Prefabricated reinforced concrete hollow column template and making method thereof

A reinforced concrete and manufacturing method technology, applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems affecting the integrity of the column, affecting the mechanical performance, etc., so as to ensure the construction quality easily, enhance the integrity, reduce time and The effect of artificial consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

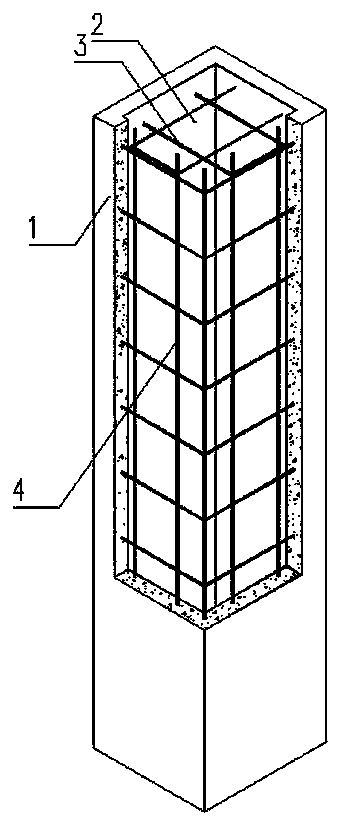

[0034] The prefabricated reinforced concrete hollow column template and its manufacturing method proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

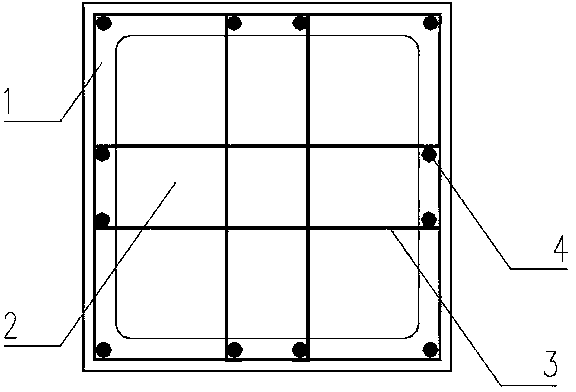

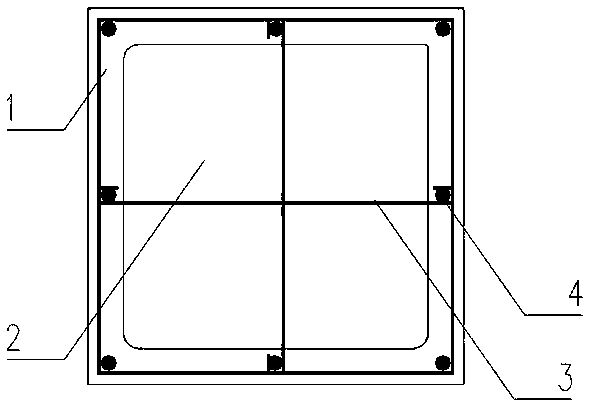

[0035] In an embodiment of the prefabricated reinforced concrete hollow column formwork proposed by the present invention, as figure 1 , the hollow column template 1 is provided with a longitudinally penetrating hollow tunnel 2; the hollow column template 1 is equipped with stirrups 3, and some stirrups 3 pass through the hollow tunnel 2. The stirrup in one direction in the hollow channel 2 has two limbs, such as figure 2 , or a limb, such as image 3 , or otherwise. The thickness of the outer wall of the hollow column formwork is determined according to the requirements of production, construction, and stress. figure 1 The middle shaded part is the cutting plane.

[0036] In another embodiment of the prefabricated reinforced concrete hollow colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com