Supporting and bar-arranging structure for arch bridge raking pile hole forming construction

A technology of inclined piles and pile holes is applied in the field of support and reinforcement structure for the construction of inclined piles of arch bridges, which can solve the problems of low mud pressure, complicated hole forming process and construction, and inability to provide sufficient wall protection pressure, and achieves reliable performance. The effect of connection, low construction cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

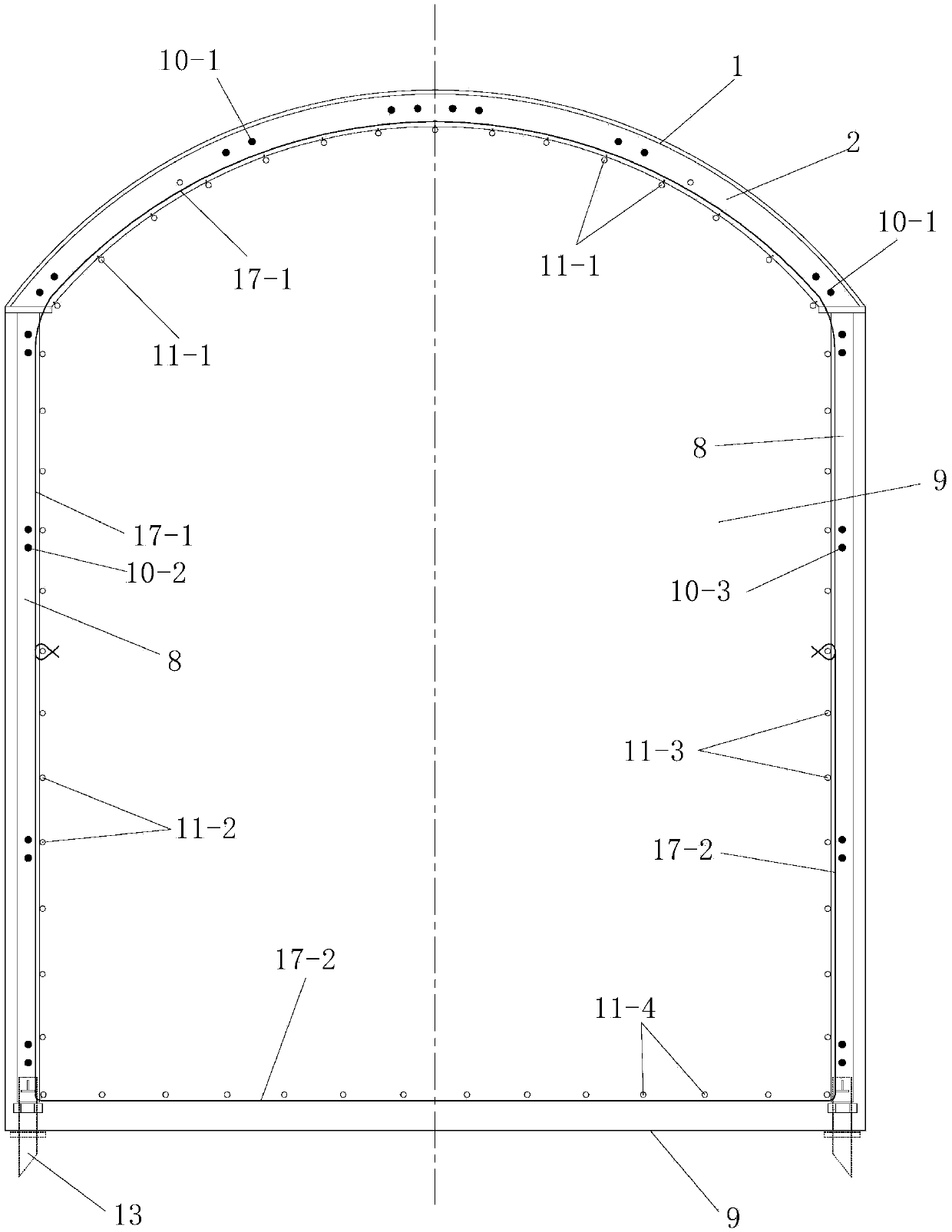

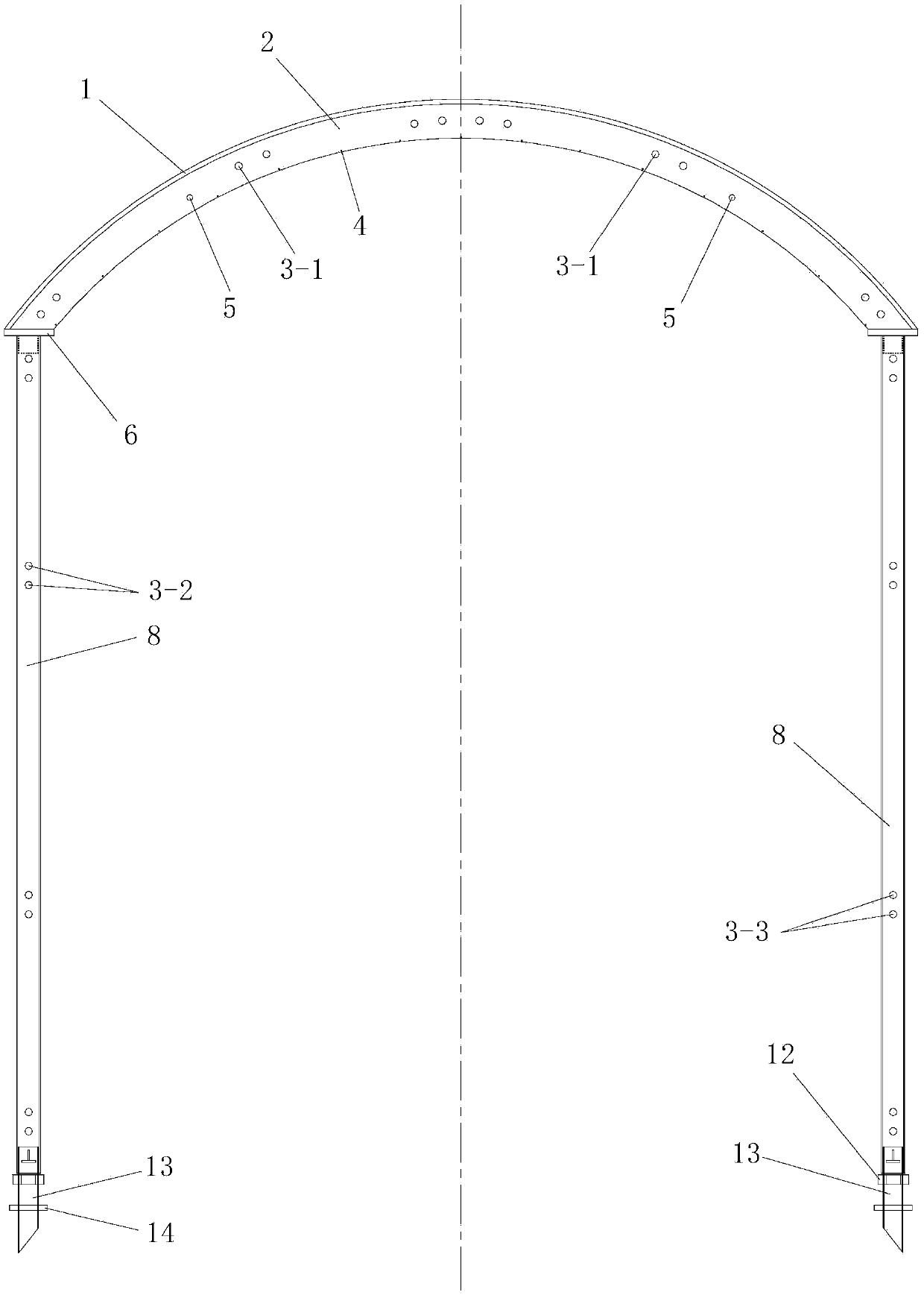

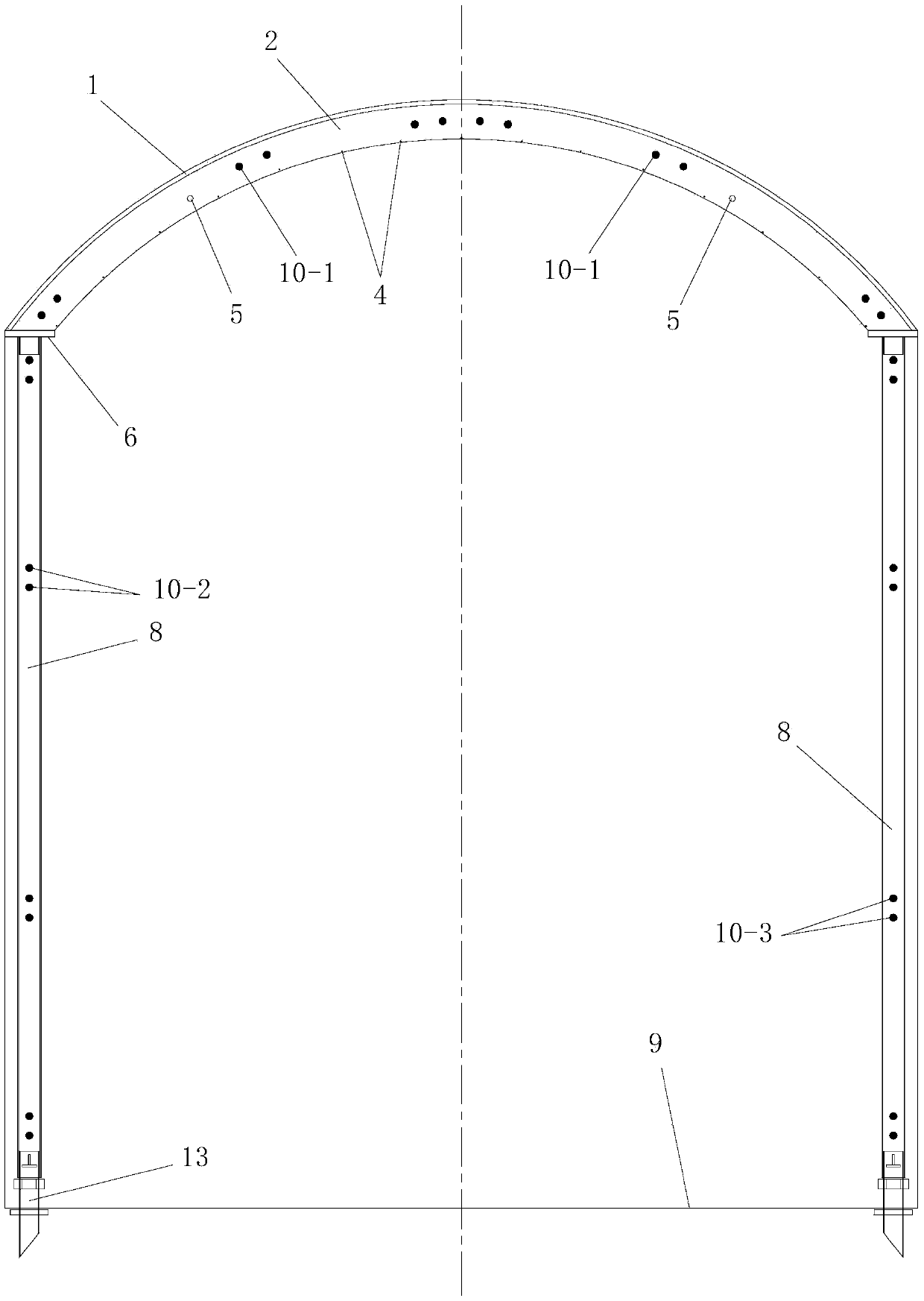

[0046] Such as figure 1 As shown, the present invention includes a plurality of support frames supported in the excavated pile holes 9, a plurality of first longitudinal connecting ribs 11-1 arranged on the inner side of the top of the pile holes 9 from left to right, A plurality of second longitudinal connecting ribs 11-2 arranged on the inner side of the left side wall of the inclined pile hole 9 from top to bottom, and a plurality of third longitudinal ribs 11-2 arranged on the inner side of the right side wall of the inclined pile hole 9 from top to bottom. The connecting rib 11-3 and the fourth longitudinal connecting rib 11-4 arranged from left to right on the inner side of the bottom of the inclined pile hole 9, the structure and size of a plurality of the supporting frames are the same and they are arranged along the inclined pile pile. The length direction of hole 9 is laid out from back to front, and a plurality of described supporting frames are all arranged in para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com