Positive and negative circulation construction technology of ultra-deep bored piles

A technology of bored piles and construction technology, which is applied in earthwork drilling, wellbore/well components, and flushing wellbore, etc. It can solve the problems of low hole-forming efficiency and unsatisfactory hole-forming quality of ultra-deep pile foundations, and achieve Improving construction efficiency and ensuring the quality of hole formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

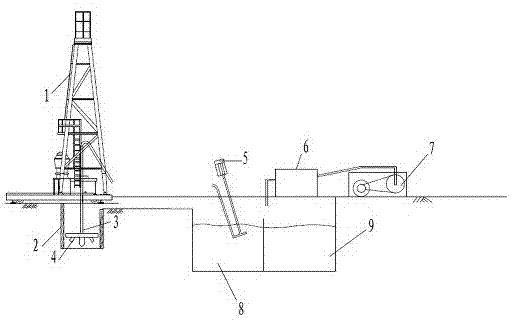

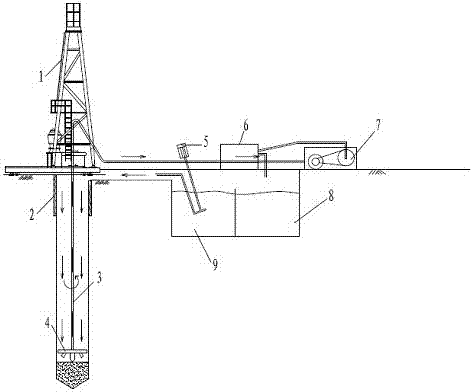

[0019] Depend on figure 1 As shown, a super-deep bored cast-in-situ pile combined forward and reverse circulation construction technology, which specifically includes the following steps:

[0020] (1) Site layout preparation

[0021] In the construction site, the drilling rig 1 is in place, the casing 2 is buried, the drill pipe 3 and the drill bit 4 are connected, a mud pool including a circulation pool 8 and a sedimentation pool 9 is arranged on site, a mud pump 5 is inserted in the mud pool, and sand removal is set around it The machine 6 and the gravel pump 7 are connected to each other using conduits;

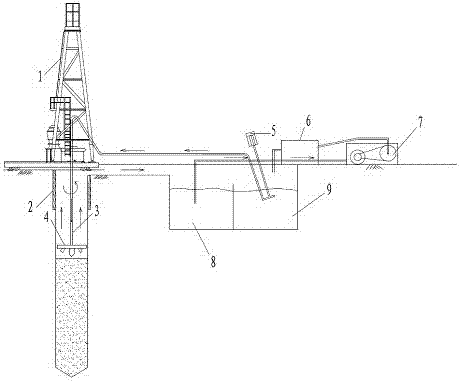

[0022] (2) Drilling of the positive circulation process in the upper clayey soil layer

[0023] Depend on figure 2 As shown, holes are formed, and the upper clayey soil layer is drilled by the positive circulation process. The mud pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com