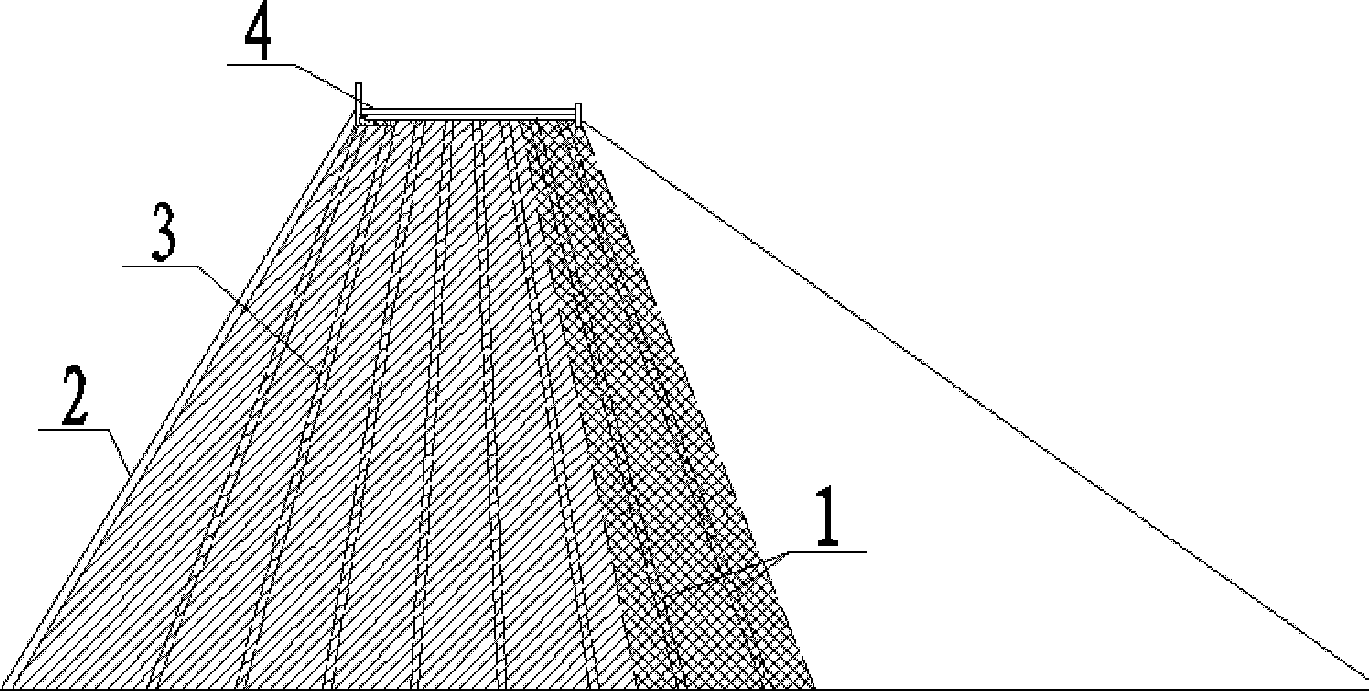

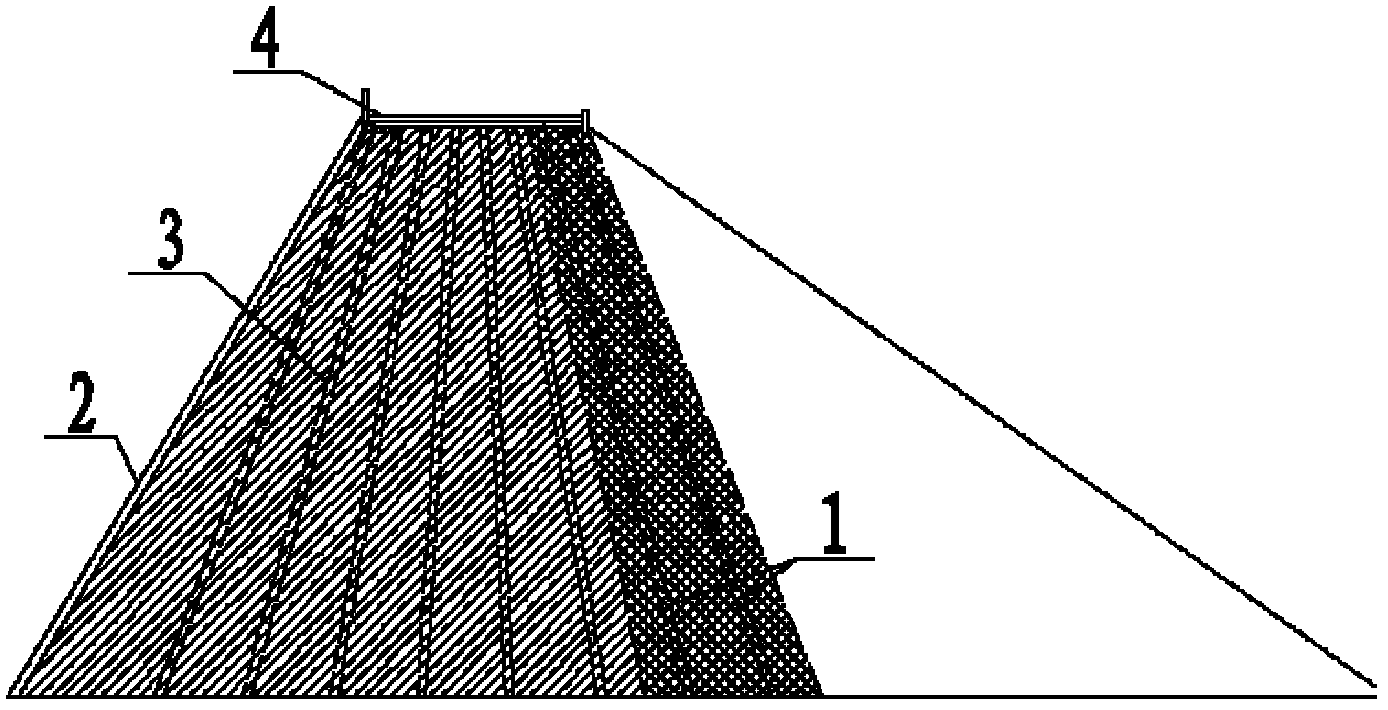

Rock-fill dam deformation control technology

A deformation control, rockfill dam technology, applied in dams, barrages, buildings, etc., can solve the problems of poor filling material uniformity, poor deformation resistance, complex dam materials, etc., to reduce porosity, short construction period, The effect of improving the resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] A construction method for deformation control of a rockfill dam includes the following steps:

[0018] ① Prepare paste-like stable slurry and cement mortar. Mix cement, water, fly ash, clay, bentonite, etc. to make a paste-like slurry, which is used for pouring; mix cement, water, sand, etc. to make mortar, which is used for filling and pouring.

[0019] ② Select a small-diameter diamond geological drilling rig and a diamond core-breaking drill bit, and adjust the core-breaking cone of the drill bit to the reamer.

[0020] ③ Install a reamer at the junction of the drill bit and the drill pipe, lengthen the core pipe to 5.0m, and install guide pipes every 10.0m on the drill pipe. The KXP-1 inclinometer is used to correct the deviation, and the deviation of the drilling hole is corrected in real time.

[0021] ④Inject clean water and cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com