the L-shaped support plate 51, a rotating frame 55 is rotatably installed on the support strip 54, and a ring gear is fixedly installed on the end of the rotating frame 55 away from the long mounting plate 1 56. The driving gear 53 is located above the ring gear 56, and the ring gear 56 meshes with the driving gear 53. The rotation of the driving gear 53 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com