Efficient and environment-friendly long spiral rock-socketed pile machine

A technology of long auger and long auger, which is applied in drilling equipment and methods, construction, earthwork drilling and mining, etc., and can solve problems such as environmental pollution, noise pollution, and inability to drill into rocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

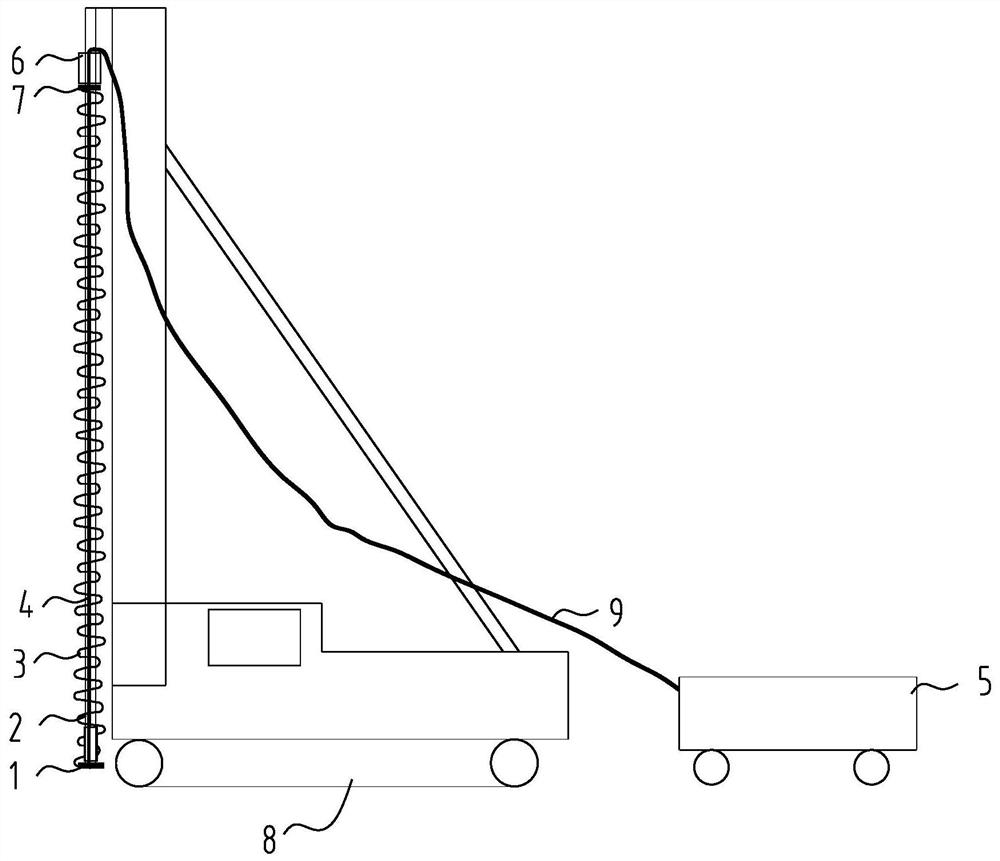

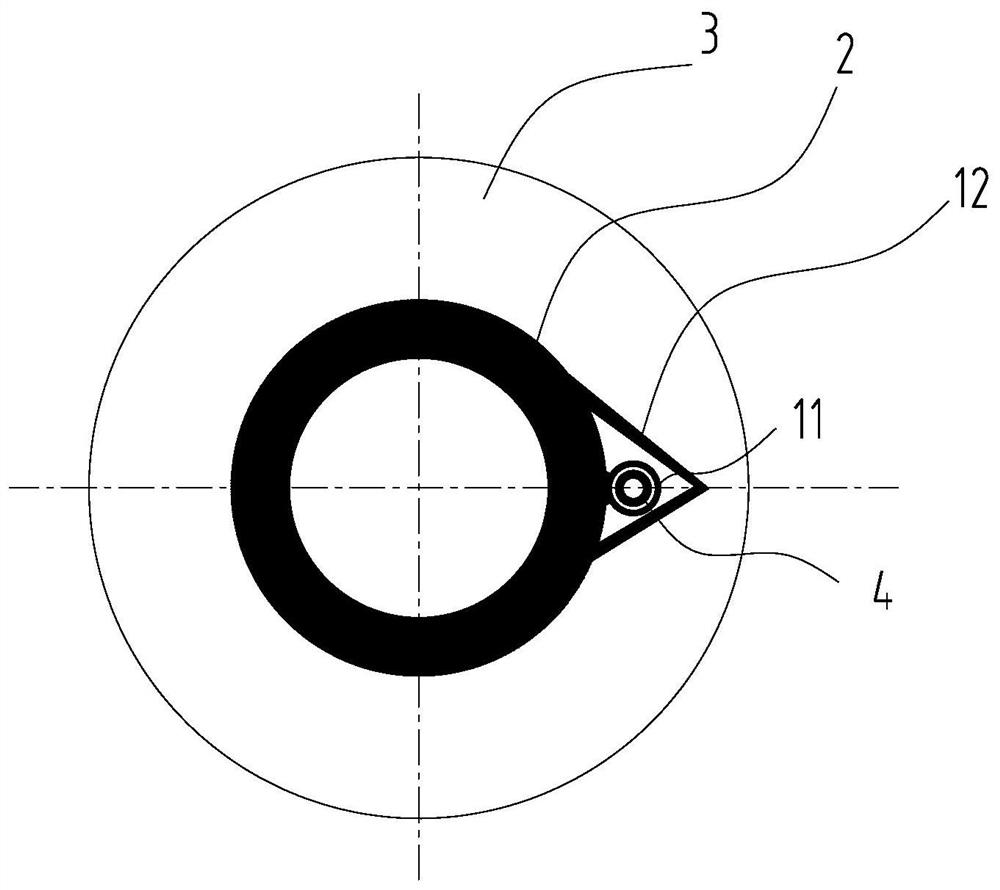

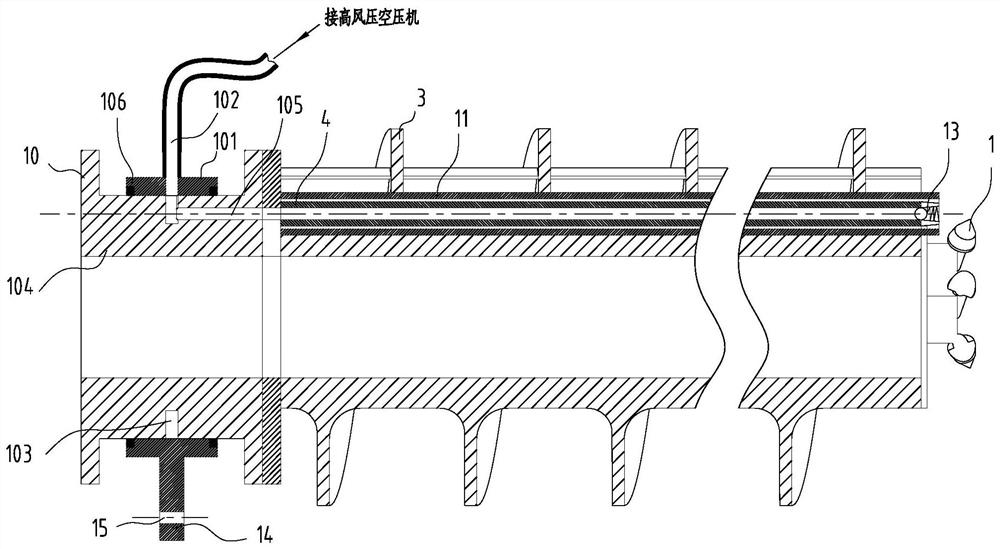

[0028] Such as Figure 1-4 As shown, a kind of high-efficiency and environment-friendly long spiral rock-socketed pile machine of the present invention comprises drill bit 1, long spiral drill rod 2, and described long spiral drill rod 2 is provided with helical blade 3; The outside of the long auger drill rod 2 is provided with an air supply outer pipe 4; the air supply outer pipe 4 passes through the helical blade 3 along the outer wall of the long auger drill rod 2;

[0029] Further, the high-efficiency and environment-friendly long spiral rock-socketed pile machine described in the present invention also includes a high wind pressure air compressor 5, a power head 6, a shock absorber 7, a long spiral drilling machine 8, and an air supply pipe 9; One end of the air supply pipe 9 is connected with the high wind pressure air compressor 5; the power head 6 is connected with the long auger drill rod 2 and is arranged on the top of the long auger drill rod 2 and the power head 6...

Embodiment 2

[0041] The difference between Embodiment 2 and Embodiment 1 is that the number of said air supply outer pipes 4 is three, and they are evenly distributed along the circumference of the cross-section of the long auger drill rod 2 .

Embodiment 3

[0043] The difference between Embodiment 2 and Embodiment 1 is that, in the high-efficiency and environment-friendly long spiral rock-socketed pile driver described in the present invention, the air supply outer pipe 4 passes through the spiral blade 3, and the air supply outer pipe 4 The number is 2, and the two air supply outer pipes 4 are evenly distributed along the circumference of the cross section of the long auger drill rod 2 .

[0044] Advantages of the present invention: by improving the drill rod structure of the long auger drilling rig, the drilling efficiency can reach 5 to 10 times that of the traditional long auger drilling rig when drilling into the rock. The bearing capacity of single pile can be increased by more than 15%. The high-pressure compressed air blows the cuttings and rock powder at the bottom of the hole generated during drilling away from the contact surface between the drill bit and the original rock, increasing the effective contact area between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com