Coal mine drilling angle measuring system and method

An angle measurement, coal mine technology, applied in the direction of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of large difference in gas drainage drilling design, hidden dangers of coal mine gas control, long operation time, etc., to ensure success. The effect of hole quality, simple operation process and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

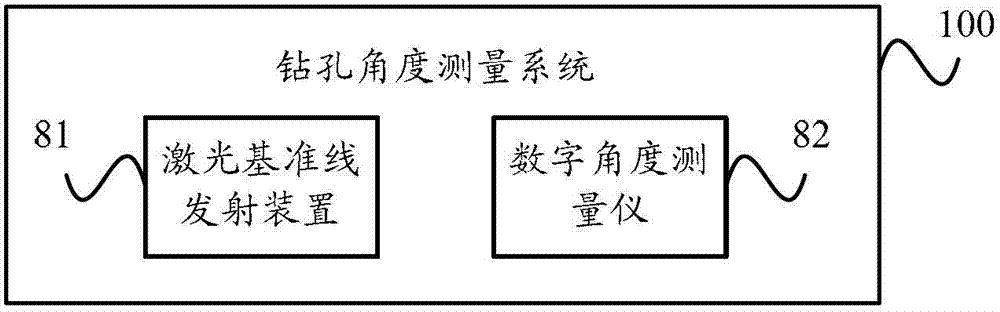

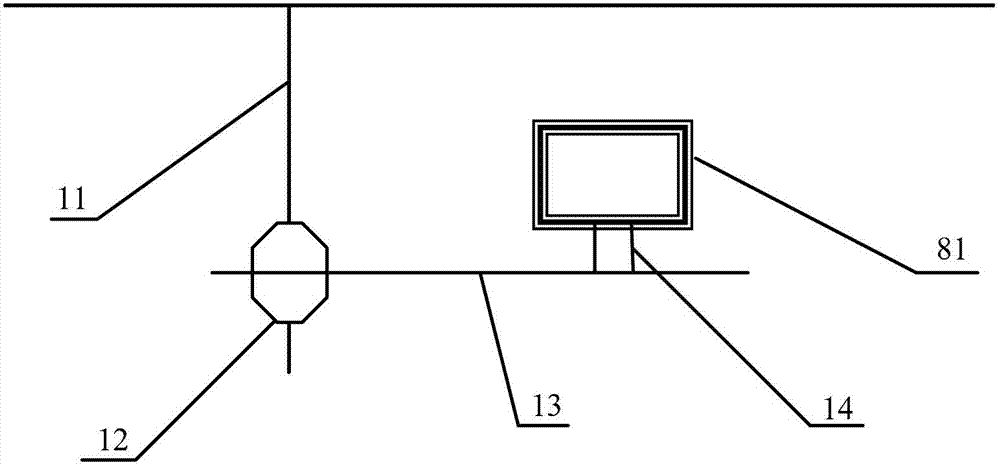

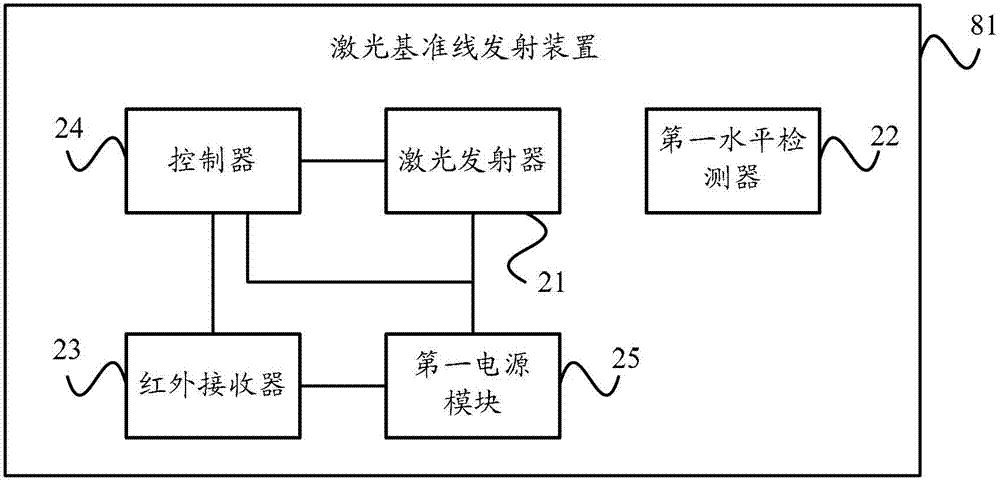

[0044] figure 1 It is a schematic structural diagram of a drilling angle measurement system for coal mines provided by an embodiment of the present invention. Such as figure 1 As shown, the coal mine drilling angle measurement system 100 provided in this embodiment can be specifically applied to the measurement process of the coal mine drilling angle. The coal mine drilling angle measurement system 100 provided in this embodiment specifically includes a laser reference line emitting device 81 for generating a first laser plane and a second laser plane that are perpendicular to each other and for adjusting the angle of the drill pipe according to the second laser plane. A digital goniometer 82 for making the measurements. The intersection line of the first laser plane and the inner wall of the roadway coincides with the middle line of the roadway, and the second laser plane intersects the drill pipe to be measured; the digital angle measuring instrument 82 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com