Joint production method of electrolytic copper-aluminium alloy and refined aluminium

A joint production, copper-aluminum alloy technology, which is applied in the technical field of combining the electrolytic production of aluminum-copper alloy and the refined aluminum smelting production process, can solve the problems of non-existent production process methods, avoid production risks, improve current efficiency, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

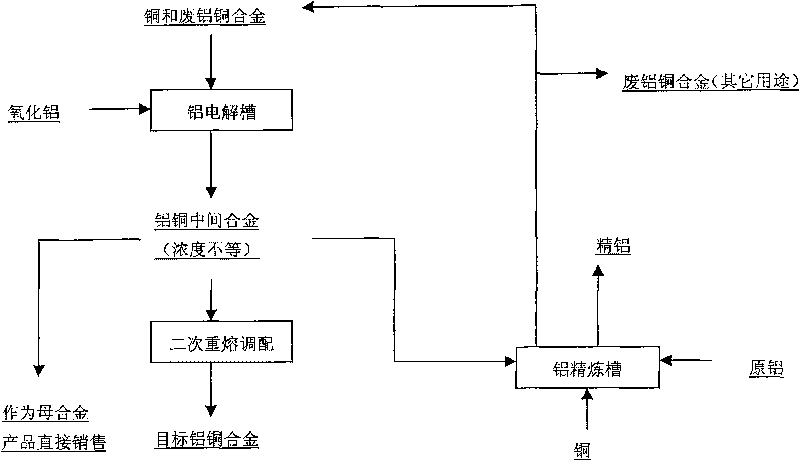

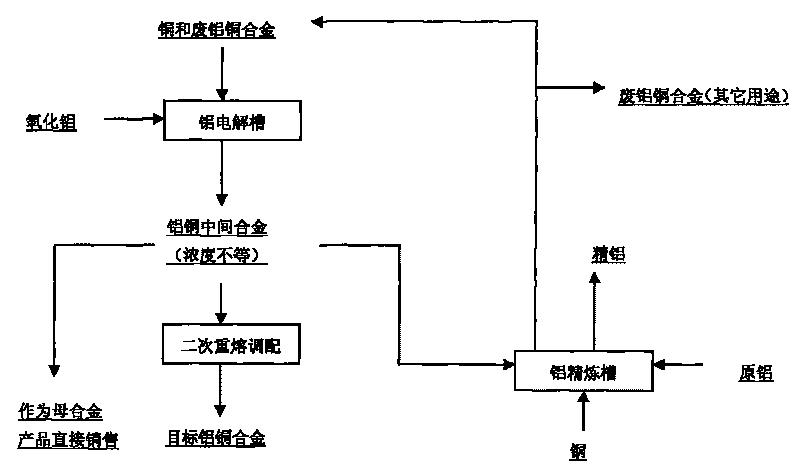

Image

Examples

Embodiment 1

[0026] The original production uses 160KA electrolytic cell, the voltage fluctuation range is 3.95~4.2V, the average cell voltage is 4.05V; the cathode current density is controlled at 0.65~0.75A / cm 2 , the fluctuation range of cathode current efficiency is 86% to 92%, the average current efficiency is 90.2%, the DC power consumption per ton of aluminum reaches 13240kW·h, and the product is primary aluminum.

[0027] Add 2% copper or waste aluminum-copper alloy (calculated by copper weight) in the cathode aluminum solution. After the production is stable, the cathode current density is maintained at 0.65-0.75A / cm 2 , the single cell voltage drops to 3.9-4.1V, the average cell voltage is 4.02V, the instantaneous current efficiency is increased to 95%, the fluctuation range is 88-93%, the average current efficiency is 90.8%, and the DC power consumption per ton of aluminum is reduced to 13200kW·h, the product is 2% aluminum-copper master alloy. The 2% aluminum-copper alloy pro...

Embodiment 2

[0029] The original production uses 160KA electrolytic cell, the voltage fluctuation range is 3.95~4.3V, the average cell voltage is 4.10V; the cathode current density is controlled at 0.65~0.75A / cm 2 , the fluctuation range of cathode current efficiency is 88% to 94%, the average current efficiency is 91.2%, the DC power consumption per ton of aluminum reaches 13400kW·h, and the product is primary aluminum.

[0030] The embodiment is as follows: about 5% of the total weight of copper or waste aluminum-copper alloy (calculated by copper weight) is added to the cathode aluminum liquid. After the production is stable, the cathode current density is maintained at 0.65-0.75A / cm 2 , the single cell voltage drops to 3.7-4.1V, the average cell voltage is 3.90V, the instantaneous current efficiency increases to 95%, the fluctuation range is 90-95%, the average current efficiency is 92.8%, and the DC power consumption per ton of aluminum drops to 12700kW·h, the product is 5% aluminum-...

Embodiment 3

[0032] The original production uses 160KA electrolytic cell, the voltage fluctuation range is 4.05~4.5V, the average cell voltage is 4.15V; the cathode current density is controlled at 0.65~0.75A / cm 2 , the fluctuation range of cathode current efficiency is 90% to 95%, the average current efficiency is 91.8%, the DC power consumption per ton of aluminum reaches 13560kW·h, and the product is primary aluminum.

[0033] The embodiment is as follows: about 10% of total weight of copper or waste aluminum-copper alloy (calculated by copper weight) is added to the cathode aluminum liquid. After the production is stable, the cathode current density is maintained at 0.65-0.75A / cm 2 , the single cell voltage drops to 3.7-4.2V, the average cell voltage is 3.95V, the instantaneous current efficiency increases to 96.7%, the fluctuation range is 91-97%, the average current efficiency is 93.7%, and the DC power consumption per ton of aluminum drops to 12550kW·h, the product is 10% aluminum-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com