Radiator performance wind tunnel test device capable of simulating multiphase flow air inlet environment

A technology of wind tunnel test and radiator, which is applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc. It can solve the inconvenience of indoor application, the lack of technology and sand particles in the radiator performance wind tunnel test device in rainy environment Easy to accumulate and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Wherein, the same components use the same symbols, such as air, rainwater, sand grains, recycled sand grains, water flow direction and other symbols, in order to enable those skilled in the art to better understand the drawings and understand the present invention. It should be clear here that the specific implementations given are only for explaining and helping understanding of the present invention, and are not intended to limit the present invention.

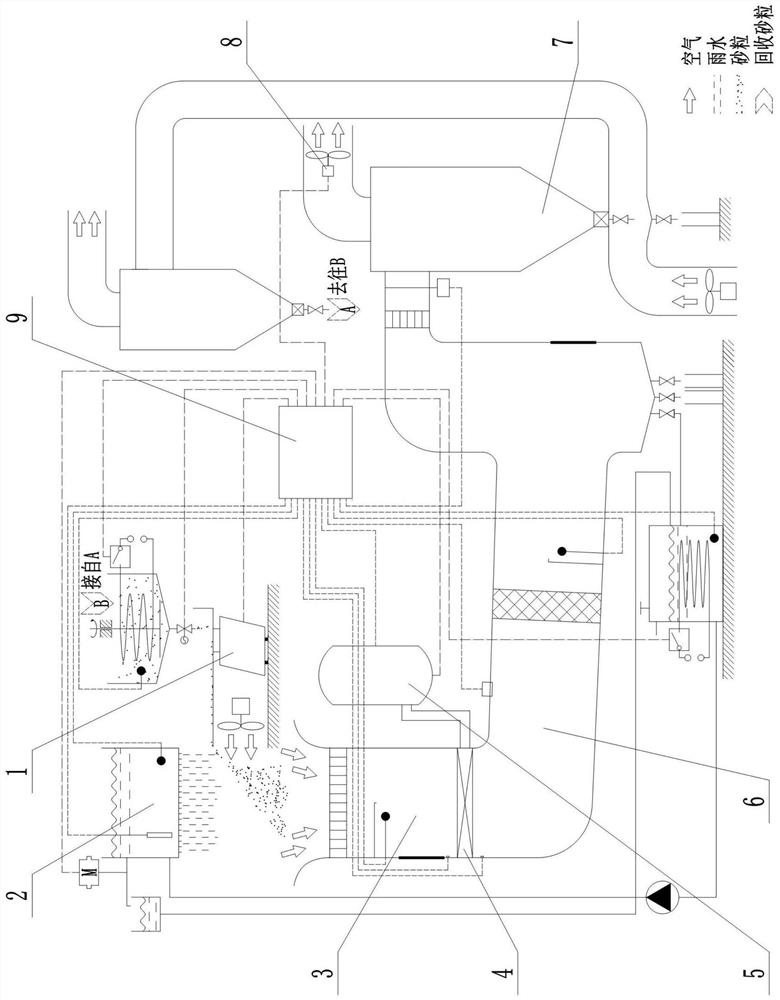

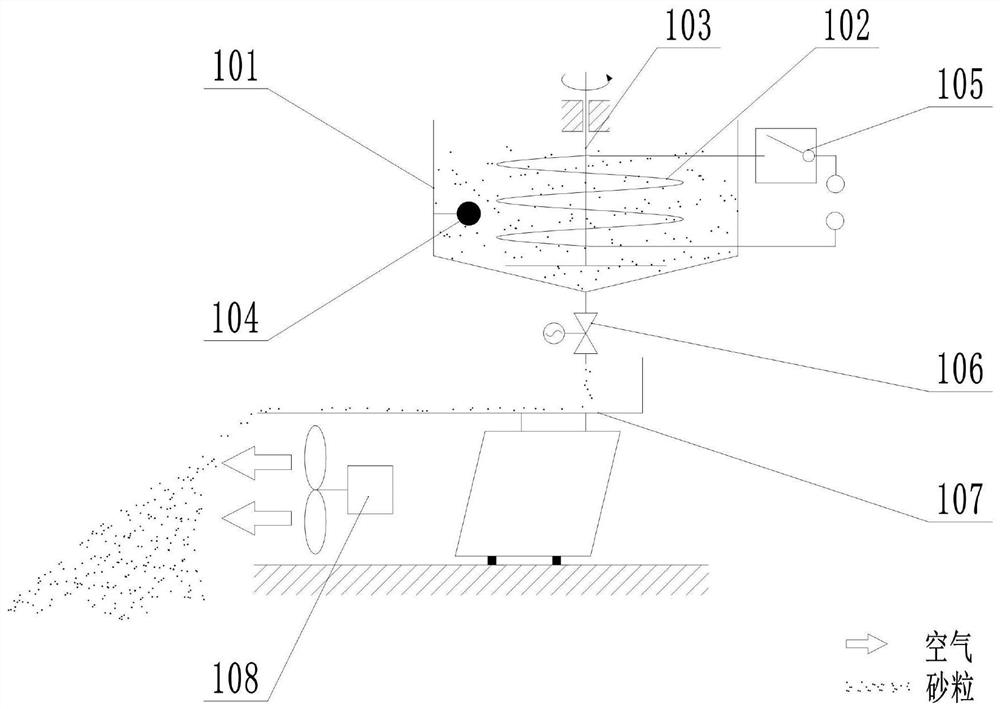

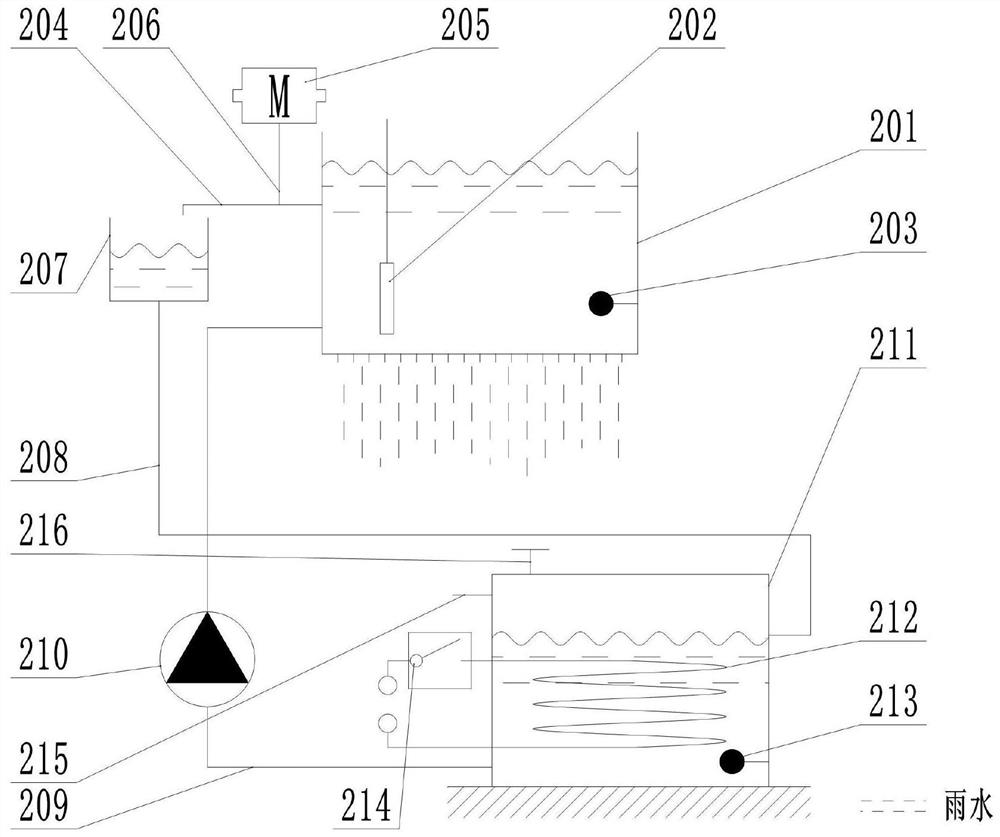

[0095] Such as figure 1As shown, a radiator performance wind tunnel test device that can simulate multi-phase flow into the wind environment, including sand dust generator 1, rain generator 2, upstream section 3, radiator 4, hot side circulation system 5, downstream Section 6, separation and recovery section 7, induced draft fan 8, measurement controller 9. Both the dust generator 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com