Long spiral drilling and percussion drilling dual-machine composite pore-forming grouting pile construction method

A technology of percussion drilling rig and long screw, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of shallow rock penetration, slow hole forming speed, and easy blocking of pipes when pouring concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The construction method of long auger drill and percussion drill dual-machine composite hole-forming cast-in-place pile provided in this embodiment includes the following steps:

[0085] (1) Construction preparation

[0086] (1) Staffing: Management personnel have clear responsibilities, workers with one specialty and multiple abilities, and special projects must hold certificates to work.

[0087] (2) According to the requirements of geological conditions and construction drawings for the depth of rock entry, and considering the mechanical efficiency, calculate the combination ratio of rotation and impact. According to calculations, the combination of one-rotation and four-flushing in this project is the best, with a total of 2 long auger drilling rigs and 8 percussion drilling rigs.

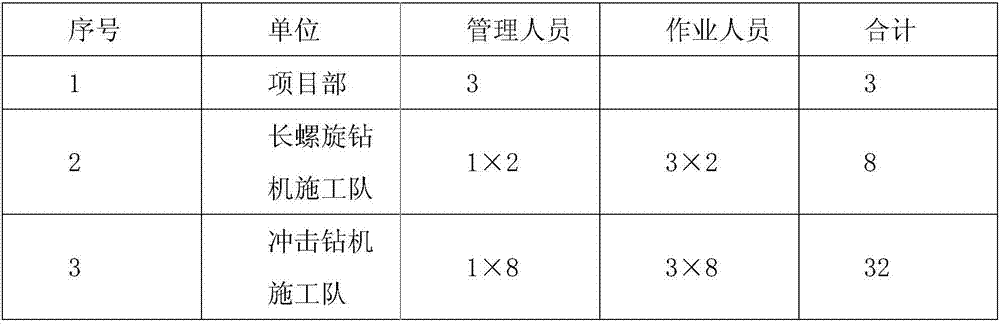

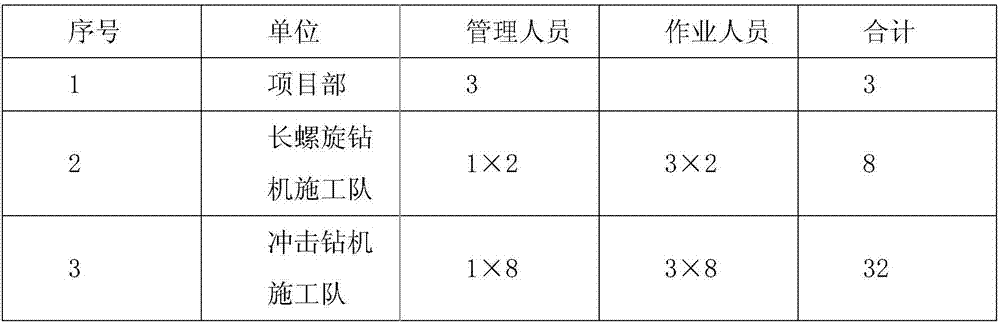

[0088] (3) See Table 2 for staffing:

[0089] Table 2 Construction staff configuration table

[0090]

[0091] (4) Technical preparation

[0092] 1) Joint review of drawings

[0...

Embodiment 2

[0148] Embodiment 2 construction method application situation and popularization and application prospect:

[0149] (1) This construction method is applied to Qingdao Iron and Steel Co., Ltd.'s urban steel plant environmental protection relocation coking area reserve coal tank project. This project is located in Dongjiakou Industrial Zone, Boli Town, Huangdao District. The total engineering volume of the pile foundation is 11580m3, and the subcontracted engineering volume 57903, the contract price is 6.7 million yuan. The design service life of this project is 50 years, the seismic fortification intensity of this project is 7 degrees, and the seismic fortification is Class C. The foundation of the project is located on the mudflat, and the upper part is backfilled with gravel. The construction is difficult and the construction period is tight. The load of the pile foundation is large, and the rock penetration is required to be deep, so a large pile foundation is required.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com