Subway station middle pile and steel pipe column construction method

A technology for subway stations and steel pipe columns, applied to artificial islands, sheet pile walls, water conservancy projects, etc., can solve problems such as high safety risks, and achieve the goal of ensuring the quality of holes, improving construction safety and construction efficiency, and ensuring verticality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be further described in detail below. The content not described in detail in the embodiments of the present invention belongs to the prior art known to those skilled in the art.

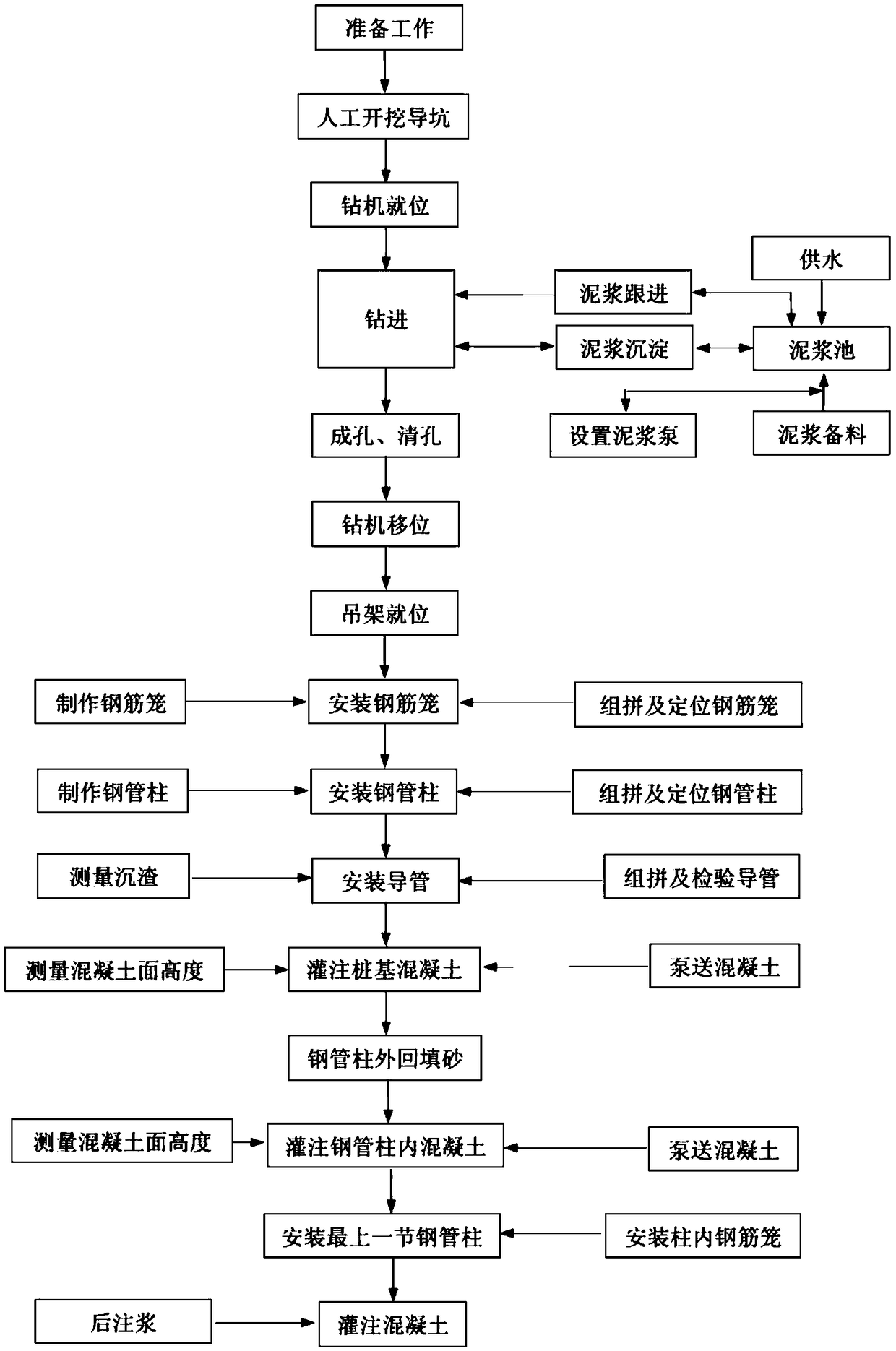

[0022] The construction method of middle pile and steel pipe column in subway station of the present invention, its preferred embodiment is:

