Superimposed integral type prefabricated shear wall edge component and mounting method

An edge member, prefabricated shear force technology, applied to building components, walls, structural elements, etc., can solve the problem of inconvenient installation of prefabricated beams and stacked prefabricated wall components, high selection of on-site hoisting machinery, and high component sleeve prices. It can achieve the effect of safe and reliable connection method, convenient installation method, and reduce woodworking workload and operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

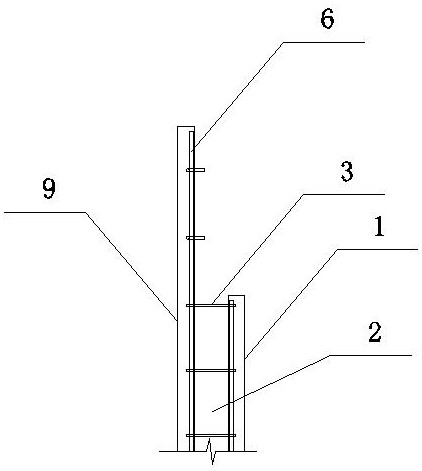

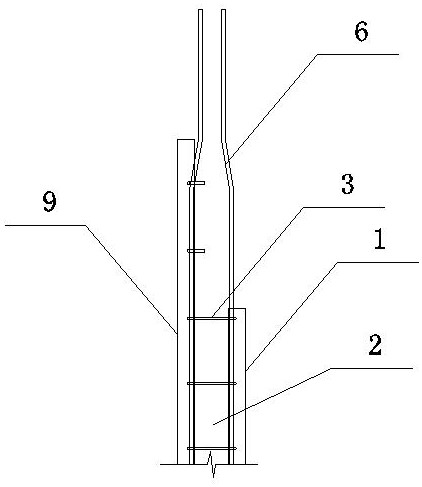

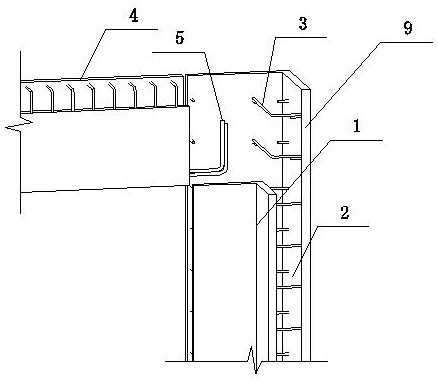

[0048] A composite integral prefabricated shear wall edge member, the edge member is composed of a back concrete sheet 9 and at least one face concrete sheet 1, the back concrete sheet and the face concrete sheet are between and adjacent The two face concrete thin slabs are all connected by reinforcement skeleton or truss reinforcement;

[0049] There is a pouring cavity 2 between the back concrete sheet and the face concrete sheet and between two adjacent face concrete sheets.

Embodiment 2

[0051] According to the composite integral prefabricated shear wall edge member described in Embodiment 1, the steel skeleton is composed of stirrups 3 , tie bars 10 and longitudinal steel bars 6 .

[0052] The longitudinal reinforcement of the edge member is arranged in the concrete thin slab or the upper end of the longitudinal reinforcement protrudes from the top of the concrete thin slab.

Embodiment 3

[0054] According to the laminated integral prefabricated shear wall edge member described in embodiment 1 or 2, the truss reinforcement is composed of a plurality of truss reinforcement main reinforcement 7 and truss reinforcement web reinforcement 8 arranged in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com