Construction method for drilling of rotary drilling rig in complicated geological formation

A technology for rotary drilling rigs and complex formations, applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc. It can solve the problems of unguaranteed punching quality, slow punching speed of percussion drilling, and large consumption of drilling tools. Achieve the effect of saving the time of replacing the drill bit, reducing the construction cost and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further elaborated and described below in conjunction with the accompanying drawings and specific embodiments.

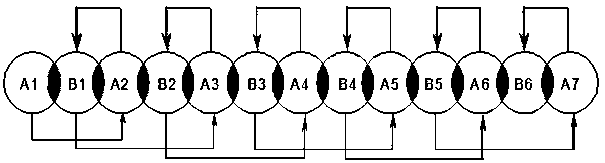

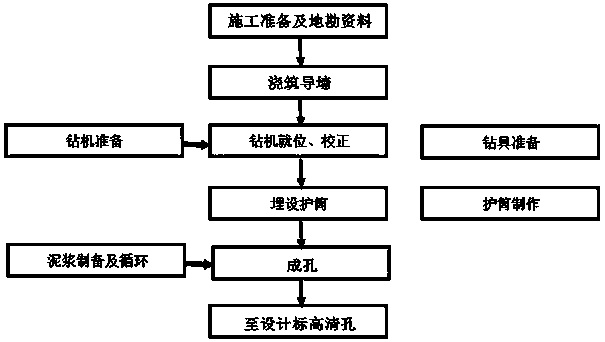

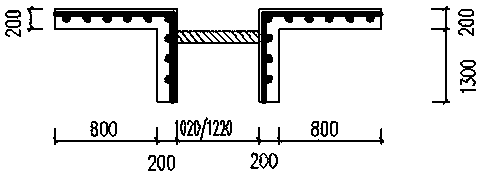

[0027] A construction method for drilling a rotary drilling rig in complex geological formations, such as Figure 1-5 As shown, it is applied to the station enclosure structure of the Sea World Station. The station enclosure structure of the Sea World Station is a drilled occlusal pile. The construction of the intermediate reinforced drilled pile before the initial setting of the plain pile may cause excessive erosion and damage to the entire plain pile body. Deformation damage such as collision will affect the structural integrity and waterproof performance, and it is not conducive to the development of multiple construction work surfaces. Therefore, the occlusal pile occlusal method adopts hard occlusal. Rotary drilling rigs are used for construction, and impact drilling rigs are used for auxiliary co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com