Huge thick hard roof high gas thick coal seam roof control and gas drainage efficiency improvement method and drilling machine

A technology of hard roof and thick coal seam, which is applied in the field of extremely thick and hard roof control, can solve problems such as long time-consuming, easy to repeat, slow effect, etc., to increase gas drainage efficiency, improve gas drainage efficiency, and improve air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments.

[0029] refer to Figure 1-Figure 5 The method for controlling and improving the air permeability of the coal seam and increasing the gas drainage efficiency of the coal seam by the extremely thick and hard roof, high gas and thick coal seam roof includes the following steps:

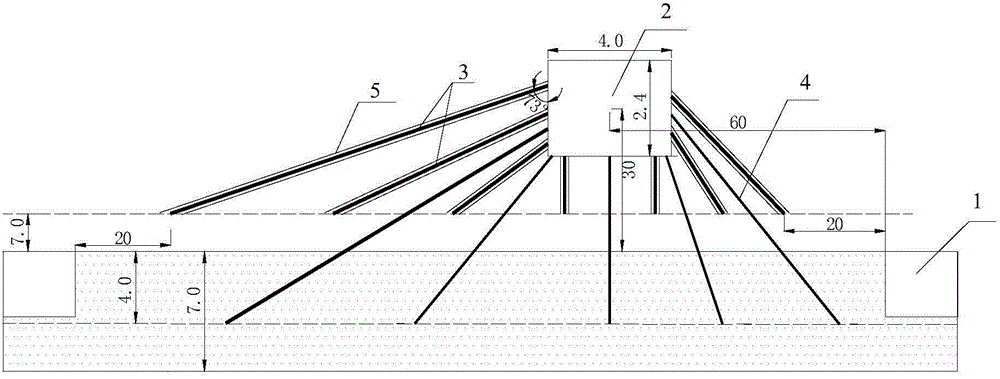

[0030] A. Construct two parallel channels 1 along the roof of the mined coal seam, and construct a high gas pumping roadway 2 parallel to the track along the channel at a vertical distance of 20-30m from the top of the mined coal seam and a horizontal distance of 40-80m from the track along the channel 1 ;

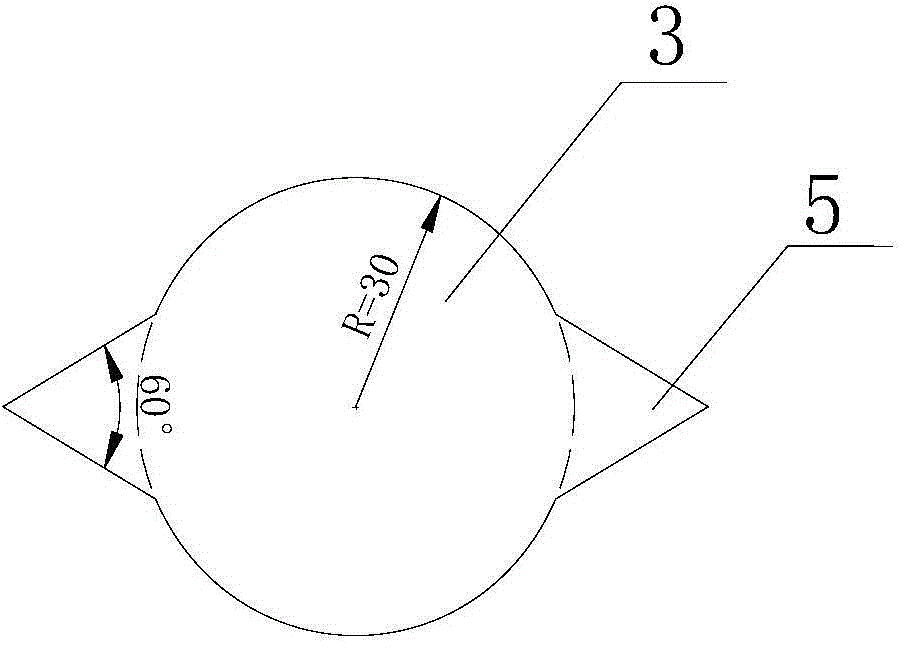

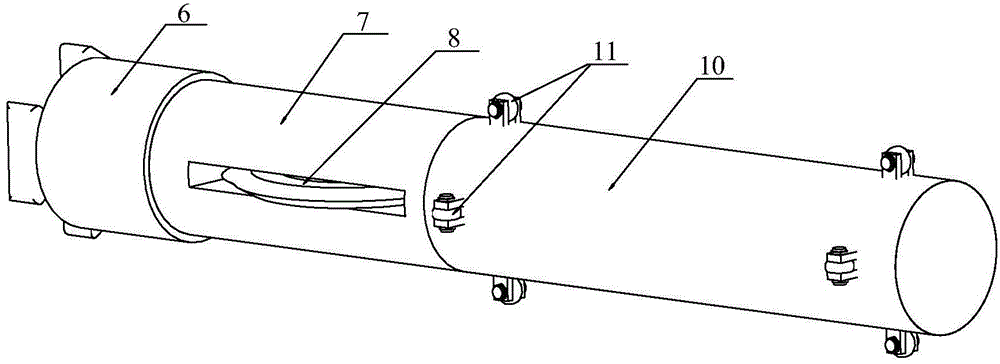

[0031] B. Construct the angular groove blast hole 3 and the circular hole 4 on the two sides and the bottom plate of the gas pumping alley 2 using special drilling tools respectively. .The angular groove blasthole 3 comprises a circular blasthole, two angular grooves 5 are arranged at the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com