[0023] Include steps:

[0024] A. Mud and preparation

[0025] Before the construction, remove the inverted arch of the pilot tunnel, build the pilot tunnel to strengthen the ring beam, and manually dig the hole, use the vertical shaft as a mud pool, and transport the slag and slurry into the shaft by pipeline, and set up a sedimentation area and a mud area in the vertical shaft. And a buffer mud pool is set in the small pilot tunnel.

[0026] B. Drilling into hole construction

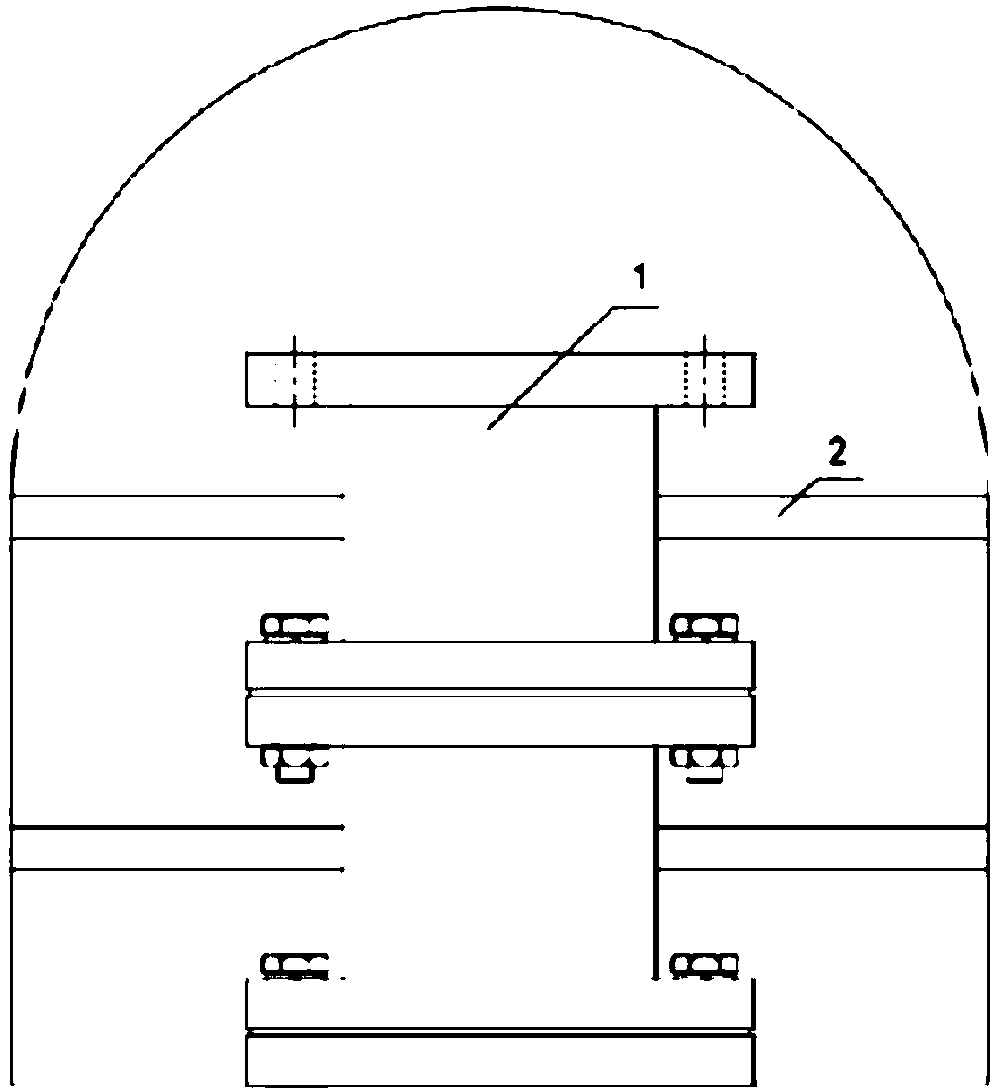

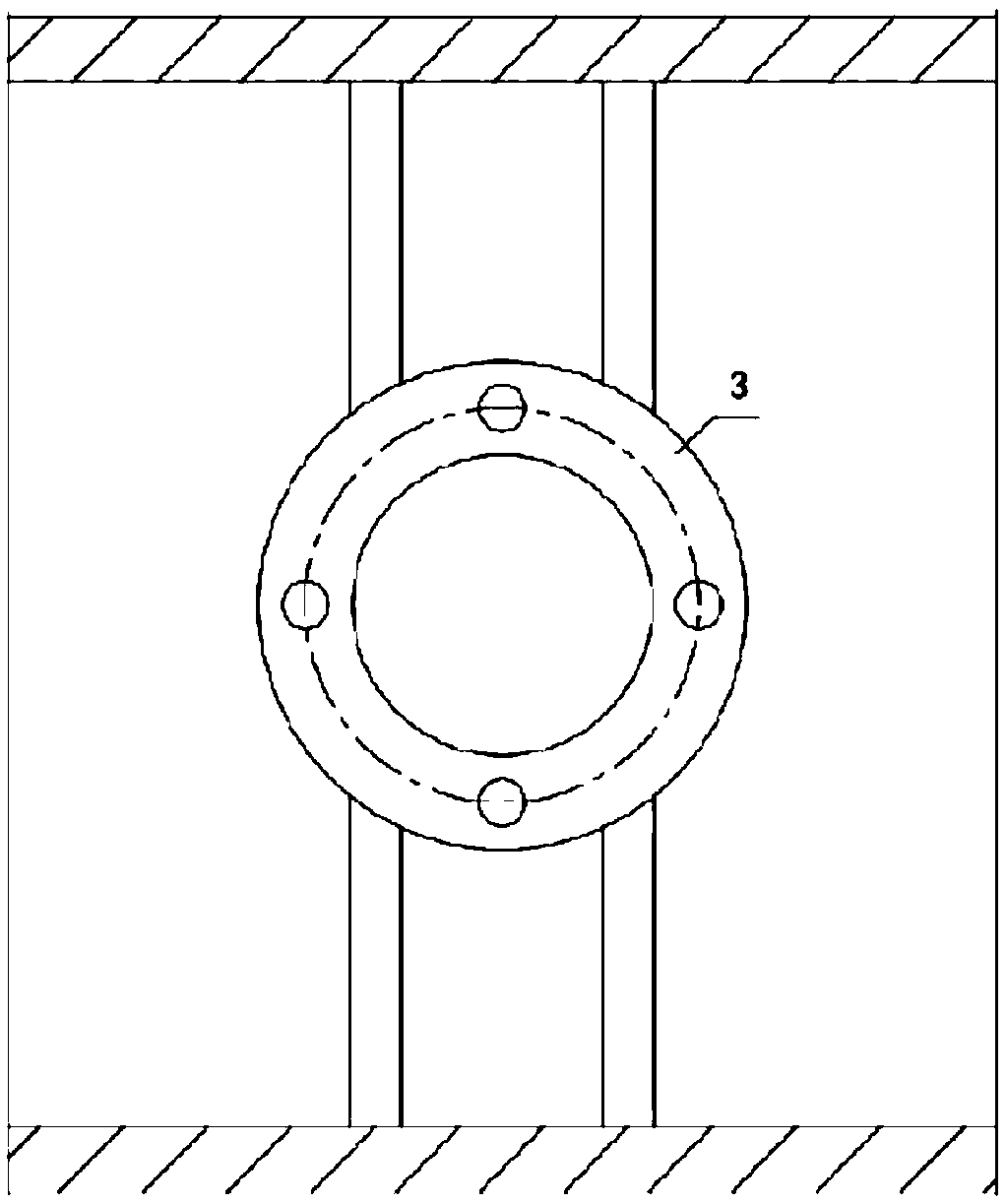

[0027] When using a reverse circulation drilling rig to form a hole, use a truss support around the drilling rig and fix it on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com