Device of drill front shaft master pin hole

A king pin hole and pre-drilling technology, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of increasing the burden on small batch trial production enterprises, high labor intensity of operators, long adjustment and processing cycle, etc., to achieve accurate and fast dimensions, The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

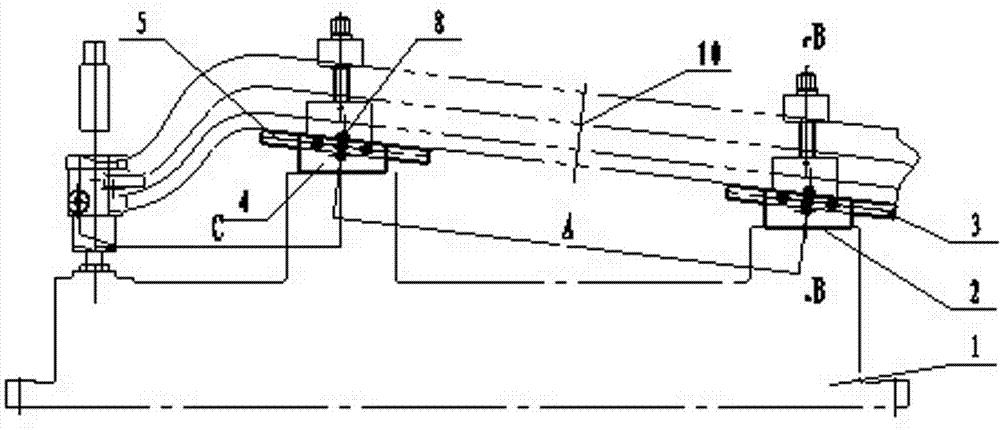

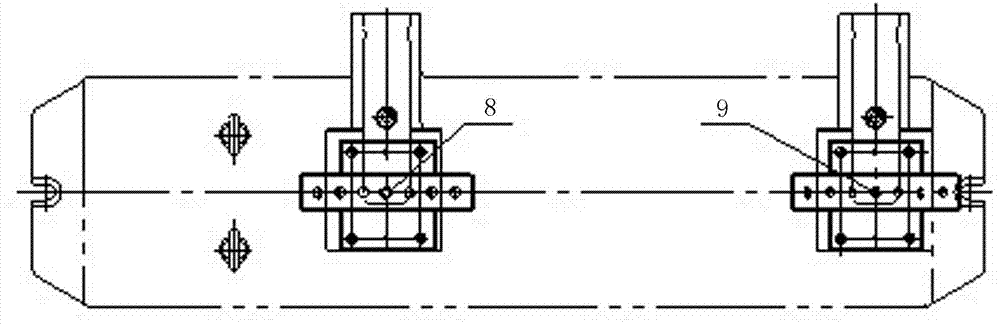

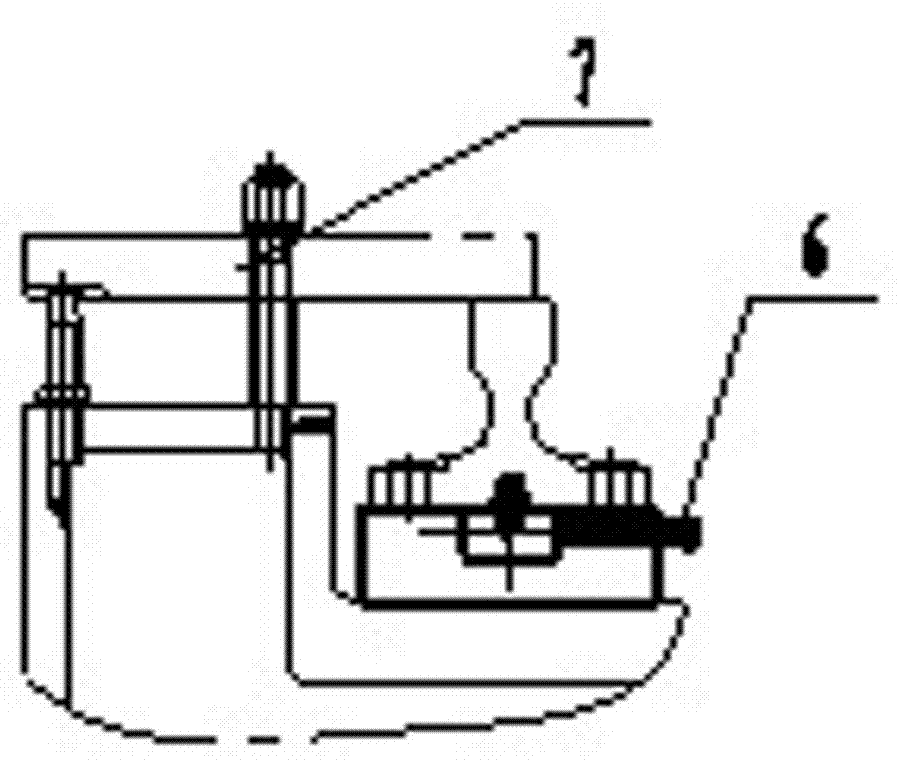

[0012] A device for drilling the kingpin hole of the front axle, such as figure 1 , figure 2 , image 3 As shown, the device includes a clamp body 1, a rear backing plate 2, a rear slide plate 3, a front backing plate 4, a front slide plate 5, a compression screw 6, a clamping device 7, a cylindrical pin 8 and a diamond pin 9, and on the clamp body 1 A rear backing plate 2, a front backing plate 4, and a clamping device 7 are provided. The back slide plate 3 is arranged on the back backing plate 2. The rear slide plate 3 is provided with a rhombus pin 9. The front slide plate 5 is arranged on the front backing plate 4. A cylindrical pin 8 is arranged on the slide plate 5 , a compression screw 6 is respectively arranged on the rear backing plate 2 and the front backing plate 4 , and the workpiece 10 is arranged on the clamping device 7 . The device adjusts the front and rear slides of the front slide 5 and the rear slide 3, thereby accurately and quickly adjusting the size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